Professional Documents

Culture Documents

Cla-Val: 50B-4KG1 / 2050B-4KG1

Uploaded by

Nazrul IslamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cla-Val: 50B-4KG1 / 2050B-4KG1

Uploaded by

Nazrul IslamCopyright:

Available Formats

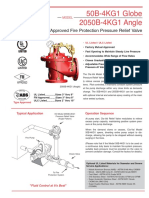

CLA-VAL 50B-4KG1 / 2050B-4KG1

Fire Protection Pressure Relief Valve

` Simple, Reliable and Accurate

x U.L. Listed

x Factory Mutual Approved

x Fast Opening to Maintain Steady Line Pressure

x Accommodates Wide Range of Flow Rates

x Closes Gradually for Surge-Free Operation

x Adjustable Pressure Settings, not Affected by

Pressure at Valve Discharge

50B-4KG1 (Globe)

The CLA-VAL Model 50B-4KG1 Globe / 2050B-4KG1

Angle Pressure Relief Valve is designed specifically to

automatically relieve excess pressure in fire protection

pumping systems. Pilot controlled, it maintains constant

system pressure at the pump discharge within very

close limits as demands change.

U.L. Listed Sizes 3" thru 8"

F.M. Approved Sizes 3" thru 8"

2050B-4KG1 (Angle)

` Typical Application

Operation Sequence:

At pump start, CLA-VAL Relief Valve modulates to

relieve excess pump capacity, maintaining positive

system pressure at the pump discharge.

When fire demand slows or ceases, CLA-VAL Model

50B-4KG1 opens, diverting entire pump output to

discharge, allowing fire pump to be stopped without

causing surging in the lines.

Fire Pump

(Please note that if the Model 50B-4KG1 is to be

used on a continuous duty basis to maintain fire-

system pressure, suitable back pressure must be

provided on the valve to prevent cavitation damage.

Consult the factory for details.)

` Valve Capacity

Valve size (mm) 50 65 80 100 150 200 250 300

NFPA 20 Pump Rating

250 300 500 1000 2500 5000 11000 16000

(GPM)

` CLA-VAL Europe www.cla-val.ch cla-val@cla-val.ch 1 - 050100DE C 02/10

© Copyright CLA-VAL Europe - Specifications subject to change without notice - no contractual illustrations.

CLA-VAL 50B-4KG1 / 2050B-4KG1

Fire Protection Pressure Relief Valve

` Dimensions

Valve size (mm)

Dimension (mm) 50 65 80 100 150 200 250 300

Threaded Ends 238 279 318 - - - - -

A 150 Flanged 238 279 305 381 508 645 756 864

A 300 Flanged 254 295 337 397 533 670 790 902

300 x 150 - - 327 389 522 657 773 883

B 84 102 116 146 200 254 300 356

C 305 311 318 330 363 414 457 522

D 38 43 65 81 109 135 235 273

Threaded Ends 121 140 159 - - - - -

E 150 Flanged 121 140 152 191 254 324 378 432

E 300 Flanged 127 149 162 200 267 337 395 451

Threaded Ends 83 102 114 - - - - -

F 150 Flanged 83 102 102 127 152 203 219 349

F 300 Flanged 89 109 111 135 165 216 236 368

G&H 152 170 197 200 216 248 337 362

Note: We recommend providing adequate space around

valve for maintenance work.

` Specifications ` Materials

Size: Main Valve Body & Cover:

x Globe 2" - 12" flanged x Ductile iron - ASTM A536

x Angle 2" - 12" flanged x Nickel-Aluminium-Bronze ASTM B148

End Details: x Protective epoxy resin coating of wetted surfaces of

x Flanged: 150 and 300 ANSI B16.5 main valve cast iron components (UL listed HNFX

EX2855

x Flanged: ISO PN10, 16, 25

x Other material available

x Other end details available

Standard Main Valve Internal Trim:

Pressure Ratings:

x Stainless Steel 316 seat and disc guide

x Class - 175 psi max.

x Stainless Steel 303 stem, stem nut and cover bearing

x Class - 300 psi max.

Standard Pilot Control System:

Pressure Adjustment Range:

x Bronze ASTM B62 with Stainless Steel 303 internal

x Available in the following relief pressure ranges:

trim

x 20-200 psi (150 Class)

x Stainless Steel 303 tubing with Stainless Steel 316

x 100-300 psi (300 Class) fittings (UL CLA-VAL Europe Standard)

Temperature Range: Main Valve and Pilot Valve:

x Water Max. 180°F / 82°C x Diaphragm and disc: Buna-N synthetic rubber

®

` Purchase Specifications

The Fire Pump Pressure Relief Valve shall modulate to relieve excess pressure in a fire protection system. It shall maintain

constant pressure in the system regardless of demand changes. It shall be pilot controlled and back pressure shall not affect

its set point. It shall be actuated by line pressure through a pilot control system and open fast in order to maintain steady

system pressure as system demand decreases. It shall close gradually to control surges and shall re-seat drip-tight within

5% of its pressure setting. The main valve shall be of the hydraulically-operated, pilot-controlled, diaphragm-type, globe or

angle valve. It shall have a single, removable, Teflon-coated seat, a grooved stem guided at both ends, and a resilient disc

with a rectangular cross section, being contained on 3 1/2 sides. No external packing glands shall be permitted and the

diaphragm shall not be used as a seating surface. The pilot control shall be a direct-acting, adjustable, spring-loaded,

diaphragm-type valve designed for modulating service to permit flow when controlling pressure exceeds spring setting. This

valve shall be UL Listed and Factory Mutual approved. It shall be the Model 50B-4KG1 (globe) or Model 2050B-4KG1

(angle) Pressure Relief Valve as manufactured by CLA-VAL Europe.

Special Note: The Model 50B-4KG1 Pressure Relief Valve is available with 300# ANSI inlet flange and 150# ANSI outlet

flange. This valve is used on higher pressure systems where 300# flange connections are required, and allows for adapting

of a discharge cone (generally supplied with 150# flange) to accommodate "atmospheric break" at relief valve discharge.

This relief valve, with 300# / 150# flanges is available on special order, and is UNDERWRITERS LABORATORIES LISTED

AND FACTORY MUTUAL APPROVED.

` CLA-VAL Europe www.cla-val.ch cla-val@cla-val.ch 2 - 050100DE C 02/10

© Copyright CLA-VAL Europe - Specifications subject to change without notice - no contractual illustrations.

CLA-VAL 50B-4KG1

Fire Pump Pressure Relief Valve

(UL approved 3" - 8")

` Operating data

1.1 ` DESCRIPTION

The Clayton 50B-4KG1 and 2050B-4KG1 pressure relief valves are diaphragm actuated pilot controlled valves designed to

maintain a relatively constant pressure at the main valve inlet. The pressure relief set point is easily adjusted within the

range shown on the pressure relief control nameplate.

1.2 ` PRESSURE RELIEF FEATURE

Pressure relief control CRL (2) is a spring loaded "normally closed" pilot control that responds to slight pressure changes at

main valve (1) inlet. An increase in inlet pressure tends to open pressure relief control (2) and a decrease in inlet pressure

tends to close pressure relief control (2). This causes main valve cover pressure to vary and the main valve (1) modulates

(opens and closes) maintaining a relatively constant pressure at the main valve inlet. A brief explanation of the opening and

closing cycle is as following:

Opening cycle:

1. Inlet pressure is directed trough the sensing line to the actuating diaphragm of control (2).

2. When force created by inlet pressure under diaphragm of control (2) exceeds the force of the spring in control (2),

control (2) opens.

3. When flow out of main valve cover chamber trough control (2) exceeds flow into the main valve cover chamber trough

strainer & orifice (3), pressure in the main valve cover chamber is reduced.

4. With reduced pressure in the main valve cover chamber and full inlet pressure under the main valve disc, the main

valve opens.

Closing cycle:

1. When force created by inlet pressure under diaphragm of control (2) is less the force of the spring in control (2) closes.

2. The main valve cover chamber is slowly pressurized trough strainer 6 orifice (3) and the main valve closes.

Pressure relief control (2) adjustment:

1. Remove plastic cap (turn counter clockwise).

2. Loosen adjusting screw jam nut (turn counter clockwise).

3. Turn adjusting screw clockwise to increase pressure relief set point (or counter clockwise to decrease set point).

4. Re-tighten jam nut.

5. Replace plastic cap.

1.3 ` CHECK VALVE FEATURE

When cover pressure is higher than inlet pressure, check valve 81-01 (4) closes. This maintains the higher pressure in the

main valve cover chamber keeping the main valve (1) closed.

1.4 ` SELF-CLEANING STRAINER

The self-cleaning strainer CLA-VAL, type X46A (6) is at the inlet of the main valve (1) screwed. The assembly of the self-

cleaning strainer (6) removes the assembly of an external filter.

The cleaning of the self-cleaning strainer (6) is requesting its removal from the main valve body (1).

` CLA-VAL Europe www.cla-val.ch cla-val@cla-val.ch 1 - 050100CE A 10/10

CLA-VAL 50B-4KG1

Fire Pump Pressure Relief Valve

(UL approved 3" - 8")

1.5 ` (E*) EUROPEAN STANDARDS

ITEM (3) - Y-strainer with incorporated orifice:

The strainer X44-A (3) is installed in the pilot supply line to protect the pilot system from foreign particles. The strainer

screen must be cleaned periodically.

1.6 ` CHECK LIST FOR PROPER OPERATION

Ƒ System valves open upstream and downstream.

Ƒ Air removed from the main valve cover and pilot system at all high points.

Ƒ Periodic cleaning of strainer (3) is recommended.

` CLA-VAL Europe www.cla-val.ch cla-val@cla-val.ch 2 - 050100CE A 10/10

You might also like

- GPX Sbro 002 e Rev 12Document2 pagesGPX Sbro 002 e Rev 12Nazrul IslamNo ratings yet

- Guidance Equipment Importers enDocument47 pagesGuidance Equipment Importers enNazrul IslamNo ratings yet

- Jindal Steel SpecificationsDocument76 pagesJindal Steel SpecificationsVignesh Chellappan NatarajanNo ratings yet

- Gardner Denver ELECTRA SAVER IIDocument68 pagesGardner Denver ELECTRA SAVER IIJAVI COMPRESORES GARDNER DENVER SULLAIR ATLAS COPCO INGERSOLL RAND KAESER100% (5)

- Manual Fire FightingDocument70 pagesManual Fire FightingAzraf HipniNo ratings yet

- Installation and Maintenance Manual For Electric Fire Pump Controllers With Automatic Transfer Switch Model GPX + GPG or GpuDocument43 pagesInstallation and Maintenance Manual For Electric Fire Pump Controllers With Automatic Transfer Switch Model GPX + GPG or GpusimonsecurityNo ratings yet

- FME3 Ch15Document39 pagesFME3 Ch15Hender MoralesNo ratings yet

- Choice of Filters Examples of Calculation: Choice of A Suitable Micron Rating Example 1: Selection Pressure FilterDocument1 pageChoice of Filters Examples of Calculation: Choice of A Suitable Micron Rating Example 1: Selection Pressure FilterNazrul IslamNo ratings yet

- Design and Protective Measures of A PFI-Plant PDFDocument105 pagesDesign and Protective Measures of A PFI-Plant PDFrehanNo ratings yet

- FnoxdocDocument57 pagesFnoxdocSanchit Pravin ChitreNo ratings yet

- Technical Manual l03Document89 pagesTechnical Manual l03Leonardo Tommy DacuNo ratings yet

- Dellorto ManualDocument34 pagesDellorto Manualmarkintosh44100% (16)

- Gas Turbine2 PDFDocument7 pagesGas Turbine2 PDFnalasekaranNo ratings yet

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDocument2 pages50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamNo ratings yet

- Factsheet Owq Pws NitrateDocument2 pagesFactsheet Owq Pws NitrateNazrul IslamNo ratings yet

- C62 and Others PDFDocument58 pagesC62 and Others PDFmuppetscrapNo ratings yet

- Dew Point and Wet Bulb TemperatureDocument8 pagesDew Point and Wet Bulb TemperatureDileep S NairNo ratings yet

- Compair L-Series-L07 - 11Document8 pagesCompair L-Series-L07 - 11Nazrul IslamNo ratings yet

- Fire Pump BrochureDocument16 pagesFire Pump BrochureAnonymous qrSsYuxyoYNo ratings yet

- Conversion Tables Formulas EtcDocument40 pagesConversion Tables Formulas EtcNazrul IslamNo ratings yet

- Manual ItDocument42 pagesManual ItGhinea EugenNo ratings yet

- Chemistry of Inorganic Nitrogen CompoundsDocument20 pagesChemistry of Inorganic Nitrogen CompoundsNazrul IslamNo ratings yet

- AB Thermal Catalog S FG AL SSDocument1 pageAB Thermal Catalog S FG AL SSNazrul IslamNo ratings yet

- Chapter 19 Membrane FiltrationDocument12 pagesChapter 19 Membrane FiltrationDheeraj ShuklaNo ratings yet

- Boiler CalculationsDocument16 pagesBoiler CalculationsBilly Moerdani100% (1)

- ASHRAE Example Room - Cooling LoadsDocument14 pagesASHRAE Example Room - Cooling LoadsSaiful Islam100% (2)

- Cost of SteamDocument13 pagesCost of SteamAlouis MutimboNo ratings yet

- VamDocument20 pagesVamab_s5036No ratings yet

- Evaluating Chiller & Chiller Plant Efficiency: Jonathan SpreemanDocument33 pagesEvaluating Chiller & Chiller Plant Efficiency: Jonathan SpreemanhoangpalestineNo ratings yet

- 11 - Micron and MeshDocument5 pages11 - Micron and MeshbarelihbNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 04 Mobilization PlanDocument9 pages04 Mobilization PlanMohd Khaidir100% (1)

- Pantente Primer DollyDocument6 pagesPantente Primer DollyJorge SotoNo ratings yet

- PYI Floor Anchor Fitting InstructionsDocument8 pagesPYI Floor Anchor Fitting InstructionsLa Corriente del GolfoNo ratings yet

- Design & Analysis of Worm & Worm GearDocument32 pagesDesign & Analysis of Worm & Worm Gearshahzadali0786100% (1)

- Lb361B Parts List: Gasket Set, Repair Kits and Special Tools Bulletins Needed For Complete Parts ListDocument8 pagesLb361B Parts List: Gasket Set, Repair Kits and Special Tools Bulletins Needed For Complete Parts ListMiGUEL pEREZNo ratings yet

- Argos FD 700Document20 pagesArgos FD 700Tony Humberto Gutierrez100% (1)

- Goyma ImpexDocument8 pagesGoyma ImpexGOYMA IMPEXNo ratings yet

- Surface Grinder: Internal Grinding and External GrindingDocument4 pagesSurface Grinder: Internal Grinding and External GrindingMuhammad HaiderNo ratings yet

- TigerDocument8 pagesTigermyo kyawNo ratings yet

- 4 Vector Manual de Operacion y Servicio PDFDocument330 pages4 Vector Manual de Operacion y Servicio PDFJair Merino AguirreNo ratings yet

- Datacard App - Get Printable Kill Team 2021 Datacards 2Document2 pagesDatacard App - Get Printable Kill Team 2021 Datacards 2ProggetNo ratings yet

- 09-Ds311 Range SBH Hydraulic Diagram - Bt00002658 - JDocument1 page09-Ds311 Range SBH Hydraulic Diagram - Bt00002658 - JJhon MontenegroNo ratings yet

- Answer Key LUSIIIIDocument1 pageAnswer Key LUSIIIIJulcon Avanceña AraizNo ratings yet

- Home Gardener: Outdoor Power EquipmentDocument5 pagesHome Gardener: Outdoor Power EquipmentjamesNo ratings yet

- TM 9 2350 261 10 HRDocument36 pagesTM 9 2350 261 10 HRsgtspolaorNo ratings yet

- Jarvis: Model EBS - 1, - H and - HS Electric Beef Brisket, Horn and Hog Splitting SawsDocument12 pagesJarvis: Model EBS - 1, - H and - HS Electric Beef Brisket, Horn and Hog Splitting SawsLilian KuhnenNo ratings yet

- ASME B16.20 Gasket Dimensions: Standard Standard With Inner RingDocument1 pageASME B16.20 Gasket Dimensions: Standard Standard With Inner RingMina MagdyNo ratings yet

- Prensas y Otros StanleyDocument7 pagesPrensas y Otros StanleyjohangomezruizNo ratings yet

- LG01 - LiuGong Wheel Loader 835H - Product KnowledgeDocument43 pagesLG01 - LiuGong Wheel Loader 835H - Product KnowledgeMUHAMMAD FAUZINo ratings yet

- Genos - L - Series - Full - Specs - Formatted - ItaDocument1 pageGenos - L - Series - Full - Specs - Formatted - ItacmganklNo ratings yet

- General Electric Automatic Washer Service BookDocument99 pagesGeneral Electric Automatic Washer Service BookJesus Rafael Mendoza BrachoNo ratings yet

- M&P15 22 Skus 12722 - 12723 - 12724 Sport Versions SpecsDocument2 pagesM&P15 22 Skus 12722 - 12723 - 12724 Sport Versions Specsbrass.pissNo ratings yet

- Forcec 2 PDFDocument16 pagesForcec 2 PDFangelNo ratings yet

- Torrent G.I Job CardDocument5 pagesTorrent G.I Job Cardshanivi vrindavanNo ratings yet

- CNC TrainingDocument19 pagesCNC TrainingMahipal Singh RanawatNo ratings yet

- Epl 1617 PDFDocument461 pagesEpl 1617 PDFetuk2100% (1)

- BSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)Document8 pagesBSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)LudiNo ratings yet

- BOMDocument1 pageBOMHytech Pvt. Ltd.No ratings yet

- FRAME DH-LM7 1500-2000 KGDocument16 pagesFRAME DH-LM7 1500-2000 KGNerijus BarbaravičiusNo ratings yet

- Reporte Maquinado IEEEDocument3 pagesReporte Maquinado IEEELuis Muñoz FrancoNo ratings yet