Professional Documents

Culture Documents

Flexpac Hold Down Ps

Uploaded by

LuisSossaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexpac Hold Down Ps

Uploaded by

LuisSossaCopyright:

Available Formats

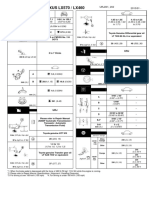

FlexPac Hold-Down Tool

Keeps string in place during stimulation, perforation, and well test operations

Applications The FlexPac* service packer hold-down tool (FLXH)

■■ Downhole testing prevents the string from moving uphole as a result of

■■ Tubing-conveyed perforating hydraulic forces acting below the packer during stimulation

or when activating a firing head. The slip design is similar

■■ Well testing

to the proven hold-down section of the PosiTrieve*

■■ Stimulating downhole packer with hold-down section.

Gauge ring

Benefits When tubing pressure becomes greater than annulus

■■ Operational simplicity pressure, a piston moves down, activating the hold-down Tubing pressure

■■ High reliability slips. The tungsten-carbide inserts on the hold-down port

■■ Durability in harsh environments slips effectively retain the upward hydraulic force that

results from the maximum differential across the packer.

Features

■■ Rugged, modular design allows running When the annulus pressure becomes greater than the tubing

one or more hydraulic hold-down tools pressure, the piston moves up, retracting the hold-down

Slips

in any position in the string slips. A straight-upward pull retracts the slips mechanically.

■■ Slips can be mechanically retracted The FLXH has a rugged, simple design and is easily Spline

■■ Gauge rings centralize the slip section redressed between operations or converted for use

for improved grip with different casing weights.

■■ Rugged slip design prevents upward Gauge ring

movement from maximum

hydraulic force

■■ Tungsten-carbide slip inserts grip

even the hardest casings

■■ Slips can be activated only if hydraulic

hold-down tool is in compression

FLXH tool.

Specifications

Model FLXH-G FLXH-F

Casing size and weight, in, lbm/ft 41⁄2, 9.5 to 13 65⁄8, 24

5, 11.5 to 21 7, 17 to 38

51⁄2, 20 to 23 75⁄8, 20 to 39

Tool ID, in [mm] 1.125 [29] 2.250 [57]

Differential pressure, psi [MPa] 15,000 [103] 15,000 [103]

Temperature, degF [degC] 340 [171] 340 [171]

Length, ft [m] 5 [1.52] 6.47 [1.97]

Weight, lbm [kg] 125 [57] 340 [154]

Service (NACE International MR0175/ISO 15156) H2S, acid H2S, acid

Tensile load, lbf [kN] 220,300 [891] 188,400 [838]

Tensile load with working pressure, lbf [kN] 179,000 [796] 171,300 [762]

Connections 23⁄ 8 REG or 23⁄ 8 PH-6 31⁄ 2 IF or 31⁄ 2 PH-6

www.slb.com/welltesting

*Mark of Schlumberger

Copyright © 2014 Schlumberger. All rights reserved. 12-TS-0150

You might also like

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELDocument2 pagesPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELHumaid ShaikhNo ratings yet

- Agitator Handbook 2005Document22 pagesAgitator Handbook 2005casda73No ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Hydra Stroke Bumper SubDocument1 pageHydra Stroke Bumper SubradiciptaNo ratings yet

- NXT-M Bop TMSDocument1 pageNXT-M Bop TMSSasan Abbasi100% (1)

- Palfinger 74002 PDFDocument8 pagesPalfinger 74002 PDFAnonymous mcCJYBoNo ratings yet

- Slip Joint PsDocument1 pageSlip Joint PsalexebhaNo ratings yet

- Viking Heavy Pump KK125Document12 pagesViking Heavy Pump KK125pauldanielmh100% (1)

- Hydraulic Jar PsDocument1 pageHydraulic Jar PsrafaelNo ratings yet

- Flowhead: Multifunction Flow Control From The Top of The WellDocument2 pagesFlowhead: Multifunction Flow Control From The Top of The WellSandro Ha100% (1)

- Snubbing Equipment 1664467576Document96 pagesSnubbing Equipment 1664467576fumar26No ratings yet

- Technical Appendix: Selecting The Proper DESTACO ClampDocument8 pagesTechnical Appendix: Selecting The Proper DESTACO ClampGurneet SinghNo ratings yet

- Flexpac Packer PsDocument2 pagesFlexpac Packer PsDeepak SareenNo ratings yet

- HMF 1430-KDocument4 pagesHMF 1430-Klauragarciazapata2No ratings yet

- DE151 Spec Sheet 02 2018Document5 pagesDE151 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- Annulus Reclosable Circulating Valve Ps PDFDocument2 pagesAnnulus Reclosable Circulating Valve Ps PDFluisNo ratings yet

- ROTEX Complete Master DRC DRS DRV CatalogDocument56 pagesROTEX Complete Master DRC DRS DRV CatalogSanjeev AroraNo ratings yet

- RH1 - Hydraulic Set Double Grip Retrievable Packer: Product No. 15-155 / 15-158Document2 pagesRH1 - Hydraulic Set Double Grip Retrievable Packer: Product No. 15-155 / 15-158hitesh kumarNo ratings yet

- Regulator Broch Flxflo SurgerelieverDocument12 pagesRegulator Broch Flxflo SurgerelieverCarlos SandinoNo ratings yet

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- Heavy-Duty Wireline Fishing (HDWF) ServicesDocument8 pagesHeavy-Duty Wireline Fishing (HDWF) ServicesJosé CastroNo ratings yet

- Drilling Jar PlacementDocument3 pagesDrilling Jar Placementrdos1467% (3)

- Port Ps PDFDocument2 pagesPort Ps PDFluisNo ratings yet

- DST Tools CatalogDocument103 pagesDST Tools CatalogSikander Mushtaq100% (1)

- Model 621 LR B Data SheetDocument1 pageModel 621 LR B Data SheetMohammed GallowNo ratings yet

- SLB ToolsDocument2 pagesSLB ToolsLuisSossaNo ratings yet

- FloorHand BLOHM BOSSDocument4 pagesFloorHand BLOHM BOSSCarlosSantamariaNo ratings yet

- Floorhand FH-80: Smart Solutions. Powerful ProductsDocument4 pagesFloorhand FH-80: Smart Solutions. Powerful ProductsArturo PerezNo ratings yet

- p51 Quantum Snap Latch Seal AssemblyDocument1 pagep51 Quantum Snap Latch Seal AssemblyPak RioNo ratings yet

- DST Tool Presentation 1Document16 pagesDST Tool Presentation 1jairaso2950No ratings yet

- Safety JointDocument1 pageSafety JointCARLOSELSOARESNo ratings yet

- Quadra PowerDocument8 pagesQuadra PowerFelipe Ribeiro da CostaNo ratings yet

- Pipe Supports Detail Training Session (Day-Ii) : Piping Department SDocument29 pagesPipe Supports Detail Training Session (Day-Ii) : Piping Department SZahoor AhmedNo ratings yet

- Gas Lift OperationsDocument4 pagesGas Lift OperationsAbdelrahman AliNo ratings yet

- ERKE Group, PTC Excavator Mounted Vibrodriver CatalogueDocument4 pagesERKE Group, PTC Excavator Mounted Vibrodriver Catalogueerkegroup100% (1)

- Class Leading Features: Easy To Operate - Simple To ServiceDocument6 pagesClass Leading Features: Easy To Operate - Simple To Servicealtair 14No ratings yet

- Lever Operated Hoists: Operation, Service and Parts ManualDocument16 pagesLever Operated Hoists: Operation, Service and Parts ManualGary CondictNo ratings yet

- VYOM Brochure - RS EngineersDocument16 pagesVYOM Brochure - RS EngineersRS Engineers and ConsultantsNo ratings yet

- Hydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownDocument4 pagesHydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownpendexxNo ratings yet

- Surface Catenary Interventions PsDocument2 pagesSurface Catenary Interventions Psditer najarNo ratings yet

- 1.concentric Butterfly Valve in Various ApplicationDocument10 pages1.concentric Butterfly Valve in Various ApplicationMaciekNo ratings yet

- Hydraulic Washing Lift: Me - WL 4.0 Sa ME - WL 4.0Document1 pageHydraulic Washing Lift: Me - WL 4.0 Sa ME - WL 4.0viahulNo ratings yet

- Ficha Tecnica - VersaliftDocument2 pagesFicha Tecnica - Versaliftalex100% (1)

- BOP TRANSPORTATION SKID SAFE OPERATING MANUAL - Rev.1Document20 pagesBOP TRANSPORTATION SKID SAFE OPERATING MANUAL - Rev.1cmrig7467% (3)

- Trmaxx Series Safety Valves PDFDocument2 pagesTrmaxx Series Safety Valves PDFArturo Treviño MedinaNo ratings yet

- 4880 - TU CD-6000 Sliding Sleeve - Part.9,11,13Document7 pages4880 - TU CD-6000 Sliding Sleeve - Part.9,11,13fjflores26No ratings yet

- Fdocuments - in - 239813017 Catalogo Varco BJDocument56 pagesFdocuments - in - 239813017 Catalogo Varco BJAbelardo CortezNo ratings yet

- Rotary Actuators HelacDocument20 pagesRotary Actuators HelacIanNo ratings yet

- Logan Sup-R-Jar Presentation R1Document18 pagesLogan Sup-R-Jar Presentation R1unduhNo ratings yet

- 9-78 HS-40 HS-55 BrochureDocument2 pages9-78 HS-40 HS-55 BrochureleoNo ratings yet

- Vanngun Assembly: Wireline and Perforating ServicesDocument2 pagesVanngun Assembly: Wireline and Perforating ServicesMiguel Angel PedrazaNo ratings yet

- Rotating Mandrel Casing HangerDocument1 pageRotating Mandrel Casing HangerJonatan StoppoNo ratings yet

- Halliburton: Rtts PackerDocument2 pagesHalliburton: Rtts PackermehrdadNo ratings yet

- Wrangler Bop Handling System PsDocument1 pageWrangler Bop Handling System PsArturo PerezNo ratings yet

- Christensen 140: Surface Core Drilling RigDocument12 pagesChristensen 140: Surface Core Drilling RigAriel100% (2)

- 08 Co 178 Realiance Saf Val 2 LRDocument2 pages08 Co 178 Realiance Saf Val 2 LRAli AliNo ratings yet

- Hydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownDocument4 pagesHydra-Jar AP Double-Acting Hydraulic Drilling Jar: Jarring DownAli mohammadNo ratings yet

- Powerscreen Conveyor BrochureDocument5 pagesPowerscreen Conveyor BrochureDaniel BianchiniNo ratings yet

- DE140 Spec Sheet 02 2018Document5 pagesDE140 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- LSV1 4-260-1 PDFDocument2 pagesLSV1 4-260-1 PDFfrancis_15inNo ratings yet

- K.J.Weber, SPE, and H. Dronkert (Delft, University of Technology)Document11 pagesK.J.Weber, SPE, and H. Dronkert (Delft, University of Technology)luisNo ratings yet

- Henson2002 PDFDocument16 pagesHenson2002 PDFluisNo ratings yet

- Scarface (Push It To The Limit) : Paul EngemannDocument1 pageScarface (Push It To The Limit) : Paul EngemannluisNo ratings yet

- Dispersion and Reservoir Heterogeneity: SPE Reservoir Engineering February 1988Document11 pagesDispersion and Reservoir Heterogeneity: SPE Reservoir Engineering February 1988luisNo ratings yet

- An Investigation of Pressure-Buildup Tests in Bounded ReservoirsDocument6 pagesAn Investigation of Pressure-Buildup Tests in Bounded ReservoirsluisNo ratings yet

- Dynamic Data Analysis: DDA © KAPPA 1988-2013Document11 pagesDynamic Data Analysis: DDA © KAPPA 1988-2013luisNo ratings yet

- Pipe Tester Valve: Pressure Tests Pipe Above The Valve While Running in HoleDocument1 pagePipe Tester Valve: Pressure Tests Pipe Above The Valve While Running in HoleluisNo ratings yet

- Port Ps PDFDocument2 pagesPort Ps PDFluisNo ratings yet

- Annulus Reclosable Circulating Valve Ps PDFDocument2 pagesAnnulus Reclosable Circulating Valve Ps PDFluisNo ratings yet

- Module-5 (Electrical Installation) - INSDocument21 pagesModule-5 (Electrical Installation) - INSGemechu TayeNo ratings yet

- 300 Ma, High PSRR, Low Quiescent Current LDO: Features DescriptionDocument24 pages300 Ma, High PSRR, Low Quiescent Current LDO: Features Descriptionjustinvil1103No ratings yet

- South Africa The Gas Company Gas BillDocument1 pageSouth Africa The Gas Company Gas Billuyên đỗNo ratings yet

- Chapter 5 JavascriptdocumentDocument122 pagesChapter 5 JavascriptdocumentKinNo ratings yet

- Ramp SectionDocument1 pageRamp SectionBhavya PatelNo ratings yet

- Functional Testing For .NET Core APIDocument6 pagesFunctional Testing For .NET Core APICristopher Coronado MoreiraNo ratings yet

- SOP For Cleaning of Bottle Filling MachineDocument4 pagesSOP For Cleaning of Bottle Filling MachineSolomon0% (1)

- 1 - 1 Student Device Program Brochure (2022-2023)Document1 page1 - 1 Student Device Program Brochure (2022-2023)keqwlng linNo ratings yet

- Sdo Batangas: Department of EducationDocument29 pagesSdo Batangas: Department of EducationEdralynNo ratings yet

- Service Quotation DZRV Radio Veritas Foundation Inc.: Human Resource Service CooperativeDocument2 pagesService Quotation DZRV Radio Veritas Foundation Inc.: Human Resource Service CooperativeKrystle Ann AguirreNo ratings yet

- Cryptography Question-BankDocument5 pagesCryptography Question-BankTriveni KulkarniNo ratings yet

- UNIT I-Summary Need of Additive ManufacturingDocument4 pagesUNIT I-Summary Need of Additive ManufacturingRajijackNo ratings yet

- Gmail - FW - Receipt For Your E-Ticket Request 14391559 - DINITHI - ALAGIYADURAGEMS, PNR# KJGLYJ, CAT A SUBLOADDocument3 pagesGmail - FW - Receipt For Your E-Ticket Request 14391559 - DINITHI - ALAGIYADURAGEMS, PNR# KJGLYJ, CAT A SUBLOADDanidu KaveenNo ratings yet

- 2014 Antelco Metric Catalogue PDFDocument48 pages2014 Antelco Metric Catalogue PDFmio ashineNo ratings yet

- 6 RedHatDocument20 pages6 RedHatkoenjavaNo ratings yet

- PWD ZP Wrd6000+ Previous - Year Mcqs With ExplanationDocument29 pagesPWD ZP Wrd6000+ Previous - Year Mcqs With ExplanationvishalNo ratings yet

- Telecom Standards ManualDocument123 pagesTelecom Standards ManualsoresaNo ratings yet

- 500,000.00 GBP (Five Hundred Thousand Great British Pounds Only) Promotion 500,000.00 Great British PoundsDocument4 pages500,000.00 GBP (Five Hundred Thousand Great British Pounds Only) Promotion 500,000.00 Great British PoundstayyabNo ratings yet

- List of Manning Agents: (Seafarers Recruiting Agent)Document19 pagesList of Manning Agents: (Seafarers Recruiting Agent)saifulNo ratings yet

- Ref - No. 2302875-11218095-5: Sakib AkhtarDocument5 pagesRef - No. 2302875-11218095-5: Sakib AkhtarMONISH NAYARNo ratings yet

- Arieyanti Dwi Astuti Badan Perencanaan Pembangunan Daerah Kabupaten Pati Jl. Raya Pati-Kudus Km. 4 Pati. 59163. Jawa TengahDocument15 pagesArieyanti Dwi Astuti Badan Perencanaan Pembangunan Daerah Kabupaten Pati Jl. Raya Pati-Kudus Km. 4 Pati. 59163. Jawa TengahFitriani 1310No ratings yet

- FIcha Tecnica LEXUSDocument2 pagesFIcha Tecnica LEXUSJair GonzalezNo ratings yet

- Andrea A. DisessaDocument26 pagesAndrea A. Disessaakli AmouchiNo ratings yet

- Liam Devaney: ProfileDocument2 pagesLiam Devaney: Profileapi-25949163No ratings yet

- 12 Commerce Public Question Paper - Sep 2020 K.expDocument13 pages12 Commerce Public Question Paper - Sep 2020 K.expmalathi SNo ratings yet

- Documents Required For S&EDocument1 pageDocuments Required For S&EAbhishek Premlata KumarNo ratings yet

- Question: 3 Using The Data in RDCHEM - RAW, The Following Equation WaDocument3 pagesQuestion: 3 Using The Data in RDCHEM - RAW, The Following Equation WaBo NguyenNo ratings yet

- Lecture 7 DP 0-1 KnapsackDocument53 pagesLecture 7 DP 0-1 KnapsackMostafizur RahamanNo ratings yet

- PowerPoint Slides To Chapter 10Document117 pagesPowerPoint Slides To Chapter 10Ashish SinghNo ratings yet