Professional Documents

Culture Documents

In Vitro Studies Regarding The Corrosion Resistance of Nicr and Cocr Types Dental Alloys

Uploaded by

Ruxandra-Elena BratuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

In Vitro Studies Regarding The Corrosion Resistance of Nicr and Cocr Types Dental Alloys

Uploaded by

Ruxandra-Elena BratuCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/286054692

In vitro Studies Regarding the Corrosion Resistance of NiCr and CoCr Types

Dental Alloys

Article in Revista de Chimie -Bucharest- Original Edition- · June 2014

CITATIONS READS

14 295

6 authors, including:

Violeta Hancu Comaneanu Raluca Monica

Titu Maiorescu University Titu Maiorescu University

23 PUBLICATIONS 47 CITATIONS 62 PUBLICATIONS 83 CITATIONS

SEE PROFILE SEE PROFILE

Doina Lucia Ghergic Mihai Cosmin Cotrut

Titu Maiorescu University Polytechnic University of Bucharest

17 PUBLICATIONS 29 CITATIONS 118 PUBLICATIONS 740 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Fabrication and surface modification of the biodegradable and permanent scaffods and implants View project

Reconstructive medicine View project

All content following this page was uploaded by Comaneanu Raluca Monica on 24 March 2016.

The user has requested enhancement of the downloaded file.

In vitro Studies Regarding the Corrosion Resistance

of NiCr and CoCr Types Dental Alloys

VIOLETA HANCU1, RALUCA-MONICA COMANEANU1*, COSTIN COMAN1, ALINA-GABRIELA FILIPESCU1, DOINA-LUCIA GHERGIC1,

MIHAI–COSMIN COTRUT2

1

Faculty of Dental Medicine, Titu Maiorescu University of Bucharest, 67A Gh. Petrascu Str., 031593, Bucharest, Romania

2

Politehnica University of Bucharest, Faculty of Material Science and Engineering, 313 Splaiul Independentei, 060042, Bucharest,

Romania

Prosthetic treatment of reduced partial edentation supposes the introduction of a foreign object into the

patient’s oral cavity, which implies an increased attention regarding the compatibility and the corrosion

resistance of the used materials with the biologic environment. The aim of this study was to compare the

corrosion resistance of six commercial samples of dental alloys from different suppliers (three types of

nickel-chromium and three types of cobalt-chromium alloys) in artificial saliva Fusayama-Meyer with different

pH: 2, 5 and 7, at room temperature (25±1°C). The samples were tested electrochemically to determine

their resistance to corrosion. The corrosion rates were obtained from the current-potential curves. The

potentiodynamic curves of the dental alloys showed that dental alloys have variations of the corrosion

parameters in all types of the studied artificial saliva. CCG have shown the lowest values of corrosion rate

irrespective of the pH of artificial saliva.

Keywords: dental alloys, biomaterials, corrosion, artificial saliva.

It is known that the quality and performances of dental Sheradent/Shera – codified CCS). The chemical

materials are beside the proper composition of dental alloy, composition of the alloys is the one given by the

the good mechanical properties, the corrosion resistance manufacturers.

and the biocompatibility [1]. Dental materials interact with Metallic alloys specimens were cast in circular moulds

living tissues they come in contact with and generate local (fig. 1), with the dimensions 13x1.5 mm, and were

or systemic responses. polished in two stages: first with sandpaper with abrasion

The main causes of failure metal-fused-to-ceramic degrees between 600 and 2,000 microns and then with

restorations are given by the corrosion degradation of diamond paste. Before testing, specimens were washed

metals or alloys, mechanic wearing and fatigue [1-4]. with distilled water and then dried.

Corrosion resistance is one of the important features of

dental materials, because after introducing into the human

body, the metallic biomaterials are subject to corrosive

medium.

The corrosion behaviour of cast alloys is one of the

important characteristics which respect the principle of

material biological safety [5].

Cobalt-chrome alloys, due to excessive hardness (350-

380 HB), have several disadvantages: scarce occlusal

adjustment, opposing teeth attrition and difficult discard

from the abutment.

Modern Ni-Cr alloys have main composition consisting Fig. 1. Samples used for corrosion investigation

of Ni (60-70%), Cr (15-20%) to which there are added small The electrochemical measurements were performed

amounts of: Mo, Al, Mn, Be, Cu, Co, Fe. using a Potentiostat / Galvanostat (model PARSTAT 4000,

Alloy corrosion resistance is due to the formation of a produced by Princeton Applied Research), controlled by a

surface protective micro-layer of chromic oxide. computer and recording the results by using VersaStudio

The corrosion resistance of six commercial dental alloys software [6]. The corrosion resistance was determined by

used in metal-fused-to-ceramic technology, alloys supplied linear polarization technique, after recording the

by different worldwide well-known producers, into artificial polarization curves. The measurements were made

saliva having different pH values was investigated by respecting the following steps:

means of linear polarization scans. - measurement of the open circuit potential (EOC) for 1

h;

Experimental part - recording the potentiodynamic polarization curves from

Six commercial dental alloys were evaluated, namely -0.1 V (vs OC) to +1.5 V (vs SCE), with a scanning rate of

Ni-Cr types (Argeloy NP/Argen – codified NP; Ugirex III/ 0.33 mV/s.

Ugin Dentaire – codified NCU; and Protechno-N8/Protechno The test cell used in the measurements consists of three

– codified NCP) and CoCr types (Argeloy NP Special/Argen electrodes: a saturated calomel electrode (SCE) used as

– codified NPS; Girobond/Amann Girrbach – codified CCG; reference electrode, a platinum electrode as counter

*email: monica_tarcolea@yahoo.co.uk

706 http://www.revistadechimie.ro REV. CHIM. (Bucharest) ♦ 65♦ No.6 ♦ 2014

Fig. 2. Variation of open circuit potential of the alloys vs. Fig. 4. Variation of open circuit potential of the alloys vs. time in

time in artificial saliva, pH=2 artificial saliva, pH=7

Fig. 3. Variation of open circuit potential of the alloys vs. time in Fig. 5. Potentiodynamic polarization curves of the alloys

artificial saliva, pH=5 in artificial saliva, pH=2

electrode and the working electrode consisted in the

analysed samples placed on a Teflon base and having the

working surface of 1 cm2.

Corrosion tests were carried out in artificial Fusayama-

Meyer saliva (with composition of 0.4 g·L-1 NaCl, 0.9 g·L-1

KCl, 1 g·L-1 urea, 0.69 g·L-1 NaH2PO4, 0.795 g·L-1 CaCl2·H2O)

at room temperature (25±1°C), according to standard

ASTM G15-97a. Since the pH of the oral cavity can decrease

below 5.0 following a meal, more aggressively acidic

conditions in the oral cavity were also simulated by

decreasing the pH (7, 5 and 2).

Results and discussions

The evolution of potential recorded under open circuit

conditions (Eoc) for the samples of the two types of studied Fig. 6 - Potentiodynamic polarization curves of the alloys in

NiCr and CoCr alloys versus time in different pH artificial artificial saliva, pH=5

saliva are presented in figures 2-4.

As a general tendency, the potential slightly increased current / surface) at the corresponding potential indicated

as the samples were immersed in the Fusayama’s solution a high corrosion rate of the alloy.

and then stabilized after 30 min, except for the NP and The comparison of the polarization curves shows a

NPS samples at pH=2 and NCP and CCG samples at pH=5 similar shape for all the curves with exceptions for each

that the potential decreased versus time. type of solution.

The curves for NiCr alloys showed that the NCU alloy The following parameters were determined from the

has the greatest electronegative value of the open circuit polarization curves, parameters which characterise the

potential (Eoc) in artificial saliva with pH=7, indicating the corrosion resistance of the analysed samples and was

weakest noble character, whereas in the case of artificial calculated the corrosion rate (CR):

saliva with pH=2 the same NCU alloy has the noblest -open circuit potential (Eoc)

character as for Eoc. -corrosion potential (Ecorr)

Taking into account the same evaluation criterion for -corrosion current density (icorr)

the CoCr alloys, in artificial saliva with pH=5, CCG alloy The main parameters of the electrochemical corrosion

has the weakest noble character and in artificial solution process are listed in table 1.

with pH=2 the same CCG alloy stands out. The corrosion rates are calculated (according to ASTM

The polarization curves for the studied dental alloys are G102-89, 2004) using the equation:

presented in figures 5-7. The current density is correlated

with the corrosion rate. A high current density (the ratio

REV. CHIM. (Bucharest) ♦ 65 ♦ No. 6 ♦ 2014 http://www.revistadechimie.ro 707

Fig. 7 - Potentiodynamic polarization curves of the

alloys in artificial saliva, pH=7

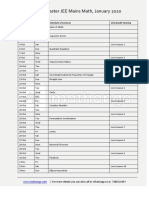

Table 1

SUMMARY OF THE

ELECTROCHEMICAL PARAMETERS

OF THE CORROSION PROCESS

EVALUATED FROM THE OCP AND

POLARIZATION MEASUREMENTS

where: percentage of Cr and Mo varies between 11-25%,

CR – corrosion rate (mm/year) respectively between 0 and 10 wt% [13].

Ki – 3.27x10-3 (μm/ mA·cm·year) In the last years, there have been introduced sub-classes

ρ – density (g/cm3) of CoCr or NiCr based alloys with Pd (25% wt), in adequate

icorr – corrosion current density (μA/cm2) quantity in order to be considered noble alloys. Unique for

EW – equivalence weight (g) this type of noble alloys is the fact that they evolved from a

For the CoCr tested alloys the best behaviour to corrosion class already existing of common alloys [14].

was for CCG alloy in saliva with pH=2 (-40.51 mV), and Unfortunately, little information is available regarding the

also the highest electronegative value of Ecorr, was for CCG properties of these specific alloys [14], which combine

alloy (-322 mV) in artificial saliva with pH=5. the properties of Pd [15-19], common alloys [13, 20] and

The NP alloy has a lower resistance to corrosion features derived from previous attempts to enrich dental

compared to the other NiCr alloys in artificial saliva with materials with Pd [21].

pH=2 and pH=5, having better corrosion resistance in

artificial saliva with neutral pH. For CoCr alloys in artificial Conclusions

saliva with pH=2 and pH=5 but as well as in neutral pH Alloys corrosion resistance was assessed based on

saliva, the lowest corrosion current density is recorded by several evaluation criteria.

CCG alloy and, therefore, this alloy showed the best The study demonstrated the importance of the content

behaviour to corrosion. of different components in dental alloys related with the

By comparing the corrosion rate for NiCr alloys, the importance of the pH of the medium.

values are close for all samples in artificial saliva with pH=5. Comparing the results of the tested alloys, they showed

Corrosion rate changes in neutral saliva, as expected, that NiCr alloys have higher electropositive values for open

decreasing for NP alloy but increasing for NCU and NCP circuit potential than those of CoCr alloys in artificial saliva

alloys which indicates a better behaviour to corrosion in with acidic pH. For CoCr alloys it was obvious that open

neutral environment, confirmed as well from the circuit potential values in artificial saliva with pH=7 are

assessment of the other corrosion parameters. more electropositive as compared to those in NiCr alloys,

Behaviour and corrosion resistance of a metal alloy with thus emphasising their nobler character.

dental destination is given by factors such as: alloy Taking into consideration the value of corrosion potential

chemical composition, its surface nature, micro-structure (Ecorr), it is considered that metals with more electropositive

(presence of structural and crevice type imperfections), Ecorr potential have a better corrosion behaviour. According

pH of the environment, temperature, oxygen content [1-4, to this criterion, for the NiCr type alloys, NCU has the best

7-11]. behaviour to corrosion in artificial saliva with pH=2 and

The corrosion behaviour of dental alloys based on CoCr NCP alloy has the best behaviour in saliva with pH=5.

and NiCr mainly depend on the percentage of Cr and Mo of It is recognised that a lower corrosion current density

the alloy [12]. In commercially available alloys, the indicates a better corrosion resistance. Thus, if we take

708 http://www.revistadechimie.ro REV. CHIM. (Bucharest) ♦ 65♦ No.6 ♦ 2014

into consideration this criteria, we can notice that NiCr carbides, nitrides and oxides, Springer Series in Materials Science,

alloys have the values of corrosion current density roughly New York, 2009.

equal in saliva with pH=5, and in the acidic one the values 10. OURA K., LIFSHITS V.G., SARANIN A.A., ZOTOV A.V., KATAYAMA M.,

are little different for NCU and NCP alloys remaining within Surface Science: An Introduction, Springer, Berlin, 2003.

the same order of magnitude, compared to NP alloy whose 11.ST. JOHN K.R., ASM Handbook, Vol. 13C, Corrosion: Environments

value increases to three order of magnitude. When dipped and Industries, ASM International, 2006, p. 820 - 825.

into artificial saliva with neutral pH the icorr values increase 12.ROACH M.D., WOLAN J.T., PARSELL D.E., BUMGARDNER J.D., Use

in the case of NCU and NCP alloys and decreases in the of XPS and cyclic polarization to evaluate the corrosion behaviour of

case of NP alloy reaching the lowest value (5.77 nA·cm-2). six Ni-Cr alloys before and after PFM firing, The Journal of Prosthetic

Dental alloys have variations of the corrosion parameters Dentistry, 2000, 84: p.623 - 634.

in all types of the studied artificial saliva. CCG have shown 13.WYLIE C.M., SHELTON R.M., FLEMING G.J., DAVENPORT A.J.,

the lowest values of corrosion rate irrespective of the Corrosion of nickel-based dental casting alloys. Dental Materials,

artificial saliva pH. 2007, 23: p.714 - 723.

14.SARANTOPOULOS D.M., BECK K.A., HOLSEN R., BERZINS D.,

References Corrosion of CoCr and NiCr dental alloys alloyed with Palladium, J.

1. POP S.-I., DUDESCU M., BRATU D. C., POP R.-V., PETRISOR M., Prosthet. Dent., 2010, 105: p.35 – 43.

PÃCURAR M., Influence of the Chemical Composition on the 15.BERZINS D.W., KAWA SHIMA I., GRAVES R., SARKAR N.K.,

Mechanical Properties of Orthodontic Archwires, Rev. Chim., 64, nr.7, Electrochemical characteristics of high Pd alloys in relation to Pd-

2013, p. 771-775 allergy, Dent. Mater., 2000, 16:p.266 -273.

2.SCHWEITZER P.A., Corrosion Engineering Handbook, 2nd edition, 16.BERZINS D.W., KAWASHIMA I., GRAVES R., SARKAR N.K., Heat

CRC Press, New York, 2007. treatment effects on electrochemical corrosion parameters of high-

3. SHREIR L.L., JARMAN R.A., BURSTEIN G.T., Corrosion: Metal/ Pd alloys, J. Mater. Sci. Mater. Med., 2008, 19:p.335 - 341.

Environment Reactions, eds. Vol.1, Newness-Butterworth, Boston, 17.CAI Z., VERMILYEA S.G., BRANTLEY W.A., In vitro corrosion

2000. resistance of high-palladium dental casting alloys, Dent. Mater., 1999,

4. ZAMFIR S., VIDU R., BRÎNZOI V., Coroziunea materialelor metalice, 15:202 - 210.

Ed. Didacticã ºi pedagogicã, RA, Bucureºti,1994. 18.SUN D., MONAGHAN P., BRANTLEY W.A., JOHNSTON W.M.,

5. WATAHA J.C., Biocompatibility of dental casting alloys: A review, J. Potentiodynamic polarization study of the in vitro corrosion behavior

Prosthet. Dent., 83: 223 - 34, 2000. of 3 high-palladium alloys and a gold-palladium alloy in 5 media, J.

6. HANCU V., COMAN C., COMÃNEANU R.M., GHERGIC D.L., Evaluarea Prosthet. Dent., 2002, 87: p.86 - 93

comparativã a restaurãrilor metalo-ceramice cu substrat de Co-Cr-Mo 19.SYVERUD M., DAHL J.E., HERO H., MORISBAK E., Corrosion and

ºi Ni-Cr-Mo, A VII-a ediþie a Congresului Internaþional al Societãþii biocompatibility testing of palladium alloy castings, Dent. Mater., 2001,

Române de Reabilitare Oralã, 2013. 17: p.7 - 13

7. ANDERSON J.M., SCOEN F.J., BROWN S.A., MERRITT K., Implant 20.ROACH M.D., WOLAN J.T., PARSELL D.E., BUMGARDNER J.D., Use

Retrieval and Evaluation, in Biomaterials Science, An Introduction to of X-ray photoelectron spectroscopy and cyclic polarization to evaluate

Materials in Medicine, 2nd Edition, Elsevier Academic Press, 2004. the corrosion behavior of six nickel-chromium alloys before and

8. PARK J., LAKES R.S. Biomaterials: An Introduction, 3rd edition, after porcelain-fused-to-metal firing. J Prosthet Dent;2000, 84: p.623-

Springer, 2007. 634.

9. GUSEV A.I., ANDREEVICH A., REMPEL A., MAGERL A.J., Disorder 21.COLON P., PRADELLE-PLASSE N., GALLAND J. Evaluation of the

and order in strongly nonstoichiometric compounds: transition metal log-term corrosion behavior of dental amalgams: influence of palladium

addition and particle morphology, Dent. Mater., 2003, 19:p.232 - 239

Manuscript received: 19.12.2013

REV. CHIM. (Bucharest) ♦ 65 ♦ No. 6 ♦ 2014 http://www.revistadechimie.ro 709

View publication stats

You might also like

- Planets, Luminaries, Asteroids, and Points in AstrologyDocument3 pagesPlanets, Luminaries, Asteroids, and Points in AstrologySushant ChhotrayNo ratings yet

- Advanced Manufacturing Processes (ALL SLIDES Gaurav Arora)Document259 pagesAdvanced Manufacturing Processes (ALL SLIDES Gaurav Arora)faizNo ratings yet

- Cobalt-Chromium Alloys in Dentistry An Evaluation of Metal Ion ReleaseDocument7 pagesCobalt-Chromium Alloys in Dentistry An Evaluation of Metal Ion ReleaseFrank LucariniNo ratings yet

- SA210 A1 Engg - Failure Analysis - Rajat PDFDocument8 pagesSA210 A1 Engg - Failure Analysis - Rajat PDFShoaib AhmedNo ratings yet

- Application of Outdoor Unitary Equipment A-Weighted Sound Power RatingsDocument19 pagesApplication of Outdoor Unitary Equipment A-Weighted Sound Power Ratingsgazi shaikhNo ratings yet

- Research Methodology-Mcq PDFDocument94 pagesResearch Methodology-Mcq PDFsuma100% (1)

- 22 - GIS Testing PDFDocument9 pages22 - GIS Testing PDFwaqas_a_shaikh4348No ratings yet

- CO2 Preferential Weld Corrosion of Longitudinally Welded Linepipe - Effect of Microstructure, Corrosion Product Layers, and The EnvironmentDocument199 pagesCO2 Preferential Weld Corrosion of Longitudinally Welded Linepipe - Effect of Microstructure, Corrosion Product Layers, and The EnvironmentRob MuggletonNo ratings yet

- Interpretation of Electrochemical Measurements Made During Micro Scale Abrasion CorrosionDocument10 pagesInterpretation of Electrochemical Measurements Made During Micro Scale Abrasion CorrosionJesus ZilchNo ratings yet

- EurJProsthodontRestDent2007v15p33 Co-Ni CorrosDocument8 pagesEurJProsthodontRestDent2007v15p33 Co-Ni CorrosGraziella TurdeanNo ratings yet

- Experimental Design For Copper Cementation Process in Fixed Bed Reactor Using Two-Level Factorial DesignDocument4 pagesExperimental Design For Copper Cementation Process in Fixed Bed Reactor Using Two-Level Factorial DesignAdonis Agüero PajueloNo ratings yet

- Edoziuno 2019 J. Phys. Conf. Ser. 1378 032064Document13 pagesEdoziuno 2019 J. Phys. Conf. Ser. 1378 032064LORENA GRIJALBA LEONNo ratings yet

- Intergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyDocument10 pagesIntergranular Pitting Corrosion of Cocrmo Biomedical Implant AlloyshameekaNo ratings yet

- Corrosion Behavior Between Dental Implant AbutmentDocument3 pagesCorrosion Behavior Between Dental Implant AbutmentMika VaughnNo ratings yet

- Experimental Design For Copper Cementation ProcessDocument5 pagesExperimental Design For Copper Cementation ProcessYashika ca20m007No ratings yet

- Inhibitors For Bronze Surfaces in AcidDocument9 pagesInhibitors For Bronze Surfaces in Acidchérifa boulechfarNo ratings yet

- Article WJPR 1509426397 PDFDocument10 pagesArticle WJPR 1509426397 PDFnaveenmi2No ratings yet

- Adsorption Behaviour of Cefapirin On Mild Steel inDocument15 pagesAdsorption Behaviour of Cefapirin On Mild Steel inNTĐ ChannelNo ratings yet

- 5daria 0Document10 pages5daria 0Ahmed IsmailNo ratings yet

- Evaluation of ICP-OES Method For Heavy Metal and Metalloids Determination in Sterile Dump MaterialDocument10 pagesEvaluation of ICP-OES Method For Heavy Metal and Metalloids Determination in Sterile Dump MaterialAhmed IsmailNo ratings yet

- In Uence of Processing Method of Cocrmo Dental Alloy On The Corrosion Behavior in Artificial SalivaDocument10 pagesIn Uence of Processing Method of Cocrmo Dental Alloy On The Corrosion Behavior in Artificial Salivanattasb97No ratings yet

- Corrosion by Weight LossDocument12 pagesCorrosion by Weight Losschima melfordNo ratings yet

- Fundamental Study On The Effectiveness of Sacrificial Point Anode For Corrosion Prevention of Steel Bars in Chloride Contaminated ConcreteDocument11 pagesFundamental Study On The Effectiveness of Sacrificial Point Anode For Corrosion Prevention of Steel Bars in Chloride Contaminated ConcreteRahmita Sari RafdinalNo ratings yet

- Furnace Lining Analysis and Design by Mathematical and Physicochemical ModelingDocument16 pagesFurnace Lining Analysis and Design by Mathematical and Physicochemical ModelingAdrian BNo ratings yet

- Investigating The Mechanism Behind Ant Nest' Corrosion On Copper TubeDocument17 pagesInvestigating The Mechanism Behind Ant Nest' Corrosion On Copper Tubeatique islamNo ratings yet

- Role of Internal Oxidation and Iron Penta CarbonylDocument13 pagesRole of Internal Oxidation and Iron Penta CarbonylSatyendra SinghNo ratings yet

- Sciencedirect: Selection and Optimization of Electrolyte For Micro Electrochemical Machining On Stainless Steel 304Document6 pagesSciencedirect: Selection and Optimization of Electrolyte For Micro Electrochemical Machining On Stainless Steel 304nirmala bogireddyNo ratings yet

- Study On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeDocument8 pagesStudy On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeNew NSskinNo ratings yet

- Toxicology Reports: Sudeep Shukla, Alka Jadaun, Vikas Arora, Raj Kumar Sinha, Neha Biyani, V.K. JainDocument13 pagesToxicology Reports: Sudeep Shukla, Alka Jadaun, Vikas Arora, Raj Kumar Sinha, Neha Biyani, V.K. JainRohit SharmaNo ratings yet

- Corrosion and Corrosion Inhibition of Pure Iron inDocument17 pagesCorrosion and Corrosion Inhibition of Pure Iron inKatNo ratings yet

- Domankova Kocsisova Slatkovsky Pinke 49Document14 pagesDomankova Kocsisova Slatkovsky Pinke 49Swarup KongarNo ratings yet

- Effect of Laser Parameters On The Corrosion Resistance of The ASTM F139 Stainless SteelDocument13 pagesEffect of Laser Parameters On The Corrosion Resistance of The ASTM F139 Stainless SteelJoão TarelhoNo ratings yet

- Article WJPR 15135744041Document16 pagesArticle WJPR 15135744041SkAliHassanNo ratings yet

- MIHAILAURENTIA Pdf614zirconiaDocument6 pagesMIHAILAURENTIA Pdf614zirconiaJosué MurilloNo ratings yet

- 10 1016@j Corsci 2014 07 001Document32 pages10 1016@j Corsci 2014 07 001uocmogiandi_aNo ratings yet

- Chalcone InhibitorDocument15 pagesChalcone InhibitorFatema HussainNo ratings yet

- BrazJOralSci 2004 3 8 p414 9Document6 pagesBrazJOralSci 2004 3 8 p414 9Jessica WestNo ratings yet

- Paper 2Document13 pagesPaper 2aseNo ratings yet

- Corrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914Document13 pagesCorrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914idanfriNo ratings yet

- Rapid High Performance Sample Digestion of Base Metal Ores U - 2016 - AnalyticalDocument6 pagesRapid High Performance Sample Digestion of Base Metal Ores U - 2016 - Analyticalfachrul.mucharam.ukNo ratings yet

- Journal Homepage: - : Manuscript HistoryDocument12 pagesJournal Homepage: - : Manuscript HistoryIJAR JOURNALNo ratings yet

- Effect of Calcium Nitrate and Sodium Nitrite On The Rebar Corrosion of Medium Carbon Steel in Seawater and Cassava FluidDocument7 pagesEffect of Calcium Nitrate and Sodium Nitrite On The Rebar Corrosion of Medium Carbon Steel in Seawater and Cassava FluidMohammed AdamuNo ratings yet

- Kruusma PDFDocument57 pagesKruusma PDFOmar ReynosoNo ratings yet

- Carlan (Serban) - Beatrice - Adriana - Art7Document9 pagesCarlan (Serban) - Beatrice - Adriana - Art7Liviu BadeaNo ratings yet

- On The Theory of CO2 Corrosion Reactions - Investigating Their Interrelation With The Corrosion Products and API-X100 Steel MicrostructureDocument14 pagesOn The Theory of CO2 Corrosion Reactions - Investigating Their Interrelation With The Corrosion Products and API-X100 Steel MicrostructureFaysal F. EliyanNo ratings yet

- (300-313) V9N5CT Kinetic Modeling For Cu and Fe Using Orange PeelDocument14 pages(300-313) V9N5CT Kinetic Modeling For Cu and Fe Using Orange Peelleelabhanu12No ratings yet

- Engineering Chemistry Syllabus 2020 21Document4 pagesEngineering Chemistry Syllabus 2020 21cat buenafeNo ratings yet

- NBA Course Plan Chemistry 22-23 ODDDocument17 pagesNBA Course Plan Chemistry 22-23 ODDAldrin D CruzNo ratings yet

- The Study of Iron-Based Nanoparticles Stability in Biological Fluids by Stripping VoltammetryDocument5 pagesThe Study of Iron-Based Nanoparticles Stability in Biological Fluids by Stripping VoltammetryJose RicardoNo ratings yet

- Antimicrobial and Anticorrosive Activity of Adsorbents Based On Chitosan Schiff's BaseDocument21 pagesAntimicrobial and Anticorrosive Activity of Adsorbents Based On Chitosan Schiff's BaseFernanda Stuani PereiraNo ratings yet

- Effect of Lead On The Machinability of Brass Alloys Using Polycrystalline Diamond Cutting ToolsDocument15 pagesEffect of Lead On The Machinability of Brass Alloys Using Polycrystalline Diamond Cutting ToolsKevin LowenchrisNo ratings yet

- Hazmat S 23 16698Document40 pagesHazmat S 23 16698Ngô Ích SơnNo ratings yet

- Paper 1Document9 pagesPaper 1Jayishnu SinglaNo ratings yet

- Theoretical and Electrochemical AssessmeDocument10 pagesTheoretical and Electrochemical Assessmechérifa boulechfarNo ratings yet

- ChadiaDocument28 pagesChadias-hadnineNo ratings yet

- Effect of 5, 5-Diphenylhydantoin On Corrosion of Mild Steel in 1M. Hydrochloric Acid SolutionDocument9 pagesEffect of 5, 5-Diphenylhydantoin On Corrosion of Mild Steel in 1M. Hydrochloric Acid SolutionSAI KATKENo ratings yet

- Critical Chloride Concentration of Rebar Corrosion in Fly Ash ConcreteDocument18 pagesCritical Chloride Concentration of Rebar Corrosion in Fly Ash ConcreteJHON WILMAR CARDENAS PULIDONo ratings yet

- V 10 P 1068Document5 pagesV 10 P 1068Ruxandra-Elena BratuNo ratings yet

- Analysis of Corrosion Rate in S 45 C Steel With Sea Water MediaDocument3 pagesAnalysis of Corrosion Rate in S 45 C Steel With Sea Water MediaUmar Hamzah WijayaNo ratings yet

- Comparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsDocument6 pagesComparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsNaoki MezarinaNo ratings yet

- The Study of Corrosion and Wear Resistance of CoppDocument9 pagesThe Study of Corrosion and Wear Resistance of CoppNoura Nour ElshamsNo ratings yet

- Int J Electrochem Sci 820131735-1758Document25 pagesInt J Electrochem Sci 820131735-1758Nadra LubisNo ratings yet

- Fullf22 863962 AgNP UPBSci DobreDocument11 pagesFullf22 863962 AgNP UPBSci Dobrenoura farahNo ratings yet

- Removalof Copper Nickeland Chromium Wastewaterusing ElectrocoagulationDocument12 pagesRemovalof Copper Nickeland Chromium Wastewaterusing ElectrocoagulationNoureddine MerahNo ratings yet

- Advances in Multifunctional Materials and Systems IIFrom EverandAdvances in Multifunctional Materials and Systems IIJun AkedoNo ratings yet

- 6 Da PDFDocument11 pages6 Da PDFSaad LiaqatNo ratings yet

- Corrosion of Dental Alloys in Artificial Saliva With Streptococcus MutansDocument12 pagesCorrosion of Dental Alloys in Artificial Saliva With Streptococcus MutansRuxandra-Elena BratuNo ratings yet

- V 10 P 1068Document5 pagesV 10 P 1068Ruxandra-Elena BratuNo ratings yet

- The Corrosive Effects of Artificial Saliva On Cast and Rapid Manufacture-Produced Cobalt Chromium AlloysDocument17 pagesThe Corrosive Effects of Artificial Saliva On Cast and Rapid Manufacture-Produced Cobalt Chromium AlloysRuxandra-Elena BratuNo ratings yet

- Eddy AxialDocument20 pagesEddy Axialandrea19711971No ratings yet

- RPI Form PDFDocument1 pageRPI Form PDFJoko WiwiNo ratings yet

- Lecture 5. Chemical Reaction (Part 2)Document38 pagesLecture 5. Chemical Reaction (Part 2)Dione Gale NavalNo ratings yet

- Effect of MG Content On Microstructure andDocument12 pagesEffect of MG Content On Microstructure andMohamed RamadanNo ratings yet

- Physics Semiconductor Device MCQDocument3 pagesPhysics Semiconductor Device MCQPradeep Singh ThakurNo ratings yet

- DS PGM Using CPPDocument18 pagesDS PGM Using CPPanand5703No ratings yet

- Schedule 90 Days Jee Main Crash Course MathongoDocument3 pagesSchedule 90 Days Jee Main Crash Course MathongoShrish DollinNo ratings yet

- 02-Continental Drift TheoryDocument22 pages02-Continental Drift Theoryapi-242405009No ratings yet

- Fkeyrouz@ndu - Edu.lb: Systems Using MATLAB, Second Edition, Prentice Hall 2002Document2 pagesFkeyrouz@ndu - Edu.lb: Systems Using MATLAB, Second Edition, Prentice Hall 2002Elio EidNo ratings yet

- Elimination of LowerDocument8 pagesElimination of LowervalentinmullerNo ratings yet

- Chapter2 - 3 - 3D Stiffness and Compliance MatricesDocument43 pagesChapter2 - 3 - 3D Stiffness and Compliance MatricesRobby GunadiNo ratings yet

- Antioxidants - MELROB - RubberDocument6 pagesAntioxidants - MELROB - RubberMarcos ROSSINo ratings yet

- TerritoriesWhitePaper V11 PDFDocument42 pagesTerritoriesWhitePaper V11 PDFMbade NDONGNo ratings yet

- MANUAL For IONIZING AIR BARDocument11 pagesMANUAL For IONIZING AIR BARGerardo BoisNo ratings yet

- Pen-Channel Flow: When You Finish Reading This Chapter, You Should Be Able ToDocument68 pagesPen-Channel Flow: When You Finish Reading This Chapter, You Should Be Able To李建道No ratings yet

- Bioresource Technology: Oscar Pardo-Planas, Hasan K. Atiyeh, John R. Phillips, Clint P. Aichele, Sayeed MohammadDocument8 pagesBioresource Technology: Oscar Pardo-Planas, Hasan K. Atiyeh, John R. Phillips, Clint P. Aichele, Sayeed Mohammadmohsen ranjbarNo ratings yet

- Data Sartocon X-Cap15 SPC2065-eDocument2 pagesData Sartocon X-Cap15 SPC2065-eJosé Ramón Devan DevanNo ratings yet

- Theory of Escalation and Intl Conflict Jo CRDocument25 pagesTheory of Escalation and Intl Conflict Jo CRfuckyou321No ratings yet

- GroupTheory SERC2015 PDFDocument43 pagesGroupTheory SERC2015 PDFsayan100% (1)

- Design Characteristics and Development of A Nozzle For Coaxial Laser CladdingDocument10 pagesDesign Characteristics and Development of A Nozzle For Coaxial Laser CladdingEduardo MendezNo ratings yet

- Pac3A Sect 600 EarthworksDocument66 pagesPac3A Sect 600 EarthworksazizuddinNo ratings yet

- Applying Perspectival Realism To Frequentist Statistics 02 - 04 - 2021Document38 pagesApplying Perspectival Realism To Frequentist Statistics 02 - 04 - 2021Capitano DrittoNo ratings yet

- MP Module 2 - Modified - CorrectDocument24 pagesMP Module 2 - Modified - Correctakhil krishnanNo ratings yet

- Ashirwad Carbonics (India) Private Limited: Co2 Recovery Plant Technical LiteratureDocument5 pagesAshirwad Carbonics (India) Private Limited: Co2 Recovery Plant Technical LiteratureRaul BautistaNo ratings yet

- The Metallurgy of Power BoilersDocument4 pagesThe Metallurgy of Power Boilersagniva dattaNo ratings yet