0% found this document useful (0 votes)

60 views6 pagesEngineering PO Processing Workflow

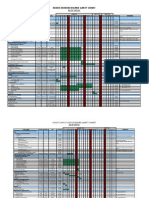

The document outlines the key responsibilities of the engineering department in the PO processing process. Engineering is responsible for technical compliance checking, GTP preparation, design plans, drawings, BOMs, catalogs, standards, type tests, cost reduction analysis, and more. They maintain related records both physically and electronically in designated folders and servers.

Uploaded by

10derCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

60 views6 pagesEngineering PO Processing Workflow

The document outlines the key responsibilities of the engineering department in the PO processing process. Engineering is responsible for technical compliance checking, GTP preparation, design plans, drawings, BOMs, catalogs, standards, type tests, cost reduction analysis, and more. They maintain related records both physically and electronically in designated folders and servers.

Uploaded by

10derCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd