Professional Documents

Culture Documents

Lithium-Sulfur Batteries: Attaining The Critical Metrics

Uploaded by

Tong YichenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lithium-Sulfur Batteries: Attaining The Critical Metrics

Uploaded by

Tong YichenCopyright:

Available Formats

Please cite this article in press as: Bhargav et al.

, Lithium-Sulfur Batteries: Attaining the Critical Metrics, Joule (2020), https://doi.org/10.1016/

j.joule.2020.01.001

COMMENTARY

Lithium-Sulfur Professor Arumugam Manthiram is the Cathode

The cathode has received the largest vol-

Cockrell Family Regents Chair in engi-

Batteries: neering and the Director of Texas ume of work among all Li-S cell compo-

Attaining Materials Institute and the Materials nents in academic literature. Here, we

Science and Engineering program at seek to highlight the critical challenges re-

the Critical the University of Texas at Austin. His maining in this area and also call attention

Metrics research interests are in the area of to the unique interplay between sulfur

materials for rechargeable batteries and the electrolyte. The electrochemistry

Amruth Bhargav,1 Jiarui He,1

and fuel cells, including novel syn- of the Li-S battery relies on the formation

Abhay Gupta,1

thesis approaches, advanced char- of soluble lithium polysulfide (LiPS) inter-

and Arumugam Manthiram1,*

acterization, and prototype device mediates during charge and discharge.

fabrication. He has authored more These redox-active species dissolve into

Amruth Bhargav is a PhD student in the than 800 publications, with 60,000 ci- the electrolyte and mediate the reaction

Materials Science and Engineering tations and an h-index of 123 (Google kinetics of charge-transfer in solution,

graduate program at the University of Scholar). See https://www.sites.utexas. which in effect regulates the achievable

Texas at Austin. He obtained his B.E. edu/manthiram for further details. capacity in the cell. The dissolution of

in Mechanical Engineering from Visves- the sulfur active material into the electro-

varaya Technological University, India, lyte highlights the need to consider the

in 2013 and a Master of Science in Me- cathode and electrolyte in conjunction,

chanical Engineering from Indiana Uni- Introduction rather than as separate decoupled en-

versity-Purdue University Indianapolis Lithium-sulfur (Li-S) batteries represent tities. For this reason, this section first

in 2016. His research mainly focuses a potential step-change advance in hu- delves into parameters governing just

on lithium-sulfur and lithium-organo- manity’s ability to electrochemically the sulfur electrode and then proceeds

sulfur batteries. store energy, because of the high to highlight metrics that best account for

gravimetric capacity and low cost of the dependencies of the cathode on the

sulfur. We are now on the precipice electrolyte.

Dr. Jiarui He is a postdoctoral fellow in

of the next phase of Li-S research,

the Texas Materials Institute at the Uni-

where new developments must Use of Carbon

versity of Texas at Austin. He obtained

palpably contribute to making the The majority of sulfur cathodes in the

his B.E. (2012) and his PhD (2018) in

Li-S technology commercially relevant. literature employ composite frame-

electronic information materials and

To take this leap, the Li-S community works containing significant amounts

devices from the University of Elec-

should recognize the shortcomings in of conductive carbon (up to 50 wt %).1

tronic Science and Technology of

the parameters being used in current This is to overcome the low electronic

China. His research interests are in the

cell designs and deliberately move to- conductivity of sulfur. However, the

area of electrochemical conversion

ward those that can fully realize the addition of large amounts of conduc-

and storage materials. He has authored

high-energy density promise of Li-S tive filler deprecates the cell-level spe-

more than 76 publications, with 3,000

batteries. In this Commentary, we cific energy. Therefore, minimization

citations and an h-index of 33 (Google

outline key areas for improvement in of carbon content in the cathode is crit-

Scholar).

the Li-S technology. Although this ical to prioritize when optimizing the

commentary is organized on subsys- sulfur cathode. Similar to Li-ion battery

Abhay Gupta is a PhD student in the tem by subsystem basis, many of these cathodes, the carbon content should

Materials Science and Engineering challenges are interdependent. The ideally be reduced to below 5%. Addi-

graduate program at the University of following subsections present parame- tionally, minimization of carbon content

Texas at Austin. He received his ters that are critical to consider in Li-S can be highly beneficial to the following

bachelor’s degree from the Hildebrand research and provide a roadmap for three parameters:

Department of Petroleum and Geosys- overcoming the obstacles that have

tems Engineering at the University of prevented the technology’s implemen- a. Porosity: Various carbons and

Texas at Austin in 2016. His research tation to date. Finally, we introduce the their composites used in Li-S

mainly focuses on lithium-sulfur batte- ‘‘five 5s’’—the critical metrics that are cathodes have a high surface

ries with an emphasis on low-tempera- essential for meeting the high-energy area (100–1500 m2 g 1) and low

ture performance. target of Li-S systems. tap density (0.1–0.3 g cm 3).2

Joule 4, 1–6, February 19, 2020 ª 2020 Elsevier Inc. 1

Please cite this article in press as: Bhargav et al., Lithium-Sulfur Batteries: Attaining the Critical Metrics, Joule (2020), https://doi.org/10.1016/

j.joule.2020.01.001

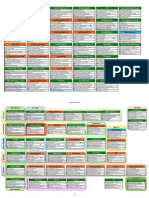

A B C they are sufficiently bound.

Contact angle = 125° Contact angle = 35°

Carbon Sulfur LiCoO2 Non-polar carbon interacts

weakly with the polar LiPSs in

solution (as seen in Figure 1D),

resulting in poor binding and

electron transfer. Consequently,

there is an incomplete conver-

1 g sample each Hydrophobicity of carbon host Hydrophilicity of polar host sion of LiPS and generation of

D E F an electronically insulating thin

500 600

E/S ratio L mg-1) E/S ratio L mg-1)

film of Li2S, which reduces the

Specific Energy (Wh kg-1)

Specific Energy (Wh kg-1)

2 3 2 3

500

400 4 5 4 5 attainable capacity.3 A sulfur

400

100% S Utilization (%)

host should be both conductive

300 90%

300 80%

and electrocatalytic. Such hosts

70%

200 60% can simultaneously facilitate

200 50%

40% LiPS binding (as observed in the

LiPS LiPS LiPS

100 100 case of polar hosts in Figure 1D)

2 4 6 8 10 12 1 2 3 4 5 6 7 8

+C + polar

host

Sulfur Loading (mg cm-2) E/C Ratio ( L [mAh]-1) while promoting electron trans-

fer, boosting its conversion and

Figure 1. Critical Cathode Parameters attainable capacity. In addition,

(A) A visual comparison of the density of microporous carbon (Ketjenblack EC-600JD), sulfur, and a

a thin, lightweight layer of such

Li-ion battery cathode, LiCoO 2 . The powders were tapped to ensure efficient packing.

polar materials could also be

(B) Interaction between water and carbon, showing its high hydrophobicity.

(C) Interaction of water with a polar host on carbon, showing greatly improved hydrophilicity. incorporated as an interlayer on

(D) A simple polysulfide-absorption test comparing carbon and a polar host. The transparent the separator to simultaneously

solution in the case of polar host shows its strong interaction with polysulfides. improve utilization and polysul-

(E) Analytical model showing the effect of sulfur loading on energy density at various E/S ratios.

fide confinement.

(F) Model showing the effect of E/C ratio (with subsequent points corresponding to increased sulfur

utilization as indicated) has on the specific energy at various E/S ratios.

Sulfur Loading

Another critical parameter to consider

The density of microporous car- based redox of LiPSs, which in when designing the sulfur cathode is

bon, sulfur, and an established turn relies on facile ion transport. the areal sulfur loading, in mg cm 2.

Li-ion battery material like This is encouraged when the Higher sulfur loading increases

LiCoO2 is visually compared liquid electrolyte can completely the areal capacity of the cathode

through the photograph in Fig- envelop (i.e., wet) the cathode (mA h cm 2). This maximizes the spe-

ure 1A. The density of carbon is particles. The hydrophobicity of cific energy of the cell, because the

strikingly low, being four and carbon resists wetting by the po- increased fraction of active material off-

nine times less dense than, lar electrolyte, as seen in Fig- sets the ‘‘dead weight’’ present from

respectively, sulfur and LiCoO2. ure 1B. Therefore, high carbon the various inactive components like

Therefore, the increased use of content in the cathode curtails the current collectors and separator.

carbon results in a highly porous wetting, resulting in poor ion The dynamic effect of sulfur loading

cathode. Large amounts of elec- transport and lowering the cell on specific energy is modeled in Fig-

trolytes are required to suffi- capacity. Hydrophilic hosts or ure 1E. In this model, the specific

ciently wet all the surfaces in surface treatments can enhance energy of a Li-S battery is plotted

such a cathode, adding appre- wettability (Figure 1C) and as a function of areal sulfur loading,

ciable weight to the cell and di- thereby facilitate electrolyte assuming that the cathode contains

minishing the specific energy. infiltration and promote LiPS 70 wt % sulfur and achieves

In order to obtain a dense cath- conversion. 1,000 mA h g 1 (~60% utilization).

ode with minimized electrolyte c. Interaction: The sulfur host matrix Further information about this model

uptake, a sulfur host should at the cathode forms the primary is provided in the Supplemental Infor-

possess low surface area (<100 electron conduction pathway for mation. It is evident that irrespective

m2 g 1) and high tap density the various redox-active species of the electrolyte amount, a sulfur

(0.7–1 g cm 3). during cycling. Effective electron loading of <4 mg cm 2 is insufficient

b. Wettability: The sulfur conversion transfer between the LiPS and to outbalance the weight of inactive

reaction depends on solution- conductive host occurs when cell components. Future investigations

2 Joule 4, 1–6, February 19, 2020

Please cite this article in press as: Bhargav et al., Lithium-Sulfur Batteries: Attaining the Critical Metrics, Joule (2020), https://doi.org/10.1016/

j.joule.2020.01.001

into the sulfur cathode should strive for conversion of remaining sulfur to Li2S. described previously, the nature of

sulfur loadings of >5 mg cm 2 in order Thus, at limited electrolyte conditions, discharge in Li-S batteries relies on the

to obtain practically relevant results. the sulfur utilization and capacity deliv- dissolution of redox-active LiPS, which

ered by the cell tends to be poor. This mediates the reaction kinetics of charge

Electrolyte-to-Sulfur (E/S) Ratio interplay between electrolyte amount transfer. This presents unique chal-

The electrolyte constitutes the largest and sulfur utilization can be described lenges and opportunities when devel-

weight fraction of a Li-S cell. Hence, it by the parameter of electrolyte/capac- oping and optimizing Li-S battery

represents the most important lever in ity (E/C) ratio, defined as the amount electrolytes. Due to the solution-medi-

altering the specific energy of the cell. of electrolyte used per unit of discharge ated reaction mechanisms, the Li-S

As highlighted above, the electrolyte capacity delivered in a cell (expressed electrolyte must be able to accommo-

and the sulfur are coupled owing to in g [A h] 1 or mL [mA h] 1). E/C ratio date and solvate a wide array of lithium

the formation of electrolyte-soluble is a consequence of sulfur utilization in polysulfide species. However, although

LiPSs. Maximizing specific energy thus the cell and thus cannot be directly the dissolution of lithium polysulfides is

necessitates the consideration of the controlled like the E/S ratio. However, essential, this also presents the conse-

electrolyte volume used in the cell as E/C ratio links the inactive weight of quence of parasitic shuttling of active

with respect to the amount of sulfur in the electrolyte to the capacity derived material to the anode. This leads to sig-

the cathode. Electrolyte/sulfur (E/S) by the cell, it is an effective determinant nificant active material loss over the

ratio (expressed in mL mg 1) is a param- of specific energy. This effect at course of cycling. An additional consid-

eter that accurately captures this de- different E/S ratios has been modeled eration is the long-term stability of the

pendency, as depicted in the model in in Figure 1F. As expected, for a given reactive lithium-metal anode in the

Figure 1E. This shows that for a given E/S ratio, a higher sulfur utilization max- presence of the chosen electrolyte.7

loading, reducing the E/S ratio greatly imizes the specific energy, which is re-

improves the specific energy. A 50% flected by a minimized E/C ratio. This Therefore, the electrolyte must simulta-

or higher gain in specific energy can can also be looked at from a specific- neously guarantee satisfactory ionic

be achieved by lowering the E/S ratio energy standpoint. In order to achieve conductivity, favorable solubility of

from 5 to 2 mL mg 1. As mentioned 325 W h kg 1, for example, a cathode LiPSs, minimization of the LiPS shuttle

above, one way to optimize the E/S ra- operating at a low E/S ratio of 2 mL effect, and long-term stability with the

tio is to tune the porosity of a cathode. mg 1 can achieve the target specific Li-metal anode. The predominantly

Although researchers are beginning to energy with only 60% sulfur utilization used ether-based electrolyte repre-

recognize the significance of this (corresponding to ~1,000 mA h g 1, sents the currently best-identified

metric, a large portion of Li-S research or an E/C ratio of 2 mL [mA h] 1). Alter- compromise among this myriad of con-

output still continues to use E/S ratios natively, a cathode operating at a high siderations. This electrolyte displays

>20 mL mg 1 or simply neglects to E/S ratio of 5 mL mg 1 can achieve this quite favorable ionic conductivity and

report E/S ratio altogether.1,4–6 This energy density so long as the sulfur uti- LiPS solubility. Additionally, ethers

fails to meet the standards of what is lization is 90% (~1,500 mA h g 1 or E/C display relatively high stability with Li-

needed in order to realistically evaluate ratio of 3.3 mL [mA h] 1). This example metal in comparison to other classes

the improvements being reported. emphasizes that the E/C ratio is a mea- of polar aprotic solvents. The effort to

Therefore, to fairly gauge the improve- sure of the effectiveness of the electro- minimize LiPS shuttling and further

ments in cathode design and make lyte in enabling utilization for a given extend the long-term stability with Li-

relevant improvements to specific en- cathode architecture. The E/C ratio metal presents significant opportu-

ergy, the community must focus on can be minimized by modulating prop- nities for liquid electrolytes and

reducing the E/S ratio below 5 mL mg 1. erties such as wettability and interac- will require continued exploration of

tion as detailed above. Therefore, new electrolyte solvents, salts, and

Electrolyte-to-Capacity (E/C) Ratio beyond just lowering the E/S ratio additives.

Conventional ether-based electrolytes below 5 mL mg 1, cathodes must be de-

can dissolve up to 8 M sulfur in the signed to also lower the E/C ratio below There are also opportunities for explo-

form of LiPSs in solution.5 Therefore, 5 mL (mA h) 1 to realistically evaluate ration of new electrolyte frameworks,

at low E/S ratios, the dissolved LiPS new improvements. such as solid-state electrolytes as well

concentration can be driven toward as sparingly solvating electrolytes. In

the saturation point of the electrolyte. Electrolyte sparingly solvating electrolytes, the sol-

The onset of electrolyte saturation by The electrolyte plays a critical role in vent is entirely coordinated by the salt

LiPS presents a barrier to further disso- the Li-S battery, beyond just ensuring in order to prevent dissolution of LiPS.

lution of active material, inhibiting the excellent ionic conductivity. As In both systems, the circumvention of

Joule 4, 1–6, February 19, 2020 3

Please cite this article in press as: Bhargav et al., Lithium-Sulfur Batteries: Attaining the Critical Metrics, Joule (2020), https://doi.org/10.1016/

j.joule.2020.01.001

A

600

B C augment the improvements brought

E/S ratio L mg-1) about by reducing E/S and E/C ratios,

Specific Energy (Wh kg-1)

500 2 3

4 5 the community should work toward us-

400 ing thin Li-foils (N/P ratio <5). This

would vastly improve both gravimetric

300

and volumetric energy density, while

200 providing a realistic view of cycle life.

3 mm 1 cm

100

0 5 10 15 20

Anode Architecture

Li anode from coin Li anode from pouch

cell after 300 cycles cell after 40 cycles Li is a relatively soft metal, with a Mohs

N/P ratio

hardness of 0.6, whereas that of a metal

Figure 2. Critical Anode and Cell Geometry Parameters like copper (Cu) is 3. This lack of robust-

(A) Model showing the variation of specific energy as a function of N/P ratio at various E/S ratios. Li ness prevents it from being able to be

anode was retrieved from a cycled (B) coin cell after 300 cycles and (C) pouch cell after 40 cycles,

rolled into thin, mechanically stable

showing vastly different Li deposition morphologies.

foils. For this reason, thin (50 mm) Li foils

generally contain a Cu foil backing.

LiPS dissolution requires the battery to degradation are key for unlocking Li-S Because Cu is very dense (8.9 g cm 3

rely on solid-state reduction from performance. versus 0.534 g cm 3 for Li), it contrib-

elemental sulfur to Li2S. This can pre- utes nearly 75% of the mass of such an

sent significant benefits for minimiza- Negative-to-Positive (N/P) Capacity anode, dramatically reducing its effec-

tion of LiPS shuttling and long-term Ratio tive capacity.9 Cu also gets corroded

stability with Li metal. However, it also Negative/positive (N/P) ratio is defined by LiPSs. These issues hinder the use

presents key difficulties in terms of re- as the areal capacity of the Li anode of thin Li foils in this format and hamper

action kinetics, particularly when using (negative electrode) to that of the sulfur the reduction of N/P below 5. There-

high sulfur loadings and minimal cathode (positive electrode). An ideal fore, future Li-S research must focus

carbon content required for practical Li-S full cell would operate at an N/P ra- on employing thin Li anodes wherein

implementation. tio of 1.8 However, excess Li is required the Li is infused into lightweight,

to offset the Li loss occurring due to robust, and lithiophilic host matrices.10

Given the diversity of approaches avail- electrolyte decomposition and solid- This will help minimize inactive current

able, it is vital to keep in mind that the electrolyte interphase (SEI) formation. collector weight while also lowering

implementation of any new electrolyte The excess Li comes at the cost of spe- the N/P ratio.

framework must strive to meet the pa- cific energy. The impact of N/P ratio on

rameters outlined in this commentary. cell-level specific energy as a function Electrolyte Decomposition

Through continued development of of different E/S ratios has been Repeated cycling of Li anode to high

conventionally solvating, sparingly sol- modeled in Figure 2A. When the N/P capacities involves the stripping and

vating, and solid-state electrolytes, the ratio is R20, the excess Li weight penal- plating of several microns of Li metal.

stringent design requirements of the izes specific energy, limiting it to Exposure of the electrolyte to fresh Li

Li-S battery could finally be met. around 150 W h kg 1. As the N/P ratio surfaces in each cycle leads to their con-

approaches unity, the specific energy sumption and a continuous growth of

increases by 100% to 200%, depending insulating SEI. This problem is further

Anode on the E/S ratio used. Additionally, the exacerbated by the non-uniform de-

Designing high-energy-density Li-S use of low N/P ratios amplifies the gains posits of high-surface-area Li metal

cells necessitates the use of a Li-metal- to specific energy brought about by with mossy and dendritic morphology.

based anode, both to offset the low reducing E/S ratio. For example, at an Particularly in the limited electrolyte en-

operating voltage (~2.1 V versus Li/ N/P ratio of 5, the specific energy in- vironments that practical Li-S operation

Li+) and match the high capacity of sul- creases by 56% when the E/S ratio is requires, this reduces the amount of

fur. However, enabling the stable reduced from 5 to 2 mL mg 1. Typical electrolyte available for stable cathode

cycling of the Li-metal anode denotes Li-S cells unfortunately use thick Li-foils operation, leading to premature cell

one of the most formidable challenges (>500 mm or N/P R20) as the anode. failure.11 The instability of the Li-metal

and largest areas for improvement Beyond simply lowering specific en- anode likely represents the single

in Li-S batteries. In this section, we ergy, this excess also compensates for greatest obstacle to implementation

look at how parameters like excess Li loss during cycling, obfuscating the of the Li-S battery. It is thus imper-

Li, anode architecture, and electrolyte true cycle life. Therefore, in order to ative to understand the Li-anode

4 Joule 4, 1–6, February 19, 2020

Please cite this article in press as: Bhargav et al., Lithium-Sulfur Batteries: Attaining the Critical Metrics, Joule (2020), https://doi.org/10.1016/

j.joule.2020.01.001

Figure 3. Attaining Critical Metrics for Li-S Batteries

(A) The five 5s showing the critical metrics required for high-energy-density Li-S batteries.

(B) Schematic showing the main issues leading to a low-energy-density configuration and the key changes to overcome these limitations toward a high-

energy-density configuration.

degradation behavior in the unique volume is utilized. This helps in the opti- the transition from a heavy, voluminous

polysulfide-rich environment of Li-S mization of important parameters like low-energy configuration shown in Fig-

batteries.8 Continued understanding E/S ratio and stack pressure. Therefore, ure 3B to a light-weight and compact

of these unique interfaces could enable testing new materials in large pouch- high-energy system as depicted in Fig-

the development of additives or artifi- cell geometries can help obtain realistic ure 3B. It is important to note that the

cial SEI layers that could eventually assessments of new modifications. The attainment of these metrics does not

overcome the challenges intrinsic to evaluation of new materials at size necessarily signal the culmination of

Li-metal anode.12 scales relevant to commercial the development path for Li-S batte-

implementation prioritizes the consid- ries. Rather, it points to the minimum

Cell Geometry eration of industry-relevant parame- metrics that the community must strive

A final overarching consideration is the ters. This will hopefully discourage the to achieve in putting our best foot for-

cell testing geometry. Studies are use of materials that cannot be pro- ward toward making Li-S batteries a

generally conducted in coin-cell geom- duced at scale and hone the commun- reality.

etries in order to evaluate the funda- ity’s attention to practical solutions.

mental performance of a new material SUPPLEMENTAL INFORMATION

in a high-throughput manner. However, Conclusion: The Five 5s for High- Supplemental Information can be

the implementation of battery materials Energy Li-S Cells found online at https://doi.org/10.

at large size scales brings about new The history of Li-ion batteries demon- 1016/j.joule.2020.01.001.

challenges that coin-cell testing fails to strates that concerted efforts in recog-

highlight. For example, at a coin-cell nizing and tackling the key technical ACKNOWLEDGMENTS

level, uniform Li stripping and plating challenges form the bedrock for their The authors would like to thank the

can be observed (Figure 2B). In commercial success. Li-S technology support by the U.S. Department of En-

contrast, at the large size scales of can undergo a similar transformation, ergy, Office of Basic Energy Sciences,

pouch-cells, uneven current densities provided the research community is in Division of Materials Science and

across the anode can cause wide varia- unison on maximizing the system-level Engineering under award number DE-

tions in the deposited morphology, specific energy. This target can be SC0005397.

which affects cycling behavior (Fig- simplified as the achievement of the

ure 2C). Another downside of coin cells following five metrics, which we title

is the ineffective volume utilization. In a the ‘‘five 5s’’ as shown in Figure 3A: sul- 1. Chung, S.-H., Chang, C.-H., and Manthiram,

typical 2032-type cell, <2% of the vol- fur loading >5 mg cm 2, carbon con- A. (2018). Progress on the Critical Parameters

for Lithium–Sulfur Batteries to be Practically

ume is occupied by the cell compo- tent <5%, E/S ratio <5 mL mg 1, E/C Viable. Adv. Funct. Mater. 28, 1801188.

nents. Whereas, in a vacuum-sealed ratio <5 mL (mA h) 1, and N/P ratio <5 2. Wild, M., and Offer, G.J. (2019). Lithium–

soft-packing pouch cell, >65% of the in pouch-type cells. This would enable Sulfur Batteries (John Wiley & Sons, Inc.).

Joule 4, 1–6, February 19, 2020 5

Please cite this article in press as: Bhargav et al., Lithium-Sulfur Batteries: Attaining the Critical Metrics, Joule (2020), https://doi.org/10.1016/

j.joule.2020.01.001

3. Klein, M.J., Veith, G.M., and Manthiram, A. Sulfur Batteries under Lean Electrolyte and High-Energy Lithium–Sulfur Batteries.

(2017). Rational Design of Lithium-Sulfur Conditions. Angew. Chem. 10.1002/ Adv. Energy Mater. 7, 1700260.

Battery Cathodes Based on Experimentally ange.201909339.

Determined Maximum Active Material 11. Cheng, X.-B., Yan, C., Huang, J.-Q., Li, P.,

Thickness. J. Am. Chem. Soc. 139, 9229– 7. Gupta, A., Bhargav, A., and Manthiram, A. Zhu, L., Zhao, L., Zhang, Y., Zhu, W., Yang,

9237. (2019). Highly Solvating Electrolytes for S.-T., and Zhang, Q. (2017). The gap between

Lithium-Sulfur Batteries. Adv. Energy Mater. long lifespan Li-S coin and pouch cells: The

4. Hagen, M., Hanselmann, D., Ahlbrecht, K., 9, 1803096. importance of lithium metal anode

Maça, R., Gerber, D., and Tübke, J. (2015).

protection. Energy Storage Materials 6,

Lithium–Sulfur Cells: The Gap between the 8. Nanda, S., Gupta, A., and Manthiram, A. 18–25.

State-of-the-Art and the Requirements for (2018). A Lithium–Sulfur Cell Based on

High Energy Battery Cells. Adv. Energy Reversible Lithium Deposition from a Li2S

Mater. 5, 1401986. 12. Yan, C., Zhang, X.-Q., Huang, J.-Q., Liu, Q.,

Cathode Host onto a Hostless-Anode

and Zhang, Q. (2019). Lithium-Anode

5. McCloskey, B.D. (2015). Attainable Substrate. Adv. Energy Mater. 8, 1801556.

Protection in Lithium-Sulfur Batteries. Trends

gravimetric and volumetric energy density of in Chemistry 1, 693–704.

Li-S and li ion battery cells with solid 9. Heligman, B.T., Kreder, K.J., and Manthiram,

separator-protected Li metal anodes. A. (2019). Zn-Sn Interdigitated Eutectic Alloy 1MaterialsScience and Engineering Program and

J. Phys. Chem. Lett. 6, 4581–4588. Anodes with High Volumetric Capacity for Texas Materials Institute, University of Texas at

Lithium-Ion Batteries. Joule 3, 1051–1063. Austin, Austin, TX 78712, USA

6. Zhao, M., Li, B.-Q., Peng, H.-J., Yuan, H.,

*Correspondence: rmanth@mail.utexas.edu

Wei, J.-Y., and Huang, J.-Q. Challenges and 10. Peng, H.-J., Huang, J.-Q., Cheng, X.-B., and

Opportunities towards Practical Lithium– Zhang, Q. (2017). Review on High-Loading https://doi.org/10.1016/j.joule.2020.01.001

6 Joule 4, 1–6, February 19, 2020

You might also like

- 1 s2.0 S209549561930909X MainDocument22 pages1 s2.0 S209549561930909X MainFrancois BornmanNo ratings yet

- Advanced Energy Materials - 2020 - Eshetu - Electrolytes and Interphases in Sodium Based Rechargeable Batteries RecentDocument41 pagesAdvanced Energy Materials - 2020 - Eshetu - Electrolytes and Interphases in Sodium Based Rechargeable Batteries RecentFahad BukhariNo ratings yet

- Advanced Science - 2021 - LuoDocument20 pagesAdvanced Science - 2021 - Luo조창흠No ratings yet

- 10 1002@aenm 202000804Document18 pages10 1002@aenm 202000804ragulaceNo ratings yet

- 2019 Nat. Rev. - Designing Polymers For Advanced Battery ChemistriesDocument19 pages2019 Nat. Rev. - Designing Polymers For Advanced Battery ChemistriesChristopher SmithNo ratings yet

- 10 1002@aenm 201903030 PDFDocument34 pages10 1002@aenm 201903030 PDFROJITAS90No ratings yet

- Challenging The Concept of Electrochemical Discharge Using Salt Solutions For LIB Recycling (Ojanen Et Al 2018)Document8 pagesChallenging The Concept of Electrochemical Discharge Using Salt Solutions For LIB Recycling (Ojanen Et Al 2018)irdantoNo ratings yet

- Adv Funct Materials - 2020 - Liu - The Cathode Choice For Commercialization of Sodium Ion Batteries Layered TransitionDocument15 pagesAdv Funct Materials - 2020 - Liu - The Cathode Choice For Commercialization of Sodium Ion Batteries Layered Transitionshao wangNo ratings yet

- Advanced Energy Materials - 2020 - Zhou - Host Materials Anchoring Polysulfides in Li S Batteries ReviewedDocument49 pagesAdvanced Energy Materials - 2020 - Zhou - Host Materials Anchoring Polysulfides in Li S Batteries ReviewedFrancois BornmanNo ratings yet

- 1 s2.0 S2666821122001995 MainDocument13 pages1 s2.0 S2666821122001995 Mainmassimo.jasimNo ratings yet

- Accounts of Chemical Research - 2021 - Understanding Conversion-Type Electrodes For Lithium Rechargeable BatteriesDocument9 pagesAccounts of Chemical Research - 2021 - Understanding Conversion-Type Electrodes For Lithium Rechargeable Batteries유현중No ratings yet

- 1 s2.0 S016943321931325X MainDocument6 pages1 s2.0 S016943321931325X MainAamir ShafiqueNo ratings yet

- Density Functional Theory For Battery MaterialsDocument16 pagesDensity Functional Theory For Battery MaterialsclasyoonNo ratings yet

- Scurt Istoric+catod+anodDocument13 pagesScurt Istoric+catod+anodAna-Maria HodorogeaNo ratings yet

- Li-S Batteries The Challenges, Chemistry, Materials, and Future Perspectives by Rezan Demir-CakanDocument363 pagesLi-S Batteries The Challenges, Chemistry, Materials, and Future Perspectives by Rezan Demir-CakanMahmoudNo ratings yet

- Designing Polymers For Advanced Battery ChemistriesDocument19 pagesDesigning Polymers For Advanced Battery ChemistriesclasyoonNo ratings yet

- Fenrg 10 1108789Document11 pagesFenrg 10 1108789thubten chogyelNo ratings yet

- Renewable and Sustainable Energy Reviews: Ghassan Zubi, Rodolfo Dufo-López, Monica Carvalho, Guzay PasaogluDocument17 pagesRenewable and Sustainable Energy Reviews: Ghassan Zubi, Rodolfo Dufo-López, Monica Carvalho, Guzay PasaogluBattula SuryaNo ratings yet

- Advanced Energy Materials - 2022 - Xu - Promoting Mechanistic Understanding of Lithium Deposition and Solid%u2010ElectrolyteDocument22 pagesAdvanced Energy Materials - 2022 - Xu - Promoting Mechanistic Understanding of Lithium Deposition and Solid%u2010ElectrolyteVinay ThakurNo ratings yet

- 10 1002@adfm 202008165Document30 pages10 1002@adfm 202008165saisasikumar26No ratings yet

- Sodium Ion BatteriesDocument22 pagesSodium Ion Batteriestudor8sirbuNo ratings yet

- Adv Funct Materials - 2020 - Zhou - Phosphorus Based Composites As Anode Materials For Advanced Alkali Metal Ion BatteriesDocument19 pagesAdv Funct Materials - 2020 - Zhou - Phosphorus Based Composites As Anode Materials For Advanced Alkali Metal Ion BatteriesMIHAINo ratings yet

- 1 s2.0 S2095809922007664 MainDocument4 pages1 s2.0 S2095809922007664 Mainpablo ignacio olmedo lopezNo ratings yet

- 1 s2.0 S2589004221014358 MainDocument44 pages1 s2.0 S2589004221014358 Mainhamed aslannejadNo ratings yet

- Fenrg 08 606494Document8 pagesFenrg 08 606494Sorina CretuNo ratings yet

- Fang 2017Document25 pagesFang 2017Dusan Soliz TorricoNo ratings yet

- Sun 2016 Cathode Loading Effect On Sulfur UtDocument9 pagesSun 2016 Cathode Loading Effect On Sulfur UtozoNo ratings yet

- Ragone PlotDocument17 pagesRagone PlotGeorge SoulNo ratings yet

- 10 1002@adfm 201907931Document14 pages10 1002@adfm 201907931rohitNo ratings yet

- Recent Progress of in Situ Transmission Electron Microscopy For Energy MaterialsDocument19 pagesRecent Progress of in Situ Transmission Electron Microscopy For Energy Materialsahmet kaan eyidoğanNo ratings yet

- Nature Reviews Materials - 2022 - Organic Batteries For A Greener Rechargeable WorldDocument17 pagesNature Reviews Materials - 2022 - Organic Batteries For A Greener Rechargeable World유현중No ratings yet

- 2D-Materials For Energy Harvesting and Storage ApplicationsDocument264 pages2D-Materials For Energy Harvesting and Storage Applicationszahidbaloch135blnNo ratings yet

- LCA of BatteriesDocument12 pagesLCA of BatteriesMuhammadAliNo ratings yet

- Wang 2014Document9 pagesWang 2014aNo ratings yet

- Artigo Sobre MembranaDocument6 pagesArtigo Sobre MembranaJoanaNo ratings yet

- Manthiram Et Al 2012 Challenges and Prospects of Lithium Sulfur BatteriesDocument10 pagesManthiram Et Al 2012 Challenges and Prospects of Lithium Sulfur Batterieszhaoyue12112001No ratings yet

- 1 s2.0 S2211285518305020 MainDocument12 pages1 s2.0 S2211285518305020 MainSa'dur RifkiNo ratings yet

- Materials: Comparative Life Cycle Assessment of A Novel Al-Ion and A Li-Ion Battery For Stationary ApplicationsDocument14 pagesMaterials: Comparative Life Cycle Assessment of A Novel Al-Ion and A Li-Ion Battery For Stationary ApplicationsAnonymous P7J7V4No ratings yet

- 30years of Lithium-Ion ReviewDocument24 pages30years of Lithium-Ion ReviewWELENTON PANISSONNo ratings yet

- A Review of Redox Electrolytes For SupercapacitorsDocument7 pagesA Review of Redox Electrolytes For SupercapacitorsMasumeh HashemiNo ratings yet

- Battery ThesisDocument4 pagesBattery Thesisaouetoiig100% (1)

- Yang 2021Document23 pagesYang 2021rafiyNo ratings yet

- Lithium Ion Battery Literature ReviewDocument7 pagesLithium Ion Battery Literature Reviewsemizizyvyw3100% (1)

- FulltextDocument12 pagesFulltextSafa SafaNo ratings yet

- 1 s2.0 S209549562100601X MainDocument19 pages1 s2.0 S209549562100601X MainHarshithNo ratings yet

- A Review of Solid Electrolyte Interphase SEI and Dendrite Formation in Lithium Batteries 2023 SpringerDocument46 pagesA Review of Solid Electrolyte Interphase SEI and Dendrite Formation in Lithium Batteries 2023 SpringerCIKARANG KOTANo ratings yet

- Solid Polymer Electrolytes Materials Designing andDocument20 pagesSolid Polymer Electrolytes Materials Designing andRajiv DubeyNo ratings yet

- Bipolar BatteryDocument7 pagesBipolar BatteryClaudio CairoNo ratings yet

- Review: Carbonyl-Coordinating Polymers For High-Voltage Solid-State Lithium Batteries: Solid Polymer ElectrolytesDocument25 pagesReview: Carbonyl-Coordinating Polymers For High-Voltage Solid-State Lithium Batteries: Solid Polymer ElectrolytesA1234 AJEFNo ratings yet

- Batteries Supercaps - 2021 - Hasa - Batteries Supercaps Beyond Lithium Ion BatteriesDocument3 pagesBatteries Supercaps - 2021 - Hasa - Batteries Supercaps Beyond Lithium Ion Batteriesexact medicalNo ratings yet

- Pre Intercalation A Valuable Approach For The Improvement of Pos - 2024 - EscieDocument15 pagesPre Intercalation A Valuable Approach For The Improvement of Pos - 2024 - Escieabrarnafis43No ratings yet

- Exploring More Functions in Binders For Lithium BatteriesDocument44 pagesExploring More Functions in Binders For Lithium BatteriesArthur Isaac Toomas IjimNo ratings yet

- A Critical Review of LiAir BatteriesDocument31 pagesA Critical Review of LiAir BatteriesAnkit GulumkarNo ratings yet

- Anode MaterialsDocument23 pagesAnode MaterialsMeruyert KarimNo ratings yet

- Advanced Energy Materials - 2021 - LiDocument27 pagesAdvanced Energy Materials - 2021 - LiXiangyv HuangNo ratings yet

- All-Solid-State Lithium-Ion and Lithium Metal Batteries-2018schnellDocument16 pagesAll-Solid-State Lithium-Ion and Lithium Metal Batteries-2018schnellRodrigo VieiraNo ratings yet

- Recent Progress of Magnetic Field Application in Lithium Based BatteriesDocument19 pagesRecent Progress of Magnetic Field Application in Lithium Based BatteriesKiki Rezki LestariNo ratings yet

- Chemical Engineering Science: Ningyuan Zhang, Chengwei Deng, Shuo Tao, Leibin Guo, Yuanhui ChengDocument7 pagesChemical Engineering Science: Ningyuan Zhang, Chengwei Deng, Shuo Tao, Leibin Guo, Yuanhui ChengSebastian LopezNo ratings yet

- 7.advanced Materials - 2018 - LiDocument24 pages7.advanced Materials - 2018 - LiMohammad Muhtasim Mashfy, 170011054No ratings yet

- Physics HL - ANSWERS - Chris Hamper - Second Edition - Pearson 2014Document52 pagesPhysics HL - ANSWERS - Chris Hamper - Second Edition - Pearson 2014vasudha100% (4)

- Sunday Afternoon, October 27, 2013: TechnologyDocument283 pagesSunday Afternoon, October 27, 2013: TechnologyNatasha MyersNo ratings yet

- 7 Quencher DesignDocument8 pages7 Quencher DesignJozsef Acs100% (1)

- (PChemI - Atkins) Chapter 4Document36 pages(PChemI - Atkins) Chapter 4Raja Akmal100% (1)

- Ex 7Document5 pagesEx 7Jean AraúzNo ratings yet

- Notes Air CompositionDocument4 pagesNotes Air CompositionOkami :]No ratings yet

- HMT03 - Heat Transfer in Forced Convection ApparatusDocument2 pagesHMT03 - Heat Transfer in Forced Convection ApparatusDayanandaNo ratings yet

- Munn - Metal-Organic Frameworks SIDocument10 pagesMunn - Metal-Organic Frameworks SIjeppoo1No ratings yet

- CBSE Class 11 Physics Notes - Surface Tension - AglaSem SchoolsDocument7 pagesCBSE Class 11 Physics Notes - Surface Tension - AglaSem SchoolsSanjeev dahiyaNo ratings yet

- Journal of Alloys and Compounds: Karandeep, H.C. Gupta, S. KumarDocument5 pagesJournal of Alloys and Compounds: Karandeep, H.C. Gupta, S. Kumarshivika gaurNo ratings yet

- Colebrook Equation Fluid Flow in PipesDocument22 pagesColebrook Equation Fluid Flow in PipesSAMUEL UDOHNo ratings yet

- The - J-Factor of Chilton and Colburn: Unit OperationDocument6 pagesThe - J-Factor of Chilton and Colburn: Unit OperationGhazy alshyal100% (1)

- CFD Analysis of Shell and Coil Heat Exchanger by Using Different Mass Flow Rate For Hot and Cold FluidDocument19 pagesCFD Analysis of Shell and Coil Heat Exchanger by Using Different Mass Flow Rate For Hot and Cold FluidIJRASETPublicationsNo ratings yet

- PVT Concepts Reservoir ConceptDocument23 pagesPVT Concepts Reservoir ConceptherikugisNo ratings yet

- HK I TermodinamikaDocument21 pagesHK I TermodinamikaPutri Desty AmeliaNo ratings yet

- Electrostatics Notes of Allen Kota BatchDocument143 pagesElectrostatics Notes of Allen Kota BatchAbhijeet ThakurNo ratings yet

- Process Design Course DME Autumn 2009Document108 pagesProcess Design Course DME Autumn 2009Srikari MulaNo ratings yet

- Thermal Analysis (ATH)Document5 pagesThermal Analysis (ATH)liapomiNo ratings yet

- PERFORM - Nodal Analysis by ExampleDocument2 pagesPERFORM - Nodal Analysis by ExampleAlfonso R. ReyesNo ratings yet

- THERMO 1 (Intro Elements Units Common Properties)Document3 pagesTHERMO 1 (Intro Elements Units Common Properties)Beaw GtNo ratings yet

- Meeting 4 Electron Spect AugerDocument39 pagesMeeting 4 Electron Spect AugerSaskya PNo ratings yet

- 9 Antifouling SystemDocument24 pages9 Antifouling SystemYuri DuriNo ratings yet

- Guidlines For Use and Care of Aminex Resin-Based ColumnsDocument32 pagesGuidlines For Use and Care of Aminex Resin-Based ColumnsSara Dolgun0% (1)

- LPGDocument8 pagesLPGraritylimNo ratings yet

- Capillary TubeDocument8 pagesCapillary Tubeziko23100% (2)

- GTCDocument80 pagesGTCmehul10941No ratings yet

- Ionization Energy and ElectronegativityDocument4 pagesIonization Energy and Electronegativityur momNo ratings yet

- Raw Material Specification Sheet - Petroflo 20Y3437 NewDocument2 pagesRaw Material Specification Sheet - Petroflo 20Y3437 NewBasty Tejano67% (3)

- Webquest Conduction Convection RadiationDocument1 pageWebquest Conduction Convection Radiationapi-259781257No ratings yet

- Chapter 17 ArReactionDocument123 pagesChapter 17 ArReaction蔡易斈No ratings yet