Professional Documents

Culture Documents

SMD Chip Chokes: Pe - 1210Ccmc Xxxs T S

Uploaded by

Bruno LeppeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMD Chip Chokes: Pe - 1210Ccmc Xxxs T S

Uploaded by

Bruno LeppeCopyright:

Available Formats

SMD CHIP CHOKES

Wire-Wound Series

Wire wound Ferrite 1210 (3225) core

Common Mode Noise suppression without

attenuating the signal

Magnetically shielded for low Rdc and High

Current

Perfect for USB2.0/3.0, IEEE1349 Fire wire

and other LVDS lines

Ideal for DC voltage supply lines for Power

over Ethernet -PoE/PoE+

PART NUMBER LEGEND

PE —1210CCMC XXXS T S

TERMINATION

PACKAGE STYLE IMPEDANCE

1210 S = Tin plating

Representative of

the impedance

value

CORE MATERIAL/RANGE

CCMC - FERRITE CHIP CHOKE STYLE PACKAGING

S = Standard Range T = Tape & Reel

Reel Size

Parts per Reel = 3000

1 Networking.PulseElectronics.com W719.A (7/18)

WIRE-WOUND CHIP CHOKES

SPECIFICATION

Electrical Specifications @ 25°C

Common Mode DC Rated Rated Withstanding Insulation

Part Number

Impedance Resistance Voltage Current Voltage Resistance

(25%)

@ 100MHz (Ω) (Ω MAX) (Vdc) (mA MAX) (Vdc) (MΩ MIN)

PE-1210CCMC161STS 160 0.15 50 680 125 10

PE-1210CCMC271STS 270 0.25 50 640 125 10

PE-1210CCMC601STS 600 0.12 50 1000 125 10

PE-1210CCMC102STS 1000 0.35 50 480 125 10

Mechanical

1.8

3.2 2.5

4.00

(0.8)

0.9 2.70

(0.8)

0.9 2.20 0.9

Impedance vs Frequency

10000

COMMON MODE

1000 PRODUCT KEY

PE-1210CCMC161STS

PE-1210CCMC271STS

Impedance (Ω)

100 PE-1210CCMC601STS

PE-1210CCMC102STS

10

1

DIFFERENTIAL MODE

0.1

1 10 100 1000 10000

Frequency (MHz)

2 Networking.PulseElectronics.com W719.A (7/18)

WIRE-WOUND CHIP CHOKES

PERFORMANCE TESTING

Electrical Testing

Storage and Operating Inductors are subjected to the

Temperature Range: extremes for 48 hours.

-40° to +85°C Then tested at 25°C There shall be no deformation

or change in appearance

Inductors are subjected to 30 cycles

Thermal:

for 30 minutes at each extreme. Inductance shall not change

-40° to +85°C by more than ±5%

Then tested at 25°C

Inductors are subjected to Q values shall not change

10 cycles of 24 hours at 70°C with by more than ±10%

Moisture Resistance 90 to 95% Relative Humidity

Then tested at 25°C

Inductors are subjected to

1000 hours at 85°C with 85% There shall be no Damaged,

Operating Life

Relative Humidity with Open or Shorted Windings

the rated current applied

Mechanical Testing

There shall be no deformation

or change in appearance

Inductors are subjected to the following:

Inductance shall not change

Temperature Range: Use a solder pot at 260C, with RMA Flux. Each

termination is immersed in 63Sn/37Pb molten solder by more than ±5%

for 4 to 6 seconds.

Q values shall not change

by more than ±10%

Recommended Solder

Heat Resistance Profile

3 Networking.PulseElectronics.com W719.A (7/18)

WIRE-WOUND CHIP CHOKES

TAPE AND REEL SPECIFICATIONS

12.8

2.3 + 0.2/-0

330

100

13.0

2.2

Parts per Tape Dimensions (mm)

Series

Reel W P1 P2 P3 H T

1210CCMC 3000 12 2 8 4 2.3 0.3

For More Information:

Americas - prodinfonetworkamericas@pulseelectronics.com | Europe - comms-Apps-Europe@pulseelectronics.com | Asia - prodinfonetworkapac@pulseelectronics.com

Performance warranty of products offered on this data sheet is limited to the parameters specified. Data is subject to change without notice. Other brand and product names mentioned herein may

be trademarks or registered trademarks of their respective owners. © Copyright, 2019. Pulse Electronics, Inc. All rights reserved.

4 Networking.PulseElectronics.com W719.A (7/18)

You might also like

- Cheap TBE Inverter TeardownsDocument33 pagesCheap TBE Inverter TeardownsWar Linux92% (12)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Transformer Design and Manufacturing Manual - Robert G. Wolpert (2004)Document130 pagesTransformer Design and Manufacturing Manual - Robert G. Wolpert (2004)jimmy67music100% (4)

- EV Charger - Application NoteDocument4 pagesEV Charger - Application Noteமுருகன்No ratings yet

- 3-Voltmeter Method of Measuring Choke Coil ParametersDocument5 pages3-Voltmeter Method of Measuring Choke Coil Parametersanjanbs100% (1)

- App Note EMC Filter Insertion Loss Simulation V1Document26 pagesApp Note EMC Filter Insertion Loss Simulation V1Rohit SainiNo ratings yet

- Amidon - Transmission - Line.transformers - HandbookDocument61 pagesAmidon - Transmission - Line.transformers - HandbookFrancesco Errante100% (3)

- Philips BV-29 - Service ManualDocument5 pagesPhilips BV-29 - Service ManualYoussef0% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- The Effects and Reduction of Common-Mode Noise and Electromagnetic Interference in High - Resolution Digital Audio Transmission SystemsDocument33 pagesThe Effects and Reduction of Common-Mode Noise and Electromagnetic Interference in High - Resolution Digital Audio Transmission Systemss3tupNo ratings yet

- User Manual 1374484Document12 pagesUser Manual 1374484gutierkNo ratings yet

- DC Components Co., LTD.: RL201 Thru RL207Document3 pagesDC Components Co., LTD.: RL201 Thru RL207cclodoaldo1577No ratings yet

- Smp50 / Smtpa / Tpa: Trisil™ For Telecom Equipment ProtectionDocument11 pagesSmp50 / Smtpa / Tpa: Trisil™ For Telecom Equipment ProtectionUdayantha WithanaNo ratings yet

- SB5150 THRU SB5200: Schottky Barrier RectifierDocument2 pagesSB5150 THRU SB5200: Schottky Barrier RectifierCube7 GeronimoNo ratings yet

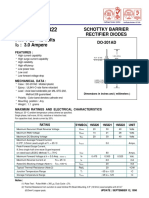

- SB5150 SB5200: Schottky Barrier Rectifier Diodes PRV: 150 200 Volts I: 5.0 AmperesDocument2 pagesSB5150 SB5200: Schottky Barrier Rectifier Diodes PRV: 150 200 Volts I: 5.0 AmperesRafael LehmkuhlNo ratings yet

- DOC000758182Document2 pagesDOC000758182Oleg ShevchenkoNo ratings yet

- THT Current Sense Transformers & InductorsDocument3 pagesTHT Current Sense Transformers & InductorschristianNo ratings yet

- DatasheetDocument2 pagesDatasheetRobmelNo ratings yet

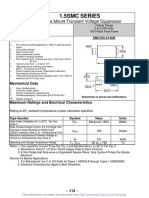

- 1.5Smc Series: Surface Mount Transient Voltage SuppressorDocument4 pages1.5Smc Series: Surface Mount Transient Voltage SuppressorHisham MohamedNo ratings yet

- DC Components Co., LTD.: S2A Thru S2MDocument2 pagesDC Components Co., LTD.: S2A Thru S2MCastro G. LombanaNo ratings yet

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener DiodesDocument2 pages1N5342 THRU 1N5388: 5W Silicon Planar Zener DiodesLeandroNo ratings yet

- E210, ES210, & EA210 Military Specified: General CharacteristicsDocument6 pagesE210, ES210, & EA210 Military Specified: General CharacteristicsNalex1No ratings yet

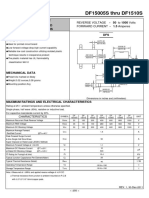

- DF1506S Hyecs00447-1Document2 pagesDF1506S Hyecs00447-1trantungson80No ratings yet

- 1N5342 Thru 1N5388Document3 pages1N5342 Thru 1N5388Juan Manuel Briones GarciaNo ratings yet

- Erc01 10Document2 pagesErc01 10WonshikNo ratings yet

- Dss12u Thru Dss125u N1873 Rev.aDocument4 pagesDss12u Thru Dss125u N1873 Rev.ayovoc13121No ratings yet

- ESDH12VD1Document5 pagesESDH12VD1EduardoPassosNo ratings yet

- Technical Data Sheet 1206 Package Phototransistor With Inner LensDocument10 pagesTechnical Data Sheet 1206 Package Phototransistor With Inner LenschauNo ratings yet

- Data Sheet: ER500 ER506Document2 pagesData Sheet: ER500 ER506Thành nguyễn ĐứcNo ratings yet

- Data Sheet: P6Smb SeriesDocument4 pagesData Sheet: P6Smb SeriesZiritt Duran DavidNo ratings yet

- Formosa MS: 1N4728A THRU 1N4764ADocument7 pagesFormosa MS: 1N4728A THRU 1N4764ARiko HusinNo ratings yet

- sk13 DiodeDocument3 pagessk13 DiodeДрагиша Небитни ТрифуновићNo ratings yet

- 10a05 Won TopDocument4 pages10a05 Won TopwakawuluhNo ratings yet

- Datasheet 1N5220Document4 pagesDatasheet 1N5220LAB14 B1No ratings yet

- DC Components Co., LTD.: 10A05 Thru 10A10Document3 pagesDC Components Co., LTD.: 10A05 Thru 10A10Faulhaber AdrianNo ratings yet

- 1.5KE Series: Silicon Avalanche DiodesDocument4 pages1.5KE Series: Silicon Avalanche DiodesPsyplant PsytranceNo ratings yet

- BAV99W (Pan Jit 強茂)Document2 pagesBAV99W (Pan Jit 強茂)c8831116No ratings yet

- Features: Maximum Ratings and Electrical CharacteristicsDocument2 pagesFeatures: Maximum Ratings and Electrical CharacteristicsJOHN BRICCO A. MATACSILNo ratings yet

- CHIPSESDDocument6 pagesCHIPSESDdexkezzNo ratings yet

- Schottky Barrier Rectifier Diodes PRV: 20 - 40 Volts I: 3.0 AmpereDocument3 pagesSchottky Barrier Rectifier Diodes PRV: 20 - 40 Volts I: 3.0 AmpereWalther EstevezNo ratings yet

- Datasheet 1.5SMC11Document4 pagesDatasheet 1.5SMC11Daniel Arcia JiménezNo ratings yet

- Flyback Transformers For 25Watt Poe Application: 遠見電子股份有限公司 Providence Electronics CorpDocument2 pagesFlyback Transformers For 25Watt Poe Application: 遠見電子股份有限公司 Providence Electronics Corpwxzcldw163.comNo ratings yet

- Fairchild Semiconductor-Qsd123-DatasheetDocument4 pagesFairchild Semiconductor-Qsd123-Datasheetapi-349977362No ratings yet

- DC Components Co., LTD.: BZT52C2V4 Thru BZT52C51Document2 pagesDC Components Co., LTD.: BZT52C2V4 Thru BZT52C51Anonymous nC9gpUWPNo ratings yet

- Hermetically Sealed Relay - Ukm300Document20 pagesHermetically Sealed Relay - Ukm300ATR Assistência Técnica (ATR)No ratings yet

- DatasheetDocument2 pagesDatasheetStuxnetNo ratings yet

- 1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-15Document3 pages1N5342 THRU 1N5388: 5W Silicon Planar Zener Diodes Features DO-15DennisSendoyaNo ratings yet

- SK22 THRU S210: Surface Mount Schottky Barrier Rectifier VOLTAGE - 20 To 100 Volts CURRENT - 2.0 AmperesDocument2 pagesSK22 THRU S210: Surface Mount Schottky Barrier Rectifier VOLTAGE - 20 To 100 Volts CURRENT - 2.0 Amperesjose aponteNo ratings yet

- DC Components Co., LTD.: SK22 Thru SK28Document2 pagesDC Components Co., LTD.: SK22 Thru SK28serrano.flia.coNo ratings yet

- W005-W10 - Single-Phase Silicon Bridge Rectifier PDFDocument2 pagesW005-W10 - Single-Phase Silicon Bridge Rectifier PDFIvan LemosNo ratings yet

- ZXM62P02E6: 20V P-Channel Enhancement Mode MosfetDocument8 pagesZXM62P02E6: 20V P-Channel Enhancement Mode MosfetMisael GonzalezNo ratings yet

- 227 110 PDFDocument2 pages227 110 PDFnassarkiNo ratings yet

- DC Components Co., LTD.: SS12 Thru SS1 10Document2 pagesDC Components Co., LTD.: SS12 Thru SS1 10Robinson BangueroNo ratings yet

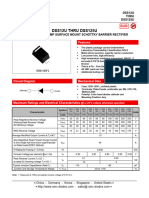

- DC Components Co., LTD.: DB151S Thru DB157SDocument2 pagesDC Components Co., LTD.: DB151S Thru DB157Smegora2007No ratings yet

- 10a10 Rectifier Diode 10a 1000v - 52214Document2 pages10a10 Rectifier Diode 10a 1000v - 52214José Luis Ramos CentenoNo ratings yet

- DB (S) 101G - DB (S) 107G: FeaturesDocument2 pagesDB (S) 101G - DB (S) 107G: FeaturesAdityaJayakarNo ratings yet

- Formosa MS: FM220-LN THRU FM2100-LNDocument2 pagesFormosa MS: FM220-LN THRU FM2100-LNMacraméNo ratings yet

- IS P627 DatasheetDocument2 pagesIS P627 Datasheetucb51525354No ratings yet

- CDBC520-G Thru936922. CDBC5100-G RevC-268425Document5 pagesCDBC520-G Thru936922. CDBC5100-G RevC-268425georgerouseNo ratings yet

- MPSA42 MPSA43: MccsemiDocument4 pagesMPSA42 MPSA43: Mccsemisigit raharjoNo ratings yet

- DatasheetDocument2 pagesDatasheetOlivares Vega Miguel AngelNo ratings yet

- DB101 (DF005) THRU DB107 (DF10) : Glass Passivated Bridge RectifierDocument2 pagesDB101 (DF005) THRU DB107 (DF10) : Glass Passivated Bridge RectifierAwadhNo ratings yet

- SMXXC Series SOT-23 210827Document5 pagesSMXXC Series SOT-23 210827??????No ratings yet

- 1 5smc33a-R6Document8 pages1 5smc33a-R6Faulhaber AdrianNo ratings yet

- RS1D, MDD Диод быстродействующий 1A 200В SMADocument3 pagesRS1D, MDD Диод быстродействующий 1A 200В SMArara221122raraNo ratings yet

- M400 D4N 003Document19 pagesM400 D4N 003Mian FahimNo ratings yet

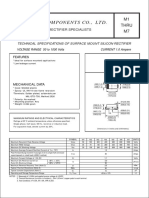

- DC Components Co., LTD.: M1 Thru M7Document2 pagesDC Components Co., LTD.: M1 Thru M7PVALVERDEANo ratings yet

- Datasheet Diode FST RecoveryDocument9 pagesDatasheet Diode FST RecoverybkcapayaniNo ratings yet

- 01B Balun - Reflections 2nd Edition Chapter 21 - Some Aspects of The Balun Problem (By Walter Maxwell W2DU)Document15 pages01B Balun - Reflections 2nd Edition Chapter 21 - Some Aspects of The Balun Problem (By Walter Maxwell W2DU)Fernando Martin100% (1)

- Siemens Micromaster 420 - ManualDocument23 pagesSiemens Micromaster 420 - ManualMarcosNo ratings yet

- Soft Ferrites - 1988Document44 pagesSoft Ferrites - 1988Aurora Parau100% (3)

- Thorn Lighting Electrical TheoryDocument60 pagesThorn Lighting Electrical TheoryRahul MishraNo ratings yet

- K&W BC-20 Charger ManualDocument29 pagesK&W BC-20 Charger ManualDon B Davidson IIINo ratings yet

- Toshiba Manual 59302Document40 pagesToshiba Manual 59302Tim WillformNo ratings yet

- Designing Transformer Slup265Document30 pagesDesigning Transformer Slup265Sheran ShahidNo ratings yet

- Franke Seminar IpohDocument113 pagesFranke Seminar IpohScalperNo ratings yet

- Chapter - 4 Hardware Implementation: Block Diagram Components Ratings Working Theory CalculationsDocument23 pagesChapter - 4 Hardware Implementation: Block Diagram Components Ratings Working Theory CalculationsDr. Gollapalli NareshNo ratings yet

- Diode Det PDFDocument112 pagesDiode Det PDFJaime LazoNo ratings yet

- Common Mode Filter Inductor Analysis: Specifications Subject To Change Without Notice. Document 200-1 Revised 11/19/02Document7 pagesCommon Mode Filter Inductor Analysis: Specifications Subject To Change Without Notice. Document 200-1 Revised 11/19/02debass3No ratings yet

- Power Transformer: (Equipped With Static Shield, Magnetic Shieid)Document5 pagesPower Transformer: (Equipped With Static Shield, Magnetic Shieid)Leonardo MarraffiniNo ratings yet

- Switching Diode Frequency DoublersDocument4 pagesSwitching Diode Frequency DoublersRadmila LugonjicNo ratings yet

- 240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 2 To 250 HPDocument52 pages240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 2 To 250 HPSyed Shahbaz AliNo ratings yet

- GSM Antenna Detection: Application NoteDocument13 pagesGSM Antenna Detection: Application NotesomxNo ratings yet

- MURATA PRODUCTS Global Part NumberingDocument67 pagesMURATA PRODUCTS Global Part Numberingrain.kam86No ratings yet

- LC Filter For DC Motor Hum RemovalDocument7 pagesLC Filter For DC Motor Hum Removalbill_gator20059105No ratings yet

- 50 60hz Inductor DesignDocument5 pages50 60hz Inductor DesignrocaoNo ratings yet

- Lexium 32 & Motors - LXM32MD18M2Document6 pagesLexium 32 & Motors - LXM32MD18M2Muhd SyawalNo ratings yet

- Physics Formula and Notes For Class 12 CBSE Board Chapter 7 ALTERNATING CURRENTDocument11 pagesPhysics Formula and Notes For Class 12 CBSE Board Chapter 7 ALTERNATING CURRENTrahulNo ratings yet

- Indramat - RexrothDocument358 pagesIndramat - RexrothDario FalquezNo ratings yet

- Electronic Components July22Document118 pagesElectronic Components July22Gustavo BritoNo ratings yet