Professional Documents

Culture Documents

Test Results of Coarse Aggregates, Bazuri & Quarry Dust To Be Used As (Granular Sub-Base Material Gradind-Iv)

Uploaded by

Manwa KhamariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Results of Coarse Aggregates, Bazuri & Quarry Dust To Be Used As (Granular Sub-Base Material Gradind-Iv)

Uploaded by

Manwa KhamariCopyright:

Available Formats

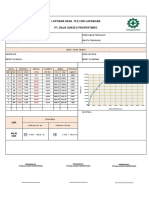

TEST RESULTS OF COARSE AGGREGATES,BAZURI & QUARRY DUST

TO BE USED AS ( GRANULAR SUB-BASE MATERIAL GRADIND-IV)

Name of Requisitioner :- SHIVAM CONDEV PVT LTD.

Reference:-Latter No:- SHIVAM/NYGH/TAH- Date:-17.02.2021

Name of the work: - " Improvement to Odagaon-Bahadajholla- Nuagaon Road from Ch: 27/00 to 43/000 KM in the District of Nayagarh Year of 2020.21."

Date of complition Test :- 22.02.2021

Tests conducted as per I: S: 2720 (Pt.I,Pt.IV,Pt.V,Pt.VIII,Pt.XVII,Pt.XXVIII & Pt.XXXX)

% passing Through Different IS Sieves of Proportioning of Materials to be Mixed in Requirment of grading

Name individual Materials the Admixture. LL,PL,PI & CBR as per

Description of IS Grading of

of the MORTH-2013

sieves in mm Admixture

Test

40 mm 10 mm 6 mm Quarry A B C D

Agg. (A) Agg. (B) Agg. (C) dust. (D) (45%) (30%) (10%) (15%) Grading-IV

75.00 100.00 100.00 100.00 100.00 100.00

45.00 + 30.000 + 10.000 + 15.000 ----

53.00 100.00 100.00 100.00 100.00 100.00

45.00 + 30.000 + 10.000 + 15.000 100

26.50 40.38 100.00 100.00 100.00 73.171

18.17 + 30.000 + 10.000 + 15.000 50-80

Grading % passing through

IS sieves

9.50 1.24 62.46 100 100.00 44.296

0.56 + 18.738 + 10.000 + 15.000 ----

4.75 0.00 22.52 70.62 100.00 28.818

0.00 + 6.756 + 7.062 + 15.000 15.35

2.36 0.00 12.98 51.24 81.38 21.225

0.00 + 3.894 + 5.124 + 12.207 ----

0.425 0.00 4.72 22.68 31.24 8.37

0.00 + 1.416 + 2.268 + 4.686 ----

0.075 0.00 1.38 5.83 19.38 3.904

0.00 + 0.414 + 0.583 + 2.907 <5

Liquid Limit in % --- --- --- --- --- --- --- --- 18.00

Atterberg's

LL<25

Limit

Plastic Limit in % --- --- --- --- --- --- --- --- ---

----

Plasticty index in % --- --- --- --- --- --- --- --- NP

PI<6.0

Compaction

Max. dry density --- --- --- --- --- --- --- --- 2.21

Modified

----

Proctor

Optimum Moisture

--- --- --- --- --- --- --- --- 6.30

Content in % ----

C.B.R Unsoaked in --- --- --- --- --- --- --- --- 47.4

% ----

C.B.R soaked in % (4

--- --- --- --- --- --- --- --- 32.1

C.B.R

days) CBR>30

Moisture Content

(after 4days --- --- --- --- --- --- --- --- 9.1

soaking)in %

----

--- --- --- --- --- --- --- --- 0.0

D.F.S in % ----

--- --- --- --- --- --- --- --- ---

Bulk density in gm/cc ----

Remarks:- (1) Admixture of above Coarse aggregates with Quarry Dust conforms to grading,LL,PI & C.B.R value of Coarse graded granular sub-base

material Grading-IV as per tabel 400-1 of MORTH-2013

This test result pertains to the sample received by this laboratory

For Asian Geotech Research Service

TEST RESULTS OF COARSE AGGREGATES,BAZURI & QUARRY DUST

TO BE USED AS ( GRANULAR SUB-BASE MATERIAL GRADIND-VI)

Name of Requisitioner :- SHIVAM CONDEV PVT LTD.

Reference:-Latter No:- SHIVAM/NYGH/TAH- Date:-17.02.2021

Name of the work: - " Improvement to Odagaon-Bahadajholla- Nuagaon Road from Ch: 27/00 to 43/000 KM in the District of Nayagarh Year of 2020.21."

Date of complition Test :- 22.02.2021

Tests conducted as per I: S: 2720 (Pt.I,Pt.IV,Pt.V,Pt.VIII,Pt.XVII,Pt.XXVIII & Pt.XXXX)

% passing Through Different IS Sieves of Proportioning of Materials to be Mixed Requirment of grading

Name individual Materials in the Admixture. LL,PL,PI & CBR as per

Description of IS Grading of

of the MORTH-2013

sieves in mm Admixture

Test

40 mm 10 mm 6 mm Quarry A B C D

Agg. (A) Agg. (B) Agg. (C) dust. (D) (25%) (30%) (30%) (15%) Grading-IV

75.00 100.00 100.00 100.00 100.00 45.00 + 30.00 + 10.00 + 15.00 100.00

----

53.00 100.00 100.00 100.00 100.00 45.00 + 30.00 + 10.00 + 15.00 100.00

100

26.50 40.38 100.00 100.00 100.00 18.17 + 30.00 + 10.00 + 15.00 73.17

75-100

Grading % passing through

IS sieves

9.50 1.24 62.46 100 100.00 0.56 + 18.74 + 10.00 + 15.00 44.30

55-75

4.75 0.00 22.52 70.62 100.00 0.00 + 6.76 + 7.06 + 15.00 28.82

30-55

2.36 0.00 12.98 51.24 81.38 0.00 + 3.89 + 5.12 + 12.21 21.23

10-25

0.425 0.00 4.72 22.68 31.24 0.00 + 1.42 + 2.27 + 4.69 8.37

0-8

0.075 0.00 1.38 5.83 19.38 0.00 + 0.41 + 0.58 + 2.91 3.90

<3

Liquid Limit in % --- --- --- --- --- --- --- --- 18.00

Atterberg's

LL<25

Limit

Plastic Limit in % --- --- --- --- --- --- --- --- ---

----

Plasticty index in % --- --- --- --- --- --- --- --- NP

PI<6.0

Compaction

Max. dry density --- --- --- --- --- --- --- --- 2.321

Modified

----

Proctor

Optimum Moisture

--- --- --- --- --- --- --- --- 6.5

Content in % ----

C.B.R Unsoaked in --- --- --- --- --- --- --- --- 46.15

% ----

C.B.R soaked in % (4

--- --- --- --- --- --- --- --- 31.25

C.B.R

days) CBR>30 %

Moisture Content

(after 4days --- --- --- --- --- --- --- --- 9.1

soaking)in %

----

--- --- --- --- --- --- --- --- 0.0

D.F.S in % ----

--- --- --- --- --- --- --- --- ---

Bulk density in gm/cc ----

Remarks:- (1) Admixture of above Coarse aggregates with Quarry Dust conforms to grading,LL,PI & C.B.R value of Coarse graded granular sub-base

material Grading-IV as per tabel 400-1 of MORTH-2013

This test result pertains to the sample received by this laboratory

For Asian Geotech Research Service

TEST RESULTS OF WMM MATERIAL

Name of Requisitioner :- SHIVAM CONDEV PVT LTD.

Reference:-Latter No:- SHIVAM/NYGH/TAH- Date:-17.02.2021

Name of the work: - " Improvement to Odagaon-Bahadajholla- Nuagaon Road from Ch: 27/00 to 43/000 KM in the District of Nayagarh Year of 2020.21."

Date of complition Test :- 22.02.2021

PROPORTIONING AND GRADING OF WMM MATERIALS

% passing Through Different IS Sieves of individual Materials Proportioning of Materials to be Mixed in the % Passing of

Description Admixture.

of IS sieves the Design Required % Passing of

in mm Admixture of Material as per table

40 mm 20 mm 10 mm 6 mm Dust A B C D E Aggregates 400-13 of MORTH

(A) (B) (C) (D) (E) (25%) (30%) (20%) (15%) (10%) 2013

53.00 100 100 100 100 100 25.00 30.00 20.00 15.00 10.00 100.00 100

45.00 100 100 100 100 100 25.00 30.00 20.00 15.00 10.00 100.00

95-100

22.40 10.63 94.52 100 100 100 2.66 28.36 20.00 15.00 10.00 76.02 60-80

11.20 3.86 24.31 93 100 100 0.97 7.29 18.55 15.00 10.00 51.81 40-60

4.75 0.00 2.86 48.92 97.25 100 0.00 0.86 9.78 14.59 10.00 35.23

25-40

2.36 0.00 0.00 19.21 60.04 94.86 0.00 0.00 3.84 9.01 9.49 22.34 15-30

0.600 0.00 0.00 11.08 25.86 63.39 0.00 0.00 2.22 3.88 6.34 12.44

8-22

0.075 0.00 0.00 2.65 2.75 18.46 0.00 0.00 0.53 0.41 1.85 2.79 0-5

PHYSICAL PROPERTIES OF AGGREGATES

TESTS OBSERVED VALUE Requirement as per Table 400-12 of

MORTH 2013

Aggregate Impact Value in % 14.59 30 % Max

Combined Flakiness & Elongation Indices in % 20.82 35 % Max

Liquid Limit in % 19

---

Atterberg's Limit Plastic Limit in % ---

P.I. < 6% as per Clause 406.2.1.2 of

Plasticity Index N.P

MORTH 2013

Optimum Moisture Conten in % 5.85

Proctor Compction of W.M.M ---

Max. Dry Density in gm/cc 2.355

This test result pertains to the sample received by this laboratory

For Asian Geotech Research Service

TEST RESULTS OF BITUMINOUS MACADAM GRADE-II MATERIAL

Name of Requisitioner :- SHIVAM CONDEV PVT LTD.

Reference:-Latter No:- SHIVAM/NYGH/TAH- Date:-17.02.2021

Name of the work: - " Improvement to Odagaon-Bahadajholla- Nuagaon Road from Ch: 27/00 to 43/000 KM in the District of Nayagarh Year of 2020.21."

Date of complition Test :- 22.02.2021

20 mm 20%

10 mm 50%

PROPORTION MOSRT&H SPECIFICATION

06 mm 15%

Stone Dust 15%

% OF PASSING Required % Passing of

SIEVE SIZE (mm) Material as per table 500-7 of

Sample-1 Sample-2 Saample-3 MORTH 2013

26.50 100.00 100.00 100.00 100

GRADATION

19.00 95.64 94.57 94.88 90-100

13.20 71.42 68.50 73.69 56-88

4.75 25.78 27.41 27.86 16-36

2.36 12.13 12.41 11.97 04-19

0.300 4.35 4.56 4.92 02-10

0.075 2.67 2.34 3.01 00-08

Optomum Binder Content 3.40% 3.3 % - 3.5 %

Bulk density of Mix 2.307 g/cc -

Aggregate Imapct Value 20.36% Maximum 30 %

Combined Flakiness & Elongation Index 25.44% Maximum 30 %

Stripping Value (Coated with Bitumen) 99.00% Min 95 % Coated required

Penetration Test (1/10 mm) 66 60-70 (For S 65 Grade)

Softening Point Test 51.65OC 40 OC to 55 OC

DuctilityTest 98 Cm Minimum 75 Cm

Flash Point Test 195 C

O

Minimum 175 OC

Fire Point Test 207 C

O

Minimum 175 OC

Water Absorption of Aggregate 0.51% Maximum 2 %

Soundness with Sodium Sulphate 10.02% Maximum 12 %

Soundness with Magnisium Sulphate 11.65% Maximum 18 %

This test result pertains to the sample received by this laboratory

For Asian Geotech Research Service

TEST RESULTS OF BITUMINOUS MACADAM GRADE-II MATERIAL

Name of Requisitioner :- SHIVAM CONDEV PVT LTD.

Reference:-Latter No:- SHIVAM/NYGH/TAH- Date:-17.02.2021

Name of the work: - " Improvement to Odagaon-Bahadajholla- Nuagaon Road from Ch: 27/00 to 43/000 KM in the District of Nayagarh Year of 2020.21."

Date of complition Test :- 22.02.2021

20 mm 20%

10 mm 50%

PROPORTION MOSRT&H SPECIFICATION

06 mm 15%

Stone Dust 15%

% OF PASSING Required % Passing of

SIEVE SIZE (mm) Material as per table 500-7 of

Sample-1 Sample-2 Saample-3 MORTH 2013

13.20 100.00 100.00 100.00 100

GRADATION

9.50 95.64 97.45 96.55 90-100

4.75 45.24 49.74 41.25 35-51

2.36 27.36 29.54 27.86 24-39

1.18 19.24 21.47 18.78 15-30

0.300 11.24 10.94 12.01 9-13

0.075 3.97 4.02 4.19 3-8

Optomum Binder Content 4.80% 5

Bulk density of Mix 2.25% -

Aggregate Imapct Value 18.90% Maximum 27 %

Combined Flakiness & Elongation Index 23.50% Maximum 30 %

Stripping Value (Coated with Bitumen) 99.00% Min 95 % Coated required

Penetration Test (1/10 mm) 66 60-70 (For S 65 Grade)

Softening Point Test 51.65OC 40 OC to 55 OC

DuctilityTest 98 Cm Minimum 75 Cm

Flash Point Test 195 C

O

Minimum 175 OC

Fire Point Test 207 C

O

Minimum 175 OC

Water Absorption of Aggregate 0.51% Maximum 2 %

Soundness with Sodium Sulphate 10.02% Maximum 12 %

Soundness with Magnisium Sulphate 11.65% Maximum 18 %

This test result pertains to the sample received by this laboratory

For Asian Geotech Research Service

You might also like

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Canal de Conduccion ConDocument2 pagesCanal de Conduccion ConLUISNo ratings yet

- Concrete Mix Design RailwayDocument35 pagesConcrete Mix Design RailwayAjit P. SinghNo ratings yet

- 01 Metrado de Explan Carretera RamadillaDocument29 pages01 Metrado de Explan Carretera RamadillaBosco Ñahui VelasqueNo ratings yet

- Metrados de Excavaciones Y Eliminación de Material ExcedenteDocument26 pagesMetrados de Excavaciones Y Eliminación de Material ExcedenteFlavio IglesiasNo ratings yet

- Detour B - EmbankmentDocument15 pagesDetour B - EmbankmentRolly Marc G. SoteloNo ratings yet

- Dry Sieve AnalysisDocument3 pagesDry Sieve AnalysisKamran JUTTNo ratings yet

- Sieve Analysis Data SheetDocument3 pagesSieve Analysis Data SheetKamran JUTTNo ratings yet

- Anexo 5 - 5 PDFDocument1 pageAnexo 5 - 5 PDFRe Sacf uNo ratings yet

- Filter Media 15.1.2015Document17 pagesFilter Media 15.1.2015Prashant SinghNo ratings yet

- BSTM22 S3.1Document1 pageBSTM22 S3.1Septian AnsoriNo ratings yet

- Theoritical Blending Sheet For Dense Bitiminious Macadam (GR Ii)Document1 pageTheoritical Blending Sheet For Dense Bitiminious Macadam (GR Ii)J Marees Kumar Thangarathinam100% (1)

- Sample Question 1: TimestampDocument9 pagesSample Question 1: Timestampsaurabh kumarNo ratings yet

- COMBINE of Sieve Analysis FGHFDocument3 pagesCOMBINE of Sieve Analysis FGHFASHOKKUMARNo ratings yet

- Prog. Dist. Areas Volumenes Clasificacion Corte Relleno Corte Relleno Vol. Cortes (M) (m2) (m2) (m3) (m3) M.S. R.SDocument3 pagesProg. Dist. Areas Volumenes Clasificacion Corte Relleno Corte Relleno Vol. Cortes (M) (m2) (m2) (m3) (m3) M.S. R.SJhonatan Miranda MamaniNo ratings yet

- DLC GradingDocument9 pagesDLC GradingAshok kumarNo ratings yet

- Analisa Saringan Halus-1Document5 pagesAnalisa Saringan Halus-1Indriya AzuarNo ratings yet

- Cuadro de Elementos de CurvaDocument4 pagesCuadro de Elementos de CurvaRoyer Roman LizarbeNo ratings yet

- Form Grain SizeDocument2 pagesForm Grain Sizeyoanita eka rahayuNo ratings yet

- Dokumen - Tips - Analisa Beton Ready Mix PDFDocument2 pagesDokumen - Tips - Analisa Beton Ready Mix PDFSunari SipilNo ratings yet

- Volumene ModificadoDocument63 pagesVolumene ModificadonelNo ratings yet

- Gradation of Material: Material 1 Material 2 Material 3 Material 4Document5 pagesGradation of Material: Material 1 Material 2 Material 3 Material 4Deputy DirectorNo ratings yet

- Conversion Cost ExampleDocument62 pagesConversion Cost ExampleTamaraGarzaNo ratings yet

- Laporan Hasil Tes CBR Lapangan Pt. Raja Sukses PropertindoDocument3 pagesLaporan Hasil Tes CBR Lapangan Pt. Raja Sukses PropertindoRatih GunNo ratings yet

- Estudio de Molienda 1Document19 pagesEstudio de Molienda 1Frank CaritasNo ratings yet

- Mix Design - DLC MujaDocument3 pagesMix Design - DLC MujaMujahid choudharyNo ratings yet

- Tutorial Chapter 2Document5 pagesTutorial Chapter 2mashiNo ratings yet

- Data Material Terpakai MingguanDocument3 pagesData Material Terpakai MingguanSUBANDI QBNo ratings yet

- Área Distancia (M) Área Medias (m2) Volumen (m3) Corte Relleno Corte Relleno Corte Progresivas (KM)Document8 pagesÁrea Distancia (M) Área Medias (m2) Volumen (m3) Corte Relleno Corte Relleno Corte Progresivas (KM)janetNo ratings yet

- Base Trial PercentDocument1 pageBase Trial PercentYasin AykanatNo ratings yet

- C4M Sieve AnalysisDocument10 pagesC4M Sieve Analysissamar varshneyNo ratings yet

- Sieve Analysis ReportDocument1 pageSieve Analysis ReportBaluku BennetNo ratings yet

- Pasa #200 Total FinoDocument3 pagesPasa #200 Total FinoAngelo Araya LemusNo ratings yet

- Tutorial Soln (Profitability Analyses)Document5 pagesTutorial Soln (Profitability Analyses)Para DiseNo ratings yet

- Marshall Stability Test PDFDocument8 pagesMarshall Stability Test PDFAnonymous FO4sHLLONo ratings yet

- Pumpable Concrete Proposed Combined Aggregates Grading LimitsDocument4 pagesPumpable Concrete Proposed Combined Aggregates Grading LimitsAndrew MwambaNo ratings yet

- Kumulativo Kada CBR - Versaun TetunDocument45 pagesKumulativo Kada CBR - Versaun TetunmgiNo ratings yet

- 04.00 PLANO DISEÑO DE VIA (Laminado) 9Document1 page04.00 PLANO DISEÑO DE VIA (Laminado) 9ERIC erNo ratings yet

- SD 221Document2 pagesSD 221peter njugunaNo ratings yet

- Exercise 1 With Computations and GraphsDocument4 pagesExercise 1 With Computations and GraphsJelaNo ratings yet

- Questão 1: % Passante AcumuladaDocument3 pagesQuestão 1: % Passante AcumuladaAndré PhelpsNo ratings yet

- Empresa de PlasticoDocument6 pagesEmpresa de PlasticoCamila Alejandra Quispe EscobarNo ratings yet

- Kship GVR: Sorce: Sankanur Cross CrusherDocument9 pagesKship GVR: Sorce: Sankanur Cross CrusherVijay Jamadar100% (1)

- RegressionDocument7 pagesRegressionapi-3805289No ratings yet

- Tamiz Pasa Pasante (MM) (%) (%) : Retenido Retenido Acumulado (%) Parcial (%)Document4 pagesTamiz Pasa Pasante (MM) (%) (%) : Retenido Retenido Acumulado (%) Parcial (%)FabioAndres VelandiaNo ratings yet

- CGT21010 HomeworkDocument5 pagesCGT21010 HomeworkBhargav D.S.No ratings yet

- Costing Calculations:: Enquiry 270 - IDocument7 pagesCosting Calculations:: Enquiry 270 - IRakesh SharmaNo ratings yet

- Sr. Descrption m3: M/s. Rawail Builders Construction of Bridge Near Burma Town, Lehtrar Road, IslamabadDocument3 pagesSr. Descrption m3: M/s. Rawail Builders Construction of Bridge Near Burma Town, Lehtrar Road, IslamabadKASHIF MUGHALNo ratings yet

- IKEA Salespivot 20200320053500350350Document182 pagesIKEA Salespivot 20200320053500350350Ahsan DharNo ratings yet

- Metrados Porvenir - SacuatunaDocument44 pagesMetrados Porvenir - Sacuatunaeduardo robles cuestasNo ratings yet

- Construction of Main Canal and Associated Structures (CH 10+000 - 41+678) On Welkayit Sugar Development Irrigation ProjectDocument12 pagesConstruction of Main Canal and Associated Structures (CH 10+000 - 41+678) On Welkayit Sugar Development Irrigation ProjectgirumNo ratings yet

- Calculo de Diagrama de MasasDocument4 pagesCalculo de Diagrama de MasasYetchan QuiveNo ratings yet

- Calculo de Diagrama de MasasDocument4 pagesCalculo de Diagrama de MasasYetchan Quive50% (2)

- Screen Analysis NotesDocument18 pagesScreen Analysis NotesAbhijit NathNo ratings yet

- Blending For DLCDocument12 pagesBlending For DLCAjit P. SinghNo ratings yet

- SMADocument1 pageSMAvarun persadNo ratings yet

- CGT21027 30APR HomeworkDocument7 pagesCGT21027 30APR HomeworkBhargav D.S.No ratings yet

- Sieve Hyd-ClassDocument2 pagesSieve Hyd-ClassMuh UmaNo ratings yet

- Metrado de Canales (Autoguardado)Document11 pagesMetrado de Canales (Autoguardado)luis enrique quispe quispeNo ratings yet

- Radar Pulse CompressionDocument19 pagesRadar Pulse Compressionmalek1p2No ratings yet

- Bgy. Poblacion SwaDocument33 pagesBgy. Poblacion SwaKim simyunnNo ratings yet

- Carbon BlackDocument15 pagesCarbon BlackBoonyarit Lurdgrienggraiying100% (1)

- Class B Output: Jeremy HeersinkDocument10 pagesClass B Output: Jeremy Heersinkdummy1957jNo ratings yet

- ECG553 Week 10-11 Deep Foundation PileDocument132 pagesECG553 Week 10-11 Deep Foundation PileNUR FATIN SYAHIRAH MOHD AZLINo ratings yet

- OneTen-Frontend Web Development FundamentalsDocument5 pagesOneTen-Frontend Web Development FundamentalsOkpetah Chioma christabelNo ratings yet

- Hypothesis Testing in Stata PDFDocument9 pagesHypothesis Testing in Stata PDFMarisela FuentesNo ratings yet

- Ebook Remote Server ManagementDocument10 pagesEbook Remote Server ManagementPiruletoNo ratings yet

- Scalping Forex With Bollinger BandDocument27 pagesScalping Forex With Bollinger BandHeru SetiawanNo ratings yet

- 2 EesyllDocument77 pages2 EesyllDileepNo ratings yet

- Java Programming For BSC It 4th Sem Kuvempu UniversityDocument52 pagesJava Programming For BSC It 4th Sem Kuvempu UniversityUsha Shaw100% (1)

- Angle Chase As PDFDocument7 pagesAngle Chase As PDFNM HCDENo ratings yet

- Practice Test Paper-2 - IJSODocument11 pagesPractice Test Paper-2 - IJSOSonal Gupta100% (5)

- Norma Astm d5731 PLTDocument6 pagesNorma Astm d5731 PLTrodriahumNo ratings yet

- An Experimental and Statistical Study of Olfactory PreferencesDocument7 pagesAn Experimental and Statistical Study of Olfactory Preferencesjungseong parkNo ratings yet

- INOI 2012 Question PaperDocument6 pagesINOI 2012 Question PaperShourya BoseNo ratings yet

- 30 MT Tyre Mounted Crane SpecificationsDocument4 pages30 MT Tyre Mounted Crane SpecificationsramyaNo ratings yet

- Crop Productivity Aroma Profile and Antioxidant Activity in Pelargonium Graveolens L-H-R Under inDocument7 pagesCrop Productivity Aroma Profile and Antioxidant Activity in Pelargonium Graveolens L-H-R Under inNo VivoNo ratings yet

- What Is Not Said: Metaphor and The Deflationary Account: Chris GenovesiDocument13 pagesWhat Is Not Said: Metaphor and The Deflationary Account: Chris GenovesimiprofesorjaviNo ratings yet

- Act std3Document7 pagesAct std3Helen B. EvansNo ratings yet

- Life Sciences Grade 10 ATP 2024Document19 pagesLife Sciences Grade 10 ATP 2024olwe149No ratings yet

- Siegel57Nonparametric PDFDocument8 pagesSiegel57Nonparametric PDFTarisna AryantiNo ratings yet

- Escape Velocity PDFDocument5 pagesEscape Velocity PDFRatriNo ratings yet

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarNo ratings yet

- Datasheet ECM 5158 Interface 4pgv1 A80401 PressDocument4 pagesDatasheet ECM 5158 Interface 4pgv1 A80401 Presslgreilly4No ratings yet

- Spicer Info - AXSM-8663 PDFDocument28 pagesSpicer Info - AXSM-8663 PDFRay Ayala100% (1)

- Flight Inspection of GAST D Approach and Taxi Guidance Systems - v1Document10 pagesFlight Inspection of GAST D Approach and Taxi Guidance Systems - v1Olivier LaylyNo ratings yet

- UNIT - 3: Fast-Fourier-Transform (FFT) Algorithms: Dr. Manjunatha. PDocument100 pagesUNIT - 3: Fast-Fourier-Transform (FFT) Algorithms: Dr. Manjunatha. PMVRajeshMaliyeckalNo ratings yet

- Velocity Analysis-Instantaneous Center MDocument7 pagesVelocity Analysis-Instantaneous Center MSuman_SamadderNo ratings yet

- Foundations of Nonlinear Algebra (John Perry)Document425 pagesFoundations of Nonlinear Algebra (John Perry)Tao-Wei HuangNo ratings yet