Professional Documents

Culture Documents

Optimizing The Delays: Laseron Delay Too Short

Optimizing The Delays: Laseron Delay Too Short

Uploaded by

Andy RokiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimizing The Delays: Laseron Delay Too Short

Optimizing The Delays: Laseron Delay Too Short

Uploaded by

Andy RokiCopyright:

Available Formats

innovators for industry

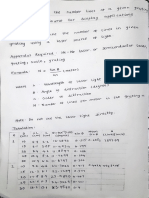

Optimizing the Delays

The following figures show the various effects of

non-optimized delays on the letters “RTC“.

LaserOn Delay too short Mark Mark Mark M

k ark

ar

Ma

At the beginning of a mark vector M Jump

rk Mark

the laser is switched on, even

k

M ar

Mark

though the mirrors have not yet

Mark

Mark

reached the necessary angular

M ar

p

Ma

Jum

Jum

velocity.

rk

k

p

Burn-in effects at the start points M

ar Jump

k ark

of the respective vectors result. Mark M

p

Jum

LaserOn Delay too long Mark Mark Mark M

k ark

ar

The laser is turned on too late at Ma

M Jump

rk Mark

the beginning of a mark vector.

k

M ar

Mark

Mark

The first part of the vector is not

Mark

marked.

M ar

p

Ma

Jum

Jum

rk

k

p

M

ar Jump

k ark

Mark M

p

Jum

LaserOff Delay too short Mark Mark Mark M

k ark

ar

Ma

The laser is turned off after the M Jump

rk Mark

last mark command of a line or

k

M ar

Mark

polyline, although the mirrors

Mark

Mark

have not yet reached the end

M ar

p

Ma

Jum

Jum

position of the vectors.

rk

k

p

The respective vectors are not M

ar Jump

k ark

marked completely. Mark M

p

Jum

LaserOff Delay too long Mark Mark Mark M

k ark

ar

Ma

The laser is turned off too late M Jump

rk Mark

after the last mark command of a

k

M ar

Mark

line or polyline. The laser is still

Mark

Mark

on, even though the mirrors have

M ar

p

Ma

Jum

Jum

already stopped or move only

rk

k

p

very slowly. M Jump

ar

k ark

The results are burn-in effects at Mark M

p

the end points of the respective Jum

vectors.

RTC®5 PC Interface Board 110

Rev. 1.9 e

7 Basic Functions for Scan Head and Laser Control

innovators for industry

Jump Delay too short Mark Mark Mark M

k ark

ar

Ma

After a jump, the first mark vector M Jump

rk Mark

has already started although the

k

M ar

Mark

scanners have not yet settled.

Mark

Mark

A running-in oscillation

M ar

p

Ma

Jum

Jum

(overshoot) will be visible.

rk

k

p

M

ar Jump

k ark

Mark M

p

Jum

Jump Delay too long

There are no visible effects if the

jump delay is too long. However,

the scanning time will be

extended.

Mark Delay too short Mark Mark Mark M

k ark

ar

Ma

Though the mirrors have not yet M Jump

rk Mark

reached the end position of the

k

M ar

Mark

last vector of a line or polyline,

Mark

Mark

the command for the succeeding M ar

p

Ma

Ju m

Jum

jump vector is already executing.

rk

k

p

The end of the mark vector is M

ar Jump

k ark

turned towards the direction of Mark M

p

the jump vector. Jum

Mark Delay too long

There are no visible effects if the

mark delay is too long, but the

scanning time will be increased.

RTC®5 PC Interface Board 111

Rev. 1.9 e

7 Basic Functions for Scan Head and Laser Control

innovators for industry

Polygon Delay too short Mark Mark Mark M

k ark

ar

Ma

The subsequent mark command M Jump

rk Mark

in a polyline is already executing,

k

M ar

Mark

although the mirrors have not yet

Mark

Mark

reached the end position of the

M ar

p

Ma

Jum

Jum

preceding mark vector.

rk

k

p

The corners of the polyline are M

ar Jump

k ark

rounded off. Mark M

p

Jum

Polygon Delay too long Mark Mark Mark M

k ark

ar

Ma

If the polygon delay is too M Jump

rk Mark

long, the mirrors are moving

k

M ar

Mark

too slowly or are even

Mark

Mark

stopping between subse-

M ar

p

Ma

Jum

Jum

quent mark commands.

rk

k

p

Since the laser is not turned M

ar Jump

k ark

off between these vectors, Mark M

p

burn-in effects occur. Jum

In the variable polygon delay

mode, a maximum length

(“edgelevel“) can be defined.

See page 104 for details.

RTC®5 PC Interface Board 112

Rev. 1.9 e

7 Basic Functions for Scan Head and Laser Control

You might also like

- Electro-Culture of PlantsDocument11 pagesElectro-Culture of PlantsAC5CHNo ratings yet

- The Nunology of The Pineal Gland by DR - NEB HERUDocument107 pagesThe Nunology of The Pineal Gland by DR - NEB HERUNeb Heru95% (41)

- Curse of The Riven SkyDocument36 pagesCurse of The Riven SkyHugo eriksson100% (2)

- 27.2 RISK ASSESSMENT and Analysis Cable Tray InstallationDocument3 pages27.2 RISK ASSESSMENT and Analysis Cable Tray InstallationsalmanNo ratings yet

- Cable Termination Failure ReasonsDocument3 pagesCable Termination Failure ReasonsImran Ahmed100% (2)

- Giantslayer - Poster Map FolioDocument5 pagesGiantslayer - Poster Map FolioGino Sansone100% (1)

- A Gestalt Perspective On Working With Group Process by John Bernard HarrisDocument15 pagesA Gestalt Perspective On Working With Group Process by John Bernard HarrisMariana BorodeaNo ratings yet

- Shallow Foundation PDFDocument75 pagesShallow Foundation PDFSweet BoyNo ratings yet

- Creep TestingDocument12 pagesCreep TestingJGV21No ratings yet

- CCTV Installation PDFDocument17 pagesCCTV Installation PDFMATE0No ratings yet

- Reign of Winter - 01 - The Snows of Summer - Interactive MapsDocument6 pagesReign of Winter - 01 - The Snows of Summer - Interactive MapsRichard BernardNo ratings yet

- Acoustic Emission - Standards and Technology UpdateDocument257 pagesAcoustic Emission - Standards and Technology Updatetobby65100% (1)

- Waste Water Treatment NotesDocument75 pagesWaste Water Treatment Noteskiran_ran99100% (1)

- QC Test For CapsulesDocument4 pagesQC Test For CapsulesMuhammad Masoom Akhtar100% (1)

- Nlcs Poster 4-18Document1 pageNlcs Poster 4-18Russell HartillNo ratings yet

- U.S. Space & Rocket Center: Rover Challenge Course 2020Document1 pageU.S. Space & Rocket Center: Rover Challenge Course 2020Diego Carhuaz VasquezNo ratings yet

- Cades Cove Fall 2022 Prescribed Burn MapDocument1 pageCades Cove Fall 2022 Prescribed Burn MapWVLT NewsNo ratings yet

- The Preparatory Survey MRT East - West Line ProjectDocument94 pagesThe Preparatory Survey MRT East - West Line ProjectJust ChristianNo ratings yet

- PKS PresentationDocument27 pagesPKS PresentationvarshaNo ratings yet

- Tugas 03Document3 pagesTugas 03Crista JuniarNo ratings yet

- Mount Jackson Trail MapDocument1 pageMount Jackson Trail MapLennyNo ratings yet

- CH 05Document23 pagesCH 05Alexaa ANo ratings yet

- Grade 4 NUMERACY ASSESSMENT RECORD SHEETDocument5 pagesGrade 4 NUMERACY ASSESSMENT RECORD SHEETibrahim phiriNo ratings yet

- Leander/Lakeline Express: CommuterDocument2 pagesLeander/Lakeline Express: CommuterNgân Hàng Ngô Mạnh TiếnNo ratings yet

- 4 910Document1 page4 910Subudhi Techno DesignNo ratings yet

- Functions PI & PII CCDocument16 pagesFunctions PI & PII CCAast PstNo ratings yet

- Corona: Temecula - Murrieta - Lake Elsinore - Corona MetrolinkDocument2 pagesCorona: Temecula - Murrieta - Lake Elsinore - Corona MetrolinkGavin WInceNo ratings yet

- Notes & Specifications Schedule of Loads: Lighting Layout Particulars SpecificationsDocument1 pageNotes & Specifications Schedule of Loads: Lighting Layout Particulars SpecificationsdrahcirNo ratings yet

- Gen4 Gen3 Gen2 Gen1 R Load 6 R Load 5 R Load 4 R Load 3 R Load 2 R Load 1Document1 pageGen4 Gen3 Gen2 Gen1 R Load 6 R Load 5 R Load 4 R Load 3 R Load 2 R Load 1Roha JavidNo ratings yet

- 007 Mathematics Model Question Paper New CourseDocument6 pages007 Mathematics Model Question Paper New CourseAashish RokayaNo ratings yet

- Assem1 Mesin Perajang Rumput GajahDocument1 pageAssem1 Mesin Perajang Rumput GajahRezaldiNo ratings yet

- List of Ineligible Candidates For The Post of Hospital AdministratorsDocument2 pagesList of Ineligible Candidates For The Post of Hospital AdministratorsCh RajeshNo ratings yet

- WPNP Map Park OverviewDocument1 pageWPNP Map Park Overviewkalistamarcia1803No ratings yet

- Magnetic Properties of MatterDocument22 pagesMagnetic Properties of Matteragrimchaudhary3No ratings yet

- Chapter06 Electrical Characteristic of MOSFETs MJL M.tech 2018Document62 pagesChapter06 Electrical Characteristic of MOSFETs MJL M.tech 2018Jayraj SONINo ratings yet

- WBS Chart 1 - A3Document1 pageWBS Chart 1 - A3engrmasgharNo ratings yet

- Cale Nda R.co M: Venkatrama & Co., Offi Ci Al Permi Ssi On Websi TeDocument23 pagesCale Nda R.co M: Venkatrama & Co., Offi Ci Al Permi Ssi On Websi TeprasannagNo ratings yet

- Siddha Galaxia BrowsiorDocument44 pagesSiddha Galaxia BrowsiorJoseph CruzNo ratings yet

- Rail Sys Aug2022Document1 pageRail Sys Aug2022jazminNo ratings yet

- Ofa9 Qiven Jratin: Grating UsingDocument3 pagesOfa9 Qiven Jratin: Grating UsingRahul KarthikNo ratings yet

- Performance Plan Program Latihan Pra Porprov Gulat Kota Semarang TH 2017Document2 pagesPerformance Plan Program Latihan Pra Porprov Gulat Kota Semarang TH 2017Lydia PermatasariNo ratings yet

- 2022 CalenderDocument12 pages2022 CalenderVinay VinnuNo ratings yet

- Map Key: Tawharanui Open SanctuaryDocument1 pageMap Key: Tawharanui Open SanctuaryJames MorrisonNo ratings yet

- Maroochy Spell SheetDocument1 pageMaroochy Spell SheetwineCentric 'Matthew Lewis'No ratings yet

- York Cycle MapDocument1 pageYork Cycle MapAdam At SummitNo ratings yet

- PRP004165 01 12A 102 - Rev 00Document8 pagesPRP004165 01 12A 102 - Rev 00Khent Alfred DerechoNo ratings yet

- Texas GeographyDocument4 pagesTexas Geographylilywright08No ratings yet

- Earth Grid MapDocument1 pageEarth Grid MapSinging Suicune100% (1)

- General Derivations .: Description MethodDocument1 pageGeneral Derivations .: Description MethodjosNo ratings yet

- Matter and MagnetismDocument13 pagesMatter and MagnetismLakshya ChaudharyNo ratings yet

- PeriodicityDocument21 pagesPeriodicityFaizan AhmedNo ratings yet

- Starchart PDFDocument1 pageStarchart PDFdamir ćajićNo ratings yet

- Phase Boundary Mapping To Obtain N-Type Mg3Sb2 Based ThermoelectricsDocument15 pagesPhase Boundary Mapping To Obtain N-Type Mg3Sb2 Based ThermoelectricsharpriyaminhasNo ratings yet

- Moving Charges and Magnetism Folder.Document1 pageMoving Charges and Magnetism Folder.sarthakyedlawar04No ratings yet

- CV Nova Ambarwati - RNODocument1 pageCV Nova Ambarwati - RNOHaris HidayatullohNo ratings yet

- 02a. Introduction To The ME Engine (Maj 2015)Document11 pages02a. Introduction To The ME Engine (Maj 2015)Thusitha DalpathaduNo ratings yet

- CL324 - Lecture 9, 9 Aug 2021Document6 pagesCL324 - Lecture 9, 9 Aug 2021Kala DarshanNo ratings yet

- O Level Electromagnetic Induction PDFDocument18 pagesO Level Electromagnetic Induction PDFsafi mohammadNo ratings yet

- Kalama Fire Evacuation MapDocument1 pageKalama Fire Evacuation MapKGW NewsNo ratings yet

- Norbury Rock DescriptionDocument2 pagesNorbury Rock DescriptionAssane LeyeNo ratings yet

- A Ltgri RN Etat Na Arks: Features On Wafer FDocument10 pagesA Ltgri RN Etat Na Arks: Features On Wafer FHAshashNo ratings yet

- Draft - Log BorDocument1 pageDraft - Log BorDeyusufNo ratings yet

- MADE EASY ESE Microprocessors 1-2Document17 pagesMADE EASY ESE Microprocessors 1-2Priyanshu GuptaNo ratings yet

- Jasper: National ParkDocument1 pageJasper: National ParkTheo WiltingNo ratings yet

- Intro 1Document8 pagesIntro 1api-3864016No ratings yet

- Các Nguyên Lý Và Hiệu Ứng 2 SvDocument19 pagesCác Nguyên Lý Và Hiệu Ứng 2 SvPhong Trinh XuanNo ratings yet

- 02 Newtonian Mechanics AdvancedDocument37 pages02 Newtonian Mechanics AdvancedRithish BarathNo ratings yet

- ACT SAT Practice CH 1 ReviewsDocument3 pagesACT SAT Practice CH 1 ReviewsYb Andik Adi CahyonoNo ratings yet

- MCQ InterferenceDocument18 pagesMCQ InterferenceMADHAVNo ratings yet

- 4 10K5 DS User Manual 422 00022 08Document16 pages4 10K5 DS User Manual 422 00022 08Rati GabisoniaNo ratings yet

- Scatterometer - WikipediaDocument21 pagesScatterometer - WikipediaShebinNo ratings yet

- Dielectrics & Polarisation: Mathew Abraham Principal KV Nmu JalgaonDocument21 pagesDielectrics & Polarisation: Mathew Abraham Principal KV Nmu JalgaonMathew AbrahamNo ratings yet

- Forces PicsDocument19 pagesForces PicsGarry Lloyd TuzonNo ratings yet

- Engineering Mechanics End SemesterDocument4 pagesEngineering Mechanics End SemesterAjay ChoudharyNo ratings yet

- WS Soln 2 6A RationalFunctionsDocument6 pagesWS Soln 2 6A RationalFunctionsSiddhant ShahNo ratings yet

- Introduction To Electrodeionization: Jeff Tate Agape Water Solutions, IncDocument26 pagesIntroduction To Electrodeionization: Jeff Tate Agape Water Solutions, Incsagor sagorNo ratings yet

- Forces: Discusssion / Activity 1Document5 pagesForces: Discusssion / Activity 1Prathmesh SinhaNo ratings yet

- Exercisesweek 1Document3 pagesExercisesweek 1api-254818047No ratings yet

- Obe Reports Hec - Report Section OutlineDocument2 pagesObe Reports Hec - Report Section OutlineDanish EjazNo ratings yet

- Student PortalDocument1 pageStudent PortalUNIVERSAL ENTERPRISESNo ratings yet

- Physics 10 (P2) 2nd TermDocument16 pagesPhysics 10 (P2) 2nd TermRahma SaleheenNo ratings yet

- Mauryaresume 1Document1 pageMauryaresume 1harry PanwarNo ratings yet

- Hazelnut Shells PDFDocument13 pagesHazelnut Shells PDFHalime Erol YücelNo ratings yet

- ClasificationDocument30 pagesClasificationSanjay SwainNo ratings yet

- PHYSICS Density of OilDocument8 pagesPHYSICS Density of OilVunnava BalajiNo ratings yet