Professional Documents

Culture Documents

Polysurlyn Vapour Moisture Barrier

Uploaded by

ameya natuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polysurlyn Vapour Moisture Barrier

Uploaded by

ameya natuCopyright:

Available Formats

Polysurlyn

Polysurlyn Moisture Barrier (PSMB) is an The preferred method for specifying metal jacketing

engineered three layer coextruded film of is to require the use of PSMB to help prevent

polyethylene and Surlyn* polymers with a total corrosion of the interior surface of the metal

film thickness of 3 mils (76 µm). jacketing and the underlying insulated pipe, tank, or

equipment. PSMB is preferred on all types of metal

PSMB is heat laminated in the factory to the jacketing including aluminum, stainless steel,

interior surface of all types of metal jacketing for galvanized steel, aluzinc, and aluminized steel types

mechanical insulation to help prevent pitting, I and II to help prevent this corrosion.

crevice, and galvanic corrosion of the interior

surface of the metal jacketing and the underlying PSMB is preferred on the metal jacketing for all

insulated pipe, tank, or equipment. applications of mechanical insulation including that

used in hot, cold, pipe, tanks, equipment, industrial,

This corrosion can occur when water enters the commercial, petrochem, and oil/gas applications.

installed insulation system through joints or

damage in the metal jacketing.

PSMB Film is colored a light blue to distinguish it

from other film types and to allow visual

PSMB consists of three film layers each carefully confirmation of its presence on the metal jacketing.

selected to yield optimum performance. Each of

the three layers is about 1 mil (25 µm) thick. The

inner layer is predominantly low-density LDPE HDPE

Metal Surlyn®

polyethylene (LDPE) for excellent adhesion after

heat lamination. The middle layer is Surlyn* for

strength. The top layer is predominantly high-

density polyethylene (HDPE) for superior

toughness and abrasion resistance.

The use of three separate film layers virtually

guarantees that there are no pinholes through the

entire film because any holes in a single layer will

not align with holes in the other layers.

Polysurlyn

You might also like

- Coating Guide: Standards Contact UsDocument26 pagesCoating Guide: Standards Contact UsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Metal Roofing Design GuideDocument32 pagesMetal Roofing Design GuideMelinda Gordon100% (4)

- Vacuum Metallizing Plastic Parts - 2Document7 pagesVacuum Metallizing Plastic Parts - 2Dede SyaechudinNo ratings yet

- Fired HeatersDocument24 pagesFired HeatersArief RachmanNo ratings yet

- Boiler Data SheetDocument10 pagesBoiler Data Sheetameya natu100% (2)

- Factories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations, 1970 Ve - Pua5 - 1970Document46 pagesFactories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations, 1970 Ve - Pua5 - 1970Exsan OthmanNo ratings yet

- TDSAlumRoll11 PDFDocument2 pagesTDSAlumRoll11 PDFAnwar SyedNo ratings yet

- Jacketing With Tedlar - PVF Both Al and SS AlloyDocument1 pageJacketing With Tedlar - PVF Both Al and SS AlloyVishnu DuttaNo ratings yet

- Aluminum Roll Jacket IngDocument1 pageAluminum Roll Jacket IngJose Angel Reza GarcesNo ratings yet

- Bitustick ALDocument45 pagesBitustick ALBavishNo ratings yet

- Bitustick P: Polyester Reinforced Waterproofing MembraneDocument2 pagesBitustick P: Polyester Reinforced Waterproofing MembraneHafnazSabeerNo ratings yet

- ENGEL Plastifizieren en PDFDocument15 pagesENGEL Plastifizieren en PDFDídia RamosNo ratings yet

- Moisture Barrier On Metal Jacketing & Kraft PaperDocument2 pagesMoisture Barrier On Metal Jacketing & Kraft Paperabidch143No ratings yet

- GTT Mark III PlaquetteDocument4 pagesGTT Mark III PlaquetteAlexandros HatzisNo ratings yet

- 6 2 1 2 7 Bitustick PDocument2 pages6 2 1 2 7 Bitustick PRobin Denkins PaulNo ratings yet

- 3LPE Coating SpecificationDocument20 pages3LPE Coating SpecificationadammzjinNo ratings yet

- 020-130 - TB - CHEMOLINE 10 M - Revision - 1.00 - 13.03.2015Document2 pages020-130 - TB - CHEMOLINE 10 M - Revision - 1.00 - 13.03.2015Alejandra ZumaranNo ratings yet

- What Is Alumina SubstrateDocument13 pagesWhat Is Alumina SubstratejackNo ratings yet

- TECH SPECS For Cabin For Jail - FINALDocument8 pagesTECH SPECS For Cabin For Jail - FINALmanzarsamanposNo ratings yet

- Bitum 3 PDFDocument2 pagesBitum 3 PDFvranceanu.ovidiu-1No ratings yet

- Emmedue M2 Panel - SpecificationsDocument14 pagesEmmedue M2 Panel - SpecificationsgreglacleNo ratings yet

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbNo ratings yet

- RAI Aluminium JacketingDocument3 pagesRAI Aluminium JacketingFaiyaz Bin Mazid AhmedNo ratings yet

- CHEMOLINE-3-CN (Pressure Part)Document2 pagesCHEMOLINE-3-CN (Pressure Part)Naveed KhalidNo ratings yet

- Profiled Metal Roofing DesignDocument32 pagesProfiled Metal Roofing DesignEJourDNo ratings yet

- Thermal Insulation Products - Jacketing & CladdingDocument15 pagesThermal Insulation Products - Jacketing & CladdingSreekumar K SNo ratings yet

- Adhesion Promoter Makes Hybrid Components Even Lighter and More RigidDocument6 pagesAdhesion Promoter Makes Hybrid Components Even Lighter and More RigidSebastian AndreoliNo ratings yet

- Plaster Profiles and Other Accessories - ENDocument9 pagesPlaster Profiles and Other Accessories - ENaayasirNo ratings yet

- Technical Specification - Klippon Roofing System V2-FinalDocument1 pageTechnical Specification - Klippon Roofing System V2-FinalRAMANNo ratings yet

- Glass Fibre Reinforced Plastic and Its Architectural ApplicationsDocument27 pagesGlass Fibre Reinforced Plastic and Its Architectural ApplicationsVipul UttamchandaniNo ratings yet

- Mark III LNG TanksDocument3 pagesMark III LNG TanksEdutamNo ratings yet

- KlimallcoDocument8 pagesKlimallcoshahzad32552372No ratings yet

- Perić Nikola PM 8-2021Document3 pagesPerić Nikola PM 8-2021Nikola PericNo ratings yet

- GFRP Roofing - CADocument16 pagesGFRP Roofing - CAEngineering ACPNo ratings yet

- ITW PSMB Vs Polykraft or PaintDocument2 pagesITW PSMB Vs Polykraft or PaintVishnu DuttaNo ratings yet

- Vacuum Metallizing Plastic PartsDocument7 pagesVacuum Metallizing Plastic PartsLuận NgôNo ratings yet

- Technical Bulletin TB-34: Steel House FramesDocument4 pagesTechnical Bulletin TB-34: Steel House FramesRaymond WongNo ratings yet

- Building Construction-V: Types of Metal CladdingDocument6 pagesBuilding Construction-V: Types of Metal CladdingShrish BaglaNo ratings yet

- Foam Fillers Tapes Sealants BrochureDocument8 pagesFoam Fillers Tapes Sealants BrochureAppavoo DeelenNo ratings yet

- M2 - Manual PDFDocument0 pagesM2 - Manual PDFFlorinHanu100% (1)

- Fradiflex Metal Waterstop Jgs TDB INTGBDocument2 pagesFradiflex Metal Waterstop Jgs TDB INTGBmulti5torpeNo ratings yet

- Ancon Thermal Break BK03Document2 pagesAncon Thermal Break BK03NguyễnTúSơnNo ratings yet

- Term Paper Presentation RPDTDocument28 pagesTerm Paper Presentation RPDTdeepeshpanjwaniNo ratings yet

- Glass Flake Coatings PDFDocument4 pagesGlass Flake Coatings PDFDinesh ChouguleNo ratings yet

- Atcoatr 111Document3 pagesAtcoatr 111farid bashaNo ratings yet

- Mea Polybit Tds Polybit Bitustick R 3000 en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick R 3000 en MeaMuhamed RiskhanNo ratings yet

- High Metal AdhesionDocument9 pagesHigh Metal AdhesionSachin KothariNo ratings yet

- Corrosion Protection of Offshore StructuresDocument10 pagesCorrosion Protection of Offshore StructuresHo Minh Viet100% (1)

- Surface Tissue: Product Information P350 SaDocument1 pageSurface Tissue: Product Information P350 SaSofya AndarinaNo ratings yet

- Foamglas Insulation SpecificationsDocument7 pagesFoamglas Insulation Specificationsjohn_p47No ratings yet

- Agri SteelDocument4 pagesAgri SteelMin KhantNo ratings yet

- DF EspumaDocument1 pageDF EspumaAndre MoutelaNo ratings yet

- GTT Mark IIIDocument4 pagesGTT Mark IIIiuliiulianNo ratings yet

- RioPipeline2017 2543 Rosenrevisedpaperibp2543 17Document9 pagesRioPipeline2017 2543 Rosenrevisedpaperibp2543 17Jose Anisio SilvaNo ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- Mea Polybit Tds Polybit Bitustick en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick en MeaVengatesh HariNo ratings yet

- Tufchem R II MembraneDocument2 pagesTufchem R II MembranehungdevelingNo ratings yet

- Catalogue of Roof SheetDocument8 pagesCatalogue of Roof Sheetcvsatheeh1No ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Ceramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsFrom EverandCeramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsWalter KrenkelNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Tme 0 A09 Tgy LST 0001 R00 EngDocument2 pagesTme 0 A09 Tgy LST 0001 R00 Engameya natuNo ratings yet

- Dynavane BulletinDocument8 pagesDynavane Bulletinhardik033No ratings yet

- Service Manual For Heavy Duty Fans: Safety Installation Operation MaintenanceDocument28 pagesService Manual For Heavy Duty Fans: Safety Installation Operation Maintenanceameya natuNo ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Tme e A01 Tgy Cal 0001 R03 EngDocument14 pagesTme e A01 Tgy Cal 0001 R03 Engameya natuNo ratings yet

- Dynavane BulletinDocument8 pagesDynavane Bulletinhardik033No ratings yet

- Bulletin ID-100Document4 pagesBulletin ID-100ameya natuNo ratings yet

- General Properties: High Purity Dense CastablesDocument1 pageGeneral Properties: High Purity Dense Castablesameya natuNo ratings yet

- Single-Stage Steam TurbinesDocument8 pagesSingle-Stage Steam Turbinesfouzi gherNo ratings yet

- Magnetic Level Gauge MagnetrolDocument9 pagesMagnetic Level Gauge Magnetrolameya natuNo ratings yet

- Boiler Efficiency Guide PDFDocument24 pagesBoiler Efficiency Guide PDFAsnfiasnfd FenfeNo ratings yet

- Steam TracingDocument18 pagesSteam TracingSyed Mujtaba Ali Bukhari100% (2)

- Steam TurbinesDocument8 pagesSteam TurbinesFachri Ramadhan100% (1)

- Polysurlyn Vapour Moisture BarrierDocument2 pagesPolysurlyn Vapour Moisture Barrierameya natuNo ratings yet

- Elliott in Refining: Plant PowerDocument1 pageElliott in Refining: Plant Powerameya natuNo ratings yet

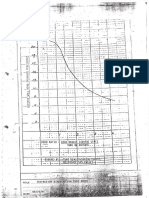

- Thinning CurveDocument1 pageThinning Curveameya natuNo ratings yet

- Department of Registration and StampsDocument1 pageDepartment of Registration and Stampsameya natuNo ratings yet

- Weight Gate ValvesDocument1 pageWeight Gate ValvesRahulTewariNo ratings yet

- Dyrhh Steam Turbine: High Back-Pressure, Large Frame Single-Stage Steam TurbineDocument2 pagesDyrhh Steam Turbine: High Back-Pressure, Large Frame Single-Stage Steam Turbineameya natuNo ratings yet

- Drill SizesDocument1 pageDrill Sizesameya natuNo ratings yet

- Brackets For Circular Platforms at Vertical VesselsDocument4 pagesBrackets For Circular Platforms at Vertical Vesselsameya natuNo ratings yet

- Outokumpu Steel Grades Properties Global StandardsDocument20 pagesOutokumpu Steel Grades Properties Global StandardsLance BlackstarNo ratings yet

- Shaft Power Calculation:: Obra "C" (2X660 MW) Thermal Power Extension ProjectDocument1 pageShaft Power Calculation:: Obra "C" (2X660 MW) Thermal Power Extension Projectameya natuNo ratings yet

- Ba-Tdl 01-En 05.2017Document33 pagesBa-Tdl 01-En 05.2017ameya natuNo ratings yet

- Weight Gate ValvesDocument1 pageWeight Gate ValvesRahulTewariNo ratings yet

- Letter - Operating Gap RecommendationDocument1 pageLetter - Operating Gap Recommendationameya natuNo ratings yet