Professional Documents

Culture Documents

CHG 50018471 Datasheet 12

Uploaded by

Norman Emmanuel CordovaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHG 50018471 Datasheet 12

Uploaded by

Norman Emmanuel CordovaCopyright:

Available Formats

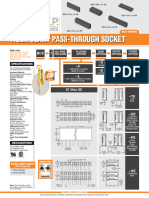

F-217 (Rev 16NOV16)

CLP–115–02–L–D

CLP–107–02–F–D–P

10 YEAR MFG

WITH 30 µ" GOLD

EXTENDED LIFE CLP–130–02–L–D

PRODUCT

HIGH MATING

CLP–116–02–F–DH

CYCLES

(1.27 mm) .050" CLP SERIES

LOW PROFILE DUAL WIPE SOCKET

High-reliability

Mates with:

SPECIFICATIONS FTSH, FTS, FW

Tiger Claw™ (1.27 mm x 1.27 mm)

contacts .050" x .050"

For complete specifications and micro pitch

recommended PCB layouts

see www.samtec.com?CLP

Insulator Material:

Black Liquid Crystal Polymer 9HHDA;9LAGFK

Contact Material:

Phosphor Bronze Low profile

Plating: CLP FTSH (2.21 mm)

Sn or Au over .087"

50 µ" (1.27 µm) Ni

Current Rating (CLP/FTSH):

3.3 A per pin

(1 pin powered per row) HORIZONTAL

Voltage Rating:

240 VAC/340 VDC

Operating Temp Range:

-55 °C to +125 °C

Contact Resistance:

10 mW Surface

Insertion Depth: mount

Top Entry = (1.40 mm) .055" Suitable for pass-through

minimum, Bottom Entry = PASS-THRU

(2.41 mm) .095" minimum applications

plus board thickness

DH Entry = (2.31 mm) .091"

to (2.67 mm) .105"

Normal Force:

60 grams (0.59 N) average

NO. PINS PLATING ROW OTHER

Max Cycles:

100 with 10 µ" (0.25 µm) Au CLP 1 PER ROW 02 OPTION OPTION OPTION

RoHS Compliant:

Yes

PROCESSING –F – BE

–D

Lead-Free Solderable: = Gold flash on = Double = Bottom Entry

Yes 02 thru 50 contact, Matte Row (Required for bottom entry

SMT Lead Coplanarity: Tin on tail applications)

(0.10 mm) .004" max (02-35)

(0.15 mm) .006" max (36-50)

–L –DH –A

= Double

= 10 µ" (0.25 µm) = Alignment Pin

RECOGNITIONS Gold on contact,

Horizontal

(Not available with –PA option)

(Requires

Matte Tin on tail FTSH–01 (05, 06, 07, 08, 10, 12, 15,

For complete scope of

recognitions see and 20, 25, 30, 40 positions only)

www.samtec.com/quality No. of Positions –G FTSH–04 (–DH option and other sizes.

Contact Samtec.)

x (1.27) .050 + (0.43) .017 = 10 µ" (0.25 µm) lead styles)

Gold

FILE NO. E111594 (1.27)

.050

(0.41) (–D only) –K

100 .016 = (4.00 mm) .157" DIA

02 (6.35)

.250 Polyimide film Pick & Place Pad

(4.57) (3.05) (4.32) (5 positions min.)

ALSO AVAILABLE .180 .120 .170

x

(3.18)

(MOQ Required)

99 01

.125 –P

• Single row (1.27) (2.54) = Pick & Place Pad

.050 .100 (5 positions min. –D only)

• Other platings

–P OPTION (Not always necessary

Contact Samtec. for auto placement.

(3.43) (2.29)

.135 See Flex Processing.)

.090

–DH –D

(1.40)

(8.25)

.325

– PA

= Pick & Place Pad

.055 (3.07) with Alignment Pin

.121 (–D only)

A If odd pins/row, alignment (Not Available with –A option)

pins are on middle position (0.89)

on centerline of the part. .035 DIA

PIN/ROW A If even pins/row, then (7.00) – TR

04-15 alignment pins are between .275

(3.56) .140 = Tape & Reel

middle two positions. –PA OPTION

Note: Some sizes, styles and 16-50 (7.11) .280

options are non-standard,

non-returnable.

WWW.SAMTEC.COM

Due to technical progress, all designs, specifications and components are subject to change without notice.

You might also like

- Low Profile Dual Wipe Socket: (1.27 MM) .050" CLP SeriesDocument1 pageLow Profile Dual Wipe Socket: (1.27 MM) .050" CLP SeriesNorman Emmanuel CordovaNo ratings yet

- Low-Profile Socket Strips: (2.54 MM) .100" PITCH - SLW/CES SERIESDocument1 pageLow-Profile Socket Strips: (2.54 MM) .100" PITCH - SLW/CES SERIESKiss IstvánNo ratings yet

- Samtec CLT-104-02-F-D-BEDocument1 pageSamtec CLT-104-02-F-D-BECADTDDNo ratings yet

- ARD SocketsDocument3 pagesARD SocketsRenan TavaresNo ratings yet

- SMT Dip & Chip Carrier Sockets: Icf, PLCC Series (2.54 MM) .100" (1.27 MM) .050"Document1 pageSMT Dip & Chip Carrier Sockets: Icf, PLCC Series (2.54 MM) .100" (1.27 MM) .050"Isaah X AndréNo ratings yet

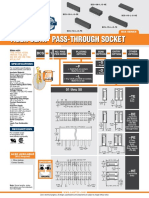

- Tiger Claw Pass-Through Socket: Entry Option ROW Option Plat Ing Op Tion No. Pins Per Row Other OptionDocument1 pageTiger Claw Pass-Through Socket: Entry Option ROW Option Plat Ing Op Tion No. Pins Per Row Other OptionValerio GalieniNo ratings yet

- LSHM-DV Series DatasheetDocument1 pageLSHM-DV Series DatasheetJonathan SanchezNo ratings yet

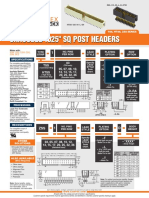

- Shrouded .025" SQ Post Headers: - D TSS Htss 03 05, 07, 08, 10, 12, 13, 15, 17, 20, 25, 32, 36 - FDocument1 pageShrouded .025" SQ Post Headers: - D TSS Htss 03 05, 07, 08, 10, 12, 13, 15, 17, 20, 25, 32, 36 - FSreenivasulu ModduNo ratings yet

- Samtec QTH QSH DatasheetDocument1 pageSamtec QTH QSH Datasheetxoveda9371No ratings yet

- Cost-Effective Rugged Sockets: SQT Series (2.00 MM) .0787"Document1 pageCost-Effective Rugged Sockets: SQT Series (2.00 MM) .0787"ramesh chivukulaNo ratings yet

- B102 ReliefDocument1 pageB102 ReliefjoseacastillolNo ratings yet

- BcsDocument1 pageBcsAlessandro CardelliNo ratings yet

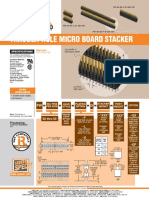

- Through-Hole Micro Board Stacker: (1,27mm) .050" FW SeriesDocument1 pageThrough-Hole Micro Board Stacker: (1,27mm) .050" FW Seriesgarm0704No ratings yet

- Kenwood Kac x1d XR 1sDocument28 pagesKenwood Kac x1d XR 1scacliuNo ratings yet

- 09A-012-193 Design Specification 01Document1 page09A-012-193 Design Specification 01roxibo3129No ratings yet

- Akg D-190es D-190es MicDocument2 pagesAkg D-190es D-190es MicClaus MolinNo ratings yet

- Fuji-Round Indicator SeriesDocument12 pagesFuji-Round Indicator Seriesheri fauziNo ratings yet

- PROFISSIONAL LINE-Compression Driver: Mounting InformationDocument2 pagesPROFISSIONAL LINE-Compression Driver: Mounting InformationDanny BoysieNo ratings yet

- CRP1196 - 33-11kV TRANSFORMER - SAHA - TSECL PDFDocument34 pagesCRP1196 - 33-11kV TRANSFORMER - SAHA - TSECL PDFkhayerpur electrical subdivisionNo ratings yet

- Válvula Relief RD-10A-25WL IB6B9 (Data Sheet)Document1 pageVálvula Relief RD-10A-25WL IB6B9 (Data Sheet)Arturo Valencia LaureanoNo ratings yet

- THM Make Prefill ValveDocument9 pagesTHM Make Prefill ValvePrime HydraulicsNo ratings yet

- Acs - Catálogo InglêsDocument3 pagesAcs - Catálogo InglêsPaulo SergioNo ratings yet

- Winters - 1WPS - Pressure SwitchDocument3 pagesWinters - 1WPS - Pressure SwitchJesus PerezNo ratings yet

- Fujikura 12S CDocument2 pagesFujikura 12S CCristian BolañosNo ratings yet

- Series Tl1105 Switches: Tact Switches - 6Mm X 6MmDocument3 pagesSeries Tl1105 Switches: Tact Switches - 6Mm X 6Mmalex kastaNo ratings yet

- Ot12Pp+ Standard Ot12Pp+ StandardDocument1 pageOt12Pp+ Standard Ot12Pp+ StandardmariopilarNo ratings yet

- Metric Oem: Series TRD-JDocument4 pagesMetric Oem: Series TRD-JCarlos PerezNo ratings yet

- Tweeter: - 25 MM (1'') - High Quality Soft Dome Tweeter - N38 Neodymium MotorDocument2 pagesTweeter: - 25 MM (1'') - High Quality Soft Dome Tweeter - N38 Neodymium Motorlolololo7No ratings yet

- Tiger Eye Flat Idc Wire CablesDocument1 pageTiger Eye Flat Idc Wire CablesOihfff CfgvgffNo ratings yet

- SFP & SFP Transceiver Interfaces: Mect D 1 RA1Document2 pagesSFP & SFP Transceiver Interfaces: Mect D 1 RA1VladimirNo ratings yet

- E-Phemt Mmic: Product Features ApplicationsDocument6 pagesE-Phemt Mmic: Product Features ApplicationsUday KrishnaNo ratings yet

- D PRXDocument1 pageD PRXDiana ArredondoNo ratings yet

- Kenwood Kac-X4dDocument32 pagesKenwood Kac-X4dMario Rodriguez JuradoNo ratings yet

- kx165 and kx155 Brochure PDFDocument6 pageskx165 and kx155 Brochure PDFnelson vasquezNo ratings yet

- Bendix-Kx155 165 PDFDocument6 pagesBendix-Kx155 165 PDFramzi hamzaouiNo ratings yet

- Tc135sd SM Sony en TextDocument26 pagesTc135sd SM Sony en TextPeter CrockerNo ratings yet

- Base Plate Uc152x152x23Document2 pagesBase Plate Uc152x152x23sonofalexanderNo ratings yet

- Calculation Sheet: Design of PadeyeDocument7 pagesCalculation Sheet: Design of PadeyeIkade SuartanaNo ratings yet

- L LL+ LL-S: KEMET Part Number: ESY227M050AH2AADocument1 pageL LL+ LL-S: KEMET Part Number: ESY227M050AH2AAPaulo RobsonNo ratings yet

- JBL Lsr25P: Technical ManualDocument3 pagesJBL Lsr25P: Technical ManualAmm RaNo ratings yet

- β3 N15a Plastic Speaker English ManualDocument11 pagesβ3 N15a Plastic Speaker English Manualnocturnoculto89No ratings yet

- Operating Manual Transmission Test Set 806A / 806ARDocument56 pagesOperating Manual Transmission Test Set 806A / 806ARKeith FoorNo ratings yet

- Relief Valve: RD-10W-X-Y-ZDocument1 pageRelief Valve: RD-10W-X-Y-ZdimakoffNo ratings yet

- Drugo Stezanje Lagergehause e 0035082-00-1Document2 pagesDrugo Stezanje Lagergehause e 0035082-00-1Slaven Dadan-NanoNo ratings yet

- Product Family: "Fuses Offer Unique Advantages Compared To Other Protective Devices."Document18 pagesProduct Family: "Fuses Offer Unique Advantages Compared To Other Protective Devices."Mihaela AntonNo ratings yet

- LSR32LRDocument2 pagesLSR32LRRafael MendozaNo ratings yet

- Fenac FNC50HDocument4 pagesFenac FNC50HAbo Elbill BosnaliNo ratings yet

- Es 20Document3 pagesEs 20haowiepowerNo ratings yet

- JBL TR125Document2 pagesJBL TR125Jose Gregorio Ortega CarrilloNo ratings yet

- Samtec Connector - MaleDocument1 pageSamtec Connector - MaleMRousstiaNo ratings yet

- Connector - Adamtech - PG - 234-242Document9 pagesConnector - Adamtech - PG - 234-242Aravind Prasad Sounder RajNo ratings yet

- Kenwood Kac-9104d SMDocument14 pagesKenwood Kac-9104d SMDiego AndroidNo ratings yet

- Samtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueDocument1 pageSamtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueJohn AllenNo ratings yet

- GT5-12D 12" Woofer - Technical Data: Specifications Sealed Box Volume (Includes Driver Displacement)Document2 pagesGT5-12D 12" Woofer - Technical Data: Specifications Sealed Box Volume (Includes Driver Displacement)mgibson2000No ratings yet

- KAC-8105D/8105DM: Service ManualDocument18 pagesKAC-8105D/8105DM: Service ManualClaudis ReyesNo ratings yet

- Monterrico MT BTDocument1 pageMonterrico MT BTCésar Luis Castillo ChiletNo ratings yet

- Winters - LVC - Pressure TransmitterDocument5 pagesWinters - LVC - Pressure TransmitterANP ENGINEERINGNo ratings yet

- Aluminum Electrolytic Capacitors Surface Mount Type VDocument11 pagesAluminum Electrolytic Capacitors Surface Mount Type VbolsterNo ratings yet

- 110-11KV TRAFO ER Panel DrawingDocument82 pages110-11KV TRAFO ER Panel Drawingchand bashaNo ratings yet

- German Volume Trainnig ResearchDocument12 pagesGerman Volume Trainnig ResearchSuRaj RaiNo ratings yet

- 1 CLP 1Document4 pages1 CLP 1Norman Emmanuel CordovaNo ratings yet

- 1 CLP 1Document4 pages1 CLP 1Norman Emmanuel CordovaNo ratings yet

- 1 CLP 1Document4 pages1 CLP 1Norman Emmanuel CordovaNo ratings yet

- Singlfuse Sf-0603Hixxxf Series FeaturesDocument5 pagesSinglfuse Sf-0603Hixxxf Series FeaturesNorman Emmanuel CordovaNo ratings yet

- 1206 Fuse New-10010729-Datasheet-1Document4 pages1206 Fuse New-10010729-Datasheet-1Norman Emmanuel CordovaNo ratings yet

- TLN Series: Tantalum Solid Electrolytic Chip Capacitors - Undertab SeriesDocument4 pagesTLN Series: Tantalum Solid Electrolytic Chip Capacitors - Undertab SeriesNorman Emmanuel CordovaNo ratings yet

- 1 CLP 1Document4 pages1 CLP 1Norman Emmanuel CordovaNo ratings yet

- 1206 Fuse New-10010729-Datasheet-1Document4 pages1206 Fuse New-10010729-Datasheet-1Norman Emmanuel CordovaNo ratings yet

- Cost Drivers in Manufacturing of PCBS: Albert SchweitzerDocument76 pagesCost Drivers in Manufacturing of PCBS: Albert SchweitzerNorman Emmanuel CordovaNo ratings yet

- Anemometro Sper Scientific PDFDocument1 pageAnemometro Sper Scientific PDFSonik MartínNo ratings yet

- Pt100-Temperature-Relay Type TR250: Digital, 3 Sensors, 3 LimitsDocument1 pagePt100-Temperature-Relay Type TR250: Digital, 3 Sensors, 3 LimitsABDUL GHAFOORNo ratings yet

- Cobra Micro Talk User ManualDocument17 pagesCobra Micro Talk User ManualDanybadNo ratings yet

- MG SeriesDocument8 pagesMG SeriesLa LamNo ratings yet

- CRST045N10N, CRSS042N10N: 100% Avalanche Tested 100% Avalanche Tested 100% Avalanche TestedDocument10 pagesCRST045N10N, CRSS042N10N: 100% Avalanche Tested 100% Avalanche Tested 100% Avalanche TestedLuis FigueroaNo ratings yet

- cgs75 VcsDocument5 pagescgs75 VcsMustafa Umut SaracNo ratings yet

- 6 Electrotechnology 4 Vocational CommunicationDocument15 pages6 Electrotechnology 4 Vocational CommunicationmfeketemartiNo ratings yet

- THERMO KING TK 61377-18-MM TKV500 and TKV600 Maintenance Manual Rev. A 01-19Document108 pagesTHERMO KING TK 61377-18-MM TKV500 and TKV600 Maintenance Manual Rev. A 01-19Vincent Marmande100% (1)

- SaikumarDocument15 pagesSaikumarSai KumarNo ratings yet

- Propagation of Voltage SagsDocument8 pagesPropagation of Voltage SagsДинка ИвановаNo ratings yet

- Leading The Way in Heavy Metals Analysis: Epsilon 5Document16 pagesLeading The Way in Heavy Metals Analysis: Epsilon 5tonyNo ratings yet

- GEH 3416 Shunt Trip DeviceDocument3 pagesGEH 3416 Shunt Trip DevicejadliftboatsetorecordsNo ratings yet

- 2007 BEICatalogDocument52 pages2007 BEICatalogPrime Energy Warehouse-YemenNo ratings yet

- Ultra Low Drop Linear RegulatorDocument2 pagesUltra Low Drop Linear RegulatorJose Helio PalmaNo ratings yet

- ARNU42GTMC4Document2 pagesARNU42GTMC4jaimegutierrezlinganNo ratings yet

- Spare Parts Catalog: 8 2007 Agi GMBH Wiener Strasse 158 A-2352 Gumpoldskirchen Austria Europe Tel.: +43-2252-606Document34 pagesSpare Parts Catalog: 8 2007 Agi GMBH Wiener Strasse 158 A-2352 Gumpoldskirchen Austria Europe Tel.: +43-2252-606Mitica ScurtuNo ratings yet

- DSD Notes Unit 2 PDFDocument18 pagesDSD Notes Unit 2 PDFVAISHAKA N RAJNo ratings yet

- (Open Ended Lab 02) : Digital Signal ProcessingDocument8 pages(Open Ended Lab 02) : Digital Signal ProcessingSyed HarisNo ratings yet

- What Causes Cables To Get Heated Up and Melt in A Circuit?Document6 pagesWhat Causes Cables To Get Heated Up and Melt in A Circuit?Fawaaz KhurwolahNo ratings yet

- No Load and Blocked Rotor TestDocument19 pagesNo Load and Blocked Rotor Testsupere100% (4)

- EPEVER Datasheet - XTRA 1Document2 pagesEPEVER Datasheet - XTRA 1M Khalif WinaryaNo ratings yet

- MRSS 11kv Feeder Instrument ListDocument27 pagesMRSS 11kv Feeder Instrument ListMohiuddin totulNo ratings yet

- Fpga WorkshopDocument4 pagesFpga WorkshopPardha Saradhi DamarlaNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNo ratings yet

- ABB Disconnector ON - EN - 20200812Document24 pagesABB Disconnector ON - EN - 20200812nyala chisolaNo ratings yet

- Cannon Connector Ms - E-RDocument24 pagesCannon Connector Ms - E-RsunhuynhNo ratings yet

- Power Transformer: (Equipped With Static Shield, Magnetic Shieid)Document5 pagesPower Transformer: (Equipped With Static Shield, Magnetic Shieid)Leonardo MarraffiniNo ratings yet

- Harman Kardon Hk980 230 SMDocument50 pagesHarman Kardon Hk980 230 SMkarol1301No ratings yet

- ADS Matching and OptimizationDocument18 pagesADS Matching and OptimizationThanhha NguyenNo ratings yet

- Technical Data Sheet: Opus A3 Standard BasicDocument9 pagesTechnical Data Sheet: Opus A3 Standard BasicNicole SmithNo ratings yet