Professional Documents

Culture Documents

Water Proofer: Application Method

Water Proofer: Application Method

Uploaded by

Isuru LakshanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Proofer: Application Method

Water Proofer: Application Method

Uploaded by

Isuru LakshanCopyright:

Available Formats

PRODUCTS & SOLUTIONS SERVICE OFFERING SUSTAINABILITY COMPANY INVESTOR RELATIONS

WATER PROOFER

Damp walls and ceilings are not only an ugly embarrassment, they are also a health and safety hazard. What starts off as ‘a little dampness’ during rainy season or on

wet surfaces, will then start peeling off the plaster coating, allowing for more water to seep in. Over a period of time water and other chemicals penetrate the walls or

slabs leading to complete deterioration of the structure. It can become a persistent headache if you don’t use the right kind of sealer, and drain your time and money

each time you have to redo the plastering.

It is more pertinent for walls and slabs that constantly get exposed to water and dampness, like your outer walls, basement, open slabs, bathrooms and pool?

TOKYO SUPERSEAL WATER PROOFER is the simplest and smartest water proofing solution, to stop the reek of dampness and ruined walls, slabs and flooring. It is

highly resistant to standing water or wind driven rain water, making it ideal for sealing your bathrooms, basement, roof slabs as well as poolside structures.

TOKYO SUPERSEAL can be applied on vertical, horizontal and overhead surfaces, be it an interior or exterior surface that requires water proofing.

TOKYO SUPERSEAL WATER PROOFER is a cement based material suitable for interior or exterior surfaces where water proofing is required.

TOKYO SUPERSEAL WATER PROOFER is highly resistant to standing water or wind driven rain water and intended for use in vertical, horizontal, and overhead

surfaces, Typical uses are in water sealing bathrooms, overhead slabs, walls, joints etc.

RECOMMENDED USAGE

CONCRETE SLABS INDOOR

BATHROOMS KITCHENS

COLUMN & OUTDOOR

SUITABLE FOR ALL MASONRY

TILING STRUCTURES

APPLICATION METHOD

MIXING

01 02 03

Empty the entire 25kg bag Mix continuously for

of TOKYO SUPERSEAL 1K 5 5 minutes (500 rpm)

Pour 6.5-7 liters of clean

Waterproofer gradually to achieve a smooth

water (room temperature)

into the same bucket paint like mixture. Mix for

into bucket.

while mixing using a stirrer 2 more minutes if required.

(rpm <500).

05

Only prepare a volume

1 which can be applied

hr

within 1 hour.

APPLICATION

01 02 03

Clean and remove all loose You may clean the surface

materials, oil, grease and with water but ensure it is

Use a brush to apply

other impurities on the completely dry before

the mix.

surface. applying the waterproofer.

04 05 06

1st 3mm

2 Apply the 1st coat with a Once the 1st coat is

hr brush horizontally, to cover completely dry, apply the

Maintain a minimum

of 3mm of total

the entire area and let it dry 2nd coat in vertical

thickness.

for 2 hours. direction.

07

Air curing is sufficient. Do

not cure the surface using

water until the 2nd coat is

completely dry.

OTHER NOTES

01 02 03

If the temperature is over Protect the applied area

Recently laid concrete or 28°C, spray water on the from rain, direct sunlight

screed surfaces should be surface to bring down the and wind during the

left to set for a minimum of temperature and wait for application time and

3 weeks before applying the surface to completely after the application is

Tokyo Superseal dry. completed (for one day).

1K Waterproofer.

04 05 06

For lasting results, apply a For edges use a Fibre Glass

For water tanks / swimming

protective layer to prevent (Alkaline resistant) or

pools maintain a 5 mm

damage to the waterproofing Polypropylene Net

thickness of Tokyo

layer. i.e. screed, plaster, (maintain width: 200mm)

Superseal 1K

paint or tiles. as a reinforcement.

Waterproofer.

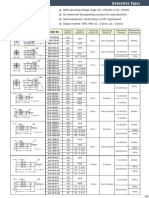

TECHNICAL DATASHEET

Characteristics Test Method Tokyo Superseal Specifications

Setting Time (h:min) TCCL INN - 01 2.45 < 6:00

Flow (Initial) TCCL INN - 05 240 -

Flow (Pot life) TCCL INN - 05 220 > 150

Flexural Strength - 1 day ( N/mm2) 3.8 -

Flexural Strength - 28 days ( N/mm2) TCCL INN - 03 13.8 >8

Compresive Strength - 1 day ( N/mm2) 8.7 -

Compresive Strength - 28 days ( N/mm2) TCCL INN - 04 24.2 > 15

Water Penetration (mm) DIN 1048 (Part 5) 0 5

INSTRUCTIONAL VIDEO

FLOORING &

TILE ADHESIVES LEVELLING WALL PLASTERS

COMPOUNDS

LIGHTWEIGHT

PREMIX CONCRETE

SOLUTIONS

PRODUCTS & SOLUTIONS SERVICE OFFERING SUSTAINABILITY COMPANY INVESTOR RELATIONS CONTACT US

Cement Laboratory Services Our Philosophy Intro Stock Info Tokyo Cement Company (Lanka) PLC

Concrete Training Academy Our Planet Timeline Financial Reports # 469 1/1, Galle Road, Colombo 3, Sri Lanka.

Cement Based Solutions Our Network Our People Facilities Board of Directors 0112 558 100 / 0112 500 466 / 0112 592 308

Aggregate Experience Center Photo Gallery Media sales@tokyocement.lk

Power Careers

You might also like

- BOYSEN® Elasti-Kote™: Description Technical DataDocument2 pagesBOYSEN® Elasti-Kote™: Description Technical DataRam Marc OnaNo ratings yet

- STP Biti'sDocument5 pagesSTP Biti'sVo Ho Uyen NhiNo ratings yet

- Boysen Paints PDFDocument15 pagesBoysen Paints PDFHale100% (2)

- AquaflexDocument3 pagesAquaflexsmart construction solution solutionNo ratings yet

- Spray C 496 2K Hs Clear: Technical Data Sheet No 802Document1 pageSpray C 496 2K Hs Clear: Technical Data Sheet No 802MarcelNo ratings yet

- Mastertop 564Document2 pagesMastertop 564Doby YuniardiNo ratings yet

- Wallscape Classic - TDSDocument3 pagesWallscape Classic - TDSaboali8686No ratings yet

- Aquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteDocument2 pagesAquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteShabbir LokhandwalaNo ratings yet

- DIVERSEY NAME Chemical Usgae ManualDocument5 pagesDIVERSEY NAME Chemical Usgae ManualArokiaraj AmalrajNo ratings yet

- Nerolac Beauty Acrylic DistemperDocument2 pagesNerolac Beauty Acrylic DistemperNavrang TyagiNo ratings yet

- Krystol T1 12 19Document3 pagesKrystol T1 12 19Jose Angel Escatel AvalosNo ratings yet

- MasterSeal - 551 v4Document2 pagesMasterSeal - 551 v4piyu114No ratings yet

- MasterSeal 555Document2 pagesMasterSeal 555dewipuspa0503No ratings yet

- CON-KORITE XTRA GDE Pork 5-07Document6 pagesCON-KORITE XTRA GDE Pork 5-07Ovidiu RaicovNo ratings yet

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Nerolac Excel PDS Rainguard Primer Project J2985 03 PDFDocument2 pagesNerolac Excel PDS Rainguard Primer Project J2985 03 PDFtusharthakreNo ratings yet

- Nerolac Exterior PrimerDocument2 pagesNerolac Exterior PrimerMahend RanNo ratings yet

- Trucare Interior Wall Primer AdvancedDocument2 pagesTrucare Interior Wall Primer AdvancedhartimakhopraNo ratings yet

- ENECRETE DuraQuartzDocument2 pagesENECRETE DuraQuartzAlfred GomoeliaNo ratings yet

- Masterseal 540 TdsDocument2 pagesMasterseal 540 TdsRhinzy CajuraoNo ratings yet

- Product Code: Datasheet No: Issue Date: A-300: Kansai Wallscape Pure Matt WithDocument2 pagesProduct Code: Datasheet No: Issue Date: A-300: Kansai Wallscape Pure Matt Withaboali8686No ratings yet

- V2100 System Leak Seal - Technical Data SheetDocument2 pagesV2100 System Leak Seal - Technical Data SheetSameer HyderNo ratings yet

- Fosroc Chemical Breaker PDFDocument2 pagesFosroc Chemical Breaker PDFKishore Kumar RajaNo ratings yet

- Decoprime Primer WTDocument2 pagesDecoprime Primer WTMonal ShindeNo ratings yet

- Dulux Ambiance Special Effect - MarbleDocument3 pagesDulux Ambiance Special Effect - MarbleAliciaNo ratings yet

- Sealbond 385 UE Epoxy UnderwaterDocument2 pagesSealbond 385 UE Epoxy UnderwaterRonalyn Lago R.C.ENo ratings yet

- Chemo Bauxite RemoverDocument1 pageChemo Bauxite Removeryaozhihua85No ratings yet

- Dura. Grout: Non-Shrink Cementitious GroutDocument2 pagesDura. Grout: Non-Shrink Cementitious GroutANILNo ratings yet

- Screedmaster: Rapid Repair MortarDocument2 pagesScreedmaster: Rapid Repair MortarAlex BocicaNo ratings yet

- Cap Dryshake HardenerDocument2 pagesCap Dryshake HardenerMedrar TareqNo ratings yet

- Premix Skim Coat: High Quality Cementitious RenderingDocument2 pagesPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyNo ratings yet

- Masterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutDocument3 pagesMasterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutGavriel NgNo ratings yet

- Tikidan Tds - Revestidan IndoorDocument2 pagesTikidan Tds - Revestidan IndoorsandeepNo ratings yet

- Duragrout: Non-Shrink Cementitious GroutDocument3 pagesDuragrout: Non-Shrink Cementitious GroutJohan ConradieNo ratings yet

- Smartcare Ultra Block 2K: HoursDocument2 pagesSmartcare Ultra Block 2K: HoursSameehu TV100% (1)

- Ceralastic: Elastomeric Waterproof CoatingDocument2 pagesCeralastic: Elastomeric Waterproof Coatingharish GiriNo ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- Ig Na PRPDocument2 pagesIg Na PRPFR LegacyNo ratings yet

- Adhere LBDocument1 pageAdhere LBadherebondNo ratings yet

- (IS 101/1987, Part 1, Sec 6) : Exterior - Aesthetics Issued - 01 2017Document2 pages(IS 101/1987, Part 1, Sec 6) : Exterior - Aesthetics Issued - 01 2017Amit DhangarNo ratings yet

- Technical Data Sheet Chryso Armourcote 560 - 6049 - 1336 PDFDocument2 pagesTechnical Data Sheet Chryso Armourcote 560 - 6049 - 1336 PDFAarish KhanNo ratings yet

- Alba DatasheetDocument1 pageAlba DatasheetAcro PaintsNo ratings yet

- Chemicals - Product InstructionsDocument6 pagesChemicals - Product InstructionsdanilminaNo ratings yet

- Probleme: Solution Champs D'ApplicationDocument2 pagesProbleme: Solution Champs D'ApplicationMOZARDNo ratings yet

- Smartcare Damp ProofDocument2 pagesSmartcare Damp ProofSazidul Islam PrantikNo ratings yet

- DIY Hydroproof DSDocument2 pagesDIY Hydroproof DSJohn MasangoNo ratings yet

- White : Exterior Wall PrimerDocument2 pagesWhite : Exterior Wall PrimerGibbs PerNo ratings yet

- Chryso ElastothaneDocument2 pagesChryso ElastothaneAbhisheK MishrANo ratings yet

- QMC® EPO-MASTER 50 - English - v1.0.0Document4 pagesQMC® EPO-MASTER 50 - English - v1.0.0Ahmed TahaNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- PDS - Moisture SealDocument2 pagesPDS - Moisture Sealjasondouglas1810workNo ratings yet

- SPC-15 Specialty Tub Tile Refinishing Kit TDS 1Document2 pagesSPC-15 Specialty Tub Tile Refinishing Kit TDS 1Tom CatNo ratings yet

- MasterSeal 530Document2 pagesMasterSeal 530dewipuspa0503No ratings yet

- HINCOL Bitumen Primer-2 (Web)Document2 pagesHINCOL Bitumen Primer-2 (Web)Tk SubhashNo ratings yet

- Grandflor Leveller UL - TDSDocument2 pagesGrandflor Leveller UL - TDSron iluminNo ratings yet

- Black and White Modern Marketing Agency Trifold BrochureDocument2 pagesBlack and White Modern Marketing Agency Trifold BrochureNemo SecretNo ratings yet

- Sika Top SealDocument2 pagesSika Top SealBilly Joe BreakfastNo ratings yet

- Asian Paints Professional Economy Texture DesignsDocument2 pagesAsian Paints Professional Economy Texture DesignsBestin JoseNo ratings yet

- Masterkure 100WBDocument2 pagesMasterkure 100WBDoby YuniardiNo ratings yet

- Table Alarm For iPASOLINK ALM Conf 1+0Document1 pageTable Alarm For iPASOLINK ALM Conf 1+0dedeputra01100% (5)

- V-2154-101-A-111 - 0A Method Statement Stairway Tank InstallationDocument24 pagesV-2154-101-A-111 - 0A Method Statement Stairway Tank InstallationWidya PrasetyaNo ratings yet

- BSBLDR401 Task2Document13 pagesBSBLDR401 Task2Winnie PPnapatNo ratings yet

- 73 Disinfecting Acid BR Cleaner Sell Sheet PDFDocument2 pages73 Disinfecting Acid BR Cleaner Sell Sheet PDFMarie Kris NogaNo ratings yet

- (IBM) System Storage SAN Volume Controller Version 6.4.0Document350 pages(IBM) System Storage SAN Volume Controller Version 6.4.0hiehie272No ratings yet

- Outline Dimension Model No .: Output Status Output Method Sensing Distance Mounting MethodDocument2 pagesOutline Dimension Model No .: Output Status Output Method Sensing Distance Mounting MethodAgus YohanesNo ratings yet

- Impact of COVID-19 in Education SectorDocument9 pagesImpact of COVID-19 in Education SectorIJRASETPublicationsNo ratings yet

- Great Lakes Transport V KRADocument10 pagesGreat Lakes Transport V KRASAMSON OCHIENG ABUOGINo ratings yet

- The Design of Competition EnginesDocument546 pagesThe Design of Competition EnginesJoão Victor Paschoal PoletiNo ratings yet

- Kings XI PunjabDocument3 pagesKings XI PunjabRakkuyil SarathNo ratings yet

- Volume I - Final Report - Dry Port PPPDocument36 pagesVolume I - Final Report - Dry Port PPPSajjadul MawlaNo ratings yet

- HydraulicDocument10 pagesHydraulicDewan VidanageNo ratings yet

- Foxit PDF Editor ManualDocument204 pagesFoxit PDF Editor ManualRochmat Dwi Karwanto50% (2)

- ASU Dance Marathon: We Are FTK! What's That Mean?Document4 pagesASU Dance Marathon: We Are FTK! What's That Mean?api-393026573No ratings yet

- 20230922Document84 pages20230922ERIC HubbardNo ratings yet

- Africa Mining 2012 AgendaDocument8 pagesAfrica Mining 2012 AgendaJuan Luis BerrioNo ratings yet

- Data Structures (Queue) : Madhuri KalaniDocument45 pagesData Structures (Queue) : Madhuri KalaniMadhuri KalaniNo ratings yet

- User Manual Reports FINGate PortalDocument103 pagesUser Manual Reports FINGate PortalAbhinav BharadwajNo ratings yet

- Class 9 History CH 4Document6 pagesClass 9 History CH 4Yash PlayNo ratings yet

- 1762-IF4 Analog Input 1762IF4.: Data FormatDocument2 pages1762-IF4 Analog Input 1762IF4.: Data Formatguruh anindraNo ratings yet

- Asonic HQ 72-102 - EnglishDocument2 pagesAsonic HQ 72-102 - EnglishCleiton Luiz CordeiroNo ratings yet

- Characteristics of A Quality Asylum SystemDocument21 pagesCharacteristics of A Quality Asylum SystemAngel VermasNo ratings yet

- Building ManagmentDocument27 pagesBuilding ManagmentSharanabasappaDegoanNo ratings yet

- Recount Text Anggi 3Document3 pagesRecount Text Anggi 3Farrel AdhipramanaNo ratings yet

- Sample Notice of DishonorDocument4 pagesSample Notice of DishonorDon CorleoneNo ratings yet

- Report LR BYOD 1Document29 pagesReport LR BYOD 1Bukan PujanggaNo ratings yet

- Meidner (1992) - Rise and Fall of The Swedish ModelDocument13 pagesMeidner (1992) - Rise and Fall of The Swedish ModelmarceloscarvalhoNo ratings yet

- Svga DatabaseDocument220 pagesSvga DatabaseJigs2009No ratings yet

- Configuration For NeoBip - (Black) V1.1 BF 30STDocument1 pageConfiguration For NeoBip - (Black) V1.1 BF 30STTECHMED REPAIRS TECHMED SALESNo ratings yet