Professional Documents

Culture Documents

Pe-Fp-Ww-Pnt-Roadmaster Bass Series 16

Uploaded by

Maziya AnisahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pe-Fp-Ww-Pnt-Roadmaster Bass Series 16

Uploaded by

Maziya AnisahCopyright:

Available Formats

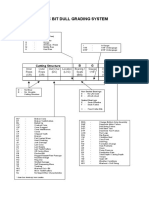

No : WW-FPST-(BASS SERIES 16 NP)-03

Hal : 1/1 CV. PREMIERE WOOD MANUFACTURING

Revisi

Tanggal

: 00

16.12.20 FLOW PROCESS & STANDART TIME

Model ROADMASTER BASS SERIES 16 NP DIVISI WOOD WORKING

Prepared : Aisyah (Prod Eng) Checked : (RnD) Approved : Imam. M (Prod Eng) Approved : Stefanus (Wood Working)

Body Board Aktif

Running Moulder V-Cut

Mulai Wrapping CNC

Saw

Body Board Pasif

Running

Mulai Saw Moulder Wrapping CNC V-Cut

Front Board Aktif

Mulai CNC Spindle Membran Router Multi Bor Coloring

Front Board Pasif

Mulai CNC Spindle Membran Router Multi Bor Coloring To FA

Back Board Aktif

Flat

Mulai CNC Multi Bor

Laminasi

Back Board Pasif

Mulai Flat CNC Multi Bor

Laminasi

Square Board

Mulai Table Saw Cross Cut

Brace Board Part 1 2

Running

Mulai Cross Cut

Saw

Profil Extrude R/L

Running

Mulai Moulder Cross Cut Spindle

Saw

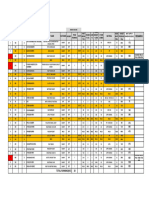

NO PART BOX SET MACHINE/TOOL PROCESS OT (SEC) NET (SEC) MAN PWR KETERANGAN / JIG

1 BODY BOARD AKTIF A RUNNING SAW Cutting Material 7.5 11 2 1Kali Running Saw ± 5Mnt 8Lbr=40Pcs

( MDF - 08MME2 ) A MOULDER Cutting Finish, Chamfer, and Groove 15 30 2

P = 1486.2 MM A WRAPPING Laminasi PVC sheet black sand emboss 0.18mm 9 12 6

L = 223MM A CNC 24 27 2

A V-CUT V-Cut Body 30 60 2

TOTAL(SEC) : 85.5 140

2 BODY BOARD PASIF P RUNNING SAW Cutting Material 7.5 11 - 1Kali Running Saw ± 5Mnt 8Lbr=40Pcs

( MDF - 08MME2 ) P MOLDER Cutting Finish, Chamfer, and Groove 15 30 -

P = 1486.2MM P WRAPPING Laminasi PVC sheet black sand emboss 0.18mm 9 12 -

L = 223MM P CNC 24 27 -

P V-CUT V-Cut Body 30 60 -

TOTAL(SEC) : 85.5 140

3 FRONT BOARD AKTIF A CNC 36 72 -

( MDF MOULDED ) A SPINDLE 25 25 1

P = 539.5 MM MEMBRAN Spray lem 20 20 2

L = 215MM Membran PVC 54.5 60 2 PVC Sheet Fiber Fabrick Membran

A Cutting PVC + Cleaning 25 25 1

A ROUTER 25 36 1

A MULTI BOR Lubang Screw 20 20 1

A COLORING 10 10 2

TOTAL(SEC) : 215.5 268.0

4 FRONT BOARD PASIF P CNC 36 72 -

( MDF MOULDED ) P SPINDLE 25 25 -

P = 539.5 MM P MEMBRAN Spray lem 20 20 -

L = 215 MM Membran PVC 54.5 60 - PVC Sheet Fiber Fabrick Membran

Cutting PVC + Cleaning 25 25 -

P ROUTER 25 36 -

P MULTI BOR Lubang Screw 20 20 -

P COLORING 10 10 -

TOTAL(SEC) : 215.5 268.0

5 BACK BOARD AKTIF A FLAT LAMINASI 5.6 7.2 5

( MDF 8MM ) A CNC 53 60 -

P = 538MM A MULTI BOR Lubang Screw 30 30 -

TOTAL(SEC) : 88.90 97.2

6 BACK BOARD PASIF P FLAT LAMINASI 5.6 7.2 -

( MDF 8MM ) P CNC 53 60 -

P = 538MM P MULTI BOR 30 30 -

TOTAL(SEC) : 88.90 97.2

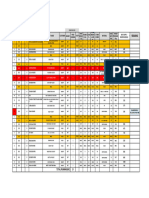

7 PROFIL EXTRUDE R/L RUNNING SAW 3.75 7.5 -

( LVL 20MM-RANDU ) MOULDER 3.6 3.6 -

CROSS CUT 36 36 1

SPINDLE Proses Trap 15 15 -

TOTAL(SEC) : 58.35 62.10

8 BRACE PART 1 2 RUNNING SAW Cutting Material 7 7 -

( MDF - 8 MM & 08 MM ) CROSS CUT 5 5 -

TOTAL(SEC) : 12.0 12.0

9 SQUARE BOARD TABLE SAW 14.4 14.4 1

CROSS CUT 5 5 -

TOTAL(SEC) : 19.4 19.40

NOTE OT (SEC) NET(SEC) MAN PWR REV NB.

MAN PWR = JUMLAH OPERATOR TOTAL : 869.55 1103.90 31

QTY (PCS) = QUANTITY (PCS) MINIMUM : 3.6 3.6 1

ST (MNT) = STANDART TIME (MNT) MAXIMUM : 54.5 72 6

NET (SEC) = NET OPERATION RATE (ACTUAL PROSESSING TIME)

OT(SEC) = OPERATING TIME (WAKTU OPERASI MESIN) STANDARD TIME / SET = TOTAL + 15% TOLERANCE 16.7 21.2 MENIT

SET = (A = ACTIVE ; P = PASIVE)

PE - FM - 001, Rev : 00.29.03.07

You might also like

- M012/M013 Service ManualDocument201 pagesM012/M013 Service ManualJean AlmeidaNo ratings yet

- Credit Card NCC BANKDocument1 pageCredit Card NCC BANKKazi Foyez AhmedNo ratings yet

- Manual Bomba KoomeyDocument95 pagesManual Bomba KoomeyDiego De JesusNo ratings yet

- Sinumerik 840dDocument713 pagesSinumerik 840dmiguel de carvalhoNo ratings yet

- LP Demo Factors Affecting ClimateDocument3 pagesLP Demo Factors Affecting ClimateAnastacia Anne Eva Camba100% (1)

- SS Surface FinishesDocument1 pageSS Surface FinishesWendyNo ratings yet

- Recommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsDocument43 pagesRecommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsAnonymous Gd0PTUQNo ratings yet

- Personal Nursing Leadership PaperDocument7 pagesPersonal Nursing Leadership Paperapi-625175559No ratings yet

- Review Related Literature (0115)Document5 pagesReview Related Literature (0115)Nesty SarsateNo ratings yet

- Pe-Fp-Ww-Roadmaster Bass Series 12Document1 pagePe-Fp-Ww-Roadmaster Bass Series 12Maziya AnisahNo ratings yet

- Pe FPST WW (Hbpro 8) 02Document4 pagesPe FPST WW (Hbpro 8) 02Maziya AnisahNo ratings yet

- Fp-Ww-Cbox D808XWBDocument1 pageFp-Ww-Cbox D808XWBMaziya AnisahNo ratings yet

- Start Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingDocument1 pageStart Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingMaziya AnisahNo ratings yet

- Divisi Wood Working: Running Saw Moulder V-CutDocument1 pageDivisi Wood Working: Running Saw Moulder V-CutMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- RMPU Stages FDocument5 pagesRMPU Stages FSachinNo ratings yet

- 6-General Miling InfoDocument5 pages6-General Miling InfoSakthi VelNo ratings yet

- Time Study of Gate Valve Body 24X150 1setupDocument4 pagesTime Study of Gate Valve Body 24X150 1setupdada kolekarNo ratings yet

- Cover Assy. SAI Valve-N7040290Document22 pagesCover Assy. SAI Valve-N7040290M Senthil SenthilNo ratings yet

- Lathe RoiDocument1 pageLathe RoiPaul Saimond TobiasNo ratings yet

- Report Generation: Gajendhiran.V M.E-Cad/CamDocument6 pagesReport Generation: Gajendhiran.V M.E-Cad/CamGajendhar KVK100% (1)

- NEPTUNE 2&2S English User Guide 20211203Document28 pagesNEPTUNE 2&2S English User Guide 20211203marknerocavalloNo ratings yet

- CJ21013 L05 LT AHU Indoor (With Breakin) 20231031 R1Document9 pagesCJ21013 L05 LT AHU Indoor (With Breakin) 20231031 R1Eddy NgNo ratings yet

- Aerospace: ApplicationsDocument36 pagesAerospace: ApplicationsKasia MazurNo ratings yet

- Drill: Mitsubishi CarbideDocument8 pagesDrill: Mitsubishi CarbideĐồng Đăng HảiNo ratings yet

- Slimline Web 0 PDFDocument84 pagesSlimline Web 0 PDFjas jaserNo ratings yet

- Plant and MachineryDocument3 pagesPlant and MachinerySM AreaNo ratings yet

- WT Tooling SystemDocument73 pagesWT Tooling SystemSiddharth PatelNo ratings yet

- SwissBlue - APKT INSERTSDocument12 pagesSwissBlue - APKT INSERTSgkhnNo ratings yet

- Lec5 Machining 2018Document70 pagesLec5 Machining 2018pointetNo ratings yet

- E CatalogDocument24 pagesE Cataloghary.dedeharyadiNo ratings yet

- Cutting Tools: Your Partner For Clever ToolingDocument9 pagesCutting Tools: Your Partner For Clever ToolingPalade LucianNo ratings yet

- Chip Breaker: (Positive)Document12 pagesChip Breaker: (Positive)ilham faqihNo ratings yet

- Mechanical Properties - Mechanical DesignDocument3 pagesMechanical Properties - Mechanical DesignrsbguesthouseNo ratings yet

- General Metal Fabrication and AssemblyDocument9 pagesGeneral Metal Fabrication and Assemblysola sido100% (1)

- General Metal Fabrication and AssemblyDocument9 pagesGeneral Metal Fabrication and Assemblysola sidoNo ratings yet

- Locating Bolts Stopper Bolts / Stopper Screws: Round Head, Round TipDocument1 pageLocating Bolts Stopper Bolts / Stopper Screws: Round Head, Round Tipnguyen HungNo ratings yet

- Neptune 2 User GuideDocument28 pagesNeptune 2 User GuideJeremy BloodNo ratings yet

- Lecture 1 CAD/CAM Branch Third ClassDocument21 pagesLecture 1 CAD/CAM Branch Third ClassMostafa AdilNo ratings yet

- Beam Calculation: ETABS 2016 16.2.1 License # 1FNVN5QQGG7FMGFDocument2 pagesBeam Calculation: ETABS 2016 16.2.1 License # 1FNVN5QQGG7FMGFrikhi khadkaNo ratings yet

- PCBN & PCD InsertsDocument36 pagesPCBN & PCD InsertsecarrilloNo ratings yet

- BM 16 - Multitask Plate and Pipe Beveller - 1910Document4 pagesBM 16 - Multitask Plate and Pipe Beveller - 1910ghostinshellNo ratings yet

- Fp-Ww-Cbox Max 09 PaDocument1 pageFp-Ww-Cbox Max 09 PaMaziya AnisahNo ratings yet

- SRF SufDocument12 pagesSRF SufarvinupNo ratings yet

- Produksi ItemDocument2 pagesProduksi ItemChalil FachroniNo ratings yet

- Date 24-02-2019 FabricationDocument1 pageDate 24-02-2019 FabricationDass DassNo ratings yet

- Gms Lathe ListDocument2 pagesGms Lathe ListByron ZapetNo ratings yet

- No.14 - MPI - BG. CREST 301 Rev01Document8 pagesNo.14 - MPI - BG. CREST 301 Rev01ariffNo ratings yet

- IADC Bit Dull Grading System PDFDocument1 pageIADC Bit Dull Grading System PDFMohamed MahmoudNo ratings yet

- 16,17 - CJ21013 L05 LT AHU Indoor 20230608Document5 pages16,17 - CJ21013 L05 LT AHU Indoor 20230608Eddy NgNo ratings yet

- Shpindeli SLFDocument60 pagesShpindeli SLFrayss1978No ratings yet

- ETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignMuhammad AhsunNo ratings yet

- Shortage List Update 21 DesDocument1 pageShortage List Update 21 Desmr5148447No ratings yet

- QTN-9394301 - Offer For M&M Crank Case Project ToolsDocument1 pageQTN-9394301 - Offer For M&M Crank Case Project ToolsNathan ChenNo ratings yet

- PT Indah Kiat Pulp & Paper TBK Summary Abnormality QC Finish Product Cs6/Fs6 Nov-19Document2 pagesPT Indah Kiat Pulp & Paper TBK Summary Abnormality QC Finish Product Cs6/Fs6 Nov-19Bujang RantauNo ratings yet

- VF HVRBDocument12 pagesVF HVRBNAHRUDIN KOLIĆNo ratings yet

- 8 5-FX56sDocument4 pages8 5-FX56snappyNo ratings yet

- RHINO Insert PDFDocument168 pagesRHINO Insert PDFtran namNo ratings yet

- Production Report of 25-10-2020Document32 pagesProduction Report of 25-10-2020Sk DipuNo ratings yet

- Process DetailDocument3 pagesProcess DetailvenkatNo ratings yet

- Kolom K1Document1 pageKolom K1Al-Fatih Kids ChannelNo ratings yet

- Lec5 Machining 2019Document87 pagesLec5 Machining 2019ED 405No ratings yet

- Shortage List Update 24 DesDocument1 pageShortage List Update 24 Desmr5148447No ratings yet

- 2016-2017 General Catalogue KyoceraDocument992 pages2016-2017 General Catalogue KyoceraZoran DjurdjevicNo ratings yet

- Magnetic Abrasive Finishing (MAF) : Dr. Manas Das Assistant ProfessorDocument41 pagesMagnetic Abrasive Finishing (MAF) : Dr. Manas Das Assistant ProfessorAshok PushparajNo ratings yet

- Fp-Ww-Cbox Max 09 PaDocument1 pageFp-Ww-Cbox Max 09 PaMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- Standard Time Final Assy: No. Model FA Grille Satuan TotalDocument20 pagesStandard Time Final Assy: No. Model FA Grille Satuan TotalMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- Academic & Scientific Poster Presentation Visualising Knowledge As A Means To Facilitate Knowledge TransferDocument19 pagesAcademic & Scientific Poster Presentation Visualising Knowledge As A Means To Facilitate Knowledge TransferMaziya AnisahNo ratings yet

- ScorecardDocument15 pagesScorecardKarthik KadambiNo ratings yet

- What Does Fire Hazards Mean?Document2 pagesWhat Does Fire Hazards Mean?Karima HijaraNo ratings yet

- Medium Ice Cube MachineDocument8 pagesMedium Ice Cube MachineAmit GaragNo ratings yet

- Jacques Lacan - Seminar On The Purloined LetterDocument11 pagesJacques Lacan - Seminar On The Purloined LetterJose Jr OrquiaNo ratings yet

- The Translation of Serious Literature & Authoritative Statements - Poetry - Patricia Iris v. RazonDocument20 pagesThe Translation of Serious Literature & Authoritative Statements - Poetry - Patricia Iris v. RazonPatricia Iris Villafuerte RazonNo ratings yet

- GlobalDocument9 pagesGlobaldaily foot ball highlightsNo ratings yet

- MCQ For MathsDocument3 pagesMCQ For MathsksamuelrajNo ratings yet

- Acknowledgement: Survey Camp Report 2015Document5 pagesAcknowledgement: Survey Camp Report 2015riyasNo ratings yet

- ApexSQL Propagate 2018 ReleasedDocument2 pagesApexSQL Propagate 2018 ReleasedPR.comNo ratings yet

- ManualDocument50 pagesManualmohan2380% (1)

- Expose PolymerDocument7 pagesExpose PolymerKarfala KandeNo ratings yet

- ICP Course Outline PDFDocument3 pagesICP Course Outline PDFIjlal NasirNo ratings yet

- Gea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFDocument2 pagesGea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFJorge A. TorresNo ratings yet

- GDT Psychology-Analysis Worksheet All ExamplesDocument12 pagesGDT Psychology-Analysis Worksheet All ExamplesDiya BajajNo ratings yet

- Bose Lifestyle RoommateDocument12 pagesBose Lifestyle Roommateatom7-2No ratings yet

- Rajala Varaprasad Reddy: ObjectiveDocument2 pagesRajala Varaprasad Reddy: ObjectiveRAKESH REDDY THEEGHALANo ratings yet

- Pythagoras School of MathematicsDocument4 pagesPythagoras School of Mathematicssulys SimanjuntakNo ratings yet

- Solucionario Capitulo 23 Paul e TippensDocument18 pagesSolucionario Capitulo 23 Paul e TippensALICIA MARIE SABILLON RAMOSNo ratings yet

- 15 Canteens and RestroomsDocument5 pages15 Canteens and RestroomsОлександра СеменкоNo ratings yet

- CFX Gs 2020r1 en Ws07 Naca0012 AirfoilDocument40 pagesCFX Gs 2020r1 en Ws07 Naca0012 Airfoilanish44No ratings yet

- Thesis Defense SlideshareDocument6 pagesThesis Defense Slidesharesprxzfugg100% (2)

- AAK500-Tutorial 2Document82 pagesAAK500-Tutorial 2dd ddNo ratings yet

- Mindful Recovery: A Case Study of A Burned-Out Elite ShooterDocument12 pagesMindful Recovery: A Case Study of A Burned-Out Elite ShooterRandy HoweNo ratings yet