Professional Documents

Culture Documents

Halliburton: Rtts Packer

Uploaded by

mehrdadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Halliburton: Rtts Packer

Uploaded by

mehrdadCopyright:

Available Formats

HALLIBURTON

Description

The RTTS Packer is a full opening,

hookwall packer used for testing, • The packer can be set and

treating, and squeeze cementing relocated as many times as

operations. In most cases, the tool necessary with simple tubing

runs with a circulating valve manipulation.

assembly.

• Tungsten carbide slips provide

The packer body includes a J-slot greater holding ability and

mechanism, mechanical slips, packer improved wear resistance in high

elements, and hydraulic slips. Large, strength casing. Pressure through

heavy duty slips in the hydraulic hold the tubing activates the slips.

down mechanism help prevent the tool

from being pumped up the hole. Drag • An optional integral circulating

springs operate the J-slot mechanism valve locks into open or closed

on ≤ 3-1/2 in. packer bodies while position during squeezing or

larger packer sizes (≥ 4 in.) use drag treating operations, and opens

blocks. Automatic J-slot sleeves are easily to allow circulation above

standard equipment on all packer the packer.

bodies.

Operation

The circulating valve, if used, is a The tool is run slightly below the

locked-open / locked closed type that desired setting position to set the

serves as both a circulating valve and packer and is then picked up and

bypass. The valve automatically rotated several turns. If the tool is on

locks in the closed position when the the bottom, only a half turn is required.

packer sets. During testing or However, in deep or deviated holes,

squeezing operations, the lock several turns with the rotary may be

prevents the valve from being pumped necessary. To maintain position, the

open. A straight J-slot in the locked- right hand torque must be held until the

open position matches with a straight mechanical slips on the tool are set and

J-slot in the packer body. This can start taking weight.

combination eliminates the need to

turn the tubing to close the circulating The pressure must be equalized across

valve or rest the packer after the the packer to unset it. As the tubing is

tubing has been displaced with picked up, the circulating valve RTTS

cement. remains closed, establishing reverse Packer

circulation around the lower end of the

Features and Benefits packer. The circulating valve is

• Full opening design of the opened for coming out of the hole

packer mandrel bore allows when the tubing is lowered, rotated to

large volumes of fluid to pump the right, and picked up.

through the tool. Tubing type

guns and other wireline tools

can be run through the packer

RTTS PACKER Page 1 of 2

HALLIBURTON

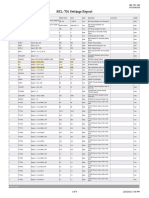

Specifications

RTTS Packer

Casing Size† 2-3/8 in. 5 in. 7 in. 9 5/8 in. 13 3/8 in.

OD 1.81 4.06 5.75 8.25 11.94

in. (cm) (4.60) (10.31) (14.61) (20.96) (30.33)

ID 0.6 1.8 2.4 3.75 3.75

in. (cm) (1.52) (4.57) (6.10) (9.52) (9.52)

2 7/8 EUE 3 7/8 CAS (box)

End Connections 1.05 10RD 2 7/8 EUE x 3 1/2 IF (pin) 4 1/2 IF

3 1/2 IF

4 1/2 IF

Length 34.34 45.98 52.10 77.58 96.99

in. (cm) (87.22) (116.79) (132.33) (197.05) (246.35)

Tensile Rating* 28,400 79,800 158,200 444,600 651,300

lb (kg) (12,900) (36,200) (71,700) (201,700) (295,400)

Working 10,000 10,000 10,000 10,000 7,500

Pressure** (69,000) (69,000) (69,000) (69,000) (51,700)

psi (kPa)

Shipping Weight 35 98 216 652 1,290

lb (kg) (16) (44) (98) (296) (585)

Note: † These are the most common sizes. Other sizes may be available.

* The tensile strength value is calculated with new tool conditions. Stress area calculations are

used to calculate tensile strength.

** Pressure rating is defined as differential pressure at the tool. (Differential pressure is the

difference in pressure between the casing annulus and the tool ID.

These ratings are guidelines only.

For more information, consult your local Halliburton representative.

Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the

contract between Halliburton and the customer that is applicable to the sale.

You might also like

- DST Tools CatalogDocument103 pagesDST Tools CatalogSikander Mushtaq100% (1)

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Rtts Circulating DeviceDocument1 pageRtts Circulating Devicebambangri1No ratings yet

- DST Tools Catalog PDF FreeDocument103 pagesDST Tools Catalog PDF FreeReza AsakerehNo ratings yet

- Wellcare Oil Tools Private LimitedDocument4 pagesWellcare Oil Tools Private LimitedPedro Andrés GarzonNo ratings yet

- RTTS Circulating ValveDocument2 pagesRTTS Circulating ValveHamid Reza BabaeiNo ratings yet

- Rtts Packer: Features and BenefitsDocument4 pagesRtts Packer: Features and Benefitsr_ergin100% (1)

- Halliburton: Slip JointDocument2 pagesHalliburton: Slip Jointsaeed65No ratings yet

- ELDER IX 5 5 X 2 375Document8 pagesELDER IX 5 5 X 2 375crni rokoNo ratings yet

- RTTS Safety JointDocument3 pagesRTTS Safety JointHamid Reza BabaeiNo ratings yet

- Wire Line Set Retrievable Packer: Drilling & Down-Hole Completion ToolsDocument11 pagesWire Line Set Retrievable Packer: Drilling & Down-Hole Completion Toolsparag padoleNo ratings yet

- Rtts PackerDocument2 pagesRtts Packersaeed65100% (2)

- Technical Services Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesTechnical Services Tel: (800) 381-9312 / Fax: (800) 791-5500RobertoNo ratings yet

- 2023 10.75 TST-2 Service PackerDocument15 pages2023 10.75 TST-2 Service PackerDhenny FarialNo ratings yet

- Section 8 Trench Adapter 10-06-14Document12 pagesSection 8 Trench Adapter 10-06-14Cesar YalanNo ratings yet

- Turbo Lux 3 Technical Data SheetDocument8 pagesTurbo Lux 3 Technical Data SheetAntonijeNo ratings yet

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaNo ratings yet

- Check-Trol: Isolation Flow Control FlangeDocument2 pagesCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6eNo ratings yet

- Champ Ion PackerDocument2 pagesChamp Ion PackerCHO ACHIRI HUMPHREYNo ratings yet

- Feeder "Te" Rotary (Airlock) : ApplicationDocument5 pagesFeeder "Te" Rotary (Airlock) : ApplicationzementheadNo ratings yet

- Drain Valve - Bussines CatalogDocument2 pagesDrain Valve - Bussines CatalogAnne SophiaNo ratings yet

- GX Annular Blowout PreventerDocument2 pagesGX Annular Blowout PreventerCarlos Munizaga100% (1)

- Lok-Set PackerDocument2 pagesLok-Set PackerlucasNo ratings yet

- CheckTrol43 PDFDocument2 pagesCheckTrol43 PDFAnonymous 7xHNgoKE6eNo ratings yet

- Hydro-Lift Core Catcher Technical Data SheetDocument2 pagesHydro-Lift Core Catcher Technical Data Sheethaoues23No ratings yet

- Tubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The WorkstringDocument2 pagesTubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The Workstringadi nugroho100% (1)

- Drill Pipe & Casing Tongs: Product CatalogDocument12 pagesDrill Pipe & Casing Tongs: Product CatalogAnonymous fBIEWgmRzNo ratings yet

- Rupture Disk FUL-FLO Sampler: HalliburtonDocument2 pagesRupture Disk FUL-FLO Sampler: Halliburtonsaeed65No ratings yet

- Petol Surgrip Casing Tongs: Patent #7,275,463Document2 pagesPetol Surgrip Casing Tongs: Patent #7,275,463RODOLFO ISIDRONo ratings yet

- Empaque Ad-1 Tension PKRDocument10 pagesEmpaque Ad-1 Tension PKRolger nino100% (2)

- TFP1305 08 2018 ObsoleteDocument8 pagesTFP1305 08 2018 Obsoletefassart.jNo ratings yet

- 2021 16.0 TST-2 Service PackerDocument15 pages2021 16.0 TST-2 Service PackerDhenny FarialNo ratings yet

- Ball Valve, Stainless Steel: ConstructionDocument19 pagesBall Valve, Stainless Steel: ConstructionSanjay MaheshNo ratings yet

- POTVDocument1 pagePOTVCap1284No ratings yet

- Smart Mag™ Rotating String Magnet BlackDocument5 pagesSmart Mag™ Rotating String Magnet BlackAjith MohandasNo ratings yet

- Pump Installation and Maintenance GuideDocument6 pagesPump Installation and Maintenance GuideMohammed Amin BenharkatNo ratings yet

- 2, 5 Inch Side Door Stripper PDFDocument16 pages2, 5 Inch Side Door Stripper PDFOvRrj AhmedNo ratings yet

- Field Well No Well 18 Update:::: 13-Jun-07 ### Tubing and Pump DataDocument1 pageField Well No Well 18 Update:::: 13-Jun-07 ### Tubing and Pump DataAndre YudhistiraNo ratings yet

- All Business.: 320D/320D L Hydraulic ExcavatorsDocument7 pagesAll Business.: 320D/320D L Hydraulic Excavatorsgarybc964No ratings yet

- Inverter Microprocessor-Controlled: Certified Kubota Mfg. CorpDocument4 pagesInverter Microprocessor-Controlled: Certified Kubota Mfg. CorpTotok SurotoNo ratings yet

- Smart Mag™ Non Rotating String Magnet BlackDocument4 pagesSmart Mag™ Non Rotating String Magnet BlackAjith MohandasNo ratings yet

- D690 Round Damper: Low-Leakage, Single-BladeDocument4 pagesD690 Round Damper: Low-Leakage, Single-BladeGustavo AyllonNo ratings yet

- Manual Serva Pump TPD600Document82 pagesManual Serva Pump TPD600Herlis Savitri88% (8)

- Alfa Laval FilterStrainer - PDDocument4 pagesAlfa Laval FilterStrainer - PDBayu RahmansyahNo ratings yet

- Sanitario + Flux + SensorDocument2 pagesSanitario + Flux + SensorFernando CaicedoNo ratings yet

- Hydraulic Tank Jack Equipment Brochure FinalDocument13 pagesHydraulic Tank Jack Equipment Brochure FinalAris MunandarNo ratings yet

- Workshopmanual xl500r 1982 Multi 09062014 2148Document100 pagesWorkshopmanual xl500r 1982 Multi 09062014 2148daqyou daqNo ratings yet

- Graseras AlemitesDocument37 pagesGraseras Alemitesjoroma58No ratings yet

- Fisher 1051 & 1052 ActuatorDocument48 pagesFisher 1051 & 1052 ActuatorArianeth BalcazarNo ratings yet

- TC1001-D Annular BOP Replacement Part CatalogDocument24 pagesTC1001-D Annular BOP Replacement Part CatalogFam Escalante OnofreNo ratings yet

- Service ToolsDocument29 pagesService ToolsRobert TirtaNo ratings yet

- 6.625 X 2.875 DLH PACKER (17-24) 935-6625-103 Rev BDocument7 pages6.625 X 2.875 DLH PACKER (17-24) 935-6625-103 Rev BDEATH ASSASSIN GAMERNo ratings yet

- Roller Screw BrochureDocument8 pagesRoller Screw BrochureRjgandhi65No ratings yet

- RB130Document17 pagesRB130pje207No ratings yet

- Mod 70 SWL 100tDocument2 pagesMod 70 SWL 100tKintali Vinod100% (1)

- DST Tool Presentation 1Document16 pagesDST Tool Presentation 1jairaso2950No ratings yet

- RAPTOR Cone CrusherDocument4 pagesRAPTOR Cone CrusherLuis Miguel La TorreNo ratings yet

- Hole volume and drilling calculationsDocument7 pagesHole volume and drilling calculationsmehrdadNo ratings yet

- Hole volume and drilling calculationsDocument7 pagesHole volume and drilling calculationsmehrdadNo ratings yet

- Tong Line PullDocument1 pageTong Line PullmehrdadNo ratings yet

- Tong Line PullDocument1 pageTong Line PullmehrdadNo ratings yet

- Recommended Minimum Make Up Torque SpecsDocument2 pagesRecommended Minimum Make Up Torque SpecsmehrdadNo ratings yet

- Recommended Minimum Make Up Torque SpecsDocument2 pagesRecommended Minimum Make Up Torque SpecsmehrdadNo ratings yet

- Hole volume and drilling calculationsDocument7 pagesHole volume and drilling calculationsmehrdadNo ratings yet

- Hammer Unions and Swivel Joints: AjouloncompanyDocument16 pagesHammer Unions and Swivel Joints: AjouloncompanyEdwin HernandezNo ratings yet

- Surface BOP Kill Sheet Provides Critical Well Control DataDocument2 pagesSurface BOP Kill Sheet Provides Critical Well Control Datarafiullah353No ratings yet

- Hydratight PDFDocument40 pagesHydratight PDFTamer Farahat100% (1)

- شماتیک کالرDocument1 pageشماتیک کالرmehrdadNo ratings yet

- موتور شماتیکDocument1 pageموتور شماتیکmehrdadNo ratings yet

- 70 OvershotDocument1 page70 OvershotmehrdadNo ratings yet

- Monbukagakusho Physics 2010 SolutionDocument26 pagesMonbukagakusho Physics 2010 SolutionIskandar Setiadi100% (11)

- Physics Form 5: WavesDocument47 pagesPhysics Form 5: WavesRamliRem100% (1)

- OISD 226 Natural Gas and CGD NetworkDocument75 pagesOISD 226 Natural Gas and CGD NetworkVartika UpretyNo ratings yet

- Green Technology ReportDocument5 pagesGreen Technology Reportdylyn jane gallegoNo ratings yet

- The Indian Coffee House at ThiruvanathapuramDocument13 pagesThe Indian Coffee House at ThiruvanathapuramAdil BackerNo ratings yet

- Unit - Iv Urban Conservation: Principles and ObjectivesDocument4 pagesUnit - Iv Urban Conservation: Principles and ObjectivesManiMannan100% (1)

- Green FrameworkDocument22 pagesGreen Frameworkjalees23No ratings yet

- Solis 1P (1 5K) 4G - V1Document24 pagesSolis 1P (1 5K) 4G - V1Jhasper ManagyoNo ratings yet

- Heat load calculation for proposed MV and control room buildingsDocument24 pagesHeat load calculation for proposed MV and control room buildingspsn_kylmNo ratings yet

- FormDocument2 pagesFormBhargav VekariaNo ratings yet

- Folleto Lavadora Carga Superior YWNE5 ComercialDocument2 pagesFolleto Lavadora Carga Superior YWNE5 ComercialKarly OrtegaNo ratings yet

- Thermo-Dynamic Steam Trap TD52-Installation Maintenance ManualDocument2 pagesThermo-Dynamic Steam Trap TD52-Installation Maintenance ManualMasroor GhouriNo ratings yet

- Reserve Power: Res Opzv BatteriesDocument8 pagesReserve Power: Res Opzv BatteriesJayson EnrileNo ratings yet

- Exercise 26 - Hyperchem 8 04 Am1 Calculations Electron Stability of Molecules AromaticityDocument4 pagesExercise 26 - Hyperchem 8 04 Am1 Calculations Electron Stability of Molecules Aromaticityapi-235187189No ratings yet

- Lennox - Mini Split - 17SEER - 9K - HP - SubmittalDocument3 pagesLennox - Mini Split - 17SEER - 9K - HP - SubmittalJose Baez C.No ratings yet

- K 1 5 KV 8.25 KV and 15 KV Vacuum Circuit Breaker Renewal Parts Pl01301011eDocument24 pagesK 1 5 KV 8.25 KV and 15 KV Vacuum Circuit Breaker Renewal Parts Pl01301011eTomy ArgoteNo ratings yet

- IEEE 841 OverviewDocument6 pagesIEEE 841 OverviewchadgvNo ratings yet

- Skid Vibration ProblemsDocument16 pagesSkid Vibration ProblemsarturomNo ratings yet

- SEL-701 Settings ReportDocument9 pagesSEL-701 Settings ReportJosé AntonioNo ratings yet

- TransformersDocument5 pagesTransformersVishakhNo ratings yet

- Zaxis-Series: Hydraulic ExcavatorDocument20 pagesZaxis-Series: Hydraulic ExcavatorvitaliyNo ratings yet

- GHG 612 RCD Technical Specifications and Ordering InformationDocument3 pagesGHG 612 RCD Technical Specifications and Ordering Informationkhairalla mohamedNo ratings yet

- Surge protection arrestor for offices and homesDocument1 pageSurge protection arrestor for offices and homesSofia Rincon GomezNo ratings yet

- DC motor speed control using chopper driveDocument6 pagesDC motor speed control using chopper driveTan Chuan ChetNo ratings yet

- Page 1 of 4: Design & Calculation Drawing Results Viva-Voce Record Total 30 40 10 10 10 100Document4 pagesPage 1 of 4: Design & Calculation Drawing Results Viva-Voce Record Total 30 40 10 10 10 100UthraNo ratings yet

- 4 - Barrier Penetration and TunnelingDocument16 pages4 - Barrier Penetration and Tunnelingdothaibinhca2004No ratings yet

- HVDC 60years PDFDocument10 pagesHVDC 60years PDFAdrian FernandezNo ratings yet

- Instruction Manual: Dossena S.N.CDocument12 pagesInstruction Manual: Dossena S.N.CRazvan SasuNo ratings yet

- GM150 Commissioning ManualDocument358 pagesGM150 Commissioning ManualLeandro MedeirosNo ratings yet

- Pump & Pump Accessories Cross Reference Sheet: Beckett Description Suntec Danfoss NotesDocument1 pagePump & Pump Accessories Cross Reference Sheet: Beckett Description Suntec Danfoss NotesMubarak BaigNo ratings yet