Professional Documents

Culture Documents

Fp-Ww-Cbox D808XWB

Uploaded by

Maziya AnisahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fp-Ww-Cbox D808XWB

Uploaded by

Maziya AnisahCopyright:

Available Formats

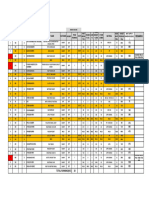

No : WW-FPST-(CBOX - D 808 XWB ) - 15

Hal : 1/1 CV. PREMIERE WOOD MANUFACTURING

Revisi

Tanggal

: 00

: 2/3/2021 FLOW PROCESS & STANDART TIME

Model : SHARP CBOX - D 808 XWB DIVISI WOOD WORKING

Prepared : Aisyah (Prod Eng) Checked : Rosi (RnD) Approved : Imam. M (Prod Eng) Approved : Dakun (Wood Working)

Body Board A/P

Flat Running

Mulai Moulder CNC Multi Bor V-Cut

Laminasi Saw

Side Board A/P

Mulai CNC Spindle Membran

Grille Board A/P

Running Running Coloring

Mulai Spindle CNC Spindle

Saw Saw

Top Cap A/P

Running

Mulai Spindle CNC Spindle Membran

Saw

To FA

Ornament Aktif

Running

Mulai Spindle Membran CNC Coloring

Saw

Ornament Pasif

Running

Mulai Spindle Membran CNC Coloring

Saw

Brace Board

Mulai Table Saw Cross Cut

Square Board

Mulai Table Saw Cross Cut

Support Chamber

Running

Mulai Table Saw MultiBor

Saw

NO PART BOX SET MACHINE/TOOL PROCESS OT (SEC) NET(SEC) MAN PWR KETERANGAN / JIG

1 BODY BOARD ACTIVE A 1 FLAT LAMINASI 6 6.7 4 PVC Sheet Black Sand Emboss A5013-910 0.18MMX1260MM

( MDF - 8MM E2 ) A 1 RUNNING SAW Cutting Material 9.4 9.9 2 1 Kali Running Saw ±5Mnt = 10 Pcs/5 Lembar

P = 1895.1 MM A 1 MOULDER 15 15 2

L = 240 MM A 1 CNC 180 210 2 1X CNC =6Mnt (2Pcs)

A 1 MULTI BOR 60 60 1

A 1 V-CUT V-Cut Body 30 35 2

TOTAL(SEC) : 210 242

2 BODY BOARD PASSIVE P 1 FLAT LAMINASI 6 6.7 4 PVC Sheet Black Sand Emboss A5013-910 0.18MMX1260MM

( MDF - 8MM E2 ) P 1 RUNNING SAW Cutting Material 9.4 9.9 2 1 Kali Running Saw ±5Mnt = 10 Pcs/5 Lembar

P = 1895.1 MM P 1 MOULDER 15 15 2

L = 240 MM P 1 CNC 180 210 2 1X CNC =6Mnt (2Pcs)

P 1 MULTI BOR 60 60 1

P 1 V-CUT V-Cut Body 30 35 2

TOTAL(SEC) : 210 242

3 SIDE BOARD ACTIVE A 2 CNC 30 34 2 1Kali CNC 3Mnt=6Pcs

( MDF - 8MM E2 ) A 2 SPINDLE 1

P = 681 MM A 2 MEMBRAN SANDING 1

L = 301 MM A 2 SPRAY LEM 51.4 51.4 2 Terdiri dari 2 Pcs (Perhitungan Total untuk 2 Pcs)

A 2 MEMBRAN 85.8 154.2 2 PVC Sheet Walnut FW4401-802A Horizontal UK 0.18MMX1260MM

A 2 LEM FINISHING 180 180 2 Lem manual menggunakan kuas untuk lipatan dalam daln di Hairdryer

A 2 CUTTING 180 180 1

TOTAL(SEC) : 527 599.6

4 SIDE BOARD PASSIVE P 2 CNC 30 30 1Kali CNC 3Mnt=6Pcs

( MDF - 8MM E2 ) P 2 SPINDLE 2

P = 681 MM P 2 MEMBRAN SANDING 1

L = 301 MM P 2 SPRAY LEM 51.4 51.4 1 Terdiri dari 2 Pcs (Perhitungan Total untuk 2 Pcs)

P 2 MEMBRAN 85.8 154.2 2 PVC Sheet Walnut FW4401-802A Horizontal UK 0.18MMX1260MM

P 2 LEM FINISHING 180 180 2 Lem manual menggunakan kuas untuk lipatan dalam daln di Hairdryer

P 2 CUTTING 180 180 2

1

TOTAL(SEC) : 527 595.6

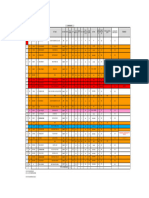

5 GRILLE BOARD ACTIVE A 1 RUNNING SAW Cutting Material 5 5.5 2 Flat PVC Black Sand Emboss

( MDF 15MM E2) A 1 SPINDLE 1

P = 520 MM A 1 RUNNING SAW 5 5.5 2

L = 234 MM A 1 CNC 50 54 2 1Kali CNC 10 Mnt = 12Pcs

A 1 SPINDLE 1

A 1 COLORING 180 180 2

TOTAL(SEC) : 240 245

6 GRILLE BOARD PASSIVE P 1 RUNNING SAW Cutting Material 5 5.5 2 Flat PVC Black Sand Emboss

( MDF 15MM E2) P 1 SPINDLE 1

P = 520 MM P 1 RUNNING SAW 5 5.5 2

L = 234 MM P 1 CNC 50 54 2 1Kali CNC 10 Mnt = 12Pcs

P 1 SPINDLE 1

P 1 COLORING 180 180 2

TOTAL(SEC) : 240 245

7 TOP CAP ACTIVE A 1 RUNNING SAW 3.5 3.9 2

( MDF 12MM E2) A 1 SPINDLE 1

P = 270.6 MM A 1 CNC 10 14 2 1Kali CNC 4Mnt=24Pcs

L = 234 MM A 1 SPINDLE 1

A 1 MEMBRAN SANDING 35 35 1

A SPRAY LEM 15 15 2

MEMBRAN 7.5 18.75 2

CUTTING 20 20 1

TOTAL(SEC) : 91 106.65

8 TOP CAP PASSIVE P 1 RUNNING SAW 3.5 3.9 2

( MDF 12MM E2) P 1 SPINDLE 1

P = 270.6 MM P 1 CNC 10 14 2 1Kali CNC 4Mnt=24Pcs

L = 234 MM P 1 SPINDLE 1

P 1 MEMBRAN SANDING 35 35 1

SPRAY LEM 15 15 2

MEMBRAN 7.5 18.75 2

CUTTING 20 20 1

TOTAL(SEC) : 91 106.65

9 ORNAMENT ACTIVE A 1 RUNNING SAW 2.3 3.4 2

( MDF 8 + 12MM) A 1 SPINDLE 1

P = 234 MM A 1 MEMBRAN SANDING 90 90 1 VM-839-H (RYGID VINYL) W/O UV (P/N: 444605-004)(KT)

L = 103.4 MM SPRAY LEM 2

MEMBRAN 40 100 2

CUTTING 60 60 1

A 1 CNC 12.4 15.3 1 1Kali CNC 13Mnt=63Pcs

A 1 COLORING 90 90 2

TOTAL(SEC) : 295 358.7

10 ORNAMENT PASSIVE P 1 RUNNING SAW 2.3 3.4 2

( MDF 8 + 12MM) P 1 SPINDLE 1

P = 234 MM P 1 MEMBRAN SANDING 90 90 1 VM-839-H (RYGID VINYL) W/O UV (P/N: 444605-004)(KT)

L = 103.4 MM SPRAY LEM 2

MEMBRAN 40 100 2

CUTTING 60 60 1

P 1 CNC 1

P 1 COLORING 180 180 2

TOTAL(SEC) : 372 433.4

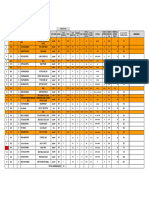

7 SUPPORT CHAMBER 2 RUNNING SAW 2

( MDF 8MM ) TABLE SAW 15 15 1

P = 240 MM MULTI BOR 1

L = 136.3 MM

TOTAL(SEC) : 15 15

8 BRACE BOARD PART 1, 2 & 3 8 TABLE SAW 24 24 1

P = 283MM, 280.4 & 233.5MM 8 CROSS CUT 40 40 1

L = 40, 40, 240MM

TOTAL(SEC) : 64 64

9 SQUARE BOARD TABLE SAW 120 120 1

CROSS CUT 160 160 1

TOTAL(SEC) : 280 120

NOTE OT (SEC) NET(SEC) MAN PWR REV NB.

MAN PWR = JUMLAH OPERATOR TOTAL : 3163.2 3372.8 124

QTY (PCS) = QUANTITY (PCS) MINIMUM : 2 3 1

ST (MNT) = STANDART TIME (MNT) MAXIMUM : 180 210 4

NET (SEC) = NET OPERATION RATE (ACTUAL PROSESSING TIME)

OT(SEC) = OPERATING TIME (WAKTU OPERASI MESIN) STANDARD TIME / SET = TOTAL + 15% TOLERANCE 60.6 64.6 MENIT

SET = (A = ACTIVE ; P = PASIVE)

PE - FM - 001, Rev : 00.29.03.07

You might also like

- Pe-Fp-Ww-Pnt-Roadmaster Bass Series 16Document1 pagePe-Fp-Ww-Pnt-Roadmaster Bass Series 16Maziya AnisahNo ratings yet

- Pe-Fp-Ww-Roadmaster Bass Series 12Document1 pagePe-Fp-Ww-Roadmaster Bass Series 12Maziya AnisahNo ratings yet

- Pe FPST WW (Hbpro 8) 02Document4 pagesPe FPST WW (Hbpro 8) 02Maziya AnisahNo ratings yet

- Start Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingDocument1 pageStart Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingMaziya AnisahNo ratings yet

- Divisi Wood Working: Running Saw Moulder V-CutDocument1 pageDivisi Wood Working: Running Saw Moulder V-CutMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- 6-General Miling InfoDocument5 pages6-General Miling InfoSakthi VelNo ratings yet

- Time Study of Gate Valve Body 24X150 1setupDocument4 pagesTime Study of Gate Valve Body 24X150 1setupdada kolekarNo ratings yet

- Frame Process PlannerDocument5 pagesFrame Process Plannerapi-538048965No ratings yet

- NEPTUNE 2&2S English User Guide 20211203Document28 pagesNEPTUNE 2&2S English User Guide 20211203marknerocavalloNo ratings yet

- Process DetailDocument3 pagesProcess DetailvenkatNo ratings yet

- Manufacturing of High-Precision Bevel Gears With Five-AxisDocument6 pagesManufacturing of High-Precision Bevel Gears With Five-AxisArtem PolozhiyNo ratings yet

- RMPU Stages FDocument5 pagesRMPU Stages FSachinNo ratings yet

- Peter Küssel - SES - 2014Document13 pagesPeter Küssel - SES - 2014Jorge Gamarra TolentinoNo ratings yet

- CNC Bits Buying Guide: CNC Milling Bit Storage TrayDocument22 pagesCNC Bits Buying Guide: CNC Milling Bit Storage TrayDiego Bustos CervantesNo ratings yet

- Report Generation: Gajendhiran.V M.E-Cad/CamDocument6 pagesReport Generation: Gajendhiran.V M.E-Cad/CamGajendhar KVK100% (1)

- Ikegai Machine Tools For Customized UseDocument34 pagesIkegai Machine Tools For Customized UseJi-Wei HoNo ratings yet

- Sinumerik 840dDocument713 pagesSinumerik 840dmiguel de carvalhoNo ratings yet

- Plant Layout: AssignementDocument25 pagesPlant Layout: AssignementAYSHU HUSSAINNo ratings yet

- General Metal Fabrication and AssemblyDocument9 pagesGeneral Metal Fabrication and Assemblysola sidoNo ratings yet

- General Metal Fabrication and AssemblyDocument9 pagesGeneral Metal Fabrication and Assemblysola sido100% (1)

- Slimline Web 0 PDFDocument84 pagesSlimline Web 0 PDFjas jaserNo ratings yet

- Production Report of 25-10-2020Document32 pagesProduction Report of 25-10-2020Sk DipuNo ratings yet

- Machine ToolDocument2 pagesMachine ToolMARIA JULIANA PENA MENDEZNo ratings yet

- Mabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004Document2 pagesMabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004dayalram100% (1)

- Daily Monitoring BD 30 November 2021 - WS Musi 2Document2 pagesDaily Monitoring BD 30 November 2021 - WS Musi 2Theo AnggaraNo ratings yet

- Shortage List Update 21 DesDocument1 pageShortage List Update 21 Desmr5148447No ratings yet

- Magnetic Abrasive Finishing (MAF) : Dr. Manas Das Assistant ProfessorDocument41 pagesMagnetic Abrasive Finishing (MAF) : Dr. Manas Das Assistant ProfessorAshok PushparajNo ratings yet

- Milling Machine DMDocument6 pagesMilling Machine DMShreya SNo ratings yet

- Neptune 2 User GuideDocument28 pagesNeptune 2 User GuideJeremy BloodNo ratings yet

- 13 Milling InsertsDocument35 pages13 Milling InsertsMehdy HosseiniNo ratings yet

- WT Tooling SystemDocument73 pagesWT Tooling SystemSiddharth PatelNo ratings yet

- Z-Carb JetStream SpeedFeedDocument2 pagesZ-Carb JetStream SpeedFeedalphatoolsNo ratings yet

- CJ21013 L05 LT AHU Indoor (With Breakin) 20231031 R1Document9 pagesCJ21013 L05 LT AHU Indoor (With Breakin) 20231031 R1Eddy NgNo ratings yet

- Cover Assy. SAI Valve-N7040290Document22 pagesCover Assy. SAI Valve-N7040290M Senthil SenthilNo ratings yet

- Visit SMIDocument2 pagesVisit SMINoval WibowoNo ratings yet

- 7 QC Tools Live ExampleDocument12 pages7 QC Tools Live ExampleKamlesh RanaNo ratings yet

- Production Flow ChartDocument1 pageProduction Flow ChartAnthony0% (1)

- Marking Pdf. Files in ACZ: 1. Category 3. Product / TypeDocument4 pagesMarking Pdf. Files in ACZ: 1. Category 3. Product / TypeRaja RoaNo ratings yet

- Marking Pdf. Files in ACZ: 1. Category 3. Product / TypeDocument2 pagesMarking Pdf. Files in ACZ: 1. Category 3. Product / TypeatakanNo ratings yet

- PT Indah Kiat Pulp & Paper TBK Summary Abnormality QC Finish Product Cs6/Fs6 Nov-19Document2 pagesPT Indah Kiat Pulp & Paper TBK Summary Abnormality QC Finish Product Cs6/Fs6 Nov-19Bujang RantauNo ratings yet

- SRF SufDocument12 pagesSRF SufarvinupNo ratings yet

- Operation Sheet (2) - UprightDocument1 pageOperation Sheet (2) - Uprightalinader20022No ratings yet

- Process Design Sheet (Flow Chart of Fabricating Welded Part) Prepared Checked ApprovedDocument1 pageProcess Design Sheet (Flow Chart of Fabricating Welded Part) Prepared Checked ApprovedHeny YuslizarNo ratings yet

- 16,17 - CJ21013 L05 LT AHU Indoor 20230608Document5 pages16,17 - CJ21013 L05 LT AHU Indoor 20230608Eddy NgNo ratings yet

- Automotive Mitsubishi Tooling PDFDocument24 pagesAutomotive Mitsubishi Tooling PDFAlex GăuruşNo ratings yet

- 4MARET2022REV1Document1 page4MARET2022REV1mr5148447No ratings yet

- C-1/2Mo 1/2Cr-1/2Mo 1Cr-1/2Mo 1 1/4Cr-1/2Mo 2 1/4Cr-1Mo 5Cr-1/2Mo 7Cr-1/2Mo 9Cr-1Mo 9Cr-1Mo-1/4V-0.4Ni 11Cr 12Cr 13Cr 17CrDocument1 pageC-1/2Mo 1/2Cr-1/2Mo 1Cr-1/2Mo 1 1/4Cr-1/2Mo 2 1/4Cr-1Mo 5Cr-1/2Mo 7Cr-1/2Mo 9Cr-1Mo 9Cr-1Mo-1/4V-0.4Ni 11Cr 12Cr 13Cr 17CrmohamedNo ratings yet

- RHINO Insert PDFDocument168 pagesRHINO Insert PDFtran namNo ratings yet

- Lathe RoiDocument1 pageLathe RoiPaul Saimond TobiasNo ratings yet

- Stationary Gantry: Lcgoc ConsoleDocument1 pageStationary Gantry: Lcgoc ConsoleCharbel TadrosNo ratings yet

- MP B158aDocument6 pagesMP B158aSurhidayat Ibn MusthafaNo ratings yet

- Djei Opi Kahru Ioeg4Document1 pageDjei Opi Kahru Ioeg4P DNo ratings yet

- Transformer Manufactuing Process Flow-ChartDocument1 pageTransformer Manufactuing Process Flow-ChartMohammed ShoaibNo ratings yet

- Drill: Mitsubishi CarbideDocument8 pagesDrill: Mitsubishi CarbideĐồng Đăng HảiNo ratings yet

- Rotor Process PlannerDocument2 pagesRotor Process Plannerapi-538048965No ratings yet

- 15JAN2022Document1 page15JAN2022mr5148447No ratings yet

- Plant and MachineryDocument3 pagesPlant and MachinerySM AreaNo ratings yet

- TapScanner 14-10-2021-20.42Document1 pageTapScanner 14-10-2021-20.42Maziya AnisahNo ratings yet

- Fp-Ww-Cbox D808XWBDocument1 pageFp-Ww-Cbox D808XWBMaziya AnisahNo ratings yet

- Fp-Ww-Cbox Max 09 PaDocument1 pageFp-Ww-Cbox Max 09 PaMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- Standard Time Final Assy: No. Model FA Grille Satuan TotalDocument20 pagesStandard Time Final Assy: No. Model FA Grille Satuan TotalMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- Academic Posters Update 051112Document2 pagesAcademic Posters Update 051112amirahNo ratings yet

- Academic & Scientific Poster Presentation Visualising Knowledge As A Means To Facilitate Knowledge TransferDocument19 pagesAcademic & Scientific Poster Presentation Visualising Knowledge As A Means To Facilitate Knowledge TransferMaziya AnisahNo ratings yet

- Company Profile MCMODocument8 pagesCompany Profile MCMOMaziya AnisahNo ratings yet

- Standard Time Final Assy: No. Model FA Grille Satuan TotalDocument20 pagesStandard Time Final Assy: No. Model FA Grille Satuan TotalMaziya AnisahNo ratings yet

- Panera Bread Case StudyDocument28 pagesPanera Bread Case Studyapi-459978037No ratings yet

- Task of ProjectDocument14 pagesTask of ProjectAbdul Wafiy NaqiuddinNo ratings yet

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet

- Lesson Plan 1Document3 pagesLesson Plan 1api-311983208No ratings yet

- Present Perfect Simp ContDocument14 pagesPresent Perfect Simp ContLauGalindo100% (1)

- Do Now:: What Is Motion? Describe The Motion of An ObjectDocument18 pagesDo Now:: What Is Motion? Describe The Motion of An ObjectJO ANTHONY ALIGORANo ratings yet

- Pre-Paid Customer Churn Prediction Using SPSSDocument18 pagesPre-Paid Customer Churn Prediction Using SPSSabhi1098No ratings yet

- Very Hungry Caterpillar Clip CardsDocument5 pagesVery Hungry Caterpillar Clip CardsARTGRAVETO ARTNo ratings yet

- Student Research Project Science ReportDocument8 pagesStudent Research Project Science Reportapi-617553177No ratings yet

- HAF350A User ManualDocument14 pagesHAF350A User ManualUEENo ratings yet

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- MC4 CoCU 6 - Welding Records and Report DocumentationDocument8 pagesMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFDocument10 pagesFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaNo ratings yet

- Ec 0301Document25 pagesEc 0301Silvio RomanNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentAditya ShanbhagNo ratings yet

- Passage Planning: Dr. Arwa HusseinDocument15 pagesPassage Planning: Dr. Arwa HusseinArwa Hussein100% (3)

- Penelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Document25 pagesPenelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Asti SherlyanaNo ratings yet

- Eng03 Module Co4Document14 pagesEng03 Module Co4Karl Gabriel ValdezNo ratings yet

- 1 AlarmvalveDocument9 pages1 AlarmvalveAnandNo ratings yet

- Coal Mining Technology and SafetyDocument313 pagesCoal Mining Technology and Safetymuratandac3357No ratings yet

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument39 pagesCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresIshor ThapaNo ratings yet

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDocument3 pagesWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comNo ratings yet

- 3-A Y 3-B Brenda Franco DíazDocument4 pages3-A Y 3-B Brenda Franco DíazBRENDA FRANCO DIAZNo ratings yet

- Aircraft Flight Control SystemDocument25 pagesAircraft Flight Control Systemthilina jayasooriyaNo ratings yet

- Ferroelectric RamDocument20 pagesFerroelectric RamRijy LoranceNo ratings yet

- NauseaDocument12 pagesNauseakazakom100% (2)

- Gandhi and The Non-Cooperation MovementDocument6 pagesGandhi and The Non-Cooperation MovementAliya KhanNo ratings yet

- S4 Computer Sciences Exercises PDFDocument2 pagesS4 Computer Sciences Exercises PDFHenriette Desanges UwayoNo ratings yet

- NCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Document8 pagesNCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Akash DasNo ratings yet

- Class 1 KeyDocument3 pagesClass 1 Keyshivamsingh.fscNo ratings yet