Professional Documents

Culture Documents

Historical and Technological Study of The 26 and 30 Mechanisms 223

Uploaded by

Ari SudrajatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Historical and Technological Study of The 26 and 30 Mechanisms 223

Uploaded by

Ari SudrajatCopyright:

Available Formats

Historical and Technological Study of the 26 and 30 Mechanisms 223

For the analysis, the contour conditions (distributed and point loads, supports,

materials, etc.) are applied to the model, the meshing is arranged and, then, the analysis

can be carried out, obtaining the corresponding results.

7.1 Figure 30. The Clock of the Small Stones

The part to analyze is the main shaft, with hand and gearwheel. It is the most vulnerable

part because it is in motion all the time.

As we can see in Fig. 10, we assign fixed supports and then insert the loads, two on

the sides, where the shaft is fixed to the main structure and, one, on the small wheel,

which is pulled by the buoy. Then, we can obtain a mesh and analyze both defor-

mations and stresses.

Fig. 10. Main shaft with hand and gearwheel of the clock water

The material of this whole part is pine wood, with a Young’s modulus of about

7000 MPa. This value can vary according to the type of wood used.

We analyze the Von Mises stresses, the part is deformed just a little since the

structure weighs very little. But, nevertheless, we appreciate that the area more prone to

stresses is on both sides of the gearwheel, in red color, as we can see in Fig. 11.

Fig. 11. Von Mises stresses in the main shaft of the water clock

7.2 Figure 26. Mechanical Well

For the well, one of the six wooden joists that form the main structure will be analyzed.

They contain the different shafts in vertical position.

224 S. Torres-Garrido et al.

First, the fixed supports are set. In this case, they are placed at the ends of the beam.

Subsequently, a load is inserted downwards, which is the shaft with gearwheels. This

one has very little mass so, the deformation will be minimal (Fig. 12).

Fig. 12. Wooden beam deformation of the main structure of the mechanical well

The material assigned is pine, we can appreciate the Von Mises stresses being the

most vulnerable area, just the center of the beam, where the load is placed. We can

appreciate the reddish colors in Fig. 13.

Fig. 13. Deformation and Von Mises stresses in the wooden beam of the main structure of the

mechanical well. (Color figure online)

8 Three-Dimensional Reconstruction

For the three-dimensional reconstruction at scale, we have chosen not to use any

manufacturing method, such as molds, machining (lathe, milling machine, etc.) or the

novel 3D printing. In addition, because they are machines of the Middle Ages, to build

prototypes to scale of the mechanical devices, common materials have been used as

wood, plastic and iron, which work with water.

The materials used are: wood, for the main structures, beams, shafts, details,

gearwheels; metal, for the brackets to join wooden beams, screws, pulleys; plastic, for

the water tanks, figure that throws the balls in the clock; thread, for the ropes. To join

the parts, it was chosen white glue or, in some cases, screwing to give greater strength,

and avoid possible breakage (Figs. 14 and 15).

You might also like

- Tri-Horse Builders PlansDocument12 pagesTri-Horse Builders PlansEucap Mdz97% (32)

- The Messeturm in Rostock - A Tensegrity Tower by SchlaichDocument7 pagesThe Messeturm in Rostock - A Tensegrity Tower by SchlaichTensegrity Wiki0% (1)

- FINITE ELEMENT 18ME73 ASSIGNMENTSDocument10 pagesFINITE ELEMENT 18ME73 ASSIGNMENTSFOODIE USNo ratings yet

- Elliptical Trammel Report 25-01-19Document16 pagesElliptical Trammel Report 25-01-19I'm the oneNo ratings yet

- ASME HST-1 - Performance Standard For Electric Chain Hoists (2012) PDFDocument32 pagesASME HST-1 - Performance Standard For Electric Chain Hoists (2012) PDFMuhammad AriqNo ratings yet

- Regrinding Mfe En-GlDocument7 pagesRegrinding Mfe En-GlGanga Dhar100% (1)

- 6 Assembly: 222 S. Torres-Garrido Et AlDocument2 pages6 Assembly: 222 S. Torres-Garrido Et AlAri SudrajatNo ratings yet

- Lab3testingfinish 171218033623Document29 pagesLab3testingfinish 171218033623jahremade jahremadeNo ratings yet

- Retrofitting RC frames with buckling restrained bracesDocument6 pagesRetrofitting RC frames with buckling restrained bracesHectoreRodriguezlNo ratings yet

- Development and Testing of Timber/concrete Shear Connectors: Typical Bridge Cross SectionDocument8 pagesDevelopment and Testing of Timber/concrete Shear Connectors: Typical Bridge Cross SectionAkbarNo ratings yet

- University of BaghdadDocument13 pagesUniversity of BaghdadDiyar NezarNo ratings yet

- ORIGAMI - Folded Plate Structures, EngineeringDocument7 pagesORIGAMI - Folded Plate Structures, EngineeringNabila Febitsukarizky BunyaminNo ratings yet

- On The Plastic Design of Timber Beams With A Complex Cross-SectionDocument7 pagesOn The Plastic Design of Timber Beams With A Complex Cross-SectionBorce StoilovskiNo ratings yet

- Reinforced Timber BeamsDocument5 pagesReinforced Timber BeamsbertinNo ratings yet

- Modeling Repaired Composite StructuresDocument14 pagesModeling Repaired Composite StructuresVicky VigneshNo ratings yet

- Finite Element Analysis of Ribbed DomeDocument8 pagesFinite Element Analysis of Ribbed DomeVishal Patel100% (1)

- Prestressed Concrete BridgesDocument19 pagesPrestressed Concrete BridgesizatyNo ratings yet

- A3 FEA of A Simple Cantilever BeamDocument6 pagesA3 FEA of A Simple Cantilever BeamDavid LamNo ratings yet

- Short Proposal Finite ElementDocument9 pagesShort Proposal Finite ElementMuhammad Ilham ZulkipllyNo ratings yet

- Steel Strucsdftures 3 - Composite Structures - Lecture Notes Chapter 10.2Document22 pagesSteel Strucsdftures 3 - Composite Structures - Lecture Notes Chapter 10.2iSoK11No ratings yet

- Composite Truss BridgesDocument6 pagesComposite Truss Bridgeszepedro_fernandes100% (1)

- New dimension for timber ripped shells with EXPO-roof in HanoverDocument8 pagesNew dimension for timber ripped shells with EXPO-roof in HanoverMariana RobuNo ratings yet

- Mom Lab ProposalDocument5 pagesMom Lab ProposalSyed Suleman Ayub - Section-BNo ratings yet

- Interlocking Folded Plate - SmallDocument13 pagesInterlocking Folded Plate - SmallClaudia TrifNo ratings yet

- EXPOSED COLUMN BASE PLATE CONNECTIONSDocument5 pagesEXPOSED COLUMN BASE PLATE CONNECTIONSsurafel abebawNo ratings yet

- Technical Note On Analysis of Support Structure - V2.1Document18 pagesTechnical Note On Analysis of Support Structure - V2.1unnicyriacNo ratings yet

- 52 Structure New PDFDocument7 pages52 Structure New PDFVino EngineeringNo ratings yet

- tmp705 TMPDocument17 pagestmp705 TMPFrontiersNo ratings yet

- Finite Element Study of Using Concrete Tie Beams to Reduce Differential SettlementDocument5 pagesFinite Element Study of Using Concrete Tie Beams to Reduce Differential SettlementrbalmodalNo ratings yet

- Box Girder 3D FEADocument8 pagesBox Girder 3D FEAJD OngNo ratings yet

- Static Linear Analysis For Trusses Structure For SDocument10 pagesStatic Linear Analysis For Trusses Structure For SMinh Nhật VuNo ratings yet

- Strand7 Roofrack AssignmentDocument17 pagesStrand7 Roofrack AssignmentJoel Forbes100% (1)

- Study On Cantilever Beam Diffraction in SolidWorksDocument7 pagesStudy On Cantilever Beam Diffraction in SolidWorksJiya MakwanaNo ratings yet

- Steel Connection Failure ModesDocument22 pagesSteel Connection Failure ModesJoshua CalaNo ratings yet

- Cold-Formed Steel Design by Spreadsheet Program: Scholars' MineDocument19 pagesCold-Formed Steel Design by Spreadsheet Program: Scholars' MineRaineir PabiranNo ratings yet

- Maximizing Composite Beam Stiffness in 4-Point BendingDocument5 pagesMaximizing Composite Beam Stiffness in 4-Point BendingqtaccNo ratings yet

- Section ModulusDocument5 pagesSection ModulusKam LauNo ratings yet

- Additional Column NotesDocument13 pagesAdditional Column NotesDaryl Gomez TimatimNo ratings yet

- The Savill Garden Gridshell Design and ConstructionDocument7 pagesThe Savill Garden Gridshell Design and ConstructionAlex RastyNo ratings yet

- Rock Mass Tunnel Support AnalysisDocument2 pagesRock Mass Tunnel Support AnalysisSanjoy SanyalNo ratings yet

- Cyclic Strut & Tie Modelling of Simple Reinforced Concrete StructuresDocument8 pagesCyclic Strut & Tie Modelling of Simple Reinforced Concrete StructuresGloomsyNo ratings yet

- Experimental Programme: (I'M Not Yet Sure But 1-1.5 MM)Document7 pagesExperimental Programme: (I'M Not Yet Sure But 1-1.5 MM)Pucho RecleNo ratings yet

- 2002 FIB SegmentDocument6 pages2002 FIB SegmentaapennsylvaniaNo ratings yet

- Analysis and Optimization of A Composite Leaf Spring: Mahmood M. Shokrieh, Davood RezaeiDocument9 pagesAnalysis and Optimization of A Composite Leaf Spring: Mahmood M. Shokrieh, Davood RezaeiVipin ShuklaNo ratings yet

- Tensile Structures: How They Work and Common TypesDocument10 pagesTensile Structures: How They Work and Common Typesaditya2053No ratings yet

- (23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion SpringsDocument6 pages(23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion Springsstefan.vince536No ratings yet

- 2 CFBDocument10 pages2 CFBN. P. JAGANNo ratings yet

- 020410340Document4 pages020410340Manikandan NagaNo ratings yet

- Desing Methods With Yielding SupportDocument13 pagesDesing Methods With Yielding SupportSriram NambiNo ratings yet

- Performance Criteria For Dissipative Steel Plate Shear Walls StructuresDocument8 pagesPerformance Criteria For Dissipative Steel Plate Shear Walls StructuresgiorgosantzelidisNo ratings yet

- Friction of Wood On Steel 3Document10 pagesFriction of Wood On Steel 3musebladeNo ratings yet

- 3-KY Tshai Et Al SDHDocument8 pages3-KY Tshai Et Al SDHAnonymous P8Bt46mk5INo ratings yet

- Mechanics of Materials Lab Lab #1 Tension Test of Metals Lab January 28, 2011 Team AluminumDocument9 pagesMechanics of Materials Lab Lab #1 Tension Test of Metals Lab January 28, 2011 Team Aluminumpianoplyr24No ratings yet

- Pedestrian BridgeDocument5 pagesPedestrian BridgeLe Xuan Hung100% (1)

- International Conference on Steel, Space and Composite Structures Parameters Design Optimisation Anchor JointDocument10 pagesInternational Conference on Steel, Space and Composite Structures Parameters Design Optimisation Anchor JointMiguel Rivera100% (1)

- Design of joints in segmental hollow box girder bridgesDocument6 pagesDesign of joints in segmental hollow box girder bridgesPunithan PunithanNo ratings yet

- The Behaviour of Composite BeamsDocument19 pagesThe Behaviour of Composite BeamssvnNo ratings yet

- AS4100 Standard Grades and SectionsDocument49 pagesAS4100 Standard Grades and SectionsKevin BaxterNo ratings yet

- Failure Analysis of A Coupled Shaft From A Shredder: Luis.g.reis@tecnico - Ulisboa.ptDocument12 pagesFailure Analysis of A Coupled Shaft From A Shredder: Luis.g.reis@tecnico - Ulisboa.ptMulugetaNo ratings yet

- Journal of Constructional Steel Research: E.L. Tan, B. UyDocument10 pagesJournal of Constructional Steel Research: E.L. Tan, B. UyvenkatesanjsNo ratings yet

- XXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkFrom EverandXXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkNo ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- 2013 Bookmatter TheatrePerformanceAndAnalogueTDocument19 pages2013 Bookmatter TheatrePerformanceAndAnalogueTAri SudrajatNo ratings yet

- Étude Du Traité de Radwan Al-Sa'ati - Muslim HeritageMuslim HeritageDocument23 pagesÉtude Du Traité de Radwan Al-Sa'ati - Muslim HeritageMuslim HeritageAri SudrajatNo ratings yet

- Astronomy As A Global Science - The Case of Islamic Astronomy - Muslim HeritageMuslim HeritageDocument5 pagesAstronomy As A Global Science - The Case of Islamic Astronomy - Muslim HeritageMuslim HeritageAri SudrajatNo ratings yet

- From Frankfurt and Cairo To Damascus - Recent Models of The Umayyad Mosque Clock - Muslim HeritageMuslim HeritageDocument7 pagesFrom Frankfurt and Cairo To Damascus - Recent Models of The Umayyad Mosque Clock - Muslim HeritageMuslim HeritageAri SudrajatNo ratings yet

- Al-Zarqali (Arzachel) - Muslim HeritageMuslim HeritageDocument1 pageAl-Zarqali (Arzachel) - Muslim HeritageMuslim HeritageAri SudrajatNo ratings yet

- On Serlio's Constructions of Ovals: Paul L. Rosin Department of Computer Science Cardiff University UKDocument15 pagesOn Serlio's Constructions of Ovals: Paul L. Rosin Department of Computer Science Cardiff University UKAri SudrajatNo ratings yet

- The University of Chicago Press The History of Science SocietyDocument18 pagesThe University of Chicago Press The History of Science SocietyAri SudrajatNo ratings yet

- Al-Jazari and The Castle Clock - Muslim HeritageMuslim HeritageDocument3 pagesAl-Jazari and The Castle Clock - Muslim HeritageMuslim HeritageAri SudrajatNo ratings yet

- Building A Model Astrolabe: Dominic FordDocument17 pagesBuilding A Model Astrolabe: Dominic FordAri SudrajatNo ratings yet

- Gears Inside of GearsDocument3 pagesGears Inside of GearsAri SudrajatNo ratings yet

- The Astrolabe For Latitude 41 Un of Simeon de Witt: An Early American Celestial PlanisphereDocument8 pagesThe Astrolabe For Latitude 41 Un of Simeon de Witt: An Early American Celestial PlanisphereAri SudrajatNo ratings yet

- Water-Clocks and Time Measurement in Classical Antiquity: J. G. LandelsDocument6 pagesWater-Clocks and Time Measurement in Classical Antiquity: J. G. LandelsAri SudrajatNo ratings yet

- Observations of planets with the Danjon astrolabeDocument14 pagesObservations of planets with the Danjon astrolabeAri SudrajatNo ratings yet

- The Liber Theoreumacie (1214) and The Early History of The: Quadrans VetusDocument24 pagesThe Liber Theoreumacie (1214) and The Early History of The: Quadrans VetusAri SudrajatNo ratings yet

- The Book as a Scientific InstrumentDocument3 pagesThe Book as a Scientific InstrumentAri SudrajatNo ratings yet

- Single Action Army, SAA, Model P, PeacemakerDocument13 pagesSingle Action Army, SAA, Model P, PeacemakerAri SudrajatNo ratings yet

- The Guns of ConstantinopleDocument14 pagesThe Guns of ConstantinopleAri SudrajatNo ratings yet

- Sa 1Document3 pagesSa 1Ari SudrajatNo ratings yet

- Clock of The Small StonesDocument14 pagesClock of The Small StonesAri SudrajatNo ratings yet

- Sa 3Document3 pagesSa 3Ari SudrajatNo ratings yet

- 220 S. Torres-Garrido Et AlDocument2 pages220 S. Torres-Garrido Et AlAri SudrajatNo ratings yet

- Historical and Technological Study of The 26 and 30 Mechanisms 215Document3 pagesHistorical and Technological Study of The 26 and 30 Mechanisms 215Ari SudrajatNo ratings yet

- 6 Assembly: 222 S. Torres-Garrido Et AlDocument1 page6 Assembly: 222 S. Torres-Garrido Et AlAri SudrajatNo ratings yet

- 224 S. Torres-Garrido Et Al.: 8 Three-Dimensional ReconstructionDocument3 pages224 S. Torres-Garrido Et Al.: 8 Three-Dimensional ReconstructionAri SudrajatNo ratings yet

- Sa 4Document2 pagesSa 4Ari SudrajatNo ratings yet

- Mechanical WellDocument12 pagesMechanical WellAri SudrajatNo ratings yet

- LEONARDO3 - Ahmad Ibn Khalaf Al-Murādī - BOOK OF SECRETSDocument3 pagesLEONARDO3 - Ahmad Ibn Khalaf Al-Murādī - BOOK OF SECRETSAri SudrajatNo ratings yet

- Leonardo3 - The Book of Secret - Doha - QatarDocument6 pagesLeonardo3 - The Book of Secret - Doha - QatarAri SudrajatNo ratings yet

- Condenser Br-Coi: Operating InstructionsDocument50 pagesCondenser Br-Coi: Operating Instructionslalit kashyap0% (1)

- Mini grinder manualDocument12 pagesMini grinder manualNeil MenezesNo ratings yet

- B31.3, Process Piping 1Document1 pageB31.3, Process Piping 1Jason FlowersNo ratings yet

- Bearing Isolator: Steam Turbine - Low TempDocument1 pageBearing Isolator: Steam Turbine - Low Tempbincoleto5536No ratings yet

- OFFSET TABLEDocument1 pageOFFSET TABLEdavid burianNo ratings yet

- Ensamble Conformadora de Chapa ExplotadaDocument1 pageEnsamble Conformadora de Chapa ExplotadaNacho ZelaliaNo ratings yet

- Functional Gage DesignDocument32 pagesFunctional Gage DesignnaveedsidhuNo ratings yet

- 6x36WS (Warrington Seale) - 6x19 & 6x36 Classification Wire RopeDocument2 pages6x36WS (Warrington Seale) - 6x19 & 6x36 Classification Wire RopeTawfiq ZidanNo ratings yet

- Actuador Valtek PDFDocument8 pagesActuador Valtek PDFEduardo Landa GonzalezNo ratings yet

- 04 Box CulvertDocument164 pages04 Box CulvertBagyaLakshmiNo ratings yet

- Kop-Grid Couplings: Table No. 4 Kop-Grid Couplings - Hubs, Grid, Cover, Seal and Fastener KitsDocument2 pagesKop-Grid Couplings: Table No. 4 Kop-Grid Couplings - Hubs, Grid, Cover, Seal and Fastener Kitsvictor perdomoNo ratings yet

- NA Region EHS Standard Manual LiftingDocument16 pagesNA Region EHS Standard Manual LiftingMarthaNo ratings yet

- Advanced Building Construction: Tubular Truss (Scale 1:20) ElevationDocument1 pageAdvanced Building Construction: Tubular Truss (Scale 1:20) ElevationPankaj DhakedNo ratings yet

- Storz ManualDocument7 pagesStorz Manualhijodebudas100% (1)

- ValvesDocument35 pagesValvescaseyNo ratings yet

- Thread Types - James Glen PDFDocument7 pagesThread Types - James Glen PDFVikranth ReddyNo ratings yet

- Table of Specification: Caraga State UniversityDocument2 pagesTable of Specification: Caraga State UniversityJsy LangNo ratings yet

- Full Tilt Feller PDFDocument13 pagesFull Tilt Feller PDFViniciusCamargosNo ratings yet

- API 6A RequirementsDocument34 pagesAPI 6A RequirementsAmol100% (1)

- Diagnostic Assessment B3 (SEC) - November 2022Document4 pagesDiagnostic Assessment B3 (SEC) - November 2022Yoshjordan LambNo ratings yet

- 2017 CATALOG: Pumps & AccessoriesDocument108 pages2017 CATALOG: Pumps & AccessoriesΓιωργος ΠαπαιωαννουNo ratings yet

- KAS 81,000,000 Pengeluaran 1. Beli Items 53,900,000 95.6% 2. Transport JKT 2,500,000 4.4% 3. Fee 4,050,000 7.2% Total Pengeluaran SisaDocument4 pagesKAS 81,000,000 Pengeluaran 1. Beli Items 53,900,000 95.6% 2. Transport JKT 2,500,000 4.4% 3. Fee 4,050,000 7.2% Total Pengeluaran SisabettafNo ratings yet

- BN655 M3X8Document1 pageBN655 M3X8Murari VenkateswarNo ratings yet

- Operating Manual Cyto-Tek 2500 Cytocentrifuge (GB)Document44 pagesOperating Manual Cyto-Tek 2500 Cytocentrifuge (GB)MOHAMMADNo ratings yet

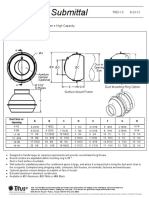

- TND-AA SubmittalDocument1 pageTND-AA Submittalhector tosarNo ratings yet

- T285RevF - 69NT40 511 300 309 311 343 345 399 PDFDocument121 pagesT285RevF - 69NT40 511 300 309 311 343 345 399 PDFSerhiiNo ratings yet