Professional Documents

Culture Documents

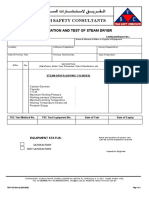

Pipeline Pressure Test Report

Uploaded by

Mark KOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipeline Pressure Test Report

Uploaded by

Mark KCopyright:

Available Formats

Client: Report No.

:

Contractor: Date:

Ref. Standard: Page 1 of 1

Cleaning, Gauging, Pressure Test & Drying Doc. No.:

Pipeline From: to: Attachment:

1.0 General Information

Test Section: From Joint No./Sec. to Joint No./Sec. Test Section Length (m):

Line No./Test Section No. Class (ANSI Rating):

Design Pressure (psi): Location Class (Acc. to ANSI/ASME B31.8):

Design Factor: Lowest point elevation: Highest point elevation:

Pipeline Size (Diameter): Pipe Material: Wall Thickness:

High Point Vent(s) Installed (Qty. ) Low Point Drain(s) Installed (Qty. )

Maximum Allowable Pressure at Lowest Point (psi):

Minimum Acceptable Test Pressure at Highest Point (psi):

2.0 Test Equipments

Air Compressor Type: Capacity:

Pressure Gauge: Qty. Capacity: Calibration Checked

Recorder: Calibration Checked

Dead Weight Tester: Calibration Checked

3.0 Cleaning

Water Volume (m3): Amount of Corrosion Inhibitor (if Applicable):

Launching Date/Time: Receiving Date/Time:

Result:

Inspected By: Sign.

4.0 Gauging

Pipeline Inside Diameter (Minimum): Gauging Plate Diameter:

Gauging Plate Material: Gauging Plate Thickness:

Launching Date/Time: Receiving Date/Time:

Result:

Inspected By: Sign.

5.0 Pressure Test

Date/Time Test Started: Date/Time Test Finished: (Duration: hr.)

Minimum Test Pressure (psi): Maximum Test Pressure (psi):

Minimum Test Temperature (˚C): Maximum Test Temperature (˚C):

Result:

Inspected By: Sign.

6.0 Dewatering & Draying

Dewatering Date/Time: Dewatering Duration: Drying Completed (Acceptable)

Quality Control TPI Inspection Client

Name: Name: Name:

Sign: Sign: Sign:

Date Date Date:

You might also like

- Vacuum Box Test Report SummaryDocument1 pageVacuum Box Test Report SummaryJindarat KasemsooksakulNo ratings yet

- Liquid Penetrant Test Record: Examinaion DetailsDocument1 pageLiquid Penetrant Test Record: Examinaion DetailschandraNo ratings yet

- Storage Tank Hydrostatic TestDocument1 pageStorage Tank Hydrostatic TestQuekchNo ratings yet

- Pipeline Hydrostatic Test Quality Control and Inspection Report FormDocument1 pagePipeline Hydrostatic Test Quality Control and Inspection Report Formmahesh100% (2)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNo ratings yet

- Pneumatic Test - Data Sheet - V1Document2 pagesPneumatic Test - Data Sheet - V1Vinoth SudalaiNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFJaco CalitzNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFAdhi PrihastomoNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFมินคุง เอโอซีNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormMHT allamNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFNatarajan Raja100% (2)

- ITP FOR SKID COMPRESSOR (Rev.0)Document14 pagesITP FOR SKID COMPRESSOR (Rev.0)Richard AdolfNo ratings yet

- Hydrotest ReportDocument1 pageHydrotest Reportshamon shajahanNo ratings yet

- HM&E - Hydrostatic Test ReportDocument1 pageHM&E - Hydrostatic Test ReportAnatolie6No ratings yet

- Hydro TestDocument1 pageHydro TestMilan BanerjeeNo ratings yet

- HM&E - Hydrostatic Test ReportDocument1 pageHM&E - Hydrostatic Test ReportAnatolie6No ratings yet

- Hydrostatic - Pneumatic Test Inspection ReportDocument1 pageHydrostatic - Pneumatic Test Inspection ReportGabriel GabeNo ratings yet

- Formular PT MCM - Ro - enDocument1 pageFormular PT MCM - Ro - enlpdtcosminNo ratings yet

- Pressure Test Report Chilled Water LineDocument1 pagePressure Test Report Chilled Water LinegaineyskNo ratings yet

- Penstock Leakage Record SheetDocument1 pagePenstock Leakage Record Sheetmujahed_muhammedNo ratings yet

- F QAQC 017 PTR Pressure Test ReportDocument1 pageF QAQC 017 PTR Pressure Test ReportmahmoudNo ratings yet

- Contractor: Project Name: No. Item Item No. DWG No. RemarkDocument1 pageContractor: Project Name: No. Item Item No. DWG No. RemarkmiladrahimianNo ratings yet

- Form QT 4 (B)Document1 pageForm QT 4 (B)Asma FarahNo ratings yet

- Hydro-Test FormatDocument1 pageHydro-Test Formatjasbir.iitdNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Water Permeability Test Data Sheet: RemarksDocument1 pageWater Permeability Test Data Sheet: RemarksDileepa DissanayakeNo ratings yet

- SIMO Research Engineers Pvt. LTDDocument7 pagesSIMO Research Engineers Pvt. LTDunicorn pressure vasselsNo ratings yet

- Daramic Pneumatic Test ReportDocument1 pageDaramic Pneumatic Test ReportSales Creative EngineeringNo ratings yet

- Storage Tank Shell Banding Quality Control and Inspection Report FormDocument1 pageStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Test Information: Pressure Test Record (Soho Appartments-Palm Jumirah)Document1 pageTest Information: Pressure Test Record (Soho Appartments-Palm Jumirah)CrippleNo ratings yet

- Checklist 1Document2 pagesChecklist 1AneeshNo ratings yet

- Steam Dryer Inspection ReportDocument1 pageSteam Dryer Inspection ReportSHARAFUDHEEN TKNo ratings yet

- QC Form 7Document1 pageQC Form 7rashid ahmadiNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Ruel fernandezNo ratings yet

- Test Information: Pressure Test Record (SAMPLE - Edit To Suit But Capture All Data Required For ASME B31 Compliance)Document1 pageTest Information: Pressure Test Record (SAMPLE - Edit To Suit But Capture All Data Required For ASME B31 Compliance)RezaNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2anon_106345234No ratings yet

- Test Information: Pressure Test Record (SAMPLE - Edit To Suit But Capture All Data Required For ASME B31 Compliance)Document1 pageTest Information: Pressure Test Record (SAMPLE - Edit To Suit But Capture All Data Required For ASME B31 Compliance)Mahmoud shawkyNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Ruel fernandezNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Bonaventure Nzeyimana100% (1)

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Joe ClarkeNo ratings yet

- Leak Test Valve ReportDocument2 pagesLeak Test Valve Reportadnansh1No ratings yet

- Valve Test ReportDocument1 pageValve Test ReportgoguluNo ratings yet

- Hydrostatic Test Report Storage TankDocument1 pageHydrostatic Test Report Storage TankJabel Oil Services Technical DPTNo ratings yet

- Expansion TankDocument2 pagesExpansion TankSHARAFUDHEEN TKNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Hydro Test ReportDocument2 pagesHydro Test ReportMubashar Saleem ChaudharyNo ratings yet

- Pneumatic Test CertificateDocument1 pagePneumatic Test CertificateAneesh JoseNo ratings yet

- Test ReportDocument7 pagesTest ReportharishNo ratings yet

- Quality Control: Concrete Pour RecordDocument1 pageQuality Control: Concrete Pour RecordBrookeNo ratings yet

- WPQR PipeDocument3 pagesWPQR PipeThanasis KyrgiazoglouNo ratings yet

- Liquid Penetrant Examination ReportDocument1 pageLiquid Penetrant Examination ReportBalmiki SinghNo ratings yet

- Air Leak Test ReportDocument2 pagesAir Leak Test ReportvinothNo ratings yet

- Air Leak Test Report: Instrumentation and Gauge Calibration RecordDocument2 pagesAir Leak Test Report: Instrumentation and Gauge Calibration Recordvinoth100% (1)

- Pressure Test Record FormDocument2 pagesPressure Test Record FormLuis MuñozNo ratings yet

- PT Shahib Sejati (Siap Cetak)Document8 pagesPT Shahib Sejati (Siap Cetak)Ade RafikNo ratings yet

- Pipe installation testing reportDocument1 pagePipe installation testing reportRrgs Bandara100% (1)

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- Sygic Europe Maps:: Home Products About Us Contact Us Inquiry News FAQDocument2 pagesSygic Europe Maps:: Home Products About Us Contact Us Inquiry News FAQMark KNo ratings yet

- Pipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingDocument1 pagePipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingMark KNo ratings yet

- Pipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingDocument1 pagePipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingMark KNo ratings yet

- Untitled 5Document1 pageUntitled 5Mark KNo ratings yet

- Pipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingDocument1 pagePipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingMark KNo ratings yet

- Etender PDFDocument14 pagesEtender PDFArunNo ratings yet

- Brochure For Filling ApplicationDocument76 pagesBrochure For Filling ApplicationAnand PujariNo ratings yet

- Brochure For Filling ApplicationDocument1 pageBrochure For Filling ApplicationMark KNo ratings yet

- Pipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingDocument1 pagePipeline Hydrostatic Test Report: Cleaning, Gauging, Pressure Test & DryingMark KNo ratings yet

- Nexon Accessories PDFDocument18 pagesNexon Accessories PDFgaduseNo ratings yet

- Common Vocabulary in Urdu and Turkish Language: A Case of Historical OnomasiologyDocument33 pagesCommon Vocabulary in Urdu and Turkish Language: A Case of Historical OnomasiologyMark KNo ratings yet

- EBY Fasteners Product Range Aug 2020Document2 pagesEBY Fasteners Product Range Aug 2020Mark KNo ratings yet

- General Power of Attorney Final (NEW)Document4 pagesGeneral Power of Attorney Final (NEW)udNo ratings yet

- PGCIL cut-off marks for AE posts by categoryDocument1 pagePGCIL cut-off marks for AE posts by categoryMark KNo ratings yet

- PaqDocument4 pagesPaqMark KNo ratings yet

- Chavani Company FolderDocument11 pagesChavani Company FolderMark KNo ratings yet

- DrawingDocument3 pagesDrawingMark KNo ratings yet

- General Power-of-Attorney DocumentDocument2 pagesGeneral Power-of-Attorney DocumentMark KNo ratings yet

- Pumps in A Thermal Electricity Generation Power Station: Level 4 Credits 2 PurposeDocument4 pagesPumps in A Thermal Electricity Generation Power Station: Level 4 Credits 2 PurposeMark KNo ratings yet

- Operate Boiler Circulating Pumps in A Thermal Electricity Generation Power StationDocument4 pagesOperate Boiler Circulating Pumps in A Thermal Electricity Generation Power StationMark KNo ratings yet

- General Power of Attorney Final (NEW)Document4 pagesGeneral Power of Attorney Final (NEW)udNo ratings yet

- Coils DrawnDocument2 pagesCoils DrawnMark KNo ratings yet

- Why Critical Thinking Is ImportantDocument19 pagesWhy Critical Thinking Is ImportantVincent Hà Quốc DũngNo ratings yet

- Resume for Firstname LastnameDocument1 pageResume for Firstname LastnameMark KNo ratings yet

- Register of Workmen Employed by Contractor: Form XiiiDocument1 pageRegister of Workmen Employed by Contractor: Form XiiiMark KNo ratings yet

- EnlistmentDocument34 pagesEnlistmentMark KNo ratings yet

- Operate Boiler Circulating Pumps in A Thermal Electricity Generation Power StationDocument4 pagesOperate Boiler Circulating Pumps in A Thermal Electricity Generation Power StationMark KNo ratings yet

- Form 10 CDocument4 pagesForm 10 CMark KNo ratings yet

- Application For Registration As A Vendor: Next PageDocument4 pagesApplication For Registration As A Vendor: Next PageMark KNo ratings yet

- Basic AerodynamicsDocument54 pagesBasic Aerodynamicskoti4unnam100% (2)

- Separator Data SheetDocument2 pagesSeparator Data SheetSamerNo ratings yet

- Total - VESSELSDocument18 pagesTotal - VESSELSTala RamezaniNo ratings yet

- Almig - Installation of New Compressor at Unilever RykDocument30 pagesAlmig - Installation of New Compressor at Unilever RykJunaid AhmedNo ratings yet

- Piping Material Spec for Gas Supply and Metering FacilitiesDocument15 pagesPiping Material Spec for Gas Supply and Metering FacilitiesChieAstutiaribNo ratings yet

- TESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveDocument132 pagesTESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- HSVC1 PP4-QA, QC Equipment Status Report - 20190828Document44 pagesHSVC1 PP4-QA, QC Equipment Status Report - 20190828nkvonNo ratings yet

- PeltonDocument7 pagesPeltonKunal Kumar DasNo ratings yet

- Question For FluidDocument4 pagesQuestion For FluidAsad UllahNo ratings yet

- Hydraulics Summer 2019Document4 pagesHydraulics Summer 2019Asad HussainNo ratings yet

- Orifice Calc: GasDocument4 pagesOrifice Calc: GasJames R. Lawrence Sr.100% (6)

- Submittal Data: VRF Outdoor Unit 38VMA432HDS5-1 - Heat PumpDocument3 pagesSubmittal Data: VRF Outdoor Unit 38VMA432HDS5-1 - Heat PumpHernandoLopezUNo ratings yet

- Wilo Datasheet - International - en - 2161331 - Cronoline Il 150 325 37 4 s1 Ie3Document5 pagesWilo Datasheet - International - en - 2161331 - Cronoline Il 150 325 37 4 s1 Ie3suwono radukNo ratings yet

- Burgmann Ts2000eDocument4 pagesBurgmann Ts2000edeyoooooNo ratings yet

- GANDHI INSTITUDE SEMINAR REPORT ON AIR BRAKING SYSTEMDocument18 pagesGANDHI INSTITUDE SEMINAR REPORT ON AIR BRAKING SYSTEMRishabhNo ratings yet

- PSV Calculation: Capacity Corection Factor Due To Back Pressure (KB)Document1 pagePSV Calculation: Capacity Corection Factor Due To Back Pressure (KB)syamsudin2006No ratings yet

- URS R404aDocument1 pageURS R404aironiteNo ratings yet

- Lista de materiales para tuberíasDocument1 pageLista de materiales para tuberíasJan pierre Arismendis paibaNo ratings yet

- Pipeline Design PDFDocument437 pagesPipeline Design PDFgilbertotiburcio100% (2)

- Weekly progress meeting LP separator bridle flushingDocument1 pageWeekly progress meeting LP separator bridle flushingJane EatonNo ratings yet

- Workover Operations Workover Rigs Workover RigsDocument2 pagesWorkover Operations Workover Rigs Workover RigsASIF SADARNo ratings yet

- IbrDocument4 pagesIbrJayesh100% (1)

- Production Optimization with PROSPERDocument6 pagesProduction Optimization with PROSPERbharath35kumar0% (1)

- Report On Gas Turbine Power PlantDocument22 pagesReport On Gas Turbine Power Plantgayatri57% (7)

- Use of Gas Tables Permitted, Assume Suitable Value For Missing DataDocument2 pagesUse of Gas Tables Permitted, Assume Suitable Value For Missing DataVenkitaraj K PNo ratings yet

- Mod 3.1 Design and Performance Analysis of Centrifugal CompressorsDocument31 pagesMod 3.1 Design and Performance Analysis of Centrifugal Compressorsinamul hasanNo ratings yet

- CH 60 CH 100 Service and Parts ManualDocument36 pagesCH 60 CH 100 Service and Parts ManualAnonymous zIC52xKlNo ratings yet

- Layout Zone Safety Untuk 5 RDocument4 pagesLayout Zone Safety Untuk 5 RIan MardiansyahNo ratings yet

- Hydraulic Diagram, Complete: Informations de ServiceDocument4 pagesHydraulic Diagram, Complete: Informations de ServiceamnayNo ratings yet

- An Explicit Equation For Friction Factor in PipeDocument2 pagesAn Explicit Equation For Friction Factor in PipeRiddhesh PatelNo ratings yet