Professional Documents

Culture Documents

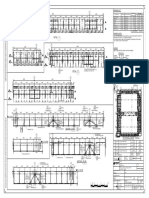

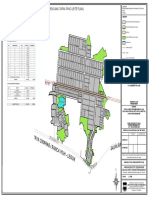

Col Line H

Uploaded by

AcfMacOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Col Line H

Uploaded by

AcfMacCopyright:

Available Formats

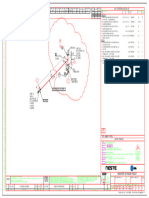

IP

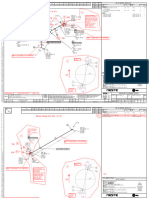

PIPING SPEC. SPEC. CORR. ALL. DES. PRESS. OPER. PRESS. DES. TEMP. OPER. TEMP. TEST PRESS. TEST. FLUID PAINT CRIT. NPD INS. INS. THK

agreements between MIDOR, Technip Italy S.p.A. and the intended recipient. The copyright in this document and/or attachments is owned by MIDOR and Technip Italy S.p.A.. while the underlying IP is owned by other Tecnology Providers and any reproduction or adaptation thereof shall require MIDOR's and/or, when

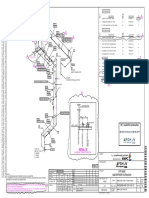

P&ID TRACING PWHT NDT S BILL OF MATERIAL SKETCH LIST

SPEC. MATERIAL RATING (mm) (Barg) (Barg) (°C) (°C) (Barg) PRESS TYPE PHASE NO. LINE (inch) TYPE (mm)

engineer the same, in any manner, without MIDOR prior written consent and/or Technip Italy S.p.A. prior written consent, and shall not put in use the information for any purpose unrelated to that for which it has been transmitted to recipient. Any disclos ure and use of the contents hereof shall be subject to any subsisting

N E POS DESCRIPTION THK1 THK2 ASBL/ IDENT DIAMETER QTY

This document and its attachments, if any, contains confidential and propietary information belonging to MIDOR, and/or other third parties, including Technip Italy S.p.A. The intended recipient of the information contained here in shall not divulge t he same to any third part or sell, trade, publish, reproduce or reverse

2544-39-PID-0021-001-1 A2A2M CS 300 lbs 3 34 29 74 27 53.86 H G - A1 >20mm 5 No 12 N 0 NO DEST (PCS/MM)

2544-39-PID-0021-001-1 A2A2M CS 300 lbs 3 34. 29. 74 27. 53.86 H G - A1 >20mm 5 No 8 N 0

FABRICATION

1 Red Te,ASME B16.9,ASTM A234 Gr.WPB + Sour Servi,BW Ends,Seamless,1 S-40 S-STD 1 CHVVZ2S 12X8 1

2 WN Flg,ASME B16.5,ASTM A105N + Sour Service,RF/BW End,300 Lbs,1 S-STD 1 CFG5EW5B 8 1

ERECTION

3 SpBld Fig8,ASME B16.48,ASTM A516N Gr.70,Between RF Flanges,300 2 CANLPWH 8 1

Lbs,2

4 WN Flg,ASME B16.5,ASTM A105N + Sour Service,RF/BW End,300 Lbs,2 S-STD 2 CFG5EW5B 8 1

5 SW Gk,ASME B16.20,RF as per ASME B16.5,-,300 Lbs,2 2 CMALEH 8 3

6 SBlt 2 HHx N,ASME B1.1/ASME B18.2.2,Full Length Threaded,2 - 150 2 CBT8U84A 7/8 12

mm Length

7 SBlt 2 HHx N,ASME B1.1/ASME B18.2.2,Full Length Threaded,2 - 180 2 CBT8U84D 7/8 12

mm Length

8 Gat Flg,API 600,ASTM A216 Gr.WCB,RF,300 Lbs,2 2 C1C4PKV 8 1

CONT. ON

PFA10-NTG01040-0001-(Existing)

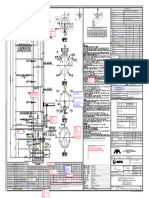

E 101565016 TP-P

REFERENCE POINT 39-009

E 101565016 N 101874300 Co

EL.14493 l

N 101878000 H Li

EL.13985 ne

F2 G5 B6 1 1

FW 12X8"NS

e BT1

L in EL.14239

l REFERENCE POINT

Co BT2 8 E 101566000

8 FW 3 254

37 STEM NORTH N 101874300

00 G5 EL.13985

342

4

98

419

254

25

PFT70_NTG39001807_0001SP001

CONT. ON

-NTG39001005-0001 TP-P

E 101564113 39-009

12"NS

N 101874300 CLASS:

EL.14239 A2A2M

CLASS:

2 A1A2M

FW

3

TAIL UP

CONT. ON Installation in close position. For final installation,

PFA10-NTG01040-0001-(Existing) position shall be according to the PID

E 101565016

N 101874300

EL.13985 F4 G5 B7

Jack Screw (See STC139C)

TOTAL NUMBER OF SPOOLS: 1

SUPPORT SYMBOLOGY

Y

COM STD or SPC support common SPC

to more than one line Special Piping Support

S-

e.g.: line support Refer to supp. dwgs collections 2544-"UNIT"-DW-1360-00

PRF STD Z X

STD or SPC support welded to pipe at Standard Piping Support

workshop during pipe spools prefabrication Refer to supp. dwgs collection 2544-00-STC-1390-00 INPUT AND OUTPUT

DATA FOR PIPELINE

MRS EFFORT ANALYSIS

Itemized Piping Supports ARE BASED ON

SYSTEM OF

For Itemized Piping Supports refer to Material Requisition 2544-00-MR-1383-001 COORDINATES AS

IN THE DRAWING

needed, Technip Italy S.p.A.'s express written approval.

MIDOR REFINERY EXPANSION

1) ALL DIMENSIONS ARE IN MILLIMITERS 1) CONSTRUCTION LINE LIST: 2544-"UNIT"-NM-1300-12 4) CONSTRUCTION SPECIFICATION FOR PIPING PREFABRICATION ERECTION AND N WELD

REFERENCE

SYMBOLOGY

2) DIMENSIONS AND LAYOUT OF SOCKET WELDED AND THREADED LINES ARE INDICATIVE ONLY AND SHALL BE CHECKED

AT JOB SITE BEFORE ERECTION DOCUMENTS 2) PIPING MATERIAL CLASSES: 2544-00-JSD-1300-01 NON DESTRUCTIVE EXAMINATION: 2544-00-MS-1320-51 N FIELD WELD

NOTES - VALID ONLY FOR U/G PIPING SKETCHES - FOR DESIGN 3) TECHNICAL SPECIFICATION FOR PIPING PREFABRICATION 5) FOR STRESS ANALYSIS "FLEXIBILITY LEVELS" AND STRESS ANALYSIS TRACED LINE No. NTG39001807-A2A2M-12"-N ISOMETRIC ID. PFT70-NTG39001807

3) TOTAL LENGTH OF U/G PIPING TO BE CONSIDERED INCLUSIVE OF EXPANSION JOINTS OR ANY EMBEDDED PIPE INTO PITS CONDITION CALCULATIONS NUMBERS REFER TO DOC.: 2544-"UNIT"-NM-1370-01

4) ISOMETRIC SKETCHES PREVAIL ON 2D AREA DRAWINGS AND ERECTION: 2544-00-MS-1300-02 SUPPORT

5) FOR 45deg MITER BENDS, ONLY ONE CONSTRUCTION WELD SHALL BE CONSIDERED (REF. TO APPLICABLE STANDARD) POSITION

PROJ. AREA DOC. TYPE SERVICE UNIT SEQUENCE N. SUBLINE SHEET OF SHEETS REV

1 27/03/20 ISSUED FOR CONSTRUCTION L.M. R.S. R.B. 0 28/02/20 ISSUED FOR CONSTRUCTION LM RS RB

REV DATE DESCRIPTION STRESS INSTR APPR. REV DATE DESCRIPTION STRESS INSTR APPR. REV DATE DESCRIPTION STRESS INSTR APPR.

2544 PFT70 ISO NTG 39 001807 0001 01 01 1

EXTRACTION DATE: 25/03/2020 14:19 Technip Italy S.p.a - 00148 ROMA - Viale Castello della Magliana, 68

You might also like

- MathWorks Interview ProcessDocument2 pagesMathWorks Interview ProcessPawan Singh100% (1)

- ZX 130-5g - Electrical Wiring DiagramDocument13 pagesZX 130-5g - Electrical Wiring DiagramPrudz86% (7)

- C32 Industrial Wiring DiagramDocument4 pagesC32 Industrial Wiring DiagramHữu Linh100% (2)

- E-Way BillDocument1 pageE-Way BillShriyans DaftariNo ratings yet

- Asme B18.24-2020Document190 pagesAsme B18.24-2020윤규섭0% (1)

- 800 Col Line: Bill of Material Sketch ListDocument1 page800 Col Line: Bill of Material Sketch ListAcfMacNo ratings yet

- TH220Document4 pagesTH220Ventsislav VenevNo ratings yet

- Singapore Expansion Project: BillofmaterialsketchlistDocument4 pagesSingapore Expansion Project: BillofmaterialsketchlistLocus Jhun MichaelNo ratings yet

- Singapore Expansion Project: BillofmaterialsketchlistDocument3 pagesSingapore Expansion Project: BillofmaterialsketchlistLocus Jhun MichaelNo ratings yet

- Industrial - PCB-ModelDocument1 pageIndustrial - PCB-ModelswapnilNo ratings yet

- Formato Ii - A Hoja de Trabajo de Requisición: Req./OcDocument1 pageFormato Ii - A Hoja de Trabajo de Requisición: Req./Ocarmando0212-1No ratings yet

- Formato IIa (L-E 5.1)Document1 pageFormato IIa (L-E 5.1)Erika AnguloNo ratings yet

- 2 1 100 M12x20 (4x), EQUALLY SPACED 378Document1 page2 1 100 M12x20 (4x), EQUALLY SPACED 378Rangel PintoNo ratings yet

- P6022mab Amd 128 11541 01 - S4Document1 pageP6022mab Amd 128 11541 01 - S4Alam MD SazidNo ratings yet

- A B J N Q: Semi - Basement Floor Plan - Overall PlanDocument6 pagesA B J N Q: Semi - Basement Floor Plan - Overall PlanKevin LowNo ratings yet

- Final Copy For ApprovalDocument2 pagesFinal Copy For Approvalcontact.loksewabookNo ratings yet

- Cause and Effect Chart Cause and Effect Chart: (Unit-: BGP Inlet Facilities)Document6 pagesCause and Effect Chart Cause and Effect Chart: (Unit-: BGP Inlet Facilities)Riky FitriadiNo ratings yet

- TK03 SP XH DL 4540 VZ4501612 21 Is0 SH.01Document1 pageTK03 SP XH DL 4540 VZ4501612 21 Is0 SH.01Rashad AlasgarovNo ratings yet

- Engine Harness P/N 0587299-00 Diagram Revision - A - : Component ListDocument1 pageEngine Harness P/N 0587299-00 Diagram Revision - A - : Component ListPabloAntonioCerdaSotoNo ratings yet

- Fabrication Materials: To Be Use A Full Length of Pipe and Adjust The DimensionDocument6 pagesFabrication Materials: To Be Use A Full Length of Pipe and Adjust The DimensionD7mey XNo ratings yet

- Cause and Effect Chart: (Unit-: BGP Inlet Facilities)Document6 pagesCause and Effect Chart: (Unit-: BGP Inlet Facilities)Riky FitriadiNo ratings yet

- Architectural Drawings 1Document13 pagesArchitectural Drawings 1Manish PandeyNo ratings yet

- 3520-SO3503232-1-IS1Document1 page3520-SO3503232-1-IS1GökhanNo ratings yet

- Cont. On: Fabrication MaterialsDocument7 pagesCont. On: Fabrication MaterialsD7mey XNo ratings yet

- PVI 6000 TL OUTD W Quick Installation Guide en RevADocument2 pagesPVI 6000 TL OUTD W Quick Installation Guide en RevA王伯恩No ratings yet

- 079254C 1g00u01 Iso CSW 1g00civ007 0001 - 0Document1 page079254C 1g00u01 Iso CSW 1g00civ007 0001 - 0Mahmoud HassanNo ratings yet

- 079254C 1g00u01 Iso CSW 1g00civ005 0001 - 0Document1 page079254C 1g00u01 Iso CSW 1g00civ005 0001 - 0Mahmoud HassanNo ratings yet

- Data Shhet For Floodlighting Masts Design Data: Internal NormalizationDocument3 pagesData Shhet For Floodlighting Masts Design Data: Internal Normalizationbrome2014No ratings yet

- Diagrama Electrico 777f JRPDocument4 pagesDiagrama Electrico 777f JRPManuel BarronNo ratings yet

- Electrical System C32 Generator Set With EMCP3: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System C32 Generator Set With EMCP3: Harness and Wire Electrical Schematic Symbolsyasser eljabaliNo ratings yet

- It5 ElecDocument1 pageIt5 Elecmanhasr80No ratings yet

- LMCPL-P2023-02-COS-43 - Working Platform - Service Rack Zone 2Document8 pagesLMCPL-P2023-02-COS-43 - Working Platform - Service Rack Zone 2Ali md YounusNo ratings yet

- 4274-CD-VD-LG201000019D1004001 - US CommentedDocument1 page4274-CD-VD-LG201000019D1004001 - US CommentedUnmesh ShuklaNo ratings yet

- Focus: All Devices and Components To Match Base Built System Make and ModelDocument1 pageFocus: All Devices and Components To Match Base Built System Make and ModelArun UdayabhanuNo ratings yet

- BA-1 Floor Plan-ModelDocument1 pageBA-1 Floor Plan-ModelEngr M.Arshad KhalidNo ratings yet

- Bill of Material: Dangote Oil Refining Company Ltd. Engineers India Limited New DelhiDocument4 pagesBill of Material: Dangote Oil Refining Company Ltd. Engineers India Limited New Delhishambu nath.vNo ratings yet

- IP Piping Specification OverviewDocument3 pagesIP Piping Specification Overviewahmed marieNo ratings yet

- Chart: Dehydration and Desalting System Akal J-1 Platform MPR A-51Document5 pagesChart: Dehydration and Desalting System Akal J-1 Platform MPR A-51figuev2208No ratings yet

- Os00002 T Bw31.za3.um02&ez18453 R03-SHT1Document1 pageOs00002 T Bw31.za3.um02&ez18453 R03-SHT1Gopalakrishnan DhandapaniNo ratings yet

- Topologi Trimegah Network - Update-2023 - v4Document6 pagesTopologi Trimegah Network - Update-2023 - v4cipto.itto01No ratings yet

- Sand Treatment Package (Asabi-A-3401) 34665W Ponticelli - Upstream LLCDocument27 pagesSand Treatment Package (Asabi-A-3401) 34665W Ponticelli - Upstream LLCTĩnh Hồ TrungNo ratings yet

- TTDBG EN 00 - Circuit (20151120)Document13 pagesTTDBG EN 00 - Circuit (20151120)Sherman KillerNo ratings yet

- DM Architectural Set 14.12.2023Document22 pagesDM Architectural Set 14.12.2023VinodNo ratings yet

- Nova Networking and KnowledgeDocument4 pagesNova Networking and KnowledgePranav NalawadeNo ratings yet

- Formato IIIa (L-E 5.1)Document2 pagesFormato IIIa (L-E 5.1)Erika AnguloNo ratings yet

- Prepone AreaDocument1 pagePrepone Areasumit pandeyNo ratings yet

- L66-20486-000 BillsDocument1 pageL66-20486-000 BillskhdfudiuNo ratings yet

- 072744C-RA1-DW-BW-31007-0-01 - 0 Change Joint W.CatDocument2 pages072744C-RA1-DW-BW-31007-0-01 - 0 Change Joint W.CatLocus Jhun MichaelNo ratings yet

- 072744C-RA1-DW-SW-31131-0-01 - 0 Change Joint W.CatDocument3 pages072744C-RA1-DW-SW-31131-0-01 - 0 Change Joint W.CatLocus Jhun MichaelNo ratings yet

- Singapore Expansion Project: Bill of Material Sketch ListDocument2 pagesSingapore Expansion Project: Bill of Material Sketch ListLocus Jhun MichaelNo ratings yet

- 072744C-RA1-DW-CH-31019-0-01 - 1S1 Change Joint NumberDocument1 page072744C-RA1-DW-CH-31019-0-01 - 1S1 Change Joint NumberLocus Jhun MichaelNo ratings yet

- 3 Denah1Document1 page3 Denah1Nadhifa Muthma InnahNo ratings yet

- MASTERPLAN New 30 70Document1 pageMASTERPLAN New 30 70Ramzy RaihanNo ratings yet

- A320 Family Maintenance Concept2019Document1 pageA320 Family Maintenance Concept2019br213No ratings yet

- Renr9477renr9477-02 - Sis 316Document2 pagesRenr9477renr9477-02 - Sis 316ait mimoune100% (1)

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- AMEC Future of OilsandsDocument16 pagesAMEC Future of OilsandsForexFFNo ratings yet

- Moves Change From Rev 1 To 1F1: Singapore Expansion ProjectDocument2 pagesMoves Change From Rev 1 To 1F1: Singapore Expansion ProjectLocus Jhun MichaelNo ratings yet

- 1801-FR02-42-R-XD-00007 - C1 - General Arrangement - S42PB542 H2S Scavenger - Gas LiftDocument1 page1801-FR02-42-R-XD-00007 - C1 - General Arrangement - S42PB542 H2S Scavenger - Gas LiftNam DHNo ratings yet

- C32with EMCP3Document4 pagesC32with EMCP3أبو أنس المسلمNo ratings yet

- A545 730 81 41 02052 - Rev 0 PDFDocument2 pagesA545 730 81 41 02052 - Rev 0 PDFFaizan Ullah KhanNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Heat ExchangerDocument16 pagesHeat ExchangerAcfMacNo ratings yet

- Workplace ViolationDocument48 pagesWorkplace ViolationAcfMacNo ratings yet

- Heat ExchangerDocument16 pagesHeat ExchangerAcfMacNo ratings yet

- ThermoDocument105 pagesThermoAcfMacNo ratings yet

- Basic CalculationsDocument17 pagesBasic CalculationsAcfMacNo ratings yet

- CBM Day 7 TH - Presentation-ManoromDocument32 pagesCBM Day 7 TH - Presentation-ManoromJenny Cecilia Ureña Zuri0% (1)

- Course On: Wastewater Pumping Stations DesignDocument26 pagesCourse On: Wastewater Pumping Stations DesignAcfMacNo ratings yet

- Compressor 2Document36 pagesCompressor 2AcfMacNo ratings yet

- TWI Welding Training 3Document58 pagesTWI Welding Training 3AcfMacNo ratings yet

- 1 - Lab - ICE - Engine Energy BalanceDocument7 pages1 - Lab - ICE - Engine Energy BalanceAcfMacNo ratings yet

- Principlesoflubricationnew 150425005327 Conversion Gate01 PDFDocument109 pagesPrinciplesoflubricationnew 150425005327 Conversion Gate01 PDFPedro ViegasNo ratings yet

- Lecture (7) : Introduction To G U IDocument15 pagesLecture (7) : Introduction To G U IAcfMacNo ratings yet

- Lecture (7) : Introduction To G U IDocument15 pagesLecture (7) : Introduction To G U IAcfMacNo ratings yet

- Graphics PDFDocument5 pagesGraphics PDFAcfMacNo ratings yet

- Lecture (7) : Introduction To G U IDocument15 pagesLecture (7) : Introduction To G U IAcfMacNo ratings yet

- 2020会社案内(英語版)Document18 pages2020会社案内(英語版)DAC ORGANIZERNo ratings yet

- Brute Force AttacksDocument9 pagesBrute Force AttacksAKSHITNo ratings yet

- Qualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIDocument23 pagesQualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIarniza blazoNo ratings yet

- Company Electronics Appliances Semiconductors South Korea's: SamsungDocument61 pagesCompany Electronics Appliances Semiconductors South Korea's: Samsunghaseeb ahmedNo ratings yet

- Remove Fuel Sub TankDocument9 pagesRemove Fuel Sub Tankthierry.fifieldoutlook.comNo ratings yet

- SRV210 - 250TC Spare PartsDocument2 pagesSRV210 - 250TC Spare PartsEnzo SovittiNo ratings yet

- Regional Campus The English and Foreign Languages UniversityDocument2 pagesRegional Campus The English and Foreign Languages UniversitySidra KhanNo ratings yet

- Beef Steaks: MethodDocument2 pagesBeef Steaks: MethodGoshigoshi AkhtarNo ratings yet

- Ultra Brochure WMDocument8 pagesUltra Brochure WMSherif AdelNo ratings yet

- Professional Education ReviewerDocument22 pagesProfessional Education ReviewerJustine WicoNo ratings yet

- Investigation of Nursing Students Knowledge of and Attitudes About Problem Based LearningDocument4 pagesInvestigation of Nursing Students Knowledge of and Attitudes About Problem Based LearningasdasdasdasNo ratings yet

- CUMSUM Process ControlDocument6 pagesCUMSUM Process Controljess fantonalgoNo ratings yet

- Customer Satisfaction in Maruti SuzukiDocument31 pagesCustomer Satisfaction in Maruti Suzukirajesh laddha100% (1)

- Lyrics: Original Songs: - JW BroadcastingDocument56 pagesLyrics: Original Songs: - JW BroadcastingLucky MorenoNo ratings yet

- Solution SellingDocument18 pagesSolution Sellingvikramgulati13090% (1)

- Cognitive Load Theory (John Sweller) : Information ProcessingDocument2 pagesCognitive Load Theory (John Sweller) : Information ProcessingNik ZazlealizaNo ratings yet

- Akuntansi Keuangan Lanjutan - Akuntansi Penggabungan UsahaDocument67 pagesAkuntansi Keuangan Lanjutan - Akuntansi Penggabungan UsahachendyNo ratings yet

- Cash and Cash EquivalentsDocument2 pagesCash and Cash EquivalentsMary Jullianne Caile SalcedoNo ratings yet

- GogikavofobifigukidonDocument2 pagesGogikavofobifigukidonMd. Bepul HossainNo ratings yet

- Script of Cca Eim EditedDocument4 pagesScript of Cca Eim EditedMhen Maugan100% (1)

- Som-Ii Uqb 2019-20Document23 pagesSom-Ii Uqb 2019-20VENKATESH METHRINo ratings yet

- Valuation of Mineral Resources in Selected FinanciDocument12 pagesValuation of Mineral Resources in Selected FinanciBill LiNo ratings yet

- MdmedichaoiceDocument324 pagesMdmedichaoicelancastd54No ratings yet

- Forum Ex 2 2Document5 pagesForum Ex 2 2Didan EnricoNo ratings yet

- Williamstown Cannabis Cultivation PlanDocument48 pagesWilliamstown Cannabis Cultivation PlanOltion JaupajNo ratings yet

- Student quiz answer sheetsDocument26 pagesStudent quiz answer sheetsSeverus S PotterNo ratings yet