Professional Documents

Culture Documents

3xMHPS H-100 (GT Only)

Uploaded by

Ade Okta YurwendraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3xMHPS H-100 (GT Only)

Uploaded by

Ade Okta YurwendraCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10

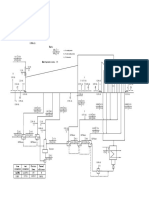

Inlet Filter

A dp= 10 millibar A

Ambient air 1,026 p N2 74,7 % 3 GTs

1,013 p 541,9 T O2 13,33 % 1,026 p

15 T 1,003 p

15 T 305,1 m CO2 3,384 % 541,9 T

299,3 m H2O 7,685 % 714,7 h

60%RH 299,3 m

0 m elev. 59,41 %RH Ar 0,8996 % 915,3 M

MW 28,43

N2 77,29 % N2 77,29 %

O2 20,74 % O2 20,74 %

CO2 0,03 % CO2 0,03 %

B H2O 1,009 % H2O 1,009 %

110052 kW X 3

B

Ar 0,9309 % Ar 0,9309 %

MW 28,86 MW 28,86

19,9 PR 18,68 PR

136755 kW 249623 kW

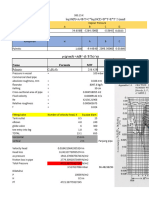

3 X MHPS H-100 (ID # 478)

1,003 p 19,96 p 19,16 p 1,026 p

C 15 T

299,3 m

458,2 T

245,8 m

1350 T

251,6 m

541,9 T

305,1 m C

59,41 %RH

dp = 0,7985 bar (4 %)

28,23 p

Cooling air 64,5 T

53,49 m 5,777 m

17,87 % airflow LHV 50135 kJ/kg

GT generator power = 110052 kW

GT heat rate = 9458 kJ/kWh

D GT efficiency = 38,06% LHV D

GT @ 100 % rating

Inlet loss = 10 millibar

Exhaust loss = 12,45 millibar

E Fuel = CH4

E

17,24 p 28,23 p

25 T 64,5 T

5,777 m 5,777 m

LHV 50047 kJ/kg LHV 50135 kJ/kg

GT fuel LHV chemical

energy input (77F/25C)

289126 kWth

Fuel compressor

787,9 kWe

F Qrej 157,3 kW F

Company: PT PLN Enjiniring

User: Windows User

Gross Power = 330156 kW, Aux. & Transformer losses = 5965 kW, Net Power Output = 324191 kW Plant Configuration: Gas Turbine: MHPS H-100 (Physical Model) - 3 units

Gross Heat Rate = 9458 kJ/kWh, Net Heat Rate = 9632 kJ/kWh (LHV) HRSG: None

G Gross Elec Eff = 38,06 %, Net Elec Eff = 37,38 %, PURPA Eff = 37,38 %, CHP (Total) Eff = 37,38 % (LHV) Steam Turbine: None G

Fuel LHV chemical energy input = 867378 kW Cooling System: None

Project:

GT PRO 28.2 Windows User Site:

2712 09-23-2020 10:34:18 file=C:\Users\adeyu\Documents\Thermoflow\MYFILES28\GTPRO.GTP Heat Balance:

p [bar], T [C], h [kJ/kg], M [kg/s], Q [kW], Steam Properties: IFC-67

Upper case M for total plant flows, lower case m for each GT/HRSG flows Date: 09-23-2020

H Notes: H

1 2 3 4 5 6 7 8 9 10

You might also like

- DUALITY OF TIME by Mohamed Haj Yousef PDFDocument495 pagesDUALITY OF TIME by Mohamed Haj Yousef PDFОлег Шматович100% (2)

- Pumps Calcul PP-RFDocument1 pagePumps Calcul PP-RFNghiaNo ratings yet

- K-Flex ST Class 0 CatalogueDocument6 pagesK-Flex ST Class 0 CatalogueBac VuNo ratings yet

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocument1 pagePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540No ratings yet

- Radiator CalculationDocument24 pagesRadiator Calculationmohammed sallem100% (2)

- Well Control Data Sheet: Well: All Values in Have To Be EnteredDocument11 pagesWell Control Data Sheet: Well: All Values in Have To Be Enteredmiguel rojasNo ratings yet

- FOS User Guide PDFDocument96 pagesFOS User Guide PDFadsrjmNo ratings yet

- Flare Calc Sheet API - RP 521Document13 pagesFlare Calc Sheet API - RP 521ionutlaur86100% (1)

- Solar System Worksheets For KS3Document7 pagesSolar System Worksheets For KS3ashleyNo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column Chartingali billNo ratings yet

- Coal Fired Boiler - PrincipalsDocument145 pagesCoal Fired Boiler - PrincipalsArfan AnwarNo ratings yet

- RCCen54 Circular Column DesignDocument94 pagesRCCen54 Circular Column Designaryadav145No ratings yet

- MWM 600Document4 pagesMWM 600Habib A. IslamNo ratings yet

- PythonDocument191 pagesPythonRajasekhar Reddy100% (1)

- Civil Prog NEW Pak Naim NewDocument3 pagesCivil Prog NEW Pak Naim NewHikari Teknologi IndonesiaNo ratings yet

- 2023-1509 TopSolid'Design TutorialDocument53 pages2023-1509 TopSolid'Design TutorialMáy TiệnNo ratings yet

- Defects in GalvanizingDocument10 pagesDefects in GalvanizingBalaji GuruNo ratings yet

- SOP-Advia Centaur XPDocument45 pagesSOP-Advia Centaur XPAniruddha Chatterjee100% (1)

- ct1 Financial Math NotesDocument48 pagesct1 Financial Math NoteshiketNo ratings yet

- Hydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGDocument9 pagesHydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGRhowelle TibayNo ratings yet

- PLTG BP BatakDocument54 pagesPLTG BP BatakAchmad Nidzar AlifNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column Chartingbunheng lonNo ratings yet

- Edf SGT6 5000F Condensing 2 PDFDocument1 pageEdf SGT6 5000F Condensing 2 PDFZhao XuanNo ratings yet

- 3xGE 9E.04 (GT Only)Document1 page3xGE 9E.04 (GT Only)Ade Okta YurwendraNo ratings yet

- 01 GTP-M-PCE Part1Document66 pages01 GTP-M-PCE Part1Ramesh-NairNo ratings yet

- 03 GTP-M-PCE Part3-2Document16 pages03 GTP-M-PCE Part3-2Ramesh-NairNo ratings yet

- Coal Fired Boiler - PrincipalsDocument145 pagesCoal Fired Boiler - Principalsfaiz_oeNo ratings yet

- Calculation - Penurunan Pressure Versus Temperature - LPGDocument1 pageCalculation - Penurunan Pressure Versus Temperature - LPGRokan PipelineNo ratings yet

- 02 GTP-M-PCE Part2Document38 pages02 GTP-M-PCE Part2Ramesh-NairNo ratings yet

- EU 200-32 MBC: Performance CurveDocument2 pagesEU 200-32 MBC: Performance CurveDidik HariantoNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Columns at A1, A2 Etc RMW 94 CHG R68Document13 pagesSpreadsheets To BS 8110: Advisory Group Columns at A1, A2 Etc RMW 94 CHG R68Kem RaiNo ratings yet

- Trabajo Turbinas de Gas 2019-1Document4 pagesTrabajo Turbinas de Gas 2019-1Fabián Yesid R. LeónNo ratings yet

- NPSHaDocument12 pagesNPSHarusyadscribdNo ratings yet

- COLUMNASDocument6 pagesCOLUMNASSUSANA DEYANIRA FLORES PEREZNo ratings yet

- YATIN KUMAR 1557 B.COM HONS Sec C - 041215 - 125513Document12 pagesYATIN KUMAR 1557 B.COM HONS Sec C - 041215 - 125513HARDEEP KUMARNo ratings yet

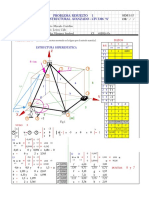

- Problema Resuelto 1 Analisis Estructural Avanzado - Civ 3306 "A"Document13 pagesProblema Resuelto 1 Analisis Estructural Avanzado - Civ 3306 "A"Michael Alex Velasquez SandovalNo ratings yet

- Amps X 100 Bus12 (Nom. KV 0.48, Plot Ref. KV 0.48) : T01 FLA - Other 65Document2 pagesAmps X 100 Bus12 (Nom. KV 0.48, Plot Ref. KV 0.48) : T01 FLA - Other 65Manuel Calvo MorenoNo ratings yet

- Heat Exchanger Specification Sheet HRS UnitsDocument1 pageHeat Exchanger Specification Sheet HRS UnitsMuneeb AkhtarNo ratings yet

- Q28743 - C1 CondenserDocument1 pageQ28743 - C1 CondenserMuneeb AkhtarNo ratings yet

- Pompa (01-07)Document59 pagesPompa (01-07)chati rifqi rafifNo ratings yet

- RCC54 Circular Column ChartingDocument1 pageRCC54 Circular Column ChartingBunheng LonNo ratings yet

- Diff. & GrilleDocument9 pagesDiff. & GrilleAbdelfatah NewishyNo ratings yet

- RapidDocument2 pagesRapidRobert MilisicNo ratings yet

- VLE Calculations - Goal SeekDocument9 pagesVLE Calculations - Goal SeekCharlinNo ratings yet

- Steam Generator Boiler-3Document1 pageSteam Generator Boiler-3ToniNo ratings yet

- Trend Water AnalisisDocument3 pagesTrend Water AnalisisHayus MaulanaNo ratings yet

- Entregable Tema 6Document4 pagesEntregable Tema 6Andrea Garcia EstellesNo ratings yet

- Banda AcehDocument10 pagesBanda Acehmakolan 236No ratings yet

- Tutorial 6Document11 pagesTutorial 6Howon LeeNo ratings yet

- Operation Report Jan 2021Document6 pagesOperation Report Jan 2021Muhammad AbyNo ratings yet

- Heat Balance DiagramDocument11 pagesHeat Balance Diagramwira hamadri pratamaNo ratings yet

- Accesss Road Kani Frame Analysis Box Culvert 782001 165Document2 pagesAccesss Road Kani Frame Analysis Box Culvert 782001 165Amit Kumar PaulNo ratings yet

- Esp Calculation Sheet - m1Document7 pagesEsp Calculation Sheet - m1Buraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- FLOWSIC 600 Pipe Size Calculation: Reference ConditionDocument1 pageFLOWSIC 600 Pipe Size Calculation: Reference Conditionprihartono_diasNo ratings yet

- Design and Construction of Tsurumi Tsubasa Bridge SuperstructureDocument10 pagesDesign and Construction of Tsurumi Tsubasa Bridge SuperstructurehobNo ratings yet

- ARCH 381 ThermodynamicsDocument11 pagesARCH 381 ThermodynamicsElanur MayaNo ratings yet

- Sheet 16 U-820 Sulfur Recovery Unit: Technical ServicesDocument1 pageSheet 16 U-820 Sulfur Recovery Unit: Technical ServicesAsad PatelNo ratings yet

- Solenoid Valve Manual Override Direct Acting 2/2 Way N.C.: Serie 93 CMDocument2 pagesSolenoid Valve Manual Override Direct Acting 2/2 Way N.C.: Serie 93 CMRamadan Salem SlimNo ratings yet

- Flare Calc Sheet API RP 521Document18 pagesFlare Calc Sheet API RP 521Cesar Ricardo Lopez ValerioNo ratings yet

- Lh-Energy Distribution - 2021Document1 pageLh-Energy Distribution - 2021hongchuyenNo ratings yet

- Ethanol PlantDocument15 pagesEthanol PlantRizvanVavanNo ratings yet

- Mill Test Certificates: TSN Wires Co., LTDDocument1 pageMill Test Certificates: TSN Wires Co., LTDNirmal WiresNo ratings yet

- Compaionwihbick: Work Case Stud Comparison With Bricks Advantages Applications FaqDocument2 pagesCompaionwihbick: Work Case Stud Comparison With Bricks Advantages Applications FaqAbhishek TapadiaNo ratings yet

- Altura De La Turbina Vs. Caudal (Α = 20°) Potencia Hidráulica De La Turbina Vs. CAUDAL (α = 20°)Document6 pagesAltura De La Turbina Vs. Caudal (Α = 20°) Potencia Hidráulica De La Turbina Vs. CAUDAL (α = 20°)Luis Argüelles SaenzNo ratings yet

- Papco N2 - Calc (By Yasin SB.)Document3 pagesPapco N2 - Calc (By Yasin SB.)nivinsNo ratings yet

- Sơ đồ cân bằng nhiệt - Heat BalanceDocument2 pagesSơ đồ cân bằng nhiệt - Heat Balancephùng thắngNo ratings yet

- Installation Pipework: Distribution Main Ring Distribution Ring 1 Distribution Ring 2Document4 pagesInstallation Pipework: Distribution Main Ring Distribution Ring 1 Distribution Ring 2Rizwan AliNo ratings yet

- Group 3 Take Off SheetsDocument3 pagesGroup 3 Take Off SheetsfancyreymartNo ratings yet

- Bearing Assembly Preload Calculation and Information - DynarollDocument2 pagesBearing Assembly Preload Calculation and Information - DynarollankitsarvaiyaNo ratings yet

- Empowerment Tech LessonsDocument34 pagesEmpowerment Tech LessonsAlyanna De LeonNo ratings yet

- Maxim Short Presentation 2020 - 1 PDFDocument24 pagesMaxim Short Presentation 2020 - 1 PDFSamuel CortesNo ratings yet

- Modelling Football Penalty Kicks: Jeffrey K. Leela and Donna M. G. ComissiongDocument11 pagesModelling Football Penalty Kicks: Jeffrey K. Leela and Donna M. G. Comissiongjanvi karnawatNo ratings yet

- Experiment 3: Study of Powder Compaction BehaviourDocument17 pagesExperiment 3: Study of Powder Compaction BehaviourBhavika TambiNo ratings yet

- .archivetempMOD01 1-1.1 Intro Python - IpynbDocument9 pages.archivetempMOD01 1-1.1 Intro Python - IpynbSekkak MarouaneNo ratings yet

- Lecture 1Document4 pagesLecture 1cristianNo ratings yet

- Data Structures and Algorithms in Java ™: Sixth EditionDocument8 pagesData Structures and Algorithms in Java ™: Sixth EditionIván Bartulin Ortiz0% (1)

- Zener DiodeDocument14 pagesZener Diodes211053176No ratings yet

- An Interview With Michael AtiyahDocument11 pagesAn Interview With Michael AtiyahXin WangNo ratings yet

- 05 Hardy 1951 The Developments in The Occlusal Patterns of Artificial TeethDocument15 pages05 Hardy 1951 The Developments in The Occlusal Patterns of Artificial Teethjorefe12No ratings yet

- Springboot 150715065142 Lva1 App6891Document57 pagesSpringboot 150715065142 Lva1 App6891lokeshgeedNo ratings yet

- International Journal of Mining Science and Technology: Jiahao Qin, Jian Zheng, Li LiDocument9 pagesInternational Journal of Mining Science and Technology: Jiahao Qin, Jian Zheng, Li LiRezaNo ratings yet

- Imc Ac - 42 02 2204 - C9Document429 pagesImc Ac - 42 02 2204 - C9ElputoAmo XDNo ratings yet

- Drilling of Composite MaterialsDocument17 pagesDrilling of Composite Materialsrinu248No ratings yet

- Akkaya Katalog EN 2019Document66 pagesAkkaya Katalog EN 2019Juan MendozaNo ratings yet

- Unit 1Document67 pagesUnit 1sophieee19No ratings yet

- Impulse and MomentumDocument4 pagesImpulse and MomentumAldrin VillanuevaNo ratings yet

- Anritsu Ms2712e User GuideDocument102 pagesAnritsu Ms2712e User GuidebtdtheaNo ratings yet

- Auditory Verbal Hallucinations in Patients With Borderline Personality Disorder Are Similar To Those in SchizophreniaDocument7 pagesAuditory Verbal Hallucinations in Patients With Borderline Personality Disorder Are Similar To Those in SchizophrenializardocdNo ratings yet

- Hardrock Romangranit ECatalogDocument22 pagesHardrock Romangranit ECatalogYuli PurnomoNo ratings yet