Professional Documents

Culture Documents

Heavy-Duty Billet Steel Hold-Down Instructions 2/20/2021: P/N 7440 and 7442

Heavy-Duty Billet Steel Hold-Down Instructions 2/20/2021: P/N 7440 and 7442

Uploaded by

Gabriel ChiavettoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heavy-Duty Billet Steel Hold-Down Instructions 2/20/2021: P/N 7440 and 7442

Heavy-Duty Billet Steel Hold-Down Instructions 2/20/2021: P/N 7440 and 7442

Uploaded by

Gabriel ChiavettoCopyright:

Available Formats

Heavy-Duty Billet Steel Hold-Down Instructions

P/N 7440 and 7442

2/20/2021

These heavy-duty hold-downs cradle and support the shaft and spread the loads over a wider area than O.E.M.

or aluminum counter parts, reducing shaft flex. These heavy-duty hold-downs are not “drop on” and require

custom fitting. Careful attention to our installation instructions will give you the best results.

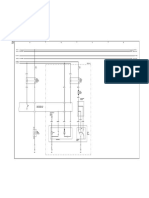

1. Install the rockers, spacers and hold-downs as shown in Illustration 1 noting the position of oil holes, in the

shafts (Illustration 2).

2. Locate the heavy-duty billet hold-downs as shown in Illustration 3. Start with the center hold-down and

work toward each end and center the rockers. The roller (or pad) on the rocker arm must be centered over

the valve stem tip (See Illustration #4). This may require shimming at one or both ends of the hold-down

with the included shims. Each rocker arm pair should have .005”/.010” side clearance.

3. Once a hold-down and shim combination is determined, do not switch parts or positions.

4. The centering of the roller tip is very important on the Small Blocks, as it also centers the rocker arm cut out

for proper spring and retainer clearance.

5. Position the remaining rockers, hold-downs, shims and spacers as required, working from the center out.

Keep all parts in their proper position.

6. With some rocker, spring, valve and retainer combinations, the underside of the rocker arm may touch the

top of the retainer on the Small Blocks. If this occurs, use a rocker shaft saddle shim combination to raise

the rockers up. .020” clearance is adequate. The clearance will be tightest when the valve is closed (see

Illustration #5 at arrow).

Tips: If it becomes necessary to remove material from the ends of the hold-downs, keep the cut as square as

possible. De-burr before final assembly. When possible, use a thin spacer between the rocker arm and the

hold-down. If your rocker arm manufacturer does not supply spacers, use one of the supplied shims from this

hold-down kit. This will minimize wear on the sides of the rocker arms.

Torque specs for the hold-down nuts: Small Blocks 35 lbs-ft

Big Blocks 40 lbs-ft

Note: When properly installed, the top of the studs will be flush with the top of the nuts, with no threads exposed on either piece.

Caution: Edelbrock Big Block Victor heads and their clones have been known to split the pedestals on the two

outer and center positions. See our website (part number HUG AUTOHEAD610) for a preventative operation.

If you have any questions, contact us!

Phone (309) 745-9558

Fax (309) 296-9990

E= E-mail: info@hughesengines.com

You might also like

- Manual Minicargador Caterpillar bh27 y bh30Document5 pagesManual Minicargador Caterpillar bh27 y bh30Pedro BarriosNo ratings yet

- Microwave Weapon Attacks Organized Stalking of Individuals With Directed EnergyDocument7 pagesMicrowave Weapon Attacks Organized Stalking of Individuals With Directed EnergyBrian BivinsNo ratings yet

- Longworth Chuck PDFDocument6 pagesLongworth Chuck PDFBen Gerez100% (2)

- Poseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Document10 pagesPoseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Marlon Alejandro Arboleda TapiaNo ratings yet

- Whyte - 146-T-120-E-120 Supplementary Service Manual Edn1Document16 pagesWhyte - 146-T-120-E-120 Supplementary Service Manual Edn1Jamie WatsonNo ratings yet

- BlueSky BlueLock ProcedureDocument2 pagesBlueSky BlueLock ProcedurealtexsteveNo ratings yet

- Guidance On Mooring System Management Plans (MSMP)Document39 pagesGuidance On Mooring System Management Plans (MSMP)PJ Apostol Alpacas100% (5)

- Automatic Transmision ISUZUDocument258 pagesAutomatic Transmision ISUZUDaniel DiazNo ratings yet

- 5" Multi-Jaw Bench Vise: Operator's ManualDocument6 pages5" Multi-Jaw Bench Vise: Operator's ManualHamid HojatiNo ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- C50L Huck BoltDocument8 pagesC50L Huck BoltEduardo Granados SánchezNo ratings yet

- Read and Understand All Instructions and Warnings Prior To Installation of System and Operation of Vehicle. Safety Warning Product Safety WarningDocument8 pagesRead and Understand All Instructions and Warnings Prior To Installation of System and Operation of Vehicle. Safety Warning Product Safety WarningDaniel EcheverriaNo ratings yet

- DODGE Type C Pillow Blocks, Flange Bearings, Hanger Bearings and UnitsDocument4 pagesDODGE Type C Pillow Blocks, Flange Bearings, Hanger Bearings and UnitsMuhammadAmmarNo ratings yet

- Instructions For The Use of Asym. Wedge Sockets DIN EN 13411 6Document3 pagesInstructions For The Use of Asym. Wedge Sockets DIN EN 13411 6manglesh1No ratings yet

- Tapered Hub Guidelines Rev3-28-03 PDFDocument4 pagesTapered Hub Guidelines Rev3-28-03 PDFPedro RiveraNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- Roatary Actuators - Micromatic Repair Manual - SS-001 Thru SS-130Document12 pagesRoatary Actuators - Micromatic Repair Manual - SS-001 Thru SS-130tungNo ratings yet

- Huck Bolt-AFS5513 C50L BrochureDocument8 pagesHuck Bolt-AFS5513 C50L BrochurePRASHANTH100% (1)

- Maintenance For Model Master Rotary TableDocument7 pagesMaintenance For Model Master Rotary Tablejdk3dNo ratings yet

- Important - Do Not Destroy: Morris Compression CouplingsDocument1 pageImportant - Do Not Destroy: Morris Compression Couplingsmramos4191No ratings yet

- Fin FanDocument4 pagesFin FanPuchit SpkNo ratings yet

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- Rear Sway Bar Installation InstructionsDocument4 pagesRear Sway Bar Installation InstructionsRaduNo ratings yet

- Unidad Rotacion Serie l30Document22 pagesUnidad Rotacion Serie l30Raphael Ruiz RamosNo ratings yet

- Mathey Operatingmanual D251seriesdoublechainclampDocument15 pagesMathey Operatingmanual D251seriesdoublechainclampkimba worthNo ratings yet

- Bondura Bolt - Assembly ProcedureDocument5 pagesBondura Bolt - Assembly ProceduresamersurfNo ratings yet

- Taper Lock BushesDocument4 pagesTaper Lock BushesGopi NathNo ratings yet

- 2531Document5 pages2531sangkil05No ratings yet

- Cherry Maxibolt® Blind Bolt SystemDocument6 pagesCherry Maxibolt® Blind Bolt SystemCHO METNo ratings yet

- Tube Turns Hinged ClosureDocument8 pagesTube Turns Hinged ClosureMarcelino Torres RenjfoNo ratings yet

- Microfinish Ball Valves: Installation Operation and Maintenance ManualDocument19 pagesMicrofinish Ball Valves: Installation Operation and Maintenance ManualMAULIK MULANINo ratings yet

- Storz ManualDocument7 pagesStorz Manualhijodebudas100% (1)

- Rotary Joint Unit: Supplementary Instruction ManualDocument17 pagesRotary Joint Unit: Supplementary Instruction ManualAntonio Montesinos ChavarríaNo ratings yet

- Packer Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2Document4 pagesPacker Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2eberthson hernandezNo ratings yet

- SB DDM 036Document6 pagesSB DDM 036Jim SharpNo ratings yet

- Assembly Instructions: Retrofit For Bridgeport Series 1 MillsDocument4 pagesAssembly Instructions: Retrofit For Bridgeport Series 1 MillsDustin_JanesNo ratings yet

- Congratulations: If You Have Any Questions, Contact Us! Phone (309) 745-9558 Fax (309) 296-9990Document1 pageCongratulations: If You Have Any Questions, Contact Us! Phone (309) 745-9558 Fax (309) 296-9990Gabriel ChiavettoNo ratings yet

- Manual Avance AutomaticoDocument20 pagesManual Avance AutomaticopesyrNo ratings yet

- 8643 IOM 300 and 400 SeriesDocument7 pages8643 IOM 300 and 400 SeriesBiju Basheer CNo ratings yet

- Information Sheet 2.1-2docxDocument8 pagesInformation Sheet 2.1-2docxErnesto CabuyadaoNo ratings yet

- Omega Elastomeric Couplings - Installation ManualDocument2 pagesOmega Elastomeric Couplings - Installation ManualmmkattaNo ratings yet

- Rear Main Seal Installation Instructions 06/05/06Document4 pagesRear Main Seal Installation Instructions 06/05/06Gabriel ChiavettoNo ratings yet

- Online HDM690Document20 pagesOnline HDM690Kyle SchwulstNo ratings yet

- Handy2m InstructionsDocument4 pagesHandy2m InstructionsMutiAra BnNo ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Using Shop ToolsDocument14 pagesUsing Shop Toolsgillian marbebe100% (1)

- Assembly TECHLOK 3 Fold English v3 2013Document2 pagesAssembly TECHLOK 3 Fold English v3 2013Chup AlaNo ratings yet

- NutsDocument3 pagesNutsMicheal JordanNo ratings yet

- WoodWard - Steering Column TechDocument6 pagesWoodWard - Steering Column TechLuiz EduardoNo ratings yet

- Connecting Rod ReplacementDocument11 pagesConnecting Rod Replacementfjafarvand100% (1)

- Fork Gold Valve Installation: DisassemblyDocument4 pagesFork Gold Valve Installation: DisassemblyTiyok HidrolikNo ratings yet

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Document9 pagesRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- Euro Ground Release Shackle Operators Instructions & Spare Parts ListDocument28 pagesEuro Ground Release Shackle Operators Instructions & Spare Parts ListGabriel AmorimNo ratings yet

- Muir 500 ManualDocument28 pagesMuir 500 ManualLight HouseNo ratings yet

- Yoke Type Hinged Closures Installation, Operation & MaintenanceDocument8 pagesYoke Type Hinged Closures Installation, Operation & MaintenanceRamNo ratings yet

- Kidwind ManualDocument4 pagesKidwind Manualapi-254384607No ratings yet

- Lifegear Owners ManualDocument26 pagesLifegear Owners ManualRoniño SuarillaNo ratings yet

- Chillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentDocument18 pagesChillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentsyhnhpc7qmNo ratings yet

- Thomas Thomas Thomas Thomas: Type Cmr/AmrDocument4 pagesThomas Thomas Thomas Thomas: Type Cmr/AmrGustavo Espinosa MartinezNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- KYMCODocument4 pagesKYMCOGabriel ChiavettoNo ratings yet

- SYMDocument4 pagesSYMGabriel Chiavetto100% (1)

- Valvulas ALFAMOTORDocument38 pagesValvulas ALFAMOTORGabriel ChiavettoNo ratings yet

- YAMAHADocument14 pagesYAMAHAGabriel ChiavettoNo ratings yet

- Assembly Tips For Hughes Engines Stroker Kits: BoringDocument4 pagesAssembly Tips For Hughes Engines Stroker Kits: BoringGabriel ChiavettoNo ratings yet

- BENELLIDocument6 pagesBENELLIGabriel ChiavettoNo ratings yet

- Rear Main Seal Installation Instructions 06/05/06Document4 pagesRear Main Seal Installation Instructions 06/05/06Gabriel ChiavettoNo ratings yet

- Tornillos TarantoDocument16 pagesTornillos TarantoGabriel ChiavettoNo ratings yet

- Asientos de ValvulasDocument6 pagesAsientos de ValvulasGabriel ChiavettoNo ratings yet

- Fastener Tensile Strength 170,000/180,000 PSI (1,171 NMM 190,000/200,000 PSI (1,309 NMM 220,000 PSI (1,515 NMMDocument1 pageFastener Tensile Strength 170,000/180,000 PSI (1,171 NMM 190,000/200,000 PSI (1,309 NMM 220,000 PSI (1,515 NMMGabriel ChiavettoNo ratings yet

- SUZUKIDocument15 pagesSUZUKIGabriel ChiavettoNo ratings yet

- Alivio: SI NO SI SIDocument15 pagesAlivio: SI NO SI SIGabriel ChiavettoNo ratings yet

- Installing A Big Block 9 Key Timing Chain SetDocument1 pageInstalling A Big Block 9 Key Timing Chain SetGabriel ChiavettoNo ratings yet

- Throttle Body Instruction Sheet: Tech NoteDocument6 pagesThrottle Body Instruction Sheet: Tech NoteGabriel ChiavettoNo ratings yet

- Timing Chain & Gear Sets Installation InstructionsDocument2 pagesTiming Chain & Gear Sets Installation InstructionsGabriel ChiavettoNo ratings yet

- Rocker Arm Bundle Current 0121Document8 pagesRocker Arm Bundle Current 0121Gabriel ChiavettoNo ratings yet

- Hughes Magnum Shaft Mount Rockers: Check For Pushrod Clearance in Tunnel. Twist The Pedestals Back & Forth WhileDocument2 pagesHughes Magnum Shaft Mount Rockers: Check For Pushrod Clearance in Tunnel. Twist The Pedestals Back & Forth WhileGabriel ChiavettoNo ratings yet

- V-6 Magnum: (Do Not Use Any Type of Gasket Sealer)Document2 pagesV-6 Magnum: (Do Not Use Any Type of Gasket Sealer)Gabriel ChiavettoNo ratings yet

- Camisas de Cilindros (24) : Codigo FadecyaDocument7 pagesCamisas de Cilindros (24) : Codigo FadecyaGabriel ChiavettoNo ratings yet

- Big Block Main Bearing Stud Girdle Kit HUG7380K For "B" & "RB" BlocksDocument6 pagesBig Block Main Bearing Stud Girdle Kit HUG7380K For "B" & "RB" BlocksGabriel ChiavettoNo ratings yet

- Lifter Preload Feb 2016Document1 pageLifter Preload Feb 2016Gabriel ChiavettoNo ratings yet

- Hug 8220Document5 pagesHug 8220Gabriel ChiavettoNo ratings yet

- #7013 Cam Snout Extension & Retainer KitDocument1 page#7013 Cam Snout Extension & Retainer KitGabriel ChiavettoNo ratings yet

- Fi Airgap Intake Installation Instructions: Adapter and Fuel Rails Will Be The Correct Updated VersionsDocument8 pagesFi Airgap Intake Installation Instructions: Adapter and Fuel Rails Will Be The Correct Updated VersionsGabriel ChiavettoNo ratings yet

- HUG7720R0919Document2 pagesHUG7720R0919Gabriel ChiavettoNo ratings yet

- Kit Contents: Shown in Fig 1 1-Stainless Steel Valley Covers Plate 6-Button Socket Head ScrewsDocument3 pagesKit Contents: Shown in Fig 1 1-Stainless Steel Valley Covers Plate 6-Button Socket Head ScrewsGabriel ChiavettoNo ratings yet

- How To Install The Hughes 1555A Rocker Arm Kit and The 1555conversion Kit (For Edelbrock 61779 & 61767)Document5 pagesHow To Install The Hughes 1555A Rocker Arm Kit and The 1555conversion Kit (For Edelbrock 61779 & 61767)Gabriel ChiavettoNo ratings yet

- The Use of Insects in Forensic Investigations - An Overview On The Scope of Forensic EntomologyDocument4 pagesThe Use of Insects in Forensic Investigations - An Overview On The Scope of Forensic EntomologyLight100% (1)

- Wiring Diagram: Rear Window DefoggerDocument1 pageWiring Diagram: Rear Window DefoggerAlexgavgray GNo ratings yet

- Msds 100102 Silicone Platinum CatalystDocument6 pagesMsds 100102 Silicone Platinum CatalystLukman Nul HakimNo ratings yet

- Rossfechten - German GuardsDocument7 pagesRossfechten - German GuardsEsgrima AntiguaNo ratings yet

- Arihant Integral CalculusDocument82 pagesArihant Integral CalculusAbhiNo ratings yet

- BHEL SOP - Work Resumption After Lock Down PDFDocument16 pagesBHEL SOP - Work Resumption After Lock Down PDFRvNo ratings yet

- Corpus Analysis (1) : Corpus Linguistics Richard XiaoDocument44 pagesCorpus Analysis (1) : Corpus Linguistics Richard XiaoIlinca PuricăNo ratings yet

- Air Freshener: Turn Smell Into Active MindDocument15 pagesAir Freshener: Turn Smell Into Active Mindcatherine narzolesNo ratings yet

- LD7890 LeadtrendDocument16 pagesLD7890 LeadtrendO6U Pharmacy RecordingsNo ratings yet

- 1734.do Alligators Eat DucksDocument4 pages1734.do Alligators Eat DuckstvrNo ratings yet

- The Opportunity: Measurement of Furnace Exit-Gas Temperature (Fegt)Document4 pagesThe Opportunity: Measurement of Furnace Exit-Gas Temperature (Fegt)muhdmsohNo ratings yet

- Gunite & ShortcreteDocument146 pagesGunite & ShortcreteSushil DhunganaNo ratings yet

- E84 in TN CMBR GVRD NB 0001 502Document35 pagesE84 in TN CMBR GVRD NB 0001 502Balaji SowrirajanNo ratings yet

- The Complexity of Environmental Protection in Sub-Saharan Africa and Reduction of Poverty Kalemba MwambazambiDocument8 pagesThe Complexity of Environmental Protection in Sub-Saharan Africa and Reduction of Poverty Kalemba MwambazambiPearl Irene Joy NiLoNo ratings yet

- 0808FT191040 - PCC - FT301Document20 pages0808FT191040 - PCC - FT301Ayush BarskerNo ratings yet

- DH RepresentationDocument3 pagesDH RepresentationChandni DayakarNo ratings yet

- History of Jainism in IndiaDocument4 pagesHistory of Jainism in Indiaketan1965No ratings yet

- Catullus 3Document73 pagesCatullus 3Eloy Medina OrvizNo ratings yet

- Chemical Comparison ListDocument6 pagesChemical Comparison ListMuhd Khir RazaniNo ratings yet

- 902900-1183 DespieceDocument448 pages902900-1183 DespieceLIBERTADNo ratings yet

- Route InformationDocument12 pagesRoute InformationSas Marian SasNo ratings yet

- Chapter 2 - 1 - Partial DerivativesDocument55 pagesChapter 2 - 1 - Partial DerivativesSafi FouadNo ratings yet

- Mattone Barile Grande - Oven - BrickWood OvensDocument25 pagesMattone Barile Grande - Oven - BrickWood OvensrjijgoiejgioegeNo ratings yet

- 8609 - 2 Spring 2019Document16 pages8609 - 2 Spring 2019Engr GM SialNo ratings yet

- Heat Exchanger Lab Report FinalDocument22 pagesHeat Exchanger Lab Report FinalAliyu AbdulqadirNo ratings yet

- Fan Performance and Fan LawsDocument6 pagesFan Performance and Fan Lawscarlos quirozNo ratings yet

- SL020 PDFDocument3 pagesSL020 PDFchidambaram kasiNo ratings yet