Professional Documents

Culture Documents

United States Patent

Uploaded by

Harry Cortez0 ratings0% found this document useful (0 votes)

5 views5 pagesPatent

Original Title

US4726955

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPatent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views5 pagesUnited States Patent

Uploaded by

Harry CortezPatent

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

United States Patent (19) 11) Patent Number: 4,726,955

Horn et al. (45) Date of Patent: Feb. 23, 1988

(54) PREPARATION OF FINELY DIVIDED, (56) References Cited

PULVERULENT CAROTENOID U.S. PATENT DOCUMENTS

PREPARATIONS

2,282,789 5/1942 Musher ................................. 426/73

75) Inventors: Dieter Horn, Heidelberg; 3,110,598 11/1963 Miller et al. ..

Hans-Juergen Quadbeck-Seeger, Bad 3,125,451 3/1964 Wingerd et al.

3,655,406 4/1972 Klaui.....

Durkheim; Peter Schaefer, 3,734,745 5/1973 Cassanelli.

Kirchheim; Wolfgang Haehnlein, 4,522,743 6/1985 Horn et al. ............................ 426/73

Friedelsheim, all of Fed. Rep. of

Germany FOREIGN PATENT DOCUMENTS

0065193 11/1982 European Pat. Off. .

73) Assignee: BASF Aktiengesellschaft,

Ludwigshafen, Fed. Rep. of Primary Examiner-Jeanette Hunter

Germany Attorney, Agent, or Firm-Keil & Weinkauf

57 ABSTRACT

21 Appl. No.: 29,808 Finely divided, pulverulent carotenoid preparations in

22 Filed: Mar. 25, 1987 which the carotenoid essentially has a particle size of

less than 0.5 micron are prepared by a process in which

(30) Foreign Application Priority Data a carotenoid is dissolved in a volatile, water-miscible,

organic solvent at from 50 to 240 C., under atmo

Apr. 4, 1986 (DE Fed. Rep. of Germany ....... 3611229 spheric or superatmospheric pressure, in less than 10

seconds, the carotenoid is precipitated in colloidal dis

51 Int. Cl. ...................... A23L 1/275; A23L 1/303; perse form from the resulting molecular disperse solu

B01J 13/00 tion by rapid mixing with milk at from 0 to 50° C., and

52 U.S. Cl. ...................................... 426/73; 426/540; the resulting dispersion is freed from the solvent and the

426/96; 426/98; 252/311; 252/306; 252/312 dispersing medium in a conventional manner.

58) Field of Search ..................... 426/73, 540, 96, 98;

252/311, 306, 312; 424/341 4 Claims, 1 Drawing Figure

U.S. Patent Feb. 23, 1988 4,726,955

1.

4,726,955

2

scribed in German Patent No. 861,637 and Swiss Patent

PREPARATION OF FINELY DIVIDED, No. 304,023, being sprayed onto the carriers. However,

PULVERULENT CAROTENOID PREPARATIONS the resulting preparations are not universally dispersa

ble in aqueous media and do not meet the usual require

The present invention relates to a process for the ments in respect of shelf life since the active ingredients

conversion of carotenoids to a finely divided, pulveru which accumulate at the surface are rapidly destroyed

lent form which is required in particular for coloring by oxidation. Finally, processes may also be mentioned

food and animal feeds. in which active ingredients in the form of their solutions

The carotenoids constitute a group of colored pig in oil are embedded in colloids, such as gelatine, to form

ments which have hues from yellow to red, are wide 10 emulsions, as described in Chimia 21 (1967), 329 and in

spread in nature and in part a characteristic color to French Patent No. 1,056,114 and U.S. Pat. No.

many foods. Important members of this class of sub 2,650,895. However, owing to the low solubility of the

stances are 6-carotene, S-apo-8-carotenal, canthaxan active ingredients in oil, the concentrations of the said

thin and citranaxanthin. These substances which can be ingredients in the resulting preparations are low.

synthesized are important colorants both for the food 15 On the other hand, known processes in which the

stuffs and animal feeds industry and for pharmaceutical active ingredient is dissolved in a water-immiscible

technology, for example as a substitute for artificial solvent, preferably a chlorohydrocarbon, such as chlo

colorants, or are of interest, for example, because of roform or methylene chloride, the solution is emulsified

their provitamin A activity. by homogenization in a gelatine/sugar solution, and

All carotenoids are insoluble in water and are also 20 finally the solvent is stripped off from the emulsion, the

only slightly soluble in fats and oils. This limited solubil active ingredient being liberated in finely crystalline

ity and the high sensitivity to oxidation prevent the form, constitute a certain advance. A process of this

relatively coarse-particled products contained in the type is described in Chimia 21 (1967), 329 and in Ger

synthesis from being used directly for coloring food or man Published Application DAS No. 1,211,911 and

animal feeds, since only a low color yield can be 25 German Laid-Open Application DOS No. 2,534,091. A

achieved and the substances in the coarsely crystalline finely divided powder is then obtained from the result

form are poorly absorbed. These effects which are dis ing suspension by removal of water.

advantageous with regard to using the carotenoids in However, this process has the disadvantage that chlo

practice are felt in particular in an aqueous medium rohydrocarbons have to be used in order to obtain a

since they are completely insoluble therein. 30 sufficiently high concentration of active ingredient in

Various methods have been described for improving the emulsion phase. Complete removal of the chlorohy

the color yield and increasing the absorption, the object drocarbons, which is necessary for toxicological rea

of all of these methods being to reduce the crystallite sons, is technically difficult.

size of the active ingredients and bring it to a particle The stated disadvantages were overcome by the pro

size range of less than 10 p.m. For example, according to 35 cess described in European Patent No. 65,193, in which,

Chimia 21 (1967), 329, 3-carotene can be milled to in order to prepare finely divided, pulverulent carote

gether with edible oil under a nitrogen atmosphere in a noid preparations, particularly for coloring food and

colloid mill to a particle size of from 2 to 5um. Accord animal feeds, a carotenoid was dissolved in a volatile,

ing to Food Technol. 12 (1958), 527, the oil coating also water-miscible organic solvent at from 50° to 240° C.,

protects the active ingredient from oxidation. The sus under atmospheric or superatmospheric pressure in less

pension which is obtained in this manner and contains than 10 seconds, the carotenoid was precipitated imme

up to 20 or 30% of active ingredient can be successfully diately in colloidal form from the resulting molecular

used for coloring fats and oils since the solubility, al disperse solution by rapid mixing with an aqueous solu

though low, is sufficient to bring the crystallites into tion of a swellable colloid at from 0 to 50 C., and the

solution and the low concentration usually employed. 45 resulting dispersion was freed from the solvent and the

On the other hand, conditioning the active ingredi dispersing medium in a conventional manner.

ents for use in an aqueous medium is much more diffi We have found, surprisingly, that milk or skimmed

cult. The carotenoids have no detectable solubility in milk can advantageously be used instead of the swell

aqueous media, and the desired coloring and absorption able colloid.

properties can only be achieved by means of a very 50 Milk is understood as meaning, in particular, full-fat

finely divided crystalline state. A particle size of less cow's milk, and skimmed milk is understood as meaning

than 1 um is desirable, but this either cannot be partially or completely skimmed milk. The milk may

achieved at all by milling or can be achieved only with furthermore be diluted with up to five times the amount

damage to the active ingredient. Attempts to dissolve of water or may contain further additives. Reconsti

the carotenoids using a water-soluble organic solubi 55 tuted milk produced from milk powder may also be

lizer, such as an alcohol or acetone, and then to precipi used.

tate them in finely crystalline form by dilution with The possibility of using milk was surprising for sev

water have been unsuccessful to date owing to the ex eral reasons:

cessively low solubility of the carotenoids in these sol 1. It is known that milk is denatured (coagulated) by the

vents. For example, the solubility of 6-carotene at room 60 addition of alcohol, the highly pH-dependent limiting

temperature in acetone is less than 0.1% by weight, and concentration decreasing in the order methanol, etha

that in ethanol is less than 0.01% by weight. nol and propanol. Acetone is known to be similar (cf.

Other processes for producing a preparation contain for example D. S. Horne and T. G. Parker, Int. J.

ing finely divided active ingredients are based on the Biol. Macromol. 3 (1981), 300.

application of these active ingredients onto carriers, 65 2. It is also known that milk can be caused to coagulate

such as starch, pectin or dried milk powder, for example by the action of heat, the coagulation times being

a solution of the active ingredient in oil, as described in highly temperature-dependent and decreasing with

German Patent No. 642,307, or in chloroform, as de increasing temperature (cf. E. Dickinson and G.

4,726,955

3 4.

Stainsby, Colloids in Food, Applied Science Publish the resulting hydrosol of the active ingredient proves

ers, London, 1982, page 449 et seq). extremely stable in the photochemical stability test.

3. A combination of the two effects, as is present in our Alternatively, the micronized active ingredient, after

process, would therefore be expected to result in a being brought to a suitable pH, can also be flocculated

substantial increase in the tendency to undergo dena together with the milk colloids and thus converted to a

turing. form from which the solvent and a major part of the

It is clear to the skilled worker that a denatured, i.e. dispersing medium can be separated off by filtration or

coagulated, milk protein system cannot effect colloi centrifuging in a simple manner. The coacervate thus

dal stabilization of a microdisperse system, such stabi obtained is then dried in a conventional manner and

lization being a precondition for the success of the O converted to granules.

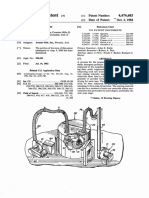

present process. It is therefore surprising that, even at Specifically, the novel process is carried out, for

process temperatures of 200 C., the process involv example, using an apparatus as shown schematically in

ing preparation of a finely divided product takes FIG. 1, the procedure being as follows.

place without problems and gives a microdisperse The apparatus consists of parts I, II and III. Part II is

active ingredient which, after the solvent has been 15 the high temperature section, while the temperatures in

stripped off, for example by distillation, can be con parts I and III are less than 50 C.

verted in a conventional manner, for example by A suspension of the carotenoid in the selected sol

spray drying, to a powder formulation. vent, in a concentration of from 2 to 20% by weight,

The carotenoids which can be used in carrying out based on the mixture, with or without the addition from

the invention are the known, accessible, natural or syn 20 0.1 to 10% by weight of stabilizers, is initially taken in

thetic members of this class of compounds which can be vessel (1). Vessel (2) containing the solvent without any

used as color-imparting agents, for example carotene, admixed carotenoid. The suspension of the active ingre

lycopene, bixin, zeaxanthin, cryptoxanthin, citranaxan dient, and the solvent, are fed to mixing chamber (7) by

thin, lutein, canthaxanthin, astaxanthin, 6-apo-4-carote 25 means of pumps (3) and (4), the ratio of the components

nal, 6-apo-8-carotenal, g-apo-12-carotenal, 6-apo in the mixture being predetermined by the choice of the

8'carotenic acid and esters of hydroxyl-containing and particular deliveries of the pumps and being selected so

carboxyl-containing members of this group, for exam that, depending on the solvent and the residence time,

ple the lower alkyl esters, preferably the methyl and the resulting carotenoid concentration in the mixing

ethyl esters. The members which have been readily 30 chamber is from 0.5 to 10% by weight, based on the

available industrially to date, such as 3-carotene, can solution. The volume of the mixing chamber (7) is such

thaxanthin, (3-apo-8-carotenal and 3-apo-8-carote that, at the selected deliveries of pumps (3) and (4), the

nates, are particularly preferred. residence time in (7) is preferably less than 1 second.

Water-miscible, thermally stable, volatile solvents Before entering the mixing chamber, the solvent is

containing only carbon, hydrogen and oxygen, such as 35 brought to the desired temperature by means of heat

alcohols, ethers, esters, ketones and acetals, are particu exchanger (6), while the suspension of active ingredient

larly suitable for carrying out the novel process. Etha is kept at temperatures above 50 C. by feeding it in via

nol, n-propanol, isopropanol, butane-1,2-diol 1-methyl the thermally insulated feed line (5). The active ingredi

ether, propane-1,2-diol 1-n-propyl ether or acetone are ent is dissolved at from 50 to 240 C., preferably from

preferably used. 150 to 200 C., by turbulent mixing in (7), and, after a

In general, solvents which exhibit not less than 10% short residence time, preferably less than second, the

miscibility with water, have a boiling point of less than resulting solution passes via (8) into the second mixing

200 C. and/or possess less than 10 carbon atoms are chamber (11), in which the active ingredient is precipi

advantageously used. tated in colloidal disperse form by mixing with milk via

To increase the stability of the active ingredient to 45 pump (9) and feed line (10). The finely divided disper

oxidative degradation, it is advantageous to add stabiliz sion of active ingredient is then discharged via line (12)

ers, such as a-tocopherol, lecithin, tert-butylhydrox and pressure control valve (13) and is fed to stock vessel

ytoluene, tert-butylhydroxyanisole or ethoxyquine. (14). In order to achieve a very high concentration of

They may be added either to the milk or to the solvent active ingredient, the dispersion can be circulated via

phase but are preferably dissolved, together with the 50 suction line (15).

colorants and the surfactant-like stabilizers, in the sol If the pressure control valve (13) is set to pressures

vent phase. In certain circumstances, it may also be above one bar, solvents can even be used at tempera

advantageous to dissolve oil or a solid in the solvent tures above their boiling point (under atmospheric pres

phase, this oil or solid then being precipitated in ex sure) in the novel process.

tremely finely divided form together with the active 55 The dispersion is converted to a pulverulent prepara

ingredient and the stated additives during mixing with tion in a conventional manner, for example as described

the the aqueous phase. A viscous liquid having a deep in German Laid-Open Application DAS No. 2,534,091,

color is obtained, from which the solvent, depending on by spray drying or spray cooling or by coating the

its boiling point, can be removed in a conventional particles, separating them off and drying them in a fluid

manner, for example by distillation, under atmospheric ized bed.

or reduced pressure, or by extraction with a water For spray drying, the dispersion is either first freed

immiscible solvent. However, the solvent is preferably from the solvent by distillation, preferably under re

removed together with the water by spray drying or duced pressure, or by extraction with a water-immisci

spray granulation. ble solvent, or the entire mixture is spray dried and the

The resulting dry powder can be redissolved in wa 65 water and solvent thus stripped off together in the spray

ter, the active ingredient being obtained in a uniformly tower.

finely divided form and having a particle size of less The carotenoid powder is obtained in a dry, freeflow

than 1 a.m. In spite of the fact that it is finely divided, ing form at the bottom of the spray tower. In some

5

4,726,955

6

cases, it may be advantageous additionally to carry out TABLE ll-continued

the entire drying procedure in a fluidized bed. Content of active

Instead of preparing the powder formulation by Type of ingredient in

spray drying, it is also possible to use any other methods 5

Example milk Carotenoid the dry powder

in order to convert the carotenoids, which are already with fully de

ionized water

in finely divided form in the water/solvent dispersion, (1:2)

into the powder form. 5 Fully skimmed Canthaxanthin 4.0%

The Examples which follow illustrate the process 6

milk, 0.3%

Fully skimmed 13-2-vitamin- 3.5%

according to the invention. 10 milk, 0.3% A acid

EXAMPLE 1.

20 g of trans-g-carotene are suspended in 240 g of a EXAMPLE 7

solution of 4 g of ascorbyl palmitate and 8 g of dl-a- 15 The procedure described in Example 1 is followed,

tocopherol in 240 g of an isopropanol azeotrope (12% except that only 2000 g of full milk is used in mixing

of water) and are mixed in mixing chamber (7) with 360 chamber (11) at a flow rate of 14 l/h. The content of

g of isopropanol azeotrope which has been heated to active ingredient in the dry powder is 7%.

230 C. in heat exchanger (6), the pressure control valve EXAMPLE 8

(13) being set at 25 bar. When the suspension is metered 20

at a rate of 2 l/h and the solvent at a rate of 3 l?h, the The procedure described in Example 1 is followed,

residence time in the mixing chamber (7) is 0.35 second. except that 4000 g of a solution of 150 g of dry milk in

The molecular disperse solution formed at 195 C. dur distilled water is used in mixing chamber (11).

We claim:

ing this procedure is then fed to mixing chamber (11), 25 1. A process for the preparation of a finely divided,

where it is mixed with 4000 g of full milk (fat content pulverulent carotenoid preparation, in which the carot

3.5%) at a flow rate of 27 l/h to precipitate the 6-caro enoid essentially has a particle size of less than 0.5 mi

tene in colloidal disperse form. A colloidal dispersion of cron, by dissolving a carotenoid in a volatile, water-mis

active ingredient which has an orange-yellow hue and is cible, organic solvent at from 50 to 240 C., under

at 50° C. is obtained in collecting vessel (14). Particle 30 atmospheric or superatmospheric pressure, in less than

size analysis of the micronized product by quasielastic 10 seconds, immediately precipitating the carotenoid in

laser light scattering gives a mean particle size of 250 colloidal disperse form from the resulting molecular

. disperse solution by rapidly mixing with an aqueous

After the solvent has been separated off under re 35 the dispersion of a colloid at from 0 to 50° C. and freeing

duced pressure at 50 C. in a distillation apparatus, a persing resulting dispersion from the solvent and the dis

medium in a conventional manner, wherein the

colloidal dispersion of active ingredient is obtained, and colloid used is milk or skimmed milk or an aqueous

this dispersion can be converted to a stable, watersolu solution of dry milk.

ble dry powder by spray drying. 2. A process for the preparation of a finely divided,

If the procedure described in Example 1 is followed 40 pulverulent carotenoid preparation as claimed in claim

but the following carotenoids or milk products are used, 1, wherein the water-miscible volatile solvent used is an

the results stated in Table 1 are obtained. alcohol, a ketone, an ester, an acetal or an ether.

TABLE 1

3. A process for the preparation of a carotenoid prep

aration as claimed in claim 2, wherein the water-misci

Content of active 45 ble volatile solvent used is acetone, butane-1,2-diol 1

Type of ingredient in methyl ether, propane-1,2-diol 1-n-propyl ether ethanol,

Example milk Carotenoid the dry powder n-propanol, isopropanol or a mixture of these.

2 Skimmed milk, £3-carotene 3.5% 4. A process as claimed in claim 1, wherein the prepa

1.5% fat ration of the molecular disperse carotenoid solution and

3 Fully skimmed 4.5% 50 the precipitation of the carotenoid in very finely dis

milk, 0.3% fat perse form are carried out continuously in two mixing

4. Fully skimmed 10% chambers connected in series.

milk, but diluted k k k k k

55

60

65

You might also like

- 1995 - HamannDkk - Process For The Preparation of Highly Concentrated Free-Flowing Aqueous Solutions of Betaines - US5464565Document5 pages1995 - HamannDkk - Process For The Preparation of Highly Concentrated Free-Flowing Aqueous Solutions of Betaines - US5464565Rizkyka AffiatyNo ratings yet

- Patente Saponificacion Oleorresina de Marigold 3Document6 pagesPatente Saponificacion Oleorresina de Marigold 3Harry CortezNo ratings yet

- US patent for emulsifiers and aqueous isocyanate emulsionsDocument9 pagesUS patent for emulsifiers and aqueous isocyanate emulsionsShabi HadashNo ratings yet

- US6040283 Concentrated Alkaline Glutaraldehyde Phenolic DisinfectantDocument5 pagesUS6040283 Concentrated Alkaline Glutaraldehyde Phenolic DisinfectantAyu WinarniNo ratings yet

- FFHGJHDocument4 pagesFFHGJHPuput AstriatiNo ratings yet

- Pan Release AgentDocument5 pagesPan Release AgentCharaf ZAHIRINo ratings yet

- Low Foam Detergent US5753606Document6 pagesLow Foam Detergent US5753606JuliardosJ.M.LubisNo ratings yet

- US4828752Document9 pagesUS4828752Abdulrahman HamdanNo ratings yet

- United States PatentDocument3 pagesUnited States PatentSmokeNo ratings yet

- US005164192A - Effervescent composition for oral rehydrationDocument4 pagesUS005164192A - Effervescent composition for oral rehydrationABCDNo ratings yet

- United States Patent (19) : Brady (45) Aug. 28, 1973Document4 pagesUnited States Patent (19) : Brady (45) Aug. 28, 1973Vansala GanesanNo ratings yet

- Almond Milk Preparation Process and Product ObtainedDocument4 pagesAlmond Milk Preparation Process and Product ObtainedQuỳnh LinhNo ratings yet

- Patent settlement acceleratorDocument4 pagesPatent settlement acceleratorDavid Diaz PadillaNo ratings yet

- Patents Soap MakingDocument7 pagesPatents Soap MakingNoviNo ratings yet

- Us4643848 Fumaric RosinDocument5 pagesUs4643848 Fumaric RosinPudien MuhamadNo ratings yet

- United States Patent (19) : 11 Patent Number: 5,358,655 (45) Date of Patent: Oct. 25, 1994Document7 pagesUnited States Patent (19) : 11 Patent Number: 5,358,655 (45) Date of Patent: Oct. 25, 1994Cheikh DjoudiNo ratings yet

- United States Patent (19) : 11 Patent Number: 4,461,660 45) Date of Patent: Jul. 24, 1984Document5 pagesUnited States Patent (19) : 11 Patent Number: 4,461,660 45) Date of Patent: Jul. 24, 1984Ben Duncan Málaga EspichánNo ratings yet

- United States Patent (19) : Quednau Mar. 21, 1995Document7 pagesUnited States Patent (19) : Quednau Mar. 21, 1995هیمن مNo ratings yet

- Pesticidal CompositionsDocument7 pagesPesticidal CompositionsAlfredo MéndezNo ratings yet

- United States Patent (19) : Bruegge Et Al. 45) Date of Patent: Oct. 29, 1991Document11 pagesUnited States Patent (19) : Bruegge Et Al. 45) Date of Patent: Oct. 29, 1991than zawNo ratings yet

- US6566329Document4 pagesUS6566329shenzengexport1980No ratings yet

- Transparent Soap Formulation and Production ProcessDocument6 pagesTransparent Soap Formulation and Production Processacit marocitNo ratings yet

- US5100534Document9 pagesUS5100534oseng sengNo ratings yet

- Us6570026 Basf 2003Document6 pagesUs6570026 Basf 2003daraj darajNo ratings yet

- United States Patent (19) : Filed. Oct. 5, 1977Document3 pagesUnited States Patent (19) : Filed. Oct. 5, 1977Alexander Franco CastrillonNo ratings yet

- US5851963Document4 pagesUS5851963AYOOLA FOLAHAN HENRY-OMOJOLANo ratings yet

- United States Patent (19) : Quednau 11 Patent Number: 45 Date of PatentDocument7 pagesUnited States Patent (19) : Quednau 11 Patent Number: 45 Date of Patentهیمن مNo ratings yet

- United States Patent (19) : Nagasawa Et AlDocument10 pagesUnited States Patent (19) : Nagasawa Et AlkausarNo ratings yet

- Lambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónDocument8 pagesLambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónAlfredo MéndezNo ratings yet

- Us 6492141Document6 pagesUs 6492141nounounaim444No ratings yet

- Us 4945186Document3 pagesUs 4945186J Venkat RamanNo ratings yet

- Patent - 1978 - US4076589 - Process For The Production of (DHA)Document4 pagesPatent - 1978 - US4076589 - Process For The Production of (DHA)Lucas CoêlhoNo ratings yet

- Patent 2 Pabrik Phenyl Ethyl AlcoholDocument5 pagesPatent 2 Pabrik Phenyl Ethyl AlcoholFaizhal DimazNo ratings yet

- Soap Making Process Patent SummaryDocument14 pagesSoap Making Process Patent SummaryEmanuel MoralesNo ratings yet

- Us 4639489Document7 pagesUs 4639489Pat22 22patNo ratings yet

- United States Patent (19) : Oftring Et AlDocument12 pagesUnited States Patent (19) : Oftring Et AljerryNo ratings yet

- United States Patent (19) : Flannigan (11) 4,451,390 45) May 29, 1984Document5 pagesUnited States Patent (19) : Flannigan (11) 4,451,390 45) May 29, 1984JutonoNo ratings yet

- US4782109Document7 pagesUS4782109ALEXANDER FRANCO CASTRILLONNo ratings yet

- United States Patent (19) 11 Patent Number: 5,269,839: Sodhi 45) Date of Patent: Dec. 14, 1993Document4 pagesUnited States Patent (19) 11 Patent Number: 5,269,839: Sodhi 45) Date of Patent: Dec. 14, 1993Alexander Franco CastrillonNo ratings yet

- Chemically Gassed Emulsion ExplosiveDocument5 pagesChemically Gassed Emulsion ExplosiveManh Loc PhanNo ratings yet

- Patente Proceso aMDEA de BASFDocument9 pagesPatente Proceso aMDEA de BASFizurietaeduardoNo ratings yet

- US Patent Manufacturing of Propylene GlycolDocument5 pagesUS Patent Manufacturing of Propylene GlycolRegiyanti RNo ratings yet

- US7169959Document3 pagesUS7169959Alam IlhamNo ratings yet

- Method of Desalting Crude OilDocument5 pagesMethod of Desalting Crude OilDavid Cruz ZamoraNo ratings yet

- Imp Paper On MicroEmulsionDocument8 pagesImp Paper On MicroEmulsionkapil KleenageNo ratings yet

- Patent 3Document4 pagesPatent 3PankajNo ratings yet

- Microorganismos ExpoDocument8 pagesMicroorganismos ExpoSofia AmadorNo ratings yet

- United States Patent (10) Patent No.: US 6,632,262 B2: Gabrielson (45) Date of Patent: Oct. 14, 2003Document7 pagesUnited States Patent (10) Patent No.: US 6,632,262 B2: Gabrielson (45) Date of Patent: Oct. 14, 2003João Victor WorkNo ratings yet

- US4684750Document4 pagesUS4684750Deep PatelNo ratings yet

- United States Patent (19) : 11) Patent Number: 5,606,102 (45) Date of Patent: Feb. 25, 1997Document9 pagesUnited States Patent (19) : 11) Patent Number: 5,606,102 (45) Date of Patent: Feb. 25, 1997Dian Agung SatyanagaraNo ratings yet

- Method for Producing GBL Uses Reaction Mixtures Containing Butanediol and AlcoholDocument4 pagesMethod for Producing GBL Uses Reaction Mixtures Containing Butanediol and Alcoholthor888888No ratings yet

- United States PatentDocument6 pagesUnited States PatentRizki HidayatNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument5 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentLechugaGuerreroHerreraNo ratings yet

- US3673106Document10 pagesUS3673106Thuận LêNo ratings yet

- US5032224 Method of Producing PulpDocument7 pagesUS5032224 Method of Producing Pulpeni rohaniNo ratings yet

- Chemical Blowing Agent Composition EndoawawDocument5 pagesChemical Blowing Agent Composition EndoawawProton HutabaratNo ratings yet

- Reactor AnaeróbicoDocument8 pagesReactor AnaeróbicoLuis BejaranoNo ratings yet

- US4614600Document9 pagesUS4614600Lab. Petroleo AGENANo ratings yet

- US4033855Document6 pagesUS4033855Nima FakherNo ratings yet

- Antioxidant Tech Paper LargeFileDocument8 pagesAntioxidant Tech Paper LargeFileHarry CortezNo ratings yet

- Carta Chifa Wong KocDocument12 pagesCarta Chifa Wong KocDeissy Karina Rivera AlcantaraNo ratings yet

- 100 MZR Multi-PlexDocument8 pages100 MZR Multi-PlexHarry CortezNo ratings yet

- The Key Inductive Bible StudyDocument16 pagesThe Key Inductive Bible StudyHarry Cortez100% (1)

- 100 MZR Multi-PlexDocument8 pages100 MZR Multi-PlexHarry CortezNo ratings yet

- Glycosperse - DSDocument2 pagesGlycosperse - DSHarry CortezNo ratings yet

- European Patent Specification: Frying CompositionDocument14 pagesEuropean Patent Specification: Frying CompositionHarry CortezNo ratings yet

- US Natural Colors in Pet Food - NEWDocument4 pagesUS Natural Colors in Pet Food - NEWHarry CortezNo ratings yet

- Natural Colorant From Marigold Chemistry and TechnologyDocument20 pagesNatural Colorant From Marigold Chemistry and TechnologyHarry CortezNo ratings yet

- TN Sucrose Esters General InformationDocument15 pagesTN Sucrose Esters General InformationStephanie HsuehNo ratings yet

- United States Patent (19) : (54) Free Flowing Modified WheyDocument8 pagesUnited States Patent (19) : (54) Free Flowing Modified WheyHarry CortezNo ratings yet

- Process for manufacturing citric acid esters of fatty acid glyceridesDocument3 pagesProcess for manufacturing citric acid esters of fatty acid glyceridesHarry CortezNo ratings yet

- United States Patent To: Inventor: Ralph Salkin, Kinnelon, N.J. Assignee: CPC International Inc., EnglewoodDocument4 pagesUnited States Patent To: Inventor: Ralph Salkin, Kinnelon, N.J. Assignee: CPC International Inc., EnglewoodHarry CortezNo ratings yet

- Status Certification Requirements Ukd-Id Product Name: Lonza LTD., 90 Boroline Road, Allendale, NJ 07410Document25 pagesStatus Certification Requirements Ukd-Id Product Name: Lonza LTD., 90 Boroline Road, Allendale, NJ 07410Harry CortezNo ratings yet

- Emulsifier system influences O/W emulsion preservationDocument3 pagesEmulsifier system influences O/W emulsion preservationHarry CortezNo ratings yet

- United States Patent To: Inventor: Ralph Salkin, Kinnelon, N.J. Assignee: CPC International Inc., EnglewoodDocument4 pagesUnited States Patent To: Inventor: Ralph Salkin, Kinnelon, N.J. Assignee: CPC International Inc., EnglewoodHarry CortezNo ratings yet

- Us3535426 - Stablization OfxanthophyllsDocument3 pagesUs3535426 - Stablization OfxanthophyllsHarry CortezNo ratings yet

- Transesterfication in The Presence of A Transparent Emulsion - Us3644333Document5 pagesTransesterfication in The Presence of A Transparent Emulsion - Us3644333Harry CortezNo ratings yet

- United States Patent Office: Patented Aug. 4, 1970Document4 pagesUnited States Patent Office: Patented Aug. 4, 1970Harry CortezNo ratings yet

- Ug Web Hbs-A100 Eu Rev 02 170413Document388 pagesUg Web Hbs-A100 Eu Rev 02 170413Harry CortezNo ratings yet

- Process For The Production of Sucrose Esters of Fatty AcidsDocument5 pagesProcess For The Production of Sucrose Esters of Fatty AcidsHarry CortezNo ratings yet

- EP0630578B1Document20 pagesEP0630578B1Harry CortezNo ratings yet

- Us3535426 - Stablization OfxanthophyllsDocument3 pagesUs3535426 - Stablization OfxanthophyllsHarry CortezNo ratings yet

- Baking Properties of Different Amaranth Flours As Wheat Bread IngredientsDocument10 pagesBaking Properties of Different Amaranth Flours As Wheat Bread IngredientsHarry CortezNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- MSDS - ActiVin™Document2 pagesMSDS - ActiVin™Harry CortezNo ratings yet

- Ug Web Hbs-A100 Eu Rev 02 170413Document388 pagesUg Web Hbs-A100 Eu Rev 02 170413Harry CortezNo ratings yet

- Wastewater TreatmentDocument46 pagesWastewater TreatmentOsmanNo ratings yet

- Student Exploration: Limiting ReactantsDocument3 pagesStudent Exploration: Limiting ReactantsJohn BrauswetterNo ratings yet

- Deltron: Velocity Premium ClearcoatDocument4 pagesDeltron: Velocity Premium ClearcoatJm KamachoNo ratings yet

- Machine Design-1 Qpaper Nit Raipur Mech 5th SemDocument20 pagesMachine Design-1 Qpaper Nit Raipur Mech 5th SemShashi Bhushan PatelNo ratings yet

- Structure and Bonding Updated 2Document82 pagesStructure and Bonding Updated 2jadabrown542No ratings yet

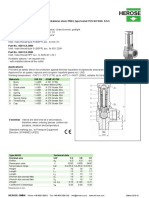

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed RaafatNo ratings yet

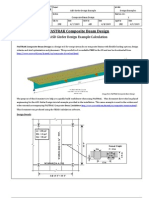

- Client: Lithium Nevada Corporation Project: Thacker PassDocument16 pagesClient: Lithium Nevada Corporation Project: Thacker PassSubrata DasNo ratings yet

- ExplosivesDocument5 pagesExplosivesgladsonNo ratings yet

- Structure Design of A Five Story HospitalDocument57 pagesStructure Design of A Five Story HospitalAmir Nazeer100% (1)

- Assignment 1Document3 pagesAssignment 1Pawan Kumar GoyalNo ratings yet

- Design Example ASD GirderDocument12 pagesDesign Example ASD GirderEdward van MartinoNo ratings yet

- Lattice Steel Towers and Steel PolesDocument7 pagesLattice Steel Towers and Steel Polesyudha_hermawan_kinoy0% (1)

- SAFETY DATA SHEET-FucdicDocument5 pagesSAFETY DATA SHEET-FucdicYousifNo ratings yet

- Heap LeachingDocument2 pagesHeap Leachingkaweesa mosesNo ratings yet

- Electrocoagulation of Wastewater Using Aluminum, Iron, and MagnesiumDocument7 pagesElectrocoagulation of Wastewater Using Aluminum, Iron, and MagnesiumPraveen KumarNo ratings yet

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Document2 pagesProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomNo ratings yet

- Module 2 1Document18 pagesModule 2 1Jeslyn MonteNo ratings yet

- June 2017 1C Que IGCSE Edexcel ChemistryDocument36 pagesJune 2017 1C Que IGCSE Edexcel ChemistryMichael EllisNo ratings yet

- Magnetic Water TreatmentDocument66 pagesMagnetic Water Treatmentmdkadry100% (2)

- C T Sun Mechanics of Aircraft Structures SolutionDocument270 pagesC T Sun Mechanics of Aircraft Structures SolutionTharshan Rajasekar60% (5)

- Pressure Vessel Fabrication - Int Dist Training 7-30-09Document41 pagesPressure Vessel Fabrication - Int Dist Training 7-30-09Mostafa Abd El Alem100% (2)

- 02 States of Matter + ExpansionDocument5 pages02 States of Matter + ExpansionmelissaNo ratings yet

- Mil PRF 5606hDocument25 pagesMil PRF 5606hApanreza VitalyNo ratings yet

- Failure AnalysisDocument29 pagesFailure AnalysisreddyNo ratings yet

- Waste Report Moldova Final 30 01Document22 pagesWaste Report Moldova Final 30 01EaP CSFNo ratings yet

- Chemistry of Engineering MaterialsDocument36 pagesChemistry of Engineering Materialsksm rachasNo ratings yet

- Aircraft Structures: Clarkson University AE212 Jha Intro-1Document11 pagesAircraft Structures: Clarkson University AE212 Jha Intro-1Baljinder SinghNo ratings yet

- Hardtop Optima Alu: Technical Data SheetDocument5 pagesHardtop Optima Alu: Technical Data SheetBiju_PottayilNo ratings yet

- Mechanical Properties: Element Content (%)Document2 pagesMechanical Properties: Element Content (%)SANNI KUMARNo ratings yet

- Laynes - Chapter 10 GasesDocument142 pagesLaynes - Chapter 10 GasescharleneNo ratings yet