Professional Documents

Culture Documents

Adjustable Pedal

Adjustable Pedal

Uploaded by

Genaro AgustinesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adjustable Pedal

Adjustable Pedal

Uploaded by

Genaro AgustinesCopyright:

Available Formats

I BODY

SECTION

ADJUSTABLE PEDAL

AP B

E

CONTENTS

PRECAUTIONS .......................................................... 2 Automatic Drive Positioner Interlocking Adjustable F

Precautions for Supplemental Restraint System Pedal ........................................................................ 3

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN- Adjustable Pedal (Only Manual Operation Model)..... 3

SIONER” .................................................................. 2 Trouble Diagnosis ..................................................... 7 G

Trouble Diagnosis Precaution .................................. 2 Removal and Installation ........................................ 14

ADJUSTABLE PEDAL SYSTEM ............................... 3

H

AP

Revision: January 2005 AP-1 2004 Titan

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER” EIS002OS

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Trouble Diagnosis Precaution EIS002OT

When you read wiring diagrams, refer to the following:

● GI-14, "How to Read Wiring Diagrams".

● PG-4, "POWER SUPPLY ROUTING CIRCUIT".

When you perform trouble diagnosis, refer to the following:

● GI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

● GI-27, "How to Perform Efficient Diagnosis for an Electrical Incident".

Check for any service bulletins before servicing the vehicle.

Revision: January 2005 AP-2 2004 Titan

ADJUSTABLE PEDAL SYSTEM

ADJUSTABLE PEDAL SYSTEM PFP:98800

A

Automatic Drive Positioner Interlocking Adjustable Pedal EIS002OU

Automatic drive positioner interlocking adjustable pedal. Refer to SE-11, "AUTOMATIC DRIVE POSITIONER"

. B

Adjustable Pedal (Only Manual Operation Model) EIS002OV

COMPONENT PARTS AND HARNESS CONNECTOR LOCATION

C

AP

LIIA2154E

SYSTEM DESCRIPTION

The adjustable pedal system power supply is controlled by pedal adjusting control unit.

Power is supplied at all times

● through 50A fuse (letter f , located in the fuse and fusible link box)

● to circuit breaker-2 terminal 2

● through circuit breaker-2 terminal 1

● to pedal adjusting control unit terminal 5, and

● through 10A fuse [No. 19, located in the fuse block (J/B)]

● to key switch and key lock solenoid terminal 3.

With the ignition switch in ON or START position, power is supplied

Revision: January 2005 AP-3 2004 Titan

ADJUSTABLE PEDAL SYSTEM

● through 10A fuse [No. 12, located in the fuse block (J/B)],

● to pedal adjusting control unit terminal 4.

Ground is supplied

● to pedal adjusting switch terminal 4 and

● to pedal adjusting control unit terminal 1

● through body grounds M57, M61 and M79.

Column Shift

When the A/T selector lever is in other than P position, ground is supplied

● to pedal adjusting control unit terminal 3

● through A/T device terminal 8

● through A/T device terminal 1

● through body grounds M57, M61 and M79.

Floor Shift

When the A/T selector lever is in other than P position and key is inserted in ignition key cylinder, power is

supplied

● to pedal adjusting control unit terminal 3

● through A/T device terminal 6

● through A/T device terminal 5

● from key switch and key lock solenoid terminal 4.

Then pedal adjusting control unit recognizes that A/T selector lever is in other than P position.

With the ignition switch in OFF or ON position and A/T selector lever is shifted to the P position, power is sup-

plied

● through pedal adjusting control unit terminal 7

● to pedal adjusting switch terminal 1.

With power supplied, pedal adjusting switch is energized.

When pedal is adjusted forward, power is supplied

● through pedal adjusting switch terminal 3

● to pedal adjusting motor terminal +.

Then ground is supplied

● to pedal adjusting motor terminal -

● through pedal adjusting switch terminal 2

● through pedal adjusting switch terminal 4

● through body grounds M57, M61 and M79.

With power and ground are supplied, accelerator and brake pedals move forward.

When pedal is adjusted backward, power is supplied

● through pedal adjusting switch terminal 2

● to pedal adjusting motor terminal -.

Then ground is supplied

● to pedal adjusting motor terminal +

● through pedal adjusting switch terminal 3

● through pedal adjusting switch terminal 4

● through body grounds M57, M61 and M79.

With power and ground are supplied, accelerator and brake pedals move backward.

Revision: January 2005 AP-4 2004 Titan

ADJUSTABLE PEDAL SYSTEM

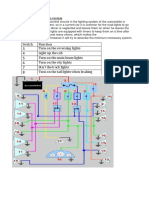

WIRING DIAGRAM — PEDAL —

A

AP

WIWA0256E

Revision: January 2005 AP-5 2004 Titan

ADJUSTABLE PEDAL SYSTEM

WIWA0191E

Revision: January 2005 AP-6 2004 Titan

ADJUSTABLE PEDAL SYSTEM

TERMINAL AND REFERENCE VALUE FOR PEDAL ADJUSTING CONTROL UNIT

TERMI- WIRE VOLTAGE (V)

A

ITEM CONDITON

NAL COLOR (Approx.)

1 B Ground — 0

B

A/T selector lever in other than P position 0

3 L/R Detent switch (key) signal

A/T selector lever in P position Battery voltage

4 G/R Ignition switch (ON or START) Ignition switch (ON or START position) Battery voltage C

5 W/L Battery power supply — Battery voltage

Ignition switch ON

0

Pedal adjusting switch power supply out- A/T selector lever in other than P position D

7 W/R

put Ignition switch ON

Battery voltage

A/T selector lever in P position

E

Trouble Diagnosis EIS002OW

WORK FLOW

1. Check the symptom and customer's requests.

F

2. Perform the preliminary check. Refer to AP-7, "PRELIMINARY CHECK" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to AP-8,

"TROUBLE DIAGNOSIS CHART BY SYMPTOM" .

G

4. Does adjustable pedal system operate normally?

YES: GO TO 5.

NO: GO TO 3.

H

5. Inspection End.

PRELIMINARY CHECK

1. CHECK ADJUSTABLE PEDAL MECHANISM AP

Check the following.

● Movable part of accelerator pedal or brake pedal is deformed, or there is foreign material in it. J

● Accelerator pedal or brake pedal is deformed or broken.

OK or NG

OK >> Preliminary check is OK. K

NG >> Repair the malfunctioning part and check again.

Revision: January 2005 AP-7 2004 Titan

ADJUSTABLE PEDAL SYSTEM

TROUBLE DIAGNOSIS CHART BY SYMPTOM

NOTE:

Always check the WORK FLOW before troubleshooting. Refer to AP-7, "WORK FLOW" .

Symptom Diagnosis / service procedure Reference page

1. Pedal adjusting control unit power supply and ground circuit

AP-8

inspection.

Adjustable pedal system does not operate. 2. Pedal adjusting switch power supply and ground circuit inspec-

AP-11

tion.

3. Pedal adjusting motor circuit inspection. AP-12

1. A/T device circuit inspection. AP-9 or AP-10

Adjustable pedal system does operate when

ignition switch is turned ON and A/T selector 2. Pedal adjusting control unit signal inspection. AP-8

lever is in other than P position.

3. Replace pedal adjusting control unit. —

Adjustable pedal system does not operate

when ignition switch is turned ON and A/T 1. A/T device circuit inspection. AP-10

selector lever is in P position.

PEDAL ADJUSTING CONTROL UNIT IGNITION SIGNAL INSPECTION

1. CHECK FUSE

Check 10A fuse [No. 12, located in fuse block (J/B)].

NOTE:

Refer to AP-3, "COMPONENT PARTS AND HARNESS CONNECTOR LOCATION" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-

4, "POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK PEDAL ADJUSTING CONTROL UNIT IGNITION POWER SUPPLY CIRCUIT

1. Disconnect pedal adjusting control unit.

2. Check voltage between pedal adjusting control unit connector

and ground.

Connector Terminal (Wire color) Voltage (V)

Condition

(+) (–) (Approx.)

Ignition switch ON Battery voltage

M14 4 (G/R) Ground

Ignition switch OFF 0

OK or NG

OK >> Pedal adjusting control unit ignition signal is OK.

NG >> Repair or replace the harness. LIIA0885E

PEDAL ADJUSTING CONTROL UNIT POWER SUPPLY AND GROUND INSPECTION

1. CHECK PEDAL ADJUSTING CONTROL UNIT OUTPUT POWER SUPPLY

1. Turn ignition switch OFF.

2. Check voltage between pedal adjusting control unit connector

M14 terminal 7 and ground.

7 (W/R) – Ground : Battery voltage

OK or NG

OK >> Pedal adjusting control unit power supply and ground is

OK.

NG >> GO TO 2.

LIIA0886E

Revision: January 2005 AP-8 2004 Titan

ADJUSTABLE PEDAL SYSTEM

2. CHECK PEDAL ADJUSTING CONTROL UNIT POWER SUPPLY CIRCUIT A

1. Disconnect pedal adjusting control unit.

2. Check voltage between pedal adjusting control unit connector

M14 terminal 5 and ground. B

5 (W/L) - Ground : Battery voltage

OK or NG C

OK >> GO TO 3.

NG >> Repair or replace the harness.

D

LIIA0887E

3. CHECK PEDAL ADJUSTING CONTROL UNIT GROUND CIRCUIT E

Check continuity between pedal adjusting control unit connector

M14 terminal 1 and ground.

F

1 (B) - Ground : Continuity should exist.

OK or NG

OK >> Replace pedal adjusting control unit. G

NG >> Repair or replace the harness.

LIIA0888E

A/T DEVICE CIRCUIT INSPECTION (FLOOR SHIFT) AP

1. CHECK PEDAL ADJUSTING CONTROL UNIT INPUT SIGNAL

1. Turn ignition switch OFF. J

2. Disconnect pedal adjusting control unit.

3. Check voltage between pedal adjusting control unit connector

and ground. K

Connector Terminal (Wire color) Voltage (V)

Condition

(+) (–) (Approx.)

L

P position 0

M14 3 (L/R) Ground

Other than P position Battery voltage

M

OK or NG

OK >> A/T device circuit is OK. LIIA2155E

NG >> GO TO 2.

2. CHECK A/T DEVICE POWER SUPPLY CIRCUIT

1. Disconnect A/T device.

2. Check voltage between A/T device connector M203 terminal 5

and ground.

5 (B/R) - Ground : Battery voltage

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

LIIA2156E

Revision: January 2005 AP-9 2004 Titan

ADJUSTABLE PEDAL SYSTEM

3. CHECK A/T DEVICE HARNESS

1. Disconnect pedal adjusting control unit.

2. Check continuity between pedal adjusting control unit connector

M14 terminal 3 and A/T device connector M203 terminal 6.

3 (L/R) - 6 (L/R) : Continuity should exist.

3. Check continuity between pedal adjusting control unit connector

M14 terminal 3 and ground.

3 (L/R) - Ground : Continuity should not exist.

OK or NG

LIIA0990E

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK A/T DEVICE

Check continuity between A/T device terminals as follows.

Terminals Condition Continuity

P position No

5 6

Other than P position Yes

OK or NG

OK >> Inspect shift lock system. Refer to AT-243, "A/T SHIFT

LOCK SYSTEM" .

NG >> Replace control device assembly. Refer to AT-243, "A/T

SHIFT LOCK SYSTEM" . LIIA0991E

A/T DEVICE CIRCUIT INSPECTION (COLUMN SHIFT)

1. CHECK PEDAL ADJUSTING CONTROL UNIT INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect pedal adjusting control unit.

3. Check continuity between pedal adjusting control unit connector

and ground.

Connector

Terminal (Wire color) Condition Continuity

P position No

M14 3 (L/R) Ground

Other than P position Yes

OK or NG

OK >> A/T device circuit is OK. LIIA2157E

NG >> GO TO 2.

2. CHECK A/T DEVICE GROUND CIRCUIT

1. Disconnect A/T device.

2. Check continuity between A/T device connector M68 terminal 1

and ground.

1 (B) - Ground : Continuity should exist.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

LIIA2158E

Revision: January 2005 AP-10 2004 Titan

ADJUSTABLE PEDAL SYSTEM

3. CHECK A/T DEVICE HARNESS A

1. Check continuity between pedal adjusting control unit connector

M14 terminal 3 and A/T device connector M68 terminal 8.

B

3 (L/R) - 8 (L/R) : Continuity should exist.

2. Check continuity between pedal adjusting control unit connector

M14 terminal 3 and ground.

C

3 (L/R) - Ground : Continuity should not exist.

OK or NG

D

OK >> GO TO 4.

NG >> Repair or replace harness. LIIA2159E

4. CHECK A/T DEVICE E

Check continuity between A/T device terminals as follows.

Terminals Condition Continuity F

P position No

1 8

Other than P position Yes

G

OK or NG

OK >> Inspect shift lock system. Refer to AT-243, "A/T SHIFT

LOCK SYSTEM" . H

NG >> Replace column shift control device. Refer to AT-240,

"SHIFT CONTROL SYSTEM" . LIIA1993E

PEDAL ADJUSTING SWITCH POWER SUPPLY AND GROUND INSPECTION AP

1. CHECK PEDAL ADJUSTING SWITCH POWER SUPPLY

1. Turn ignition switch OFF. J

2. Disconnect pedal adjusting switch.

3. Check voltage between pedal adjusting switch connector M96

terminal 1 and ground. K

1 (W/R) - Ground : Battery voltage

OK or NG L

OK >> GO TO 3.

NG >> GO TO 2.

LIIA0894E

M

2. CHECK PEDAL ADJUSTING SWITCH HARNESS

1. Disconnect pedal adjusting control unit.

2. Check continuity between pedal adjusting control unit connector

M14 terminal 7 and pedal adjusting switch connector M96 termi-

nal 1.

7 (W/R) - 1 (W/R) : Continuity should exist.

3. Check continuity between pedal adjusting control unit connector

M14 terminal 7 and ground.

7 (W/R) - Ground : Continuity should not exist.

OK or NG LIIA0895E

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness.

Revision: January 2005 AP-11 2004 Titan

ADJUSTABLE PEDAL SYSTEM

3. CHECK PEDAL ADJUSTING SWITCH GROUND CIRCUIT

Check continuity between pedal adjusting switch connector M96 ter-

minal 4 and ground.

4 (B) - Ground : Continuity should exist.

OK or NG

OK >> Pedal adjusting switch power supply and ground circuit

is OK.

NG >> Repair or replace the harness.

LIIA0896E

PEDAL ADJUSTING MOTOR CIRCUIT INSPECTION

1. CHECK PEDAL ADJUSTING SWITCH

1. Turn ignition switch OFF.

2. Disconnect pedal adjusting switch.

3. Check continuity between pedal adjusting switch terminals as

follows.

Terminals Condition Continuity

Pedal adjusting switch forward. Yes

1

Pedal adjusting switch neutral. No

3

Pedal adjusting switch backward. Yes

4

Pedal adjusting switch neutral. No LIIA0897E

Pedal adjusting switch backward. Yes

1

Pedal adjusting switch neutral. No

2

Pedal adjusting switch forward. Yes

4

Pedal adjusting switch neutral. No

OK or NG

OK >> GO TO 2.

NG >> Replace pedal adjusting switch.

2. CHECK PEDAL ADJUSTING MOTOR HARNESS

1. Disconnect pedal adjusting motor.

2. Check continuity between pedal adjusting switch connector M96

terminals 2, 3 and pedal adjusting motor connector E109 termi-

nals +, -.

2 (SB) - - (R) : Continuity should exist.

3 (V) - + (G) : Continuity should exist.

3. Check continuity between pedal adjusting switch connector M96

terminals 2 (SB), 3 (V) and ground.

2 (SB) - Ground : Continuity should not exist. LIIA1319E

3 (V) - Ground : Continuity should not exist.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between pedal adjusting switch and pedal adjusting motor.

Revision: January 2005 AP-12 2004 Titan

ADJUSTABLE PEDAL SYSTEM

3. CHECK PEDAL ADJUSTING MOTOR POWER SUPPLY A

1. Connect pedal adjusting switch.

2. Check voltage between pedal adjusting motor and ground.

B

Connector Terminal (Wire color) Voltage (V)

Condition

(+) (–) (Approx.)

Pedal adjusting switch C

Battery voltage

+ (G) forward

Other than above 0

M14 Ground

Pedal adjusting switch D

Battery voltage

- (R) backward LIIA1320E

Other than above 0

E

OK or NG

OK >> Replace pedal adjusting motor. Refer to AP-14, "Removal and Installation" .

NG >> Repair or replace harness.

F

AP

Revision: January 2005 AP-13 2004 Titan

ADJUSTABLE PEDAL SYSTEM

Removal and Installation EIS002OX

Refer to ACC-2, "ACCELERATOR CONTROL SYSTEM" and BR-6, "BRAKE PEDAL" .

Revision: January 2005 AP-14 2004 Titan

You might also like

- Adjustable Pedal: SectionDocument14 pagesAdjustable Pedal: SectionFelipe FarfanNo ratings yet

- Accelerator Control System: SectionDocument8 pagesAccelerator Control System: SectionMarco BrupenNo ratings yet

- Acc PDFDocument4 pagesAcc PDFChukiat SupapNo ratings yet

- Acc PDFDocument4 pagesAcc PDFRoberto SalazarNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionDiplomadoEsanNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionJimmyNo ratings yet

- Adjustable PedalDocument18 pagesAdjustable PedalErickson GarciaNo ratings yet

- (TM) Nissan Manual de Taller Nissan Versa 2007Document4 pages(TM) Nissan Manual de Taller Nissan Versa 2007Jheral Manzanedo cruzNo ratings yet

- Accelarator Control SystemDocument4 pagesAccelarator Control Systempietruszka1No ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionTonyNo ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: SectionEdni OropezaNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionJesus MendezNo ratings yet

- Infiniti g25 2006 AccDocument4 pagesInfiniti g25 2006 AccNacho MowjiNo ratings yet

- Acc PDFDocument4 pagesAcc PDFNadol SwasnateeNo ratings yet

- Infiniti Fx45 Accelarator Control SystemDocument4 pagesInfiniti Fx45 Accelarator Control SystemxxersanNo ratings yet

- Accelerator Control SystemDocument4 pagesAccelerator Control SystemPaolo MadambaNo ratings yet

- Instrument Panel: SectionDocument25 pagesInstrument Panel: SectionemenelikNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionMudvayne Hard CoreNo ratings yet

- Audio-Visual System: SectionDocument12 pagesAudio-Visual System: Sectionภาคภูมิ ถ้ำทิมทองNo ratings yet

- Auto Cruise Control System: SectionDocument2 pagesAuto Cruise Control System: Sectionprueba2021No ratings yet

- Ip PDFDocument6 pagesIp PDFCarlos Eduardo ZelidonNo ratings yet

- Accelerator Control System: SectionDocument3 pagesAccelerator Control System: SectionBrian GNo ratings yet

- 2007 Nissan Murano Accelerator Control SystemDocument4 pages2007 Nissan Murano Accelerator Control SystemJimTuckerNo ratings yet

- Acc PDFDocument8 pagesAcc PDFCarlos Eduardo ZelidonNo ratings yet

- Section: I BodyDocument6 pagesSection: I BodyMohamed HarbNo ratings yet

- Auto Cruise Control SystemDocument2 pagesAuto Cruise Control SystemAlex HernandezNo ratings yet

- Acc PDFDocument6 pagesAcc PDFStiven Martinez ValenciaNo ratings yet

- Manual Accesorios Nissan MuranoDocument6 pagesManual Accesorios Nissan MuranoStiven Martinez ValenciaNo ratings yet

- Accelerator Control System: SectionDocument11 pagesAccelerator Control System: SectionJoe CanchicaNo ratings yet

- Acc PDFDocument6 pagesAcc PDFShin ItoNo ratings yet

- Accelerator Control SystemDocument5 pagesAccelerator Control Systemhenry_zambranoNo ratings yet

- Cinturón de SeguridadDocument12 pagesCinturón de Seguridadastroboy2666No ratings yet

- Rear Suspension: SectionDocument12 pagesRear Suspension: SectionABBAS ALINo ratings yet

- Seat Belt: SectionDocument15 pagesSeat Belt: SectionMaiChiVuNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionEder ChaveiroNo ratings yet

- Seat Belts: SectionDocument12 pagesSeat Belts: SectionemenelikNo ratings yet

- Cruise Control System: SectionDocument3 pagesCruise Control System: SectioncesarNo ratings yet

- Acc PDFDocument4 pagesAcc PDFIsaac Galvez EscuderoNo ratings yet

- Accelerator Control System: SectionDocument3 pagesAccelerator Control System: SectionRolfy Jampol AyzanoaNo ratings yet

- Instrument Panel: SectionDocument16 pagesInstrument Panel: SectionJimmyNo ratings yet

- Ip Navara DDocument6 pagesIp Navara DJean MoralesNo ratings yet

- NIssan D40 Seat BeltDocument11 pagesNIssan D40 Seat BeltBuddhika HidurangalaNo ratings yet

- Acc PDFDocument5 pagesAcc PDFstaff055No ratings yet

- Parking Brake System: SectionDocument12 pagesParking Brake System: SectionOmar JimenezNo ratings yet

- Acc PDFDocument7 pagesAcc PDFronaldNo ratings yet

- Nissan March k13 Htr12de Factory Service ManualDocument20 pagesNissan March k13 Htr12de Factory Service ManualWillie100% (50)

- Audio, Visual, Navigation & Telephone Sys-TEM: SectionDocument10 pagesAudio, Visual, Navigation & Telephone Sys-TEM: SectionmadurangaNo ratings yet

- Section: SERVICE INFORMATION ...........................Document11 pagesSection: SERVICE INFORMATION ...........................madurangaNo ratings yet

- RF PDFDocument10 pagesRF PDFROSILENE PASSOSNo ratings yet

- Parking Brake System: SectionDocument10 pagesParking Brake System: SectionHanselPerezAguirreNo ratings yet

- Seat Belts: SectionDocument10 pagesSeat Belts: SectionEduardo ColinNo ratings yet

- Audio, Visual & Telephone System: SectionDocument12 pagesAudio, Visual & Telephone System: SectionEduardo ColinNo ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: SectiontecnicofigueroaNo ratings yet

- Accelerator Control System: SectionDocument3 pagesAccelerator Control System: SectionmadurangaNo ratings yet

- Exhaust System: SectionDocument5 pagesExhaust System: SectionDudu RodriguesNo ratings yet

- Exhaust System: SectionDocument8 pagesExhaust System: SectionABBAS ALINo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionOleksandrNo ratings yet

- Instrument Panel: SectionDocument14 pagesInstrument Panel: SectionOscar Villaseñor100% (1)

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- 1 90 PDFDocument90 pages1 90 PDFWilson Acosta LiñanNo ratings yet

- 91 150 PDFDocument60 pages91 150 PDFWilson Acosta LiñanNo ratings yet

- EilDocument5 pagesEilWilson Acosta LiñanNo ratings yet

- SistemaDocument2 pagesSistemaWilson Acosta LiñanNo ratings yet

- Mskficndowjxkrncjskfifkxmgiekdnckfkkfkfkfnfñfkckckdkfjfjfkfkfkfkf FJFJKFKF DJFJFJF DKFKFKF FJFKF KDKFKF DKFKF DKFKF FKFKF KFKFK DJFKF FKFKF DKFKDocument4 pagesMskficndowjxkrncjskfifkxmgiekdnckfkkfkfkfnfñfkckckdkfjfjfkfkfkfkf FJFJKFKF DJFJFJF DKFKFKF FJFKF KDKFKF DKFKF DKFKF FKFKF KFKFK DJFKF FKFKF DKFKWilson Acosta LiñanNo ratings yet

- Mskficndowjxkrncjskfifkxmgiekdnckfkkfkfkfnfñfkckckdkfjfjfkfkfkfkf FJFJKFKF DJFJFJF DKFKFKF FJFKF KDKFKF DKFKF DKFKF FKFKF KFKFK DJFKF FKFKF DKFKDocument4 pagesMskficndowjxkrncjskfifkxmgiekdnckfkkfkfkfnfñfkckckdkfjfjfkfkfkfkf FJFJKFKF DJFJFJF DKFKFKF FJFKF KDKFKF DKFKF DKFKF FKFKF KFKFK DJFKF FKFKF DKFKWilson Acosta LiñanNo ratings yet

- Automotive Lighting SystemDocument4 pagesAutomotive Lighting SystemWilson Acosta Liñan100% (1)

- Sub WooferV OutV OutDocument1 pageSub WooferV OutV OutWilson Acosta LiñanNo ratings yet

- LED Diode: Characteristics of Led DiodesDocument7 pagesLED Diode: Characteristics of Led DiodesWilson Acosta LiñanNo ratings yet

- UM3561A Three Siren Sound GeneratorDocument4 pagesUM3561A Three Siren Sound GeneratorYuksel NuhogluNo ratings yet

- Manual Da Soft Starter Da ABB Modelo PSE 300Document110 pagesManual Da Soft Starter Da ABB Modelo PSE 300Laurimar Vendrusculo100% (1)

- Firekab Fleco FE180 PDRDocument2 pagesFirekab Fleco FE180 PDRBinh VoNo ratings yet

- 2011 G 1.4 DOHC MFI Control System Schematic DiagramsDocument1 page2011 G 1.4 DOHC MFI Control System Schematic DiagramsbryanNo ratings yet

- TeSys GV2 - GV2ME06Document9 pagesTeSys GV2 - GV2ME06Md Abu BorhanNo ratings yet

- Half Wave Converter With R, RL and RLE Load: Vidyalankar Institute of Technology (VIT)Document12 pagesHalf Wave Converter With R, RL and RLE Load: Vidyalankar Institute of Technology (VIT)Reetik KothariNo ratings yet

- Power Autotransformer 220//110/30 KV Unit Required Guarantee D Technical PerformancesDocument3 pagesPower Autotransformer 220//110/30 KV Unit Required Guarantee D Technical Performancesamulya00428No ratings yet

- Tramp Metal Detector MODEL 1230 Installation & Operation ManualDocument32 pagesTramp Metal Detector MODEL 1230 Installation & Operation ManualmiguelperuperuNo ratings yet

- Brief Hostory of ElectromagneticsDocument5 pagesBrief Hostory of ElectromagneticsLUIS FERNANDO PENA BALANTANo ratings yet

- 2022-23 Microwave and Radar Engineering 7th SemDocument2 pages2022-23 Microwave and Radar Engineering 7th SemPulkit GoelNo ratings yet

- Direct-Current Dynamos: Construction & Armature WindingsDocument43 pagesDirect-Current Dynamos: Construction & Armature WindingsHane MinasalbasNo ratings yet

- TI Intro To FOCDocument55 pagesTI Intro To FOCName24122021No ratings yet

- DC Shunt Motor Exp7 PDFDocument10 pagesDC Shunt Motor Exp7 PDFGopinath B L NaiduNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Wireless ElectricityDocument26 pagesWireless ElectricityJames jill100% (1)

- Valle - Exercise No. 25 - Test QuestionsDocument7 pagesValle - Exercise No. 25 - Test Questionsasdf ghjklNo ratings yet

- mXT1664T2-C2U 1v1 Datasheet DXDocument94 pagesmXT1664T2-C2U 1v1 Datasheet DXRosa María AmoneNo ratings yet

- Ceiling Fans: Only 1 Out of These Justifies The Five-Star RatingDocument7 pagesCeiling Fans: Only 1 Out of These Justifies The Five-Star RatingSurbhi SabharwalNo ratings yet

- DVD Home Theater Sound System: SA-PT160E SA-PT160EB SA-PT160EGDocument104 pagesDVD Home Theater Sound System: SA-PT160E SA-PT160EB SA-PT160EGsaul64No ratings yet

- Solar Nighthawk Light, NH50 - NH200 60wDocument13 pagesSolar Nighthawk Light, NH50 - NH200 60wMarío QuirogaNo ratings yet

- Trailblazer 325 DieselDocument8 pagesTrailblazer 325 DieselBruno RubioNo ratings yet

- A General Unified Approach To Modelling Switching Dc-To-Dc Converters in Discontinuous Conduction ModeDocument22 pagesA General Unified Approach To Modelling Switching Dc-To-Dc Converters in Discontinuous Conduction ModeannaNo ratings yet

- Technical Specifications ABB VD4Document11 pagesTechnical Specifications ABB VD4Anonymous JGCKFUNo ratings yet

- Developments of High Voltage Porcelain Post-Insulators: T. Morocutti, T. Berg, M. Muhr G. GödelDocument4 pagesDevelopments of High Voltage Porcelain Post-Insulators: T. Morocutti, T. Berg, M. Muhr G. GödelNurulazmi Bin Abd RahmanNo ratings yet

- Rfic Final QB Copy-2Document4 pagesRfic Final QB Copy-2chsampoorna5No ratings yet

- Boonar Owner's ManualDocument1 pageBoonar Owner's ManualAnonymous OZRLFfgNo ratings yet

- Question PaperDocument2 pagesQuestion PapertrsureshNo ratings yet

- Energy Saving Electric Bulbs (CFL) vs. Energy Consuming Incandescent BulbsDocument13 pagesEnergy Saving Electric Bulbs (CFL) vs. Energy Consuming Incandescent Bulbsyogesh280785No ratings yet

- CMXT3904 Surface Mount Silicon Dual NPN Transistors DescriptionDocument4 pagesCMXT3904 Surface Mount Silicon Dual NPN Transistors Descriptionjavier venturaNo ratings yet

- Colour Based Sensor Pick and Place Robot PPDDocument26 pagesColour Based Sensor Pick and Place Robot PPDJagdhara KarthiNo ratings yet