Professional Documents

Culture Documents

PASES, AIRE 448308 LB - HR REVaa1.SEG

Uploaded by

TIPAZO0 ratings0% found this document useful (0 votes)

5 views1 pageOriginal Title

PASES, AIRE 448308 LB.HR REVaa1.SEG

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pagePASES, AIRE 448308 LB - HR REVaa1.SEG

Uploaded by

TIPAZOCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

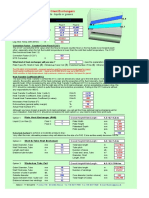

Aspen Exchanger Design and Rating Air Cooled V12

File: C:\..\..\..\..\T1-235 T2-118 CON 219 TUBOS, DOS PASES, AIRE MEDIDA Printed: 28/7/2021 at 23:34:11

VENT. LB.HR v1.EDR

Overall Performance

Rating / Checking OutSide Tube Side

Total mass flow rate lb/h 404652 48308

Vapor mass lb/h 404652 404652 48308 48282,1

Liquid mass lb/h 0 0 0 25,9

Vapour mass quality 1 1 1 0,9995

Temperature °F 105 138,03 235,59 118,8

Dew point / Bubble point temperatures °F 124,56 -368,23

Humidity ratio

Operating pressure inH2O / psi 403,03 403,03 514,25 512,72

Film coefficients BTU/(h-ft²-F) 97,41 110,82

Fouling resistance ft²-h-F/BTU 0,0028 0,0023

Velocity (highest) ft/s 9,5 / 10,05 22,6 / 18,09

Pressure drop (allow./calc.) psi / psi 0,029 / 0,003 3,63 / 1,53

Total heat exchanged BTU/h 3216206 Bay per unit 1 Tube OD 1 in

Overall bare coef. (dirty/clean) BTU/(h-ft²-F) 40,72 / 51,39 Bundles/bay 1 Tube tks 0,065 in

Effective MTD °F 40,63 Tubes/bundle 218 Tube length 30 ft

Effective surface (bare tube) ft² 1665,2 Rows deep 4 Fin OD 1,9685 in

Effective surface (total) ft² 28257,9 Tube passes 2 Fin tks 0,015 in

Area ratio: actual/required 0,86 Fans/bay 2 Fin frequency 132 #/ft

Heat Transfer Resistance

Outside / Fouling / Wall / Fouling / Tube side

Outside Tube side

You might also like

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- HEAT EXCHANGER SPECIFICATION SHEETDocument1 pageHEAT EXCHANGER SPECIFICATION SHEETHudaFiHayyatNo ratings yet

- Aspen Exchanger Design Rating Shell TubeDocument2 pagesAspen Exchanger Design Rating Shell TubeLuis Enrique Leyva Ovalle100% (1)

- Design of a Distillation Column for Separating Benzene and TolueneDocument75 pagesDesign of a Distillation Column for Separating Benzene and Toluenefadyah100% (1)

- Heat Exchanger Specification SheetDocument32 pagesHeat Exchanger Specification SheetWijayantoNo ratings yet

- Heat exchanger rating data sheetDocument1 pageHeat exchanger rating data sheetFadhila Ahmad AnindriaNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Aspen Exchanger Design Rating SheetDocument2 pagesAspen Exchanger Design Rating SheetLuis Enrique Leyva OvalleNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- Fire Suppression Calculations PDFDocument13 pagesFire Suppression Calculations PDFripcurlzNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- Ea 102Document2 pagesEa 102Najmul SaqibNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Ac-8 DSDocument2 pagesAc-8 DSOwais AhmedNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- T1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segDocument1 pageT1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segTIPAZONo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10Alex AgualemaNo ratings yet

- Output_ITEM NO. 106773_20 inch at 10000 Kg per hrDocument1 pageOutput_ITEM NO. 106773_20 inch at 10000 Kg per hryadav yadavNo ratings yet

- Output_ITEM NO. 113486_24 inch at 10000 KghrDocument1 pageOutput_ITEM NO. 113486_24 inch at 10000 Kghryadav yadavNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- E-105 Cooler-IIIDocument1 pageE-105 Cooler-IIIAl FareshNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- Gas Chiller DatasheetDocument2 pagesGas Chiller DatasheetidilfitriNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Caso de Studio Xchanger 1Document5 pagesCaso de Studio Xchanger 1fabianNo ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- General Lay-Out of AB&CO Heat ExchangersDocument1 pageGeneral Lay-Out of AB&CO Heat Exchangersfernando garza0% (1)

- 30 TR IG Tube PDFDocument1 page30 TR IG Tube PDFshree awateNo ratings yet

- Data Desain CCHE-TEMA PDFDocument1 pageData Desain CCHE-TEMA PDFFilippo AlfendroNo ratings yet

- CHEMCAD unit process simulation for LNG vaporizationDocument2 pagesCHEMCAD unit process simulation for LNG vaporizationLuthfi LegooNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Thermal and Hydraulic AnalysisDocument1 pageThermal and Hydraulic AnalysisSikander MushtaqNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- case 2Document1 pagecase 2nirajkulkarni09No ratings yet

- Aspen Exchanger Design for Heat RecoveryDocument5 pagesAspen Exchanger Design for Heat Recoveryريم تكروريNo ratings yet

- Juice Heater 1Document1 pageJuice Heater 1vijendrNo ratings yet

- Serial Number:: Document TypeDocument19 pagesSerial Number:: Document TypeAhmed KhairiNo ratings yet

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryNo ratings yet

- Sizing AircoolerDocument4 pagesSizing AircoolerpettypatelNo ratings yet

- case 3Document1 pagecase 3nirajkulkarni09No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- Hoja de Cálculo en CONCENTRIC REDUCER - A234 (1. ANSI) ORIGINALDocument12 pagesHoja de Cálculo en CONCENTRIC REDUCER - A234 (1. ANSI) ORIGINALTIPAZONo ratings yet

- Hoja de Cálculo en CAÑO 01 - V.10Document49 pagesHoja de Cálculo en CAÑO 01 - V.10TIPAZONo ratings yet

- Hoja de Cálculo en Pipe - PULG. ORIGINALDocument4 pagesHoja de Cálculo en Pipe - PULG. ORIGINALTIPAZONo ratings yet

- Design Table for Concentric Pipe ReducersDocument10 pagesDesign Table for Concentric Pipe ReducersTIPAZONo ratings yet

- Hoja de Cálculo en Pipe PULG UNIDAD MIMIMETROSDocument4 pagesHoja de Cálculo en Pipe PULG UNIDAD MIMIMETROSTIPAZONo ratings yet

- Pipe Schedule DimensionsDocument50 pagesPipe Schedule DimensionsTIPAZONo ratings yet

- Design Table for Semi-Ellipsoidal Pipe Head DimensionsDocument6 pagesDesign Table for Semi-Ellipsoidal Pipe Head DimensionsTIPAZONo ratings yet

- Hoja de Cálculo en Pipe - A106 - Metric (1. Ansi) Modificado A NpsDocument6 pagesHoja de Cálculo en Pipe - A106 - Metric (1. Ansi) Modificado A NpsTIPAZONo ratings yet

- Pipe Schedule and Dimensions ChartDocument4 pagesPipe Schedule and Dimensions ChartTIPAZONo ratings yet

- Hoja de Cálculo en END CAP - 15-150 NB - EDITABLEDocument8 pagesHoja de Cálculo en END CAP - 15-150 NB - EDITABLETIPAZONo ratings yet

- Hoja de Cálculo en Pipe - A106 - Metric (1. Ansi) Modificado A NpsDocument6 pagesHoja de Cálculo en Pipe - A106 - Metric (1. Ansi) Modificado A NpsTIPAZONo ratings yet

- Hoja de Cálculo en PIPE - A106 - METRIC (1. ANSI) MODIFICADO V.1Document80 pagesHoja de Cálculo en PIPE - A106 - METRIC (1. ANSI) MODIFICADO V.1TIPAZONo ratings yet

- Hoja de Cálculo en Brida EDITADODocument27 pagesHoja de Cálculo en Brida EDITADOTIPAZONo ratings yet

- Hoja de Cálculo en PIPE - A106 - METRIC (1. ANSI)Document70 pagesHoja de Cálculo en PIPE - A106 - METRIC (1. ANSI)TIPAZONo ratings yet

- Hoja de Cálculo en CAÑO 01 - V.10Document49 pagesHoja de Cálculo en CAÑO 01 - V.10TIPAZONo ratings yet

- Hoja de Cálculo en 0. CAP, BW, SCH, ASTM A234 GR WPB - MODIFICADO 17-02-2021Document27 pagesHoja de Cálculo en 0. CAP, BW, SCH, ASTM A234 GR WPB - MODIFICADO 17-02-2021TIPAZONo ratings yet

- Hoja de Cálculo en Threaded Coupling - EDITABLEDocument2 pagesHoja de Cálculo en Threaded Coupling - EDITABLETIPAZONo ratings yet

- Hoja de Cálculo en ANSI RF WN - A105 (1. ANSI) - DEFAULT2Document4 pagesHoja de Cálculo en ANSI RF WN - A105 (1. ANSI) - DEFAULT2TIPAZONo ratings yet

- Hoja de Cálculo en CAP, BW, SCH, ASTM A234 GR WPBDocument8 pagesHoja de Cálculo en CAP, BW, SCH, ASTM A234 GR WPBTIPAZONo ratings yet

- Hoja de Cálculo en Brida EDITADODocument27 pagesHoja de Cálculo en Brida EDITADOTIPAZONo ratings yet

- Hoja de Cálculo en End Cap - 15-150 NB - Editable v.2Document8 pagesHoja de Cálculo en End Cap - 15-150 NB - Editable v.2TIPAZONo ratings yet

- Operating, Service and Maintenance Manual: Powermaster Series 20,000 LBDocument20 pagesOperating, Service and Maintenance Manual: Powermaster Series 20,000 LBTIPAZONo ratings yet

- Hoja de Cálculo en End Cap - 15-150 NB - Editable v.2Document8 pagesHoja de Cálculo en End Cap - 15-150 NB - Editable v.2TIPAZONo ratings yet

- Osha 1910 TocDocument6 pagesOsha 1910 TocTIPAZONo ratings yet

- Hoja de Cálculo en FLG WELD NECK, CLASE, SCH, ASTM A105 - PULGADAS MODIFICADO 1Document3 pagesHoja de Cálculo en FLG WELD NECK, CLASE, SCH, ASTM A105 - PULGADAS MODIFICADO 1TIPAZONo ratings yet

- Hoja de Cálculo en ANSI RF WN - A105 (1. ANSI) - DEFAULT2Document4 pagesHoja de Cálculo en ANSI RF WN - A105 (1. ANSI) - DEFAULT2TIPAZONo ratings yet

- Respiratory ProtectionDocument42 pagesRespiratory ProtectionDaniel YamamuraNo ratings yet

- Wall Thickness and Dimensions for LRBW ElbowsDocument2 pagesWall Thickness and Dimensions for LRBW ElbowsTIPAZONo ratings yet

- Api - Spec - 6a - RTJ (Juntas Dielectricas)Document6 pagesApi - Spec - 6a - RTJ (Juntas Dielectricas)TIPAZONo ratings yet

- Osha 1910 TocDocument6 pagesOsha 1910 TocTIPAZONo ratings yet

- Line Index Table For Miano-18 Wellhead CompressionDocument2 pagesLine Index Table For Miano-18 Wellhead CompressionHafiz AkhtarNo ratings yet

- Forced Convection Boiling Inside Helically-Coiled TubesDocument15 pagesForced Convection Boiling Inside Helically-Coiled TubesAmoul DhahriNo ratings yet

- Energy-Saving: Ammonia Refrigeration Applications Using Pump CirculationDocument11 pagesEnergy-Saving: Ammonia Refrigeration Applications Using Pump CirculationbarelihbNo ratings yet

- Fluid Mechanics SanfoundaryDocument277 pagesFluid Mechanics Sanfoundaryengineersalam786No ratings yet

- ICDA - MX Line - MRPL - Multiphase Flow Modeling Report Draft 1.0Document16 pagesICDA - MX Line - MRPL - Multiphase Flow Modeling Report Draft 1.0Anonymous AtAGVssJNo ratings yet

- Phases and SolutionsDocument105 pagesPhases and SolutionsMolina ThirumalNo ratings yet

- Gupta - Gupta Civil Complete SolutionDocument5,933 pagesGupta - Gupta Civil Complete SolutionSabahat MehboobNo ratings yet

- Devonshire 1954Document47 pagesDevonshire 1954George AcostaNo ratings yet

- Wet Gas Metering by Isokinetic SamplingDocument25 pagesWet Gas Metering by Isokinetic Samplingspotty81100% (1)

- Surface and Interface Chemistry Solid/liquid Interface: Valentim M. B. Nunes Engineering Unit of IPT 2014Document21 pagesSurface and Interface Chemistry Solid/liquid Interface: Valentim M. B. Nunes Engineering Unit of IPT 2014Kevin CárdenasNo ratings yet

- Special Review For Mechanical Engineering: ThermodynamicsDocument1 pageSpecial Review For Mechanical Engineering: ThermodynamicsRosalie cabeltesNo ratings yet

- Physics Module 2 THERMAL KINETIC THEORYDocument2 pagesPhysics Module 2 THERMAL KINETIC THEORYnatural mysticNo ratings yet

- Xample: Internal Incompressible Viscous FlowDocument2 pagesXample: Internal Incompressible Viscous Flowวีรินทร์ ขนิษดาNo ratings yet

- Rock and Fluids - Porosity ExperimentDocument6 pagesRock and Fluids - Porosity ExperimentLaura DemarchNo ratings yet

- LT DPT (LRV & URV) CalcDocument3 pagesLT DPT (LRV & URV) CalcKarthikeyanNo ratings yet

- Chapter (5) Part (1) (MOS Cap)Document40 pagesChapter (5) Part (1) (MOS Cap)Ahmed SalehNo ratings yet

- CH 11 Practice QuestionsDocument5 pagesCH 11 Practice QuestionsDana Georgiana CrivoiNo ratings yet

- Exam 12005 Solution KeyDocument5 pagesExam 12005 Solution Keyfr hedaiatNo ratings yet

- Separation and Classification of SolidsDocument16 pagesSeparation and Classification of SolidsSham FerrerNo ratings yet

- Atomic and Molecular Structure ExplainedDocument20 pagesAtomic and Molecular Structure Explainedke.No ratings yet

- Effects of Viscosity of Fluids On Centrifugal Pump Performance and Flow Pattern in The Impeller PDFDocument6 pagesEffects of Viscosity of Fluids On Centrifugal Pump Performance and Flow Pattern in The Impeller PDFLAlvesNo ratings yet

- Chem 11Document12 pagesChem 11AmaliaNo ratings yet

- Flooding Prediction in Trickle BedsDocument8 pagesFlooding Prediction in Trickle BedsMichał KisielewskiNo ratings yet

- Clathrate Hydrates of Natural GasesDocument1 pageClathrate Hydrates of Natural GaseshamadahutpNo ratings yet

- Fouling FactorDocument2 pagesFouling FactorJesaya ValentinoNo ratings yet

- Properties of Liquid SimpleDocument3 pagesProperties of Liquid SimpleOsadreuasa100% (3)

- Tutorial - Transport Eqn, EosDocument15 pagesTutorial - Transport Eqn, Eossiti azilaNo ratings yet