Professional Documents

Culture Documents

Ione-Aa00-Pe-Cm-0005 Hse Procedure For Pre Start-Up Safety Review - Rev. A

Uploaded by

YusufOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ione-Aa00-Pe-Cm-0005 Hse Procedure For Pre Start-Up Safety Review - Rev. A

Uploaded by

YusufCopyright:

Available Formats

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 1/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

HSE PROCEDURE FOR PRE START-UP SAFETY REVIEW

PROJECT : KARBALA REFINERY PROJECT

LOCATION : KARBALA, IRAQ

EMPLOYER : STATE COMPANY FOR OIL PROJECTS (SCOP)

A 31 OCT 19 ISSUED FOR REVIEW Y. H. YEO J. B. KIM Y.S.KIM Y.B.IM H.S.HWANG

REVD REVD APPRD CONFD

REV. DATE DESCRIPTION PRPD CHKD

(PQM) (PM) (PD) (SCOP)

Joint Venture of Hyundai Engineering & Construction Co., Ltd., GS Engineering & Construction Co., Ltd., SK Engineering &

Construction Co., Ltd., and Hyundai Engineering Co., Ltd.,

Note :

a) Revision bar(vertical line) shall be placed in the right hand margin to indicate where the changes has been made

b) PRPD = Prepared by, CHKD = Checked by, REVD = Reviewed by, APPRD = Approved by, CONFD = Confirmed by

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 2/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

REVISION HISTORY

Rev Date Description Page

A 31 OCT 19 Initial Issue -

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 3/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

TABLE OF CONTENTS

1. GENERAL ...................................................................................................................................................4

2. DEFINITIONS, ABBREVIATIONS AND ACRONYMS ...............................................................................4

3. REFERENCE ..............................................................................................................................................5

4. ROLE AND RESPONSIBILITY...................................................................................................................6

5. INTRODUCTION .........................................................................................................................................7

6. EXECUTION OF PSSR...............................................................................................................................7

6.1. System Identification ................................................................................................................... 7

6.2. PSSR Team formation .................................................................................................................. 8

6.3. Execution ...................................................................................................................................... 8

6.4. Documents Validation .................................................................................................................. 8

6.5. Pre Start-Up Items ........................................................................................................................ 8

6.6. Follow Up ...................................................................................................................................... 9

7. ARCHIVING, DOCUMENT STORAGE AND TRACEABILITY ..................................................................9

8. ATTACHMENT ..........................................................................................................................................10

8.1. ATTACHMENT A: CHECK SHEETS .........................................................................................10

8.2. ATTACHMENT B: Post Start-Up Items Form ............................................................................21

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 4/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

1. GENERAL

The scope of the Pre Start-Up Safety Review (PSSR) is to provide the project with suitable

evidence to the effect that, at the time the plants are notified Ready for Start Up, all conditions

for safe operation have been met.

This Procedure has been prepared in order to specify in detail the scope, methods and

responsibilities for execution of the Pre Start-up Safety Review, and to provide the relevant

check-lists of Safety Critical Items. This procedure will be applied to all PSSR activities

respectively Operating Units and BSU (Black Start-Up) to be executed by CONTRACTOR.

2. DEFINITIONS, ABBREVIATIONS AND ACRONYMS

“Pre-commissioning or PRECOMMISSIONING” means all checks,

cleaning and testing of Plant and its implementation without

introducing hydrocarbons or permanently energizing or pressure said

Pre-commissioning

Plant. Pre-commissioning includes all activities implemented between

the completion of construction activities and Ready for

Commissioning

Commissioning or COMMISSIONING” means all activities associated

with preparing or testing functionalities of the Plant or part thereof prior

to initial START-UP up to the condition of Plant “ready for START-UP”.

Commissioning

When the COMMISSIONING activities are completed, the condition

of Plant “ready for START-UP” is achieved, a “Plant ready for START-

UP” certificate is issued and the Plant is handed over to COMPANY.

“Mechanical Completion” is the stage when the construction and

installation of equipment, piping, instrumentation, cabling, electrical

equipment, etc. have been demonstrated as mechanically complete

Mechanical Completion

and all PRECOMMISSIONING activities including inspections,

cleaning, testing as well as documentation requirements have been

fulfilled.

Process Safety A compilation of chemical hazard, technology, and equipment

Information documentation needed to manage process safety.

Pre Start-up Safety Review (or Pre Start-Up HSE Review): a final

PSSR

check by all involved disciplines to confirm readiness for Start-Up.

Entity in charge to collaborate with the PSSR Leader in his actions

PSSR Coordinator

and works. (HSE Commissioning Coordinator)

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 5/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

Entity in charge to perform the PSSR and ensuring the completion of

PSSR Leader

all corrective action items. (Area Commissioning Manager)

The overall electronically generated Punch List, which identifies all

Punch List Punch Items by system, sub-system, site and discipline, capable of

being sorted by category, and any combination of the above.

Ready for Start-up means all construction, pre-commissioning and

commissioning activities have been completed. At this stage all

Ready for Start-Up

necessary, chemicals etc. have been installed and the unit is ready

to receive feed.

Start-Up” means introduction of feedstocks into process Plant with

the express purpose of producing a product for the first time; this is

Start-Up

often referred to as “oil in”. This activity will be carried out by the

Operation personnel of the CONTRACTOR.

A set of equipment and components (including foundations,

structures, mechanical, electrical and control systems, piping and

System

associated parts) that perform a single service, function and

operation as a process, utility system and/or facility.

Smallest and most practical unit of the scope of work for all

Subsystem disciplines within a system which can be commissioned

independently.

3. REFERENCE

Contractual documents referenced for preparing this HSE PROCEDURE FOR

PRE START-UP SAFETY REVIEW are as below.

• Contracts :

a) EPC Contract Finalization Meeting(Technical) 21st-24th Jan 2014 Amman, Jordan

b) CONTRACT DOCUMENTS Volume3. Contractor’s Scope of Work – Section1.8

Precommissioning / Commissioning and Start-up

c) IONE-AA00-PE-CM-0001 PRECOMMISSIONING & COMMISSIONING EXECUTION PLAN

d) IONE-AA00-PE-QA-0001 Project Quality Plan

e) IONE-AA00-PE-HS-0050 Pre-Commissioning & Commissioning HSE Plan

f) IONE-AA00-PE-CM-0003 Systems and Subsystem subdivision

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 6/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

4. ROLE AND RESPONSIBILITY

PROJECT MANAGER FOR CONSTRUCTION

The Project Manager for Construction is responsible for:

Ensuring the implementation of the PSSR Process;

Ensuring the provision of adequate resources for the execution of the review.

AREA COMMISSIONING MANAGER

The Area Commissioning Manager is responsible for:

Initiating the PSSR Process;

Preliminarily defining “Applicable Items” of the checklist;

Building the PSSR Team;

Supporting the HSE Manager or HSE Commissioning Coordinator for the scheduling and

coordination of PSSR activities;

Ensuring the completion of all corrective action items within the scope of his/her field of

competence prior to start-up;

Ensuring the close-out of all action items arising from the review.

HSE MANAGER/ HSE COMMISSIONING COORDINATOR

The HSE Manager/ HSE Commissioning Coordinator is responsible for:

Supporting the Area Commissioning Manager for the development of the PSSR review;

Supporting the Area Commissioning Manager for the PSSR Team Building;

Scheduling and coordinating PSSR activities;

Facilitating the PSSR and issuing the Review Report to the interested parties;

Ensuring preparation of the Close-Out Report;

Ensuring that all corrective action items deemed necessary for completion prior to start-up

have in fact been completed;

Ensuring that all post-start-up corrective action items have been completed.

DISCIPLINE REPRESENTATIVE

Specialists of disciplines will be available to participate to PSSR.

Each Discipline Representative shall:

Review (or participate in the joint review of) all items regarding the safety of operations

relating to his/her own discipline, as indicated in the “Responsibility” column of the checklist;

Guaranteed full cooperation and support to PSSR staff in the application and closure of

PSSR actions;

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 7/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

Ensure the close out of their own items

5. INTRODUCTION

As per OSHA Standard 1910.119 “Process Safety Management of Highly Hazardous Chemicals”:

The Pre Start-up Safety Review shall confirm that prior to the introduction of highly hazardous

chemicals to a process:

i) Construction and equipment is in accordance with design specification;

ii) Safety, operating, maintenance and emergency procedure are in place and are adequate;

iii) For new facilities, a process hazard analysis has been performed and recommendations have

been resolved or implemented before Start-up ( …);

iv) Training of each employee involved in operating a process has been completed.

Prior to the introduction of any hazardous material into the process, the PSSR shall confirm that:

Units and BSU Area as built and commissioned are in accordance with the design

specifications related to safety;

Safety issues have been adequately addressed in the Final Project Documents file available

at the site;

All changes made to the project during the construction and commissioning phases have

been documented and reviewed for their possible impact on the safety of operations. All

related documents are updated accordingly and available as (red marked) “Master Copy” to

the Employer as well as to the Commissioning Teams.

Emergency procedures are in place;

Training of the employees in safety, maintenance and operating the process has been

completed.

6. EXECUTION OF PSSR

6.1. System Identification

Area Commissioning Manager and the HSE Manager or HSE Commissioning Coordinator will

cover respectively the role of PSSR Leader and PSSR Coordinator. They shall identify if the

system which is going to be Started-Up needs a PSSR to be performed.

PSSR Leader and PSSR Coordinator shall preliminarily define the applicability of each Item of

the checklist (Attachment A), specifying the “Not Applicable” Items in the “Status” column.

They shall check the HAZOP report in order to evaluate the presence of criticality related to the

Start-Up phase already analyzed, informing the personnel involved in the Start-Up on all the

safety issues that emerged in Engineering phase.

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 8/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

6.2. PSSR Team formation

The Pre Start-up Safety Review shall be carried out as a multidisciplinary team job.

Depending upon the Risk related to the System, PSSR Leader and PSSR Coordinator might add

to the Pre Start-Up Safety Review team some figures choosing among:

ROTATING/STATIONARY ENGINEER or SUPERINTENDENT

PIPING ENGINEER or SUPERINTENDENT

ELECTRICAL ENGINEER or SUPERINTENDENT

INSTRUMENT ENGINEER or SUPERINTENDENT

CIVIL(STEEL STRUCTURE) ENGINEER or SUPERINTENDENT

QC MANAGER (If Required)

HSE MANAGER

HSE COMMISSIONING COORDINATOR

COMMISSIONING SUPERINTENDENT

AREA COMMISSIONING MANAGER

EMPLOYER REPRESENTATIVES

Once the Team has been built, the PSSR Leader organizes a meeting at which all the Team

members are summoned.

6.3. Execution

All Team members must participate to the meeting, in order to revise the main topics of the PSSR,

checking the effective applicability of the PSSR Items identified by the PSSR Leader and defining

the Post Start-Up Items.

During the meeting, each Applicable Item is assigned to a Team Member, establishing a due date

for the completion. The items already closed at the moment of the PSSR beginning will be added

and eventual related documents shall be attached.

The Post Start-Up Items, which completion is not mandatory before the Start-Up date, shall be

copied in the “Post Start-Up Items Form” (Attachment B).

In this phase each Team member gathers the information related to the Items of his/her concern

and composes all the documentation needed.

6.4. Documents Validation

At this stage we have the formalization of PSSR through the completion of the documentation,

whether paper or electronic, making sure that all actions to be completed have been resolved

before the Start-Up. The progress of the activities to be completed after the Start-Up should also

be tracked.

6.5. Pre Start-Up Items

In order to obtain of the authorization for the Start-Up, the PSSR Leader must verify that the Pre

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 9/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

Start-Up Items are closed. The items are:

Tool Box Talk about Start-Up activities;

Field verification of the System/Subsystem and the affected area;

Suspension of “open” Work Permits on the System/subsystem and the affected area.

Consistency of the system with the operating manual.

6.6. Follow Up

After that the Start-Up has been performed, each Team member must follow the actions of his/her

concern until their closure. The documentation related to each closed action is gathered and

compiled.

7. ARCHIVING, DOCUMENT STORAGE AND TRACEABILITY

The functions/units and the positions involved in the activities regulated by this procedure shall

ensure, each for matters under its responsibility and also by means of the information systems used,

the traceability of data and information and shall provide for storing and archiving the produced

hardcopy and/or electronic documentation, in order to enable the reconstruction of the different steps

of the process.

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 10/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

8. ATTACHMENT

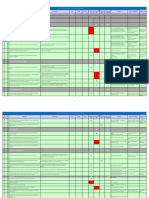

8.1. ATTACHMENT A: CHECK SHEETS

A. # B. REFERENCE

1 SIGN OFF FORM

2 OPERATION CHECK LIST

3 ROTATING/STATIONARY/PIPING/STEEL REVIEW CHECK LIST

4 ELECTRICAL REVIEW CHECK LIST

5 INSTRUMENT CHECK LIST

6 HSE CHECK LIST

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 11/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

PRE START- UP SAFETY REVIEW SIGN OFF FORM

OPERATING UNIT:

REVIEW TEAM MEMBERS CHECK OUT

We have made the Pre Start-Up Safety Review and with the best of our knowledge, the plant is safe for

start up

NAME SIGNATURE DATE

ROTATING/STATIONARY/PIPING ENGINEER

ELECTRICAL ENGINEER or SUPERINTENDENT

INSTRUMENT ENGINEER or SUPERINTENDENT

CIVIL ENGINEER or SUPERINTENDENT

HSE MANAGER

HSE COMMISSIONING COORDINATOR

COMMISSIONING SUPERINTENDENT

HDGSK JV AREA COMMISSIONING MANAGER

EMPLOYER REPRESENTITIVES

(Additional Attendee)

(Additional Attendee)

(Additional Attendee)

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 12/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

PRE START- UP SAFETY REVIEW OPERATION CHECK LIST

OPERATING UNIT:

YES NO N/A REMARK

1 Is the Operating Manual approved?

Are operators trained to start up, operate and

2.A

shutdown the new/modified unit?

Are operators trained to respond to utility failures

2.B including emergency shutdowns, as per operation

manual?

Are all temporary blinds removed according to

3.A

established blind list?

Are all normal process operating blinds re-

3.B

installed?

Are all permanent blinds and spectacle position

3.C

confirmed for normal operations?

Are pipe drain/vent valves closed and

4.A

plugged/capped or end blinded?

Are vessels drain/vent valves closed and

4.B

plugged/capped or end blinded?

Are normally operating PSV block valves Lock

5 Open (LO), and standby one Lock Close (LC) and

labelled?

Are the sewers, the collection pits and the close

6

areas clear from trash and construction wastes?

7 Are all the Interlocks in place?

Has the inerting of the entire unit been achieved if

8

applicable?

9 Is the flare or temporary vent stack available?

10 Is housekeeping acceptable?

Are all equipment labelling clear, visible and

11 according to specifications (color coding, directional

information provided etc.)?

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 13/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

YES NO N/A NAME SIGN. DATE

12 Is the emergency response plan in place?

Has been the relevant System/Subsystem

13

commissioning activities completed?

COMMENTS

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 14/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

ROTA/STA/PIPING/STEEL

PRE START- UP SAFETY REVIEW REVIEW CHECK LIST

OPERATING UNIT:

YES NO N/A REMARK

Are the testing/checks on equipment, including

1 Safety Devices associated with the safe start up,

shutdown and operation of the facilities completed?

Are isolation and drained system for maintenance

2

sufficient?

3 Equipment labelling clear?

4 All vent line is directed to safe area?

5 Is the insulation installed as required?

Is there in place a spill response procedure to

6

properly manage any oil or chemical spill?

Are all equipment manuals and specifications for

7 maintenance and operations available according to

requirements?

8 Are all special tools available for maintenance?

Have plant standards been followed for stairways,

9

platforms, ramps & fixed ladders?

Is the head clearance in walkway and working areas

10

adequate?

Do the accessibility for safe operation considered as

11

per 3D Model Review result?

Do clearances around access, where loading or

12 unloading facilities are installed, comply with access

specification?

Are fireproofing structural steel has been Installed as

13

per requirement?

COMMENTS

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 15/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

ELECTRICAL REVIEW CHECK

PRE START- UP SAFETY REVIEW LIST

OPERATING UNIT:

YES NO N/A REMARK

Has grounding system been measured and meet

1

with specification for each equipment?

Have electrical power disconnecting/connecting

2

been installed lock out tagging system?

3 Have all label START-STOP been installed?

4 Has Lightning System been installed properly?

Has Safety Sign for electrical apparatus/panel

5

(Energizing panel only) been installed?

6 Has cathodic protection been installed and tested?

Are the closed areas clear from trash and

7 construction wastes (especially flammable

material)?

Do all the systems and subsystems of the operating

8

unit have the Mechanical Completion Certificate?

Are the access and clearance around the panels

9

adequate?

Are the Panels free of accumulation of dust and

10

dirt?

Is the ECS/PMS controlling smoothly in the

11 operation of system (subsystem)? (Except for

function not required to direct operation)

Are the Labelling and circuits identification in

12

panels correct?

Do communication devices (radio system etc.)

13

comply with certification?

Are PA System, Process CCTV system tested and

14

operational?

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 16/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

YES NO N/A REMARK

Are all fire escape routes and exit doors, alarm

15 points and firefighting equipment clear of

obstructions?

Is Fire/Gas Detection System at its place for the

16

area under concern and is it functional?

Is Fire Extinguishing System at its place for the

17

area under concern and is it functional?

Are all voltage warning labels installed on the

18

electrical apparatus?

Has the Normal Lighting System been installed

19

properly?

Has the Emergency Lighting System been installed

20

properly?

Was Grounding and Lightning Protection system

21

installed completely with proper bonding?

Were Motor Cable Boxes checked properly for any

22

loose connection and cleanliness?

COMMENTS

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 17/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

PRE START- UP SAFETY REVIEW INSTRUMENT CHECK LIST

OPERATING UNIT:

YES NO N/A REMARK

Have all field instruments (transmitters,

1 switches, dampers, valves, etc.) been

calibrated/Function tested and documented?

2 Have DCS system been tested and functional?

Are emergency safety valves / shutdown

3

systems tested to be functional?

Are detectors / alarms calibrated, tested and

4

functional?

Are control instrument, interlock system fail

5

safe?

Is the antenna power of all radio devices within

6

acceptable limits?

Are the control panels clearly labelled and

7

Identified?

Do instrument tubing run safe or protected

8

from hazardous materials?

9 Is the Field Punch Items closed?

10 Is MIMIC/ Matrix panel tested and operational?

Unless otherwise agreed, all force and MOS

11

signals removed? All Alarm INHIBIT removed?

12 Fire &Gas system tested and operational

13 Alarm systems tested and operational

Are ALL of pressure safety valve tested and

14

certified?

COMMENTS

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 18/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

PRE START- UP SAFETY REVIEW HSE CHECK LIST

OPERATING UNIT:

YES NO N/A REMARK

Are the following safety and fire protection equipment

installed and tested to be functional?

• Fire extinguishers

1

• Self Contain Breathing Apparatus

• Personal Protective Equipment (PPE)

• Hazard Warning Signs

Are the following fixed safety and fire protection

equipment installed and tested to be functional?

• Hydrants, monitors, hose boxes and hose reels

2 • Water Spray and foam system

• Fire Extinguishers

• Safety showers and eyewash

• Emergency Lighting

Has the Fire Safety Equipment Listing been revised

3

and updated to reflect new equipment?

Have relevant material safety data sheets been

4

updated and made available?

Are Safety Equipment & Escape Route Layout and

5.A Safety Shower & Eye Wash Layout available?

Are Emergency Escape Routes properly signposted?

Are the installations at site are compliant with the

5.B

design?

Do safety showers provide a hazard to people (slips),

6 product (contamination of systems), or ingress to

electrical switchgear or equipment?

7 Are windsocks in place and visible?

Are Firefighting equipment and escape routes

8.A

accessible?

Are the escape routes, muster points marked and

8.B

accessible?

Are all firefighting equipment installed as per the

9

firefighting system layout?

10 Are Punch Lists related to HSE closed?

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 19/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

YES NO N/A REMARK

Have adequate arrangements been made for the

11 identification, classification and safe disposal/storage

of all wastes materials?

12 Are Punch Lists related to HSE closed?

Have plans been made for the containment and

13

disposal of the discharges from relieving devices?

Are drainage systems adequate to handle design

14

case flows and flooding test has been done?

Have adequate arrangements been made, prior to

15 start-up, for the identification, classification, and safe

disposal of all waste?

Have bump/trip hazards been properly identified and

16 adequately marked?

Have all sharp edges been removed?

Has proper guarding, handrails/barriers, been

17 provided to prevent and minimize falls, bump, slip,

trap, crush and cut?

Has sufficient lighting been provided so that operation,

18 servicing, maintenance, and repair of the facilities can

be carried out?

Have all overhead fixtures, for example, pipe-hangers,

pipe sleeves, pipe sleeve covers, valve handles, floor

19

opening covers, etc., which could fall or be dislodged,

been properly secured?

Has all access to dangerous moving parts or danger

zones created by the equipment, been prevented by

20

the provision of the correct guards, interlocks and/or

barriers?

Has safe access been provided to the equipment that

21

requires operator access for normal operations?

Is the equipment provided with the properly identified

START/STOP and EMERGENCY controls that are

22

positioned for safe operation without hesitation, or

loss of time, and without ambiguity?

Are all display screens, dials and START/STOP/

EMERGENCY buttons positioned so that they are

23

readily visible and accessible by the operating

personnel? (Except for PIB operation case)

Has all pipe work, tanks, and equipment containing

24

hazardous materials been adequately labeled?

Are there any gaps between platforms and equipment

25

that could create a foot hazard?

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 20/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

YES NO N/A REMARK

Has all scaffolding and construction equipment been

26 removed?

Is housekeeping acceptable?

Have signs been posted where noise levels excess

27

85dB?

Have signs been posted for PSVs exceeding noise

28

levels of 110dB (A) at 1 meter?

29 Are the inspection and testing of relief devices?

30 Fire proofing and passive fire protection completed

COMMENTS

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

PROJECT PROCEDURE

HSE PROCEDURE FOR

PROJ. 2171

PRE START-UP SAFETY REVIEW

DOC. NO. : IONE-AA00-PE-CM-0005

KARBALA REFINERY PROJECT Rev. A Page 21/21

Ref. FEED DOC. No. : 2342-AA00-JSM-901

8.2. ATTACHMENT B: Post Start-Up Items Form

ITEMS STATUS NOTE RESPONSIBILITY DUE DATE

DOCUMENTATION

SYSTEM READINESS

SAFETY SYSTEM READINESS

HDGSK JV Gran Seoul Tower 1, 33, Jong-ro, Jongno-gu, Seoul, Korea

You might also like

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- RAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREDocument57 pagesRAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREKhan Wasim100% (1)

- Pre-Startup Safety Review (PSSR)Document4 pagesPre-Startup Safety Review (PSSR)EcoNo ratings yet

- Manual For SIEP-led HSE AuditingDocument60 pagesManual For SIEP-led HSE AuditingClive NicliNo ratings yet

- Pa 020 0028 - PSSRDocument18 pagesPa 020 0028 - PSSRrizqi widodo100% (1)

- Petroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Document15 pagesPetroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Anjani Prabhakar0% (1)

- (III) PSSR Procedure (Rev00)Document19 pages(III) PSSR Procedure (Rev00)ahmedNo ratings yet

- Chemical Hazard ProcedureDocument23 pagesChemical Hazard Proceduregshdavid100% (2)

- Override Bypass ControlDocument26 pagesOverride Bypass ControlRajesh Krishnamoorthy100% (2)

- SP-1074 Pom PDFDocument24 pagesSP-1074 Pom PDFHari Prakash GrandheyNo ratings yet

- 06 - Pre-Startup Safety Review PDFDocument8 pages06 - Pre-Startup Safety Review PDFRashad FaizNo ratings yet

- YPMT OPS PR 0027 - 旁路管理程序 OverrideBypass Management ProcedureDocument21 pagesYPMT OPS PR 0027 - 旁路管理程序 OverrideBypass Management ProcedureShanying PengNo ratings yet

- CP-206-Management of Change - CoP PDFDocument28 pagesCP-206-Management of Change - CoP PDFSyed Muhammad Mohsin100% (1)

- KPI Process SafetyDocument6 pagesKPI Process SafetyKrishnan RajappanNo ratings yet

- Pre Startup Safety ReviewDocument29 pagesPre Startup Safety ReviewAhsan100% (1)

- Wyn032 PDFDocument21 pagesWyn032 PDFWahjudi MuhammadNo ratings yet

- Getting HSE Right PDFDocument62 pagesGetting HSE Right PDFTammanurRaviNo ratings yet

- Process Safety AuditDocument21 pagesProcess Safety AuditKailash Pandey100% (2)

- Maaden MSHEM Safety Documents 10Document27 pagesMaaden MSHEM Safety Documents 10ShadifNo ratings yet

- Attachment - I: Pre Start-Up Safety Review Checklist - 1Document15 pagesAttachment - I: Pre Start-Up Safety Review Checklist - 1HamzaNoumanNo ratings yet

- Ep 95-0313 HazopDocument88 pagesEp 95-0313 HazopManjunathBVenkatesh100% (5)

- Commissioning and Startup - Increase Certainty Through Advanced PlanningDocument5 pagesCommissioning and Startup - Increase Certainty Through Advanced PlanningBramJanssen76100% (2)

- ExxonMobil Process Hazard Analysis ProtocolDocument5 pagesExxonMobil Process Hazard Analysis ProtocolzironelNo ratings yet

- 09.0 Pre StartupDocument13 pages09.0 Pre StartupChandraSekaranBm100% (1)

- PR-1159 - Commissioning and Start-UpDocument117 pagesPR-1159 - Commissioning and Start-Upalokc100% (1)

- Industrial Hygiene ProgramDocument11 pagesIndustrial Hygiene ProgramkavithaNo ratings yet

- HSSE & SP Audit ProcedureDocument41 pagesHSSE & SP Audit Proceduregangadharan000100% (3)

- Six Steps To Effectively Update and Revalidate PHAsDocument8 pagesSix Steps To Effectively Update and Revalidate PHAspolaris44No ratings yet

- Omcl Management of ChangesDocument7 pagesOmcl Management of ChangesHans LeupoldNo ratings yet

- Bow TieDocument2 pagesBow TieAnonymous ocCa18RNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: Corporate HSE AuditsDocument21 pagesPetroleum Development Oman L.L.C.: Document Title: Corporate HSE AuditsMashur Al JunaibiNo ratings yet

- PSSR FormDocument16 pagesPSSR Formmythee100% (5)

- Hazard. Norma Shell. Shell StandardDocument86 pagesHazard. Norma Shell. Shell Standardgustavoemir100% (1)

- PR-1159 - Commissioning and Start-UpDocument116 pagesPR-1159 - Commissioning and Start-Uparsalan100% (2)

- Pdo HseDocument33 pagesPdo HseElencheliyan Pandeeyan0% (1)

- SP-1231 - HSE Specification - Occupational HealthDocument32 pagesSP-1231 - HSE Specification - Occupational HealthKhawaja Kashif QadeerNo ratings yet

- Chevron Richmond Refinery Site-Safety-PlanDocument121 pagesChevron Richmond Refinery Site-Safety-Plankanakarao1No ratings yet

- Pre Start Up Safety ReviewDocument8 pagesPre Start Up Safety ReviewAhmed MorsyNo ratings yet

- Altona Safety Case SummaryDocument32 pagesAltona Safety Case SummarymeoffgNo ratings yet

- United Energy Pakistan's Energy Isolation ProcedureDocument53 pagesUnited Energy Pakistan's Energy Isolation ProcedureJamal Shah100% (1)

- 025 Pre-Startup Project Safety Review 1302Document9 pages025 Pre-Startup Project Safety Review 1302Vipin SomasekharanNo ratings yet

- PR-1159 - Commissioning and Start-UpDocument117 pagesPR-1159 - Commissioning and Start-UpIngemar David Quintero Simonpietri100% (1)

- Ep 95 0300 - (Hemp)Document86 pagesEp 95 0300 - (Hemp)lsaishankar100% (1)

- 3.1.1 Overpressure Protection Basic RulesDocument21 pages3.1.1 Overpressure Protection Basic RulesFranklin RevillNo ratings yet

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- Self Assessment - PSIDocument32 pagesSelf Assessment - PSIYota PentawanNo ratings yet

- Operational ReadinessDocument11 pagesOperational Readinessjefersonlage100% (2)

- 3 - Start-Up ProcedureDocument96 pages3 - Start-Up ProcedureBanjo MirandillaNo ratings yet

- Permit To Work: Construction & Commissioning Procedures ManualDocument16 pagesPermit To Work: Construction & Commissioning Procedures ManualALADINHENo ratings yet

- Understanding Oil and Gas HSE Management (37Document34 pagesUnderstanding Oil and Gas HSE Management (37Madhur ChopraNo ratings yet

- Hazard Identification (Hazid) Study Diesel Engine Generator (Deg) 3 River Water IntakeDocument18 pagesHazard Identification (Hazid) Study Diesel Engine Generator (Deg) 3 River Water IntakeXiang JintaoNo ratings yet

- Safety ObservationsDocument15 pagesSafety ObservationsPavleNo ratings yet

- OIMS Exxon-Mobil PDFDocument16 pagesOIMS Exxon-Mobil PDFAle SanzNo ratings yet

- Lessons From Texas City (By BP)Document26 pagesLessons From Texas City (By BP)sl18280% (1)

- DSM-AW-201607 - Process Control Domain Security IncidentsDocument3 pagesDSM-AW-201607 - Process Control Domain Security IncidentssushantNo ratings yet

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- Pre Safety ReviewDocument27 pagesPre Safety ReviewMagesh KumarNo ratings yet

- SWP Bypassing Critical Protections GuidelinesDocument10 pagesSWP Bypassing Critical Protections Guidelinesesakkiraj1590100% (1)

- A Practical Approach to Hazard Identification for Operations and Maintenance WorkersFrom EverandA Practical Approach to Hazard Identification for Operations and Maintenance WorkersNo ratings yet

- f202 - Field Engineering Duties and ResponsibilitiesDocument6 pagesf202 - Field Engineering Duties and ResponsibilitiesYusufNo ratings yet

- 1 - Underground Piping InstallationDocument6 pages1 - Underground Piping InstallationYusufNo ratings yet

- 1 - Pressure Testing of PipingDocument4 pages1 - Pressure Testing of PipingYusufNo ratings yet

- Underground Sewers and Piping Installation ProceduresDocument7 pagesUnderground Sewers and Piping Installation ProceduresYusufNo ratings yet

- 2 - Field Fabrication of Pipe SpoolsDocument2 pages2 - Field Fabrication of Pipe SpoolsYusufNo ratings yet

- 2 - Pneumatic TestingDocument2 pages2 - Pneumatic TestingYusufNo ratings yet

- 2 - Pipe Priming, Coating & WrappingDocument2 pages2 - Pipe Priming, Coating & WrappingYusufNo ratings yet

- Chevron Spec for Smooth Bore Cargo and Submarine HoseDocument18 pagesChevron Spec for Smooth Bore Cargo and Submarine HoseYusufNo ratings yet

- Bechtel Company Quality RecordsDocument8 pagesBechtel Company Quality RecordsYusufNo ratings yet

- Stainless Steel Piping Fabrication-EGDocument8 pagesStainless Steel Piping Fabrication-EGYusufNo ratings yet

- 212-04a - INSPECTION AND TEST STATUSDocument5 pages212-04a - INSPECTION AND TEST STATUSYusufNo ratings yet

- Field Hydrostatic Testing of Piping Systems-EGDocument9 pagesField Hydrostatic Testing of Piping Systems-EGYusufNo ratings yet

- 1 - Cleaning of Piping Systems and EquipmentDocument4 pages1 - Cleaning of Piping Systems and EquipmentYusufNo ratings yet

- Chevron Specification for Smooth Bore Cargo and Submarine HoseDocument19 pagesChevron Specification for Smooth Bore Cargo and Submarine HoseYusufNo ratings yet

- 221-03a - HANDLING CUSTOMER COMPLAINTSDocument5 pages221-03a - HANDLING CUSTOMER COMPLAINTSYusufNo ratings yet

- Bechtel Quality Procedure for Calibration of Measuring EquipmentDocument7 pagesBechtel Quality Procedure for Calibration of Measuring EquipmentYusufNo ratings yet

- Pneumatic Test CalculationDocument23 pagesPneumatic Test CalculationYusufNo ratings yet

- 220-04a - STATISTICAL TECHNIQUESDocument6 pages220-04a - STATISTICAL TECHNIQUESYusufNo ratings yet

- Bechtel Quality Audit ProcedureDocument17 pagesBechtel Quality Audit ProcedureYusufNo ratings yet

- 210-05 - Inspection and TestingDocument13 pages210-05 - Inspection and TestingYusufNo ratings yet

- Document and Data ControlDocument8 pagesDocument and Data ControlYusufNo ratings yet

- 203-04a - PROJECT COST CONTROL AND PLANNINGDocument12 pages203-04a - PROJECT COST CONTROL AND PLANNINGYusufNo ratings yet

- 204-05 - Design ControlDocument18 pages204-05 - Design ControlYusufNo ratings yet

- Bechtel Limited Company Quality System ProceduresDocument14 pagesBechtel Limited Company Quality System ProceduresYusufNo ratings yet

- 207-04a - Control of Customer Supplied MaterialsDocument7 pages207-04a - Control of Customer Supplied MaterialsYusufNo ratings yet

- 202-05 - Response To EnquiriesDocument9 pages202-05 - Response To EnquiriesYusufNo ratings yet

- Bechtel's Engineering Design Control ProcedureDocument16 pagesBechtel's Engineering Design Control ProcedureYusufNo ratings yet

- 206-05 - ProcurementDocument10 pages206-05 - ProcurementYusufNo ratings yet

- CP - 110 - Back Injury PreventionDocument8 pagesCP - 110 - Back Injury PreventionYusufNo ratings yet

- Implementing a Safe Work Observation ProcessDocument8 pagesImplementing a Safe Work Observation ProcessYusufNo ratings yet

- 0625 s11 QP 31Document20 pages0625 s11 QP 31Haider AliNo ratings yet

- AR88 DManualDocument27 pagesAR88 DManualprawnstranglerNo ratings yet

- E Command4HPC 4SeriesInstallationManualDocument32 pagesE Command4HPC 4SeriesInstallationManualChrisNielsenNo ratings yet

- High Energy Rate Forming (HERF) Processes: Asst - Professor, Mechanical Engg. NIT&MS, BangaloreDocument13 pagesHigh Energy Rate Forming (HERF) Processes: Asst - Professor, Mechanical Engg. NIT&MS, Bangalorejainvikram8498No ratings yet

- HKV-8 Valve Catalog SPLRDocument128 pagesHKV-8 Valve Catalog SPLRCabrera RodriguezNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- (DRGEM) GXR X-Ray Generator Catalogue R3.4Document2 pages(DRGEM) GXR X-Ray Generator Catalogue R3.4Jairo ManzanedaNo ratings yet

- Daewoo Cn071 Chassis Dvq13h1fc TV-VCR SM OnlyDocument99 pagesDaewoo Cn071 Chassis Dvq13h1fc TV-VCR SM OnlyJose GuerreroNo ratings yet

- Restoration of My Atwater Kent Model 40 Radio SetDocument25 pagesRestoration of My Atwater Kent Model 40 Radio SetRandom73100% (9)

- 4 - A S SahneyDocument26 pages4 - A S SahneyMahendra RathoreNo ratings yet

- Hackspace 001Document132 pagesHackspace 001Jose Eduardo Sanchez Larreta100% (1)

- 20AF41Document37 pages20AF41Javier Jutiapa50% (2)

- HA Series Hematology AnalyzerDocument43 pagesHA Series Hematology AnalyzerFrankie Lam75% (4)

- He158c Experimental Manual PDFDocument113 pagesHe158c Experimental Manual PDFElizabeth Thomas0% (1)

- Manual de Procedimiento Raire CPC RDC y RAINDocument4 pagesManual de Procedimiento Raire CPC RDC y RAINjoseph taliNo ratings yet

- HOVAL Industrial BoilersDocument12 pagesHOVAL Industrial BoilersnisussNo ratings yet

- Drive A CFL From 6v or 12vDocument1 pageDrive A CFL From 6v or 12vJohn ApostleNo ratings yet

- FORMER DANFOSS MARINE SYSTEMS TANK CONTENTS TRANSMITTER MAS 2600 INSTALLATION MANUALThe title is less than 40 characters and starts with "TITLEDocument27 pagesFORMER DANFOSS MARINE SYSTEMS TANK CONTENTS TRANSMITTER MAS 2600 INSTALLATION MANUALThe title is less than 40 characters and starts with "TITLEJohn LockNo ratings yet

- Service KHS 9-12 71 Series Rev D-39070745Document104 pagesService KHS 9-12 71 Series Rev D-39070745hawk789No ratings yet

- Terminologia OBD2Document13 pagesTerminologia OBD2Matías LeónNo ratings yet

- Tube Liquid Sensor: OPB350 / OCB350 Series (Calibration Circuit Available)Document8 pagesTube Liquid Sensor: OPB350 / OCB350 Series (Calibration Circuit Available)Oscar Javier Alvarado ZarabandaNo ratings yet

- Remi Obd CodesDocument8 pagesRemi Obd CodesSonny RaymundoNo ratings yet

- ServiceManuals LG Washing WD14030D WD14030D Service ManualDocument36 pagesServiceManuals LG Washing WD14030D WD14030D Service ManualBill100% (5)

- GSW - Frequently Asked QuestionsDocument17 pagesGSW - Frequently Asked QuestionsShishan AhmadNo ratings yet

- EN - 5040-0-8002 - Instructions For Use PROGNOST SH - V7.0 - 2022-01-20Document29 pagesEN - 5040-0-8002 - Instructions For Use PROGNOST SH - V7.0 - 2022-01-20LệnhHồXungNo ratings yet

- MW512 GW512 MW612 GW612 GW712 MWC12 GWC12 GWM12 GWL12 Service Manual PDFDocument62 pagesMW512 GW512 MW612 GW612 GW712 MWC12 GWC12 GWM12 GWL12 Service Manual PDFpowersonicNo ratings yet

- Triton Relays Normally Open Vs Normally Closed PDFDocument2 pagesTriton Relays Normally Open Vs Normally Closed PDFMariane LopesNo ratings yet

- 4422-2 MST Service Unit Confidential Internal Use Only 5084422 01Document21 pages4422-2 MST Service Unit Confidential Internal Use Only 5084422 01Tanyawat SahsakmontriNo ratings yet

- Chapter 4 Shell and Tube Heat ExchangersDocument45 pagesChapter 4 Shell and Tube Heat Exchangerslockas222No ratings yet