Professional Documents

Culture Documents

Jaw Crusher Series Technical Specification

Jaw Crusher Series Technical Specification

Uploaded by

Ramganesh RamachandranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jaw Crusher Series Technical Specification

Jaw Crusher Series Technical Specification

Uploaded by

Ramganesh RamachandranCopyright:

Available Formats

SANDVIK JAW CRUSHER

SERIES

TECHNICAL SPECIFICATION

HIGH CAPACITY JAW CRUSHERS

AND LOW COST PER TON

Sandvik’s top-of-the-line CJ-type jaw crushers are

specifically built for your primary applications where

resizing is the key objective. They allow the material

to be processed within your crushing plant. To ensure

optimum performance, the jaw crusher needs to have Product picture to be placed here.

a good feed level and a homogeneous feed.

Our jaw crushers are of the single-toggle type and

feature a deep, symmetrical crushing chamber, a

large feed opening for its size, and an ideal nip angle

that offers smooth material flow and high reduction

efficiency.

ADVANTAGES

Jaw crushers are normally capable of a reduction Safe and easy operation and maintenance

ratio of 1:2 or 1:3. This ratio is affected by the feed Proven technology with welded design offer

material’s bulk density, crushability, size distribution a reliable operation

and moisture content – among other factors – and will High capacity

affect the crushing chamber performance. High reduction

Deep symmetrical crushing chamber and optimized nip angle

The nip angle is the angle between the fixed and maximizes size reduction and production capacity

moving jaw plates. Our Sandvik CJ crushers have Wider intake opening offers possibility to handle larger feed

an optimum nip angle in the 16-23 degree range.

FEED SIZE

CRUSHER CSS (MM)* FEED OPENING (MM) MAX FEED (MM)** WEAR PLATE (MM)*** JAW SHIM PLATE (MM)****

CJ211 60-200 1,100 x 700 630 10 2 x 30*****

CJ409 40-180 895 x 660 600 6 -

CJ411 70-225 1,045 x 840 750 6 -

CJ412 70-275 1,200 x 830 750 6 2 x 30

CJ612 115-275 1,200 x 1,100 990 12 50

CJ613 130-300 1,300 x 1,070 1,070 6 50*****

CJ615 115-300 1,500 x 1,070 960 15 50

CJ815 145-300 1,500 x 1,300 1,170 15 50

* Minimum CSS is depending on Work Index

** Apply for regularly shaped material. Occasional larger lumps can be accepted, but if material is irregularly

shaped, difficulties may be also experienced with smaller lumps.

*** Wear plates are installed on both sides as standard. This is to prevent impact on the frame and jaw.

**** The jaw shim plate is installed on the fixed side, except on CJ211 and CJ412 where the two plates are installed

on both sides. This is optional equipment.

***** Jaw shim plate is installed instead of the wear plate.

CAPACITIES IN MTPH CAPACITIES IN STPH

CSS (MM) CJ211 CSS (INCH) CJ211

60 110-160 2 3/8 115-165

70 120-180 2 3/4 130-200

80 135-205 3 1/8 150-225

90 150-230 3 1/2 165-255

100 160-250 4 175-275

125 195-310 5 215-340

150 230-370 6 250-410

170 265-430 7 290-475

200 300-490 8 330-540

The left figures refer to fines removed from feed and the right refers to fines included in the feed.

The Sandvik jaw crusher above is designed for the motor sizes listed in RPG and technical specifications. This

means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive

and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

Warranty will not cover this!

Capacity figures apply for clean, friable and dry granite with a bulk density of 1.6 t/m³ (100 lbs./cu.ft.) or compact

density 2.65 g/cm³.

2 SANDVIK JAW CRUSHER SERIES

CAPACITIES IN MTPH

CJ612

CSS (MM) CJ409 CJ411 CJ412 CJ612 WEDGE SETTING CJ613 CJ615 CJ815

50 85-115

75 100-160 150-200 165-220

100 125-200 200-265 220-290

125 150-235 245-325 270-355 300-395 300-395 330-430 385-495

150 175-275 295-390 325-430 355-465 355-465 385-505 445-590 480-625

175 (200-320) (340-445) 385-505 405-530 405-530 440-575 505-665 545-710

200 (385-505) 445-580 455-595 455-595 495-650 570-745 610-800

225 (430-565) 495-650 (505-660 550-730 630-825 675-885

250 550-720 (560-735) 605-810 (700-920) 745-975

275 605-790 (610-805) 660-885 (765-1000) (820-1070

300 715-960 (825-1085) (885-1160

CAPACITIES IN STPH

CJ612

CSS (INCH) CJ409 CJ411 CJ412 CJ612 WEDGE SETTING CJ613 CJ615 CJ815

2 95-125

3 110-175 165-220 180-245

4 140-220 220-290 245-320

5 165-260 270-360 300-390 330-435 330-435 365-475 425-495

6 190-300 325-430 360-475 390-515 390-515 425-555 490-650 530-690

7 (220-350) (375-490) 425-555 445-585 445-585 485-635 555-735 600-780

8 (425-555) 490-640 500-655 500-655 545-715 630-820 670-880

9 (475-625) 545-715 (555-730) 605-805 695-910 745-975

10 605-795 (620-810) 670-895 (770-1015) 820-175

11 665-870 (670-890) 730-975 (845-1100) (905-1180

12 790-1060 (910-1195) (975-1280

( ) CSS may not be possible to obtain with some jaw plate patterns.

The left figures refer to fines removed from feed and the right refers to fines included in the feed.

The Sandvik jaw crusher line is designed for the motor sizes listed in RPG and technical specifications. This

means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive

and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

Warranty will not cover this!

Capacity figures apply for clean, friable and dry granite with a bulk density of 1.6 t/m³ (100 lbs./cu.ft.) or compact

density 2.65 g/cm³.

SANDVIK JAW CRUSHER SERIES 3

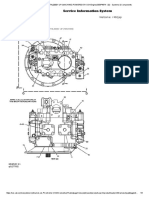

DIMENSIONS* AND WEIGHTS

L

W3

W2

W1

H

Jmax

D

CJ211

Jmax, Max height from jaw (mm) 1,585

TF, Overall feed height (mm) n/a

F, Feed height (mm) 1,120

L, Max Length (mm) 2,386

H, Height (mm) 1,735

TH, Overall height (mm) n/a

W1, Width flywheels (mm) 2,054

W2, Width shaft (mm) 2,082

W3, Width cylinder (mm) 2,447

D, Flywheel diameter (mm) 1,230

Weight*** (kg) 14,300

Crushers speed (rpm) 270

Mom. Of inertia, J (kgm2) 388

* Detailed installation drawings can be found on the Sandvik Intranet or through your Sandvik contact

*** Figures are approximate weights. The weight for each individual unit will vary depending on type of jaw plates,

use of shim plate or not, manufacturing tolerances etc.

L

W2

W1

TH

Jmax

TF

CJ409 CJ409** CJ411 CJ412 CJ412**

Jmax, Max height from jaw (mm) 1,780 1,780 2,032 2,098 2,098

TF, Overall feed height (mm) 1,580 1,580 1,882 1,938 1,938

F, Feed height (mm) n/a n/a n/a 1,590 n/a

L, Max Length (mm) 2,554 2,554 2,986 3,230 3,230

H, Height (mm) n/a n/a n/a 2,603 2,374

TH, Overall height (mm) 2,383 2,230 2,815 2,950 2,668

W1, Width flywheels (mm) 1,723 1,723 1,965 2,208 2,428

W2, Width shaft (mm) 1,882 1,882 2,093 2,336 n/a

W3, Width cylinder (mm) n/a n/a n/a 2,571 2,569

D, Flywheel diameter (mm) 1,605 1,300 1,865 1,865 1,300

Weight*** (kg) 13,200 13,500 20,600 25,200 26,500

Crushers speed (rpm) 270 270 240 240 240

Mom. Of inertia, J (kgm2) 610 510 1,490 1,490 1,050

* Detailed installation drawings can be found on the Sandvik Intranet or through your Sandvik contact

** Special version with compact flywheel used for mobile units

*** Figures are approximate weights. The weight for each individual unit will vary depending on type of jaw plates,

use of shim plate or not, manufacturing tolerances etc.

4 SANDVIK JAW CRUSHER SERIES

L

W2

W1

TH

Jmax

TF

CJ612 CJ613 CJ615 CJ815

Jmax, Max height from jaw (mm) 2,700 2,902 2,695 3,319

TF, Overall feed height (mm) 2,520 2,678 2,394 3,045

F, Feed height (mm) n/a n/a n/a n/a

L, Max Length (mm) 3,996 3,762 4,117 4,496

H, Height (mm) n/a n/a n/a n/a

TH, Overall height (mm) 3,508 3,843 3,330 4,186

W1, Width flywheels (mm) 2,199 2,326 2,876 2,750

W2, Width shaft (mm) 2,347 2,468 2,992 2,894

W3, Width cylinder (mm) 2,826**** n/a n/a n/a

D, Flywheel diameter (mm) 1,865/1,600 2,170 1,760 2,170

Weight*** (kg) 39,000 41,500 53,000 63,500

Crushers speed (rpm) 210 225 200 200

Mom. Of inertia, J (kgm2) 2,080 2,610 3,130 4,200

* Detailed installation drawings can be found on the Sandvik Intranet or through your Sandvik contact

** Special version with compact flywheel used for mobile units

*** Figures are approximate weights. The weight for each individual unit will vary depending on type of jaw plates,

use of shim plate or not, manufacturing tolerances etc.

**** Only if the option hydraulic wedge setting is chosen

DRIVE AND MOTOR

V-BELT

NO. OF TYPE/LENGTH* MOTOR PULLEY MOTOR SPEED MOTOR

CRUSHER V-BELTS (STANDARD FITTING) P.C.D (MM) *** (RPM) (KW/HP)

CJ211 7 SPC/4,750 335 MGT100 985 90/125

CJ409 6 SPC/800 440 MGT100 985 75/100

CJ409** 7 SPC/7,500 355 MGT100 985 75/100

CJ411 8 SPC/9,000 450 MGT125 985 110/150

CJ412 8 SPC/9,000 450 MGT125 985 132/180

CJ412** 9 SPC/8,000 315 MGT100 985 132/180

CJ612 8 SPC/10,600 400 MGT100 985 160/220

CJ613 8 SPC/11,200 500 MGT125 985 160/220

CJ615 11 SPC/9,500 355 MGT100 985 200/275

CJ815 8 SPC/11,200 440 MGT125 985 200/275

* Other types and lengths are available.

** Special version with compact flywheel used for mobile units.

*** 50 Hz

SANDVIK JAW CRUSHER SERIES 5

6 SANDVIK JAW CRUSHER SERIES

SELECTION OF JAW PLATES

Sandvik offers seven teeth patterns and up to three alloy selections (M1, M2, M8) to suit the different types of

quarrying and mining applications. Our patterns include Wide Teeth (WT), Wide Wave (WW), Corrugated (C),

Coarse Corrugated (CC), Sharp Teeth (ST), Heavy Duty (HD), Heavy Duty Ultra-Thick (UT).

M1 is the standard alloy, offering high resistance to shock and impact. It also work well with hard rock. Our M2 and

M8 alloys offer high resistance to abrasive rock, but have lower resistance to shock and impact.

The optimal jaw plate selection can be determined based on the rock/ore type characteristics (WI, AI) and the

feed characteristics (friction, gradation).

WIDE TEETH (WT) WIDE WAVE (WW) SHARP TEETH (ST)

Good wear resistance. For feed with a lot of fines. For slabby and less abrasive feed material. For flaky feed material with a lot of fines.

Can be used on both fixed and moving sides. Feed is relatively easy to crush. Good gripping ability.

Good top-size control. Very good top-size control.

Highly recommended if the AI is not too high.

CORRUGATED (C) COARSE CORRUGATED (CC) HEAVY DUTY (HD)

Suitable for less abrasive material. For abrasive material. For very abrasive material.

Good for small CSS settings. For feed with a lot of fines. Less top-size control.

Good top-size control. Used for large CSS settings. Can be combined with a CC moving plate.

Good top-size control.

HD ULTRA-THICK (UT)

Contact your local Sandvik rep to help you select

the right plate combination for your application.

For very abrasive material.

Less top-size control.

Fixed plate based on our

HD pattern with an extra 30 mm

thickness for longer wear life.

To be used with the CC moving plate.

SANDVIK JAW CRUSHER SERIES 7

CJ211 (J11) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE C ST HD/CC

M1 Fixed 400.2207-001 400.0739-001 400.2870-001

Moving 400.1101-001 400.0738-001 400.2869-001

M2 Fixed 400.2207-002 400.0739-002 400.2870-002

Moving 400.1101-002 400.0738-002 400.2869-001

All jaw plates are one piece unless otherwise stated.

CHEEK PLATES

Upper plate 400.0639-001 Lower plate -

DEFLECTOR PLATE 400.3136-001

CRUSHING CHAMBERS

CORRUGATED (C) SHARP TEETH (ST) HEAVY DUTY/COARSE CORRUGATED (HD/CC)

Suitable for less abrasive material. For flaky feed material with a lot of fines. For very abrasive material.

For feed with a lot of fines. Good gripping ability. Used for large CSS settings.

Good for small CSS settings. Very good top-size control. Good top-size control

Good top-size control. Highly recommended if the

AI is not too high.

8 SANDVIK JAW CRUSHER SERIES

CJ409 (JM907) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE WT C

M1 Fixed 400.0483-001 400.0418-001

Moving 400.0483-001 400.0417-001

M2 Fixed 400.0483-002 400.0418-002

Moving 400.0483-002 400.0417-002

All jaw plates are one piece unless otherwise stated.

CHEEK PLATES

Upper plate 10-314-386-000 Lower plate 10-314-404-000

DEFLECTOR PLATE 10-314-479-000

CRUSHING CHAMBERS

WIDE TEETH (WT) CORRUGATED (C)

Good wear resistance. Suitable for less abrasive material.

For feed with a lot of fines. For feed with a lot of fines.

Can be used on both fixed Good for small CSS settings.

and moving sides. Good top-size control.

SANDVIK JAW CRUSHER SERIES 9

CJ411 (JM1108) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE WT C CC

M1 Fixed 400.0436-001 400.0409-001 400.0437-001

Moving 400.0436-001 400.0410-001 400.0433-001

M2 Fixed 400.0436-002 400.0409-002 400.0437-002

Moving 400.0436-002 400.0410-002 400.0433-002

All jaw plates are one piece unless otherwise stated.

CHEEK PLATES

Upper plate 10-314-262-000 Lower plate 10-314-263-000

DEFLECTOR PLATE 10-214-384-000

CRUSHING CHAMBERS

WIDE TEETH (WT) CORRUGATED (C) COARSE CORRUGATED (CC)

Good wear resistance. Suitable for less abrasive material. For abrasive material.

For feed with a lot of fines. For feed with a lot of fines. For feed with a lot of fines.

Can be used on both fixed and moving sides. Good for small CSS settings. Used for large CSS settings.

Good top-size control. Good top-size control.

10 SANDVIK JAW CRUSHER SERIES

CJ412 (JM1208) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE WT C CC ST HD HD/CC

M1 Fixed 400.0411-001 400.0407-001 400.0425-001 402.4744-01 400.0413-001 400.0413-001

Moving 400.0411-001 400.0408-001 400.0420-001 402.4745-01 400.0412-001 400.0420-001

M2 Fixed 400.0411-002 400.0407-002 400.0425-002 402.4744-02 400.0413-002 400.0413-002

Moving 400.0411-002 400.0408-002 400.0420-002 402.4745-02 400.0412-002 400.0420-002

All jaw plates are one piece unless otherwise stated.

CHEEK PLATES

Upper plate 10-314-262-000 Lower plate 10-314-263-000

DEFLECTOR PLATE BG00541518

CRUSHING CHAMBERS

WIDE TEETH (WT) CORRUGATED (C) COARSE CORRUGATED (CC)

Good wear resistance. Suitable for less abrasive material. For abrasive material.

For feed with a lot of fines. For feed with a lot of fines. For feed with a lot of fines.

Can be used on both fixed Good for small CSS settings. Used for large CSS settings.

and moving sides. Good top-size control. Good top-size control.

SHARP TEETH (ST) HEAVY DUTY (HD) HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For flaky feed material with a lot of fines. For very abrasive material. For very abrasive material.

Good gripping ability. Less top-size control. Used for large CSS settings.

Very good top-size control. Can be combined with a Good top-size control.

Highly recommended if the CC moving plate.

AI is not too high.

SANDVIK JAW CRUSHER SERIES 11

CJ612 (JM1211) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE CC ST WW HD HD/CC

M1 Fixed 400.2266-001 402.4747-01 400.0440-001* 400.0426-001* 400.0426-001*

Fixed middle - - 400.0442-001 400.0427-001 400.0427-001

Moving 400.0443-001 402.4748-01 400.0438-001* 400.0423-001* 400.0443 -001

Moving middle - - 400.0439-001 400.0424-001 -

M2 Fixed 400.2266-002 402.4747-02 400.0440-002* 400.0426-002* 400.0426-002*

Fixed middle - 400.0442-002 400.0427-002 400.0427-002

Moving 400.0443-002 402.4748-02 400.04383-002* 400.0423-002* 400.0443 -002

Moving middle - - 400.0439-002 400.0424-002 -

All jaw plates are one piece unless otherwise stated.

*Two pieces

CHEEK PLATES

Upper plate 402.4239-01 Lower plate 402.4635-01

DEFLECTOR PLATE 402.4250-00

CRUSHING CHAMBERS

COARSE CORRUGATED (CC) SHARP TEETH (ST) WIDE WAVE (WW)

For flaky feed material with a lot of fines. For slabby and less abrasive feed material.

For abrasive material.

Good gripping ability. Feed is relatively easy to crush.

For feed with a lot of fines.

Very good top-size control. Good top-size control.

Used for large CSS settings.

Good top-size control. Highly recommended if the

AI is not too high.

HEAVY DUTY (HD) HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For very abrasive material. For very abrasive material.

Less top-size control. Used for large CSS settings.

Can be combined with a CC moving plate. Good top-size control.

12 SANDVIK JAW CRUSHER SERIES

CJ613 (JM1312) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE C CC ST UT/CC

M1 Fixed 400.0447-001 400.0422-001 400.0963-001 BG00372142-01

Moving 400.0446-001 400.0421-001 400.0964-001 400.0421-001

M2 Fixed 400.0447-002 400.0422-002 - BG00372142-02

Moving 400.0446-002 400.0421-002 - 400.0421-002

M8 Fixed - - 400.0963-004 -

Moving - - 400.0964-004 -

All jaw plates are one piece unless otherwise stated.

CHEEK PLATES

Upper plate 10-214-351-000 Lower plate 10-214-352-000

Upper plate (HX900) BG00395192 Lower plate (HX900) BG00395193

DEFLECTOR PLATE BG00643389

CRUSHING CHAMBERS

CORRUGATED (C) COARSE CORRUGATED (CC) SHARP TEETH (ST)

Suitable for less abrasive material. For abrasive material. For flaky feed material with a lot of fines.

For feed with a lot of fines. For feed with a lot of fines. Good gripping ability.

Good for small CSS settings. Used for large CSS settings. Very good top-size control.

Good top-size control. Good top-size control. Highly recommended if the

AI is not too high.

ULTRA THICK/COARSE CORRUGATED (UT/CC)

For very abrasive material.

Used for large CSS settings.

Less top-size control.

UT fixed plate offers longer wear life.

SANDVIK JAW CRUSHER SERIES 13

CJ615 (JM1511) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE CC ST HD HD/CC

M1 Fixed 400.0485-001 400.0490-001 400.0434-001* 400.0434-001*

Fixed middle - - 400.0435-001 400.0435-001

Moving 400.0488-001 400.0491-001 400.0434-001* 400.0488-001

Moving middle - - 400.0435-001 -

M2 Fixed 400.0485-002 - 400.0434-002* -

Fixed middle - - 400.0435-002 -

Moving - - 400.0434-002* -

Moving middle - - 400.0435-002 -

M8 Fixed 400.0485-004 400.0490-004 400.0434-004* 400.0434-004*

Fixed middle - - 400.0435-004 400.0435-004

Moving 400.0488-004 400.0491-004 400.0434-004 400.0488-004

Moving middle - - 400.0435-004 -

All jaw plates are one piece unless otherwise stated.

*Two pieces

CHEEK PLATES

Upper plate 402.4521-01 Lower plate 402.4522-01

DEFLECTOR PLATE 402.4500-00

CRUSHING CHAMBERS

COARSE CORRUGATED (CC) SHARP TEETH (ST) HEAVY DUTY (HD)

For abrasive material. For flaky feed material with a lot of fines. For very abrasive material.

For feed with a lot of fines. Good gripping ability. Less top-size control.

Used for large CSS settings. Very good top-size control. Can be combined with a CC moving plate.

Good top-size control. Highly recommended if the

AI is not too high.

HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For very abrasive material.

Used for large CSS settings.

Good top-size control.

14 SANDVIK JAW CRUSHER SERIES

CJ815 (JM1513) JAW CRUSHING SOLUTIONS

JAW PLATES

ALLOY MIX PLATE CC ST HD HD/CC

M1 Fixed 400.0473-001* 400.0780-001 400.0463-001** 400.0463-001**

Fixed middle - - 400.0462-001* 400.0462-001*

Moving 400.0472-001* 400.0779-001 400.0460-001** 400.0472-001*

Moving middle - - 400.0461-001* -

M2 Fixed - - 400.0463-002** -

Fixed middle - - 400.0462-002* -

Moving - - 400.0460-002** -

Moving middle - - 400.0461-002* -

M8 Fixed 400.0473-004* 400.0780-004 400.0463-004** 400.0463-004**

Fixed middle - - 400.0463-004* 400.0462-004*

Moving 400.0472-004* 400.0779-004 400.0460-004** 400.0472-004*

Moving middle - - 400.0461-004* -

All jaw plates are one piece unless otherwise stated.

*Two pieces

**Four pieces

CHEEK PLATES

Upper plate 402.4361-01 Lower plate 402.4622-01

DEFLECTOR PLATE 402.4337-00

CRUSHING CHAMBERS

COARSE CORRUGATED (CC) SHARP TEETH (ST) HEAVY DUTY (HD)

For abrasive material. For flaky feed material with a lot of fines. For very abrasive material.

For feed with a lot of fines. Good gripping ability. Less top-size control.

Used for large CSS settings. Very good top-size control. Can be combined with a CC moving plate.

Good top-size control. Highly recommended if the

AI is not too high.

HEAVY DUTY/COARSE CORRUGATED (HD/CC)

For very abrasive material.

Used for large CSS settings.

Good top-size control.

SANDVIK JAW CRUSHER SERIES 15

TS5-1181/ENG/METRIC © Sandvik Mining and Rock Technology 2019 SANDVIK is a registered trademark owned by Sandvik Intellectual Property AB in Sweden and other countries.

Sandvik Mining and Rock Technology reserves the right to make changes to the information on this data sheet without prior notification

to users. Please contact a Sandvik representative for clarification on specifications and options.

ROCKTECHNOLOGY.SANDVIK

You might also like

- ManualDocument196 pagesManualXavier MereloNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

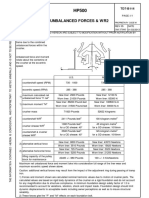

- hp300 PDFDocument2 pageshp300 PDFsam samin100% (1)

- Corolla 2016diagrama completo-1ZR-TDocument29 pagesCorolla 2016diagrama completo-1ZR-TJose david Martinez apazaNo ratings yet

- Current Revision Approved: Eccentric Assy, 68H/SbsDocument1 pageCurrent Revision Approved: Eccentric Assy, 68H/Sbscapslive_001No ratings yet

- Svedala 1208 PDFDocument8 pagesSvedala 1208 PDFrobertoNo ratings yet

- KEESTRACK Productoverview - 5.17 - Eng - Web - 11Document43 pagesKEESTRACK Productoverview - 5.17 - Eng - Web - 11Антон ЛазаровNo ratings yet

- 2.3 - Td7-B152-E-04Document17 pages2.3 - Td7-B152-E-04Julio Suarez Zedano100% (2)

- Parts List in Alphabetical Order: Brand Model Productid Product Description WT Oem No DWG RemarksDocument240 pagesParts List in Alphabetical Order: Brand Model Productid Product Description WT Oem No DWG Remarkslandago50% (4)

- HP4 Spear PartsDocument135 pagesHP4 Spear PartsDmitry Sidlak50% (2)

- PBG Cone CrusherDocument14 pagesPBG Cone CrusherFaizal Ghalib100% (1)

- Crusher Guide Ch440Document5 pagesCrusher Guide Ch440biro_4100% (1)

- c116 Pitmany AssyDocument2 pagesc116 Pitmany AssyYeco MachineryNo ratings yet

- Air Blower ONLY FOR HP500 HP3-4-5-6: Customer Provided Informations Start/StopDocument34 pagesAir Blower ONLY FOR HP500 HP3-4-5-6: Customer Provided Informations Start/StopRoque LlamoccaNo ratings yet

- Content Inhalt Contenido Sisällysluettelo InnehållDocument129 pagesContent Inhalt Contenido Sisällysluettelo InnehållLina JiaNo ratings yet

- 4500 VSI Operation Manual PDFDocument114 pages4500 VSI Operation Manual PDFkgeorge_24No ratings yet

- HP200 300 400 500 Electrical Drawings D100001249 1Document4 pagesHP200 300 400 500 Electrical Drawings D100001249 1Arturo Ramos Nuñez100% (1)

- HP500 Technical Specifications Instructions TD7 B114 E 05Document1 pageHP500 Technical Specifications Instructions TD7 B114 E 05Arturo Ramos Nuñez100% (1)

- JM1312-06 WPC R222.307.en-02Document12 pagesJM1312-06 WPC R222.307.en-02cachitNo ratings yet

- C110Document53 pagesC110Lina Jia100% (1)

- New Holland Crawler Dozer d180 en Service ManualDocument20 pagesNew Holland Crawler Dozer d180 en Service Manualcorey100% (46)

- CH440-01 WPC R223.1325-01 PDFDocument18 pagesCH440-01 WPC R223.1325-01 PDFJuanchido007100% (1)

- SANDVIK CJ411:01: Wear Parts CatalogDocument12 pagesSANDVIK CJ411:01: Wear Parts CatalogECU Mod100% (1)

- Instrucciones de Operación y Montaje SMCP 63x75Document138 pagesInstrucciones de Operación y Montaje SMCP 63x75gytomanNo ratings yet

- PDF Conciliacion Materiales DLDocument96 pagesPDF Conciliacion Materiales DLCarlos Augusto100% (1)

- Cobra 290 & 290R Illustrated Parts Catalog - Revision 1.0Document449 pagesCobra 290 & 290R Illustrated Parts Catalog - Revision 1.0andrew stablesNo ratings yet

- CH430 01 02 IMA S223 651 en 02 PDFDocument33 pagesCH430 01 02 IMA S223 651 en 02 PDFferneyarrieta38100% (2)

- Mechanical Drawings: Original InstructionsDocument20 pagesMechanical Drawings: Original InstructionsJayantha parakrama ThennakoonNo ratings yet

- 2009破碎机备件及耗材重量Document184 pages2009破碎机备件及耗材重量Lina JiaNo ratings yet

- GP300 enDocument76 pagesGP300 eneaglego00100% (5)

- SANDVIK CJ411:01: Operator's ManualDocument80 pagesSANDVIK CJ411:01: Operator's ManualECU Mod100% (2)

- Sandvik JM907 Crusher Parts ManualDocument1 pageSandvik JM907 Crusher Parts ManualTomas Chien100% (1)

- CH420-01 WPC R223.1327.en-01 PDFDocument16 pagesCH420-01 WPC R223.1327.en-01 PDFleonidas cespedesNo ratings yet

- TC66-Series Cone Crushers IOM Manual - Rev.4 - Conos Trio LinderosDocument74 pagesTC66-Series Cone Crushers IOM Manual - Rev.4 - Conos Trio LinderosFrancisco Vera100% (3)

- Norberg HP Application Guide 2602 HiresDocument12 pagesNorberg HP Application Guide 2602 HiresNancy J100% (1)

- Moledor de Impacto VerticalDocument128 pagesMoledor de Impacto VerticalAdrian Alonso Bustos GonzalezNo ratings yet

- SANDVIK CS660:01: Spare Parts CatalogDocument36 pagesSANDVIK CS660:01: Spare Parts CatalogMf Lui100% (1)

- SANDVIK CH660:01: Spare Parts CatalogDocument34 pagesSANDVIK CH660:01: Spare Parts CatalogEduardo100% (1)

- Sandvik JM806 Crusher Parts ManualDocument1 pageSandvik JM806 Crusher Parts ManualTomas ChienNo ratings yet

- Application Guide Nordberg GP Series Cone CrushersDocument14 pagesApplication Guide Nordberg GP Series Cone CrushersAndrey Gyrych100% (1)

- Barmac B7150SE S N B7100179Document147 pagesBarmac B7150SE S N B7100179Javier Jimenez PerezNo ratings yet

- HP500 Technical Specifications Instructions TD7 B114 E 05Document4 pagesHP500 Technical Specifications Instructions TD7 B114 E 05Arturo Ramos NuñezNo ratings yet

- 06.CH430-04 Installation Instructions S223.1256-02 en-USDocument70 pages06.CH430-04 Installation Instructions S223.1256-02 en-USAtef YagoubiNo ratings yet

- Ensamble Trituradora de ConoDocument266 pagesEnsamble Trituradora de ConoIrving Dirzo CarrilloNo ratings yet

- User Manual: HPT Series Efficient Hydraulic Cone CrushersDocument183 pagesUser Manual: HPT Series Efficient Hydraulic Cone Crusherseka rizky sujono100% (1)

- Lokotrack LT300HP S N 77675Document763 pagesLokotrack LT300HP S N 77675Oscar BermeoNo ratings yet

- Terex Crushers (DA) CompressedDocument24 pagesTerex Crushers (DA) CompressedAnonymous OVhnLp100% (1)

- CJ409-01 SPC R222.333.en-04Document18 pagesCJ409-01 SPC R222.333.en-04Marcos Guardia100% (2)

- Nordberg CVB204 S/N 50940011 Toc Specification: Tue, 30 Jun 2015 1Document59 pagesNordberg CVB204 S/N 50940011 Toc Specification: Tue, 30 Jun 2015 1Abdul Latif100% (2)

- CTHS430-02 OMM S223.857.en-01Document118 pagesCTHS430-02 OMM S223.857.en-01Patricio Tamayo100% (5)

- Sravya Infracon Supplies Crusher Spare Parts For MetsoDocument2 pagesSravya Infracon Supplies Crusher Spare Parts For MetsoajithNo ratings yet

- SANDVIK CJ211:01: Spare Parts CatalogDocument16 pagesSANDVIK CJ211:01: Spare Parts CatalogAndrey StrukovNo ratings yet

- Sandvik VSI Crusher Parts ManualDocument3 pagesSandvik VSI Crusher Parts ManualTomas Chien100% (1)

- ASRi20 OM S223.531.en-02Document96 pagesASRi20 OM S223.531.en-02mlchoquehuanca100% (4)

- ASRi20 SPC R223.1355.en-01Document18 pagesASRi20 SPC R223.1355.en-01bodhy852003100% (2)

- Sandvik Crusher Spare PartsDocument47 pagesSandvik Crusher Spare PartsАленка ДерзковаNo ratings yet

- Trio TV85 VSI Parts Manual (SN. 078) PDFDocument25 pagesTrio TV85 VSI Parts Manual (SN. 078) PDFChancadores Chile100% (1)

- CH420-01 WPC R223.1327-01Document16 pagesCH420-01 WPC R223.1327-01ferneyarrieta38100% (1)

- ASRi20 SPC R223 1355 en 01 PDFDocument18 pagesASRi20 SPC R223 1355 en 01 PDFThinhNo ratings yet

- Geartec Turbogetriebe PrintDocument24 pagesGeartec Turbogetriebe PrintZacEffortNo ratings yet

- Technical Data MJC SeriesDocument4 pagesTechnical Data MJC SeriesBenjamin MurphyNo ratings yet

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604No ratings yet

- Shell Moulding - For WebDocument4 pagesShell Moulding - For WebKRISHNA KANT GUPTANo ratings yet

- Installation Instructions: Fittings and PortsDocument5 pagesInstallation Instructions: Fittings and PortsVictor Lo Dastek UnichipNo ratings yet

- Electronics 11 02162Document18 pagesElectronics 11 02162Shah ZaidNo ratings yet

- MHD56472 - ed5-CE PartsDocument24 pagesMHD56472 - ed5-CE Partsmarwa mahmoudNo ratings yet

- Screwdriver: Tool ScrewsDocument4 pagesScrewdriver: Tool Screwscotton byNo ratings yet

- Nmp830 HP Series Micro Diaphragm Gas Pumps: Advantages Possible Areas of UseDocument4 pagesNmp830 HP Series Micro Diaphragm Gas Pumps: Advantages Possible Areas of UseAhmad FarisNo ratings yet

- 1 Ingeniería ToyotaDocument2 pages1 Ingeniería Toyotaalexander pintoNo ratings yet

- Identificacion de Piezas de 320D FalDocument5 pagesIdentificacion de Piezas de 320D Falcriscc7No ratings yet

- Delta Planetary Gearbox: PA SeriesDocument2 pagesDelta Planetary Gearbox: PA SeriesPratik TapadiaNo ratings yet

- ETM - CIG Carens FJDocument1 pageETM - CIG Carens FJHendra GunawanNo ratings yet

- SIME Power Unit PDFDocument10 pagesSIME Power Unit PDFGabriel SianencoNo ratings yet

- SARFAESI Property Expo 10Document163 pagesSARFAESI Property Expo 10Recovery & Legal Section CO ChennaiNo ratings yet

- Datasheet 4057 4457 3-Way Pilot Valves Rev1Document7 pagesDatasheet 4057 4457 3-Way Pilot Valves Rev1Tuan NguyenNo ratings yet

- Aerius VB1115 Parts Manual Rev BDocument13 pagesAerius VB1115 Parts Manual Rev BNicola BattaglinoNo ratings yet

- Hydraulic Bench Test Procedures (Hydraulic Components)Document3 pagesHydraulic Bench Test Procedures (Hydraulic Components)CarlosNo ratings yet

- Sp8300 Part CatalogoDocument111 pagesSp8300 Part CatalogoLeonard FreitasNo ratings yet

- CHR Brochure PDFDocument9 pagesCHR Brochure PDFLuk Ming YinNo ratings yet

- Mitsubishi Marine Engine Line Up2023Document12 pagesMitsubishi Marine Engine Line Up2023kokokNo ratings yet

- Engine SpecificationsDocument3 pagesEngine SpecificationsGabriel Andres ValenciaNo ratings yet

- MD7 - Manutençao e GarantiaDocument104 pagesMD7 - Manutençao e GarantiaAssistência Carbus100% (1)

- Certificate of Inspection and Pass: Robyn MossDocument3 pagesCertificate of Inspection and Pass: Robyn MossAnonymous yzHVcM5No ratings yet

- Display HidraulicoDocument21 pagesDisplay HidraulicoFrancisco JúniorNo ratings yet

- 1230ES Spec SheetDocument2 pages1230ES Spec Sheetbilly_bNo ratings yet

- 2022 Volkswagen Golf R HatchbackDocument6 pages2022 Volkswagen Golf R HatchbackOverhauled ArtsNo ratings yet

- FUCHS Product Line 2015Document76 pagesFUCHS Product Line 2015Dicky AgusmanNo ratings yet

- Vehicle Dynamics Assignment, by Garbe ChukuluDocument10 pagesVehicle Dynamics Assignment, by Garbe ChukuluGarbe Chukulu67% (3)

- Chapter 03 CompleteDocument80 pagesChapter 03 CompleteUbeimar Rivera OspinaNo ratings yet