Professional Documents

Culture Documents

Drill Pipe Performance Sheet: Pipe Body Specification Tool Joint Specification

Uploaded by

Lenin Merchán MartínezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Pipe Performance Sheet: Pipe Body Specification Tool Joint Specification

Uploaded by

Lenin Merchán MartínezCopyright:

Available Formats

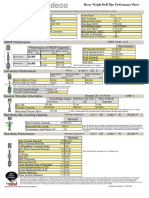

Drill Pipe Performance Sheet

4/21/2021

Pipe Body Specification Tool Joint Specification

Pipe Body OD in 3.5 Connection Type and Size GPDS™ 38

Pipe Body Wall Thickness - Nominal Weight 0.368 in - 13.3 lb/ft Benchmark GPmark™

Pipe Body Grade S135 SmoothEdge™ Height per side in N/A

Drill Pipe Length Range 2 Tool Joint SMYS psi 120,000

- Max ft 32.0 Connection OD in 4.875

- Min ft 30.0 Connection ID in 2.438

Type of Upset EU Pin Tong Length in 10.0

Max Upset OD in 3.875 Box Tong Length in 12.5

Tong Length includes hardbanding if applicable Thread Compound Friction Factor (FF) 1.0

Pipe Body Performance Tool Joint Performance

Nominal API Premium Max Make-Up Torque (Recommended) ft-lbs 17,400

80% Inspection Class 14,500

Min Make-Up Torque ft-lbs

Burst Pressure * psi 24,840 22,700

Min TJ OD (API Premium) in 4.57

Collapse Pressure * psi 25,400 21,630

Min TJ OD for Counterbore in 4.57

Slip Crushing Capacity * lbs 381,300 301,100

Drift Size in 2.313

- Assumed Slip Length in 16.5

The maximum make-up torque should be applied when possible.

- Assumed Transverse Load Factor (K) 4.2 To maximize connection operational tensile, a MUT (T4) = 14,700 should be applied.

Adjusted Weight ** lbs/ft 15.46

Fluid Displacement ** US gal/ft 0.24 Advisories and Warnings for Drill Pipe

Bbls/ft 0.0056 Advisories:

Fluid Capacity ** US gal/ft 0.29 Warnings:

Bbls/ft 0.007

* With no axial load or bending in string ** Best estimate with coating

Note: Oil field barrel equivalent to 42 US gal Note: Nominal burst calculated at 87.5% RBW per API

The Technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be consider as a

recommendation. The user is fully responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the

results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall

thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only

and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings,

acceptable use of the product, maintain safe operating practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin

and box IDs, tool joint ID refers to the pin ID. Per Chapter DS, Section DS-16 of the drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

All references to any internal standards or specifications are per the current edition/revision at the point of manufacturing, unless otherwise stated. All references to any external standards or specifications are

per the current edition/revision at the original purchase order (P.O.) date, unless otherwise stated.

Grant Prideco L. P. | 10100 Houston Oaks Dr. | Houston, TX 77064 | www.nov.com/grantprideco 1

Drill Pipe Performance Sheet

4/21/2021

Combined Loading for Drill Pipe Connection Wear Table

Connection: GPDS™ 38 4.875" x 2.438" (120 KSI SMYS ) Friction Factor: 1.0 Connection: GPDS™ 38 4.875" x 2.438" (120 KSI SMYS ) Friction Factor: 1.0

Pipe: 3.5" OD 0.368" Wall Thickness S135 80% Inspection Class Tool Joint OD (in) Max MUT(ft-lbs) Min MUT(ft-lbs)

At Max MUT (17400 ft-lbs ) At Min MUT (14500 ft-lbs ) 4.875 17400 14500

Operational Assembly Max Operational Assembly Max 4.847 17400 14500

Torque(ft-lbs) Tension(lbs) Torque(ft-lbs) Tension(lbs) 4.82 17100 14200

0 381900 0 381900 4.792 16600 13800

800 381700 700 381700 4.764 16100 13400

1700 381000 1400 381300 4.736 15600 13000

2500 380100 2100 380600 4.709 15100 12600

3400 378600 2800 379600 4.681 14600 12200

4200 376800 3500 378400 4.653 14100 11800

5100 374400 4100 377000 4.625 13700 11400

5900 371800 4800 375200 4.598 13200 11000

6800 368400 5500 373100 4.57 12700 10600

7600 365000 6200 370700

8500 360600 6900 368000 Elevator Capacity

9300 356300 7600 365000 Elevator Bore Diameter: 3.96875" Elevator SMYS: 110,100 psi Box Taper Angle: 18 deg

10200 350900 8300 361700 Connection: GPDS™ 38 3.5" 0.368" wall EU S135

11000 345600 9000 358000 Tool Joint OD (in.) Elevator Hoist Capacity (lbs)

11900 339000 9700 354000 No Wear 1/32" Wear Factor

12700 332600 10400 349600 4.875 693000 671500

13600 324800 11000 345600 4.847 669500 648000

14400 317100 11700 340500 4.82 646900 625400

15300 307800 12400 335100 4.792 623700 602100

16100 298800 13100 329200 4.764 600500 579000

4.736 577500 556000

4.709 555500 533900

The Technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be

consider as a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume

4.681 532700 511200

responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated 4.653 510100 488600

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions 4.625 487700 466100

(remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user

4.598 466100 444600

to determine the appropriate performance ratings, acceptable use of the product, maintain safe operating practices, and to apply a prudent safety factor suitable

for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter DS, Section DS-16 of the drilling manual,

4.57 443900 422400

it is recommended that drilling torque should not exceed 80% of MUT.

All references to any internal standards or specifications are per the current edition/revision at the point of manufacturing, unless otherwise stated. All references to any external standards or specifications are

per the current edition/revision at the original purchase order (P.O.) date, unless otherwise stated.

Grant Prideco L. P. | 10100 Houston Oaks Dr. | Houston, TX 77064 | www.nov.com/grantprideco 2

You might also like

- E.1.8.1-COC-2-7.8 Inch (75 Jts DP)Document23 pagesE.1.8.1-COC-2-7.8 Inch (75 Jts DP)özgüncNo ratings yet

- 5inch Nc50 Pipe SpecsDocument36 pages5inch Nc50 Pipe SpecsMichaelNo ratings yet

- E.1.9.1-COC-2-7.8 Inch (3 Jts PJ)Document20 pagesE.1.9.1-COC-2-7.8 Inch (3 Jts PJ)özgüncNo ratings yet

- Heavy Weight Drill Pipe Performance Sheet: Pipe Body Specification Tool Joint SpecificationDocument2 pagesHeavy Weight Drill Pipe Performance Sheet: Pipe Body Specification Tool Joint SpecificationLenin Merchán MartínezNo ratings yet

- Tubing Specification DataDocument1 pageTubing Specification DataAadil HaroonNo ratings yet

- Odessa Office Tubing SpecsDocument1 pageOdessa Office Tubing SpecsGeorge IkpeNo ratings yet

- CDS VAM® FJL 5.5in. 17lb-ft N80 Q API Drift 4.767in.Document1 pageCDS VAM® FJL 5.5in. 17lb-ft N80 Q API Drift 4.767in.yair_segaNo ratings yet

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDocument3 pages4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (1)

- CDS VAM TOP ® 2.875in. 7.8lb-ft L80 Type 1 API Drift 2.229in.Document1 pageCDS VAM TOP ® 2.875in. 7.8lb-ft L80 Type 1 API Drift 2.229in.BaurzhanNo ratings yet

- 4 XT 39 B SDECFDocument1 page4 XT 39 B SDECFredaNo ratings yet

- CDS VAM® 21 9.625in. 47lb-ft L80 Type 1 API Drift 8.525in.Document1 pageCDS VAM® 21 9.625in. 47lb-ft L80 Type 1 API Drift 8.525in.Muhamad Ibrahim AsyamNo ratings yet

- CDS DINO VAM 13.375in. 68lb-ft N80 Q API Drift 12.259in.Document1 pageCDS DINO VAM 13.375in. 68lb-ft N80 Q API Drift 12.259in.ThierryNo ratings yet

- 3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Document5 pages3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Jcchcc JcchccNo ratings yet

- CDS VAM TOP ® 3.5in. 9.2lb-ft L80 Type 1 API Drift 2.867in. 87.5%Document1 pageCDS VAM TOP ® 3.5in. 9.2lb-ft L80 Type 1 API Drift 2.867in. 87.5%anon_798581734100% (1)

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- Tubing Performance Data Sheet: Pipe Size & Weight: 2-7/8 - 6.50lb/ft Pipe Grade: L-80 Range: 2 Tool Joint: EUEDocument1 pageTubing Performance Data Sheet: Pipe Size & Weight: 2-7/8 - 6.50lb/ft Pipe Grade: L-80 Range: 2 Tool Joint: EUEHanyNo ratings yet

- CDS DINO VAM 13.375in. 54.5lb-ft K55 API Drift 12.459in.Document1 pageCDS DINO VAM 13.375in. 54.5lb-ft K55 API Drift 12.459in.ThierryNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- Drill Pipe Data & Performance Sheet: 5" 19.50# S-135 R2 NC50 (4-1/2 IF)Document2 pagesDrill Pipe Data & Performance Sheet: 5" 19.50# S-135 R2 NC50 (4-1/2 IF)Valee kienNo ratings yet

- 4.0 Drill Pipe W XT39 ConnectionsDocument1 page4.0 Drill Pipe W XT39 ConnectionsDugas DeivyNo ratings yet

- TS6 3.5 Tubing 15.8ppfDocument1 pageTS6 3.5 Tubing 15.8ppfKhairilsyam Abdul RashidNo ratings yet

- Cds Dino Vam 13.375in. 72lb-Ft p110 API Drift 12.191in. 87.5%Document1 pageCds Dino Vam 13.375in. 72lb-Ft p110 API Drift 12.191in. 87.5%secanggang.scgdNo ratings yet

- Wedge 513® 5.500 0.476 TN 110Cr13S 09172020Document1 pageWedge 513® 5.500 0.476 TN 110Cr13S 09172020Aqshin BabaevNo ratings yet

- CDS VAM TOP ® 4.5in. 12.6lb-ft L80 13CR API Drift 3.833in.Document1 pageCDS VAM TOP ® 4.5in. 12.6lb-ft L80 13CR API Drift 3.833in.ThierryNo ratings yet

- CDS VAM TOP ® 3.5in. 12.7lb-ft P110 API Drift 2.625in. 87.5%Document1 pageCDS VAM TOP ® 3.5in. 12.7lb-ft P110 API Drift 2.625in. 87.5%Dugas DeivyNo ratings yet

- CDS VAM® 21 CW CW 9.625in. 47lb-ft P110 API Drift 8.525in.Document1 pageCDS VAM® 21 CW CW 9.625in. 47lb-ft P110 API Drift 8.525in.Anh Tuan NguyenNo ratings yet

- 2.875 Eue 6.50 L80 TubingDocument1 page2.875 Eue 6.50 L80 TubingALEX MAKANGANo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- 3.500 - 0.254 - P110 - 12112021 Wedge 563Document1 page3.500 - 0.254 - P110 - 12112021 Wedge 563CARLOS SANCHEZNo ratings yet

- TPS-Multiseal-TS-6-ConnectionDocument1 pageTPS-Multiseal-TS-6-ConnectionKhairilsyam Abdul RashidNo ratings yet

- Drill pipe performance and safety advisoryDocument3 pagesDrill pipe performance and safety advisoryLuis Alberto García CórdovaNo ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- MS6-3500-1295-110 DatasheetDocument1 pageMS6-3500-1295-110 DatasheetKhairilsyam Abdul RashidNo ratings yet

- 3.500 - 0.254 - N80Q - 01052021 BlueDocument1 page3.500 - 0.254 - N80Q - 01052021 BlueCARLOS SANCHEZNo ratings yet

- Wedge 463® 5.500_0.415_Q125-IC_11172023Document1 pageWedge 463® 5.500_0.415_Q125-IC_11172023gemsiesNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- Wedge 533: Pipe Body DataDocument1 pageWedge 533: Pipe Body DataRoger quiruchi negrettyNo ratings yet

- Premiere patented torque ring technical specificationsDocument1 pagePremiere patented torque ring technical specificationstibismtxNo ratings yet

- SIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3Document1 pageSIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3gojiNo ratings yet

- 4in DP 14# IU S135T XTF39 (5.00 x2.5625)Document7 pages4in DP 14# IU S135T XTF39 (5.00 x2.5625)Pavin PiromNo ratings yet

- 3.500 P110 12.95ppf TSHDDocument1 page3.500 P110 12.95ppf TSHDDeepak RanaNo ratings yet

- CDS VAM® 21 9.625in. 47lb-ft L80 Type 1 API Drift 8.525in. 87.5%Document1 pageCDS VAM® 21 9.625in. 47lb-ft L80 Type 1 API Drift 8.525in. 87.5%Budi INo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- 3-1/2Document1 page3-1/2Mohamed FikryNo ratings yet

- CDS VAM TOP ® 7.625in. 29.7lb-ft L80 13CR API Drift 6.750in.Document1 pageCDS VAM TOP ® 7.625in. 29.7lb-ft L80 13CR API Drift 6.750in.ThierryNo ratings yet

- Premiere BTC Data Sheet - 10-3-4 51.0 LB - P110Document1 pagePremiere BTC Data Sheet - 10-3-4 51.0 LB - P110Yamid Caballero SolanoNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Api Eue 2.875 0.217 N80Q 08112022Document1 pageApi Eue 2.875 0.217 N80Q 08112022Cluis KeNo ratings yet

- CDS VAM® 21 HT 9.625in. 47lb-ft P110 API Drift 8.525in. 87.5%Document1 pageCDS VAM® 21 HT 9.625in. 47lb-ft P110 API Drift 8.525in. 87.5%Mohammad AnnasNo ratings yet

- CDS VAM TOP ® 9.625in. 47lb-ft P110 API Drift 8.525in. 87.5%Document1 pageCDS VAM TOP ® 9.625in. 47lb-ft P110 API Drift 8.525in. 87.5%anon_798581734No ratings yet

- Wedge 533 Dopeless: Pipe Body DataDocument1 pageWedge 533 Dopeless: Pipe Body DataGiorgina RamirezNo ratings yet

- 19 DP 5 01 Ows Spec SheetDocument2 pages19 DP 5 01 Ows Spec SheetresapradistaNo ratings yet

- CDS VAM® 21 7in. 26lb-ft L80 13CR API Drift 6.151in.Document1 pageCDS VAM® 21 7in. 26lb-ft L80 13CR API Drift 6.151in.ANSHARULLAH HASSANNo ratings yet

- 5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)Document2 pages5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)humberto Nascimento100% (1)

- Technical Specifications New Premium 5" OD Drill Pipe, S-135, NC-50 Conn'sDocument2 pagesTechnical Specifications New Premium 5" OD Drill Pipe, S-135, NC-50 Conn'sمحمد المحموديNo ratings yet

- 3.500 Blue® - 0.254 - L80 - Type - 1 - 12172021Document1 page3.500 Blue® - 0.254 - L80 - Type - 1 - 12172021CARLOS SANCHEZNo ratings yet

- 64-2103 Tweco Supra XT SEDHDocument2 pages64-2103 Tweco Supra XT SEDHcarlosNo ratings yet

- 4.000 S135 XT39 Drill Pipe Rental Saltire EnergyDocument3 pages4.000 S135 XT39 Drill Pipe Rental Saltire Energyr.cruzNo ratings yet

- Automatic Transaxle System GuideDocument23 pagesAutomatic Transaxle System GuideChristian Linares AbreuNo ratings yet

- TS802 - Support StandardDocument68 pagesTS802 - Support StandardCassy AbulenciaNo ratings yet

- Straddles and Pack-Off Equipment 5-1Document12 pagesStraddles and Pack-Off Equipment 5-1Sergio H. MonjeNo ratings yet

- SV 3 Safety ValveDocument7 pagesSV 3 Safety ValveWanderley FonsecaNo ratings yet

- IBR QualificationDocument12 pagesIBR Qualificationsanjayyadav2009100% (2)

- Asme B16.21Document21 pagesAsme B16.21Anant RubadeNo ratings yet

- July 2015 Master Plumber Terms IncludedDocument5 pagesJuly 2015 Master Plumber Terms Includedzenzen1100% (1)

- Catwalk Operation ManualDocument18 pagesCatwalk Operation ManualNelsonParedesNo ratings yet

- Rockassist (EN ISO 12241) Online Thermal Calculation Tool: License HolderDocument4 pagesRockassist (EN ISO 12241) Online Thermal Calculation Tool: License HolderbkstevensonNo ratings yet

- Cable Tray CatalogDocument152 pagesCable Tray CatalogJohn Bihag100% (1)

- 0682 - Additional Change Route Cable - Elv & SecDocument173 pages0682 - Additional Change Route Cable - Elv & SecBagus SaputroNo ratings yet

- ONGC Effluent Plant Pipe Installation GuideDocument14 pagesONGC Effluent Plant Pipe Installation GuideNithin Mathai100% (1)

- Series 900 BrochureDocument40 pagesSeries 900 BrochureLungisaniNo ratings yet

- BBA - Under Floor HeatingDocument8 pagesBBA - Under Floor HeatingPaul KwongNo ratings yet

- Pttep Arthit Field Development Central Facilities: Piping Material Class Specification A-1-PP-PI-SP-0011Document45 pagesPttep Arthit Field Development Central Facilities: Piping Material Class Specification A-1-PP-PI-SP-0011api-19762124100% (1)

- Jola GB AbleDocument16 pagesJola GB AbleRoberto C RuizNo ratings yet

- Straub Couplings Catalog 2017Document24 pagesStraub Couplings Catalog 2017kman548No ratings yet

- PennBarry Fumex Catalog FXDocument32 pagesPennBarry Fumex Catalog FXArmando MantillaNo ratings yet

- Cgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe InstallationDocument31 pagesCgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe Installationdiki anggriawanNo ratings yet

- Architectural Reviewers - Building UtilitiesDocument110 pagesArchitectural Reviewers - Building Utilitieskharen100% (18)

- Basic Aircraft Maintenance Training - Aircraft Maintenance Practices Course - EASA Part-66 - EASA PART-147 - FL Technics TrainingDocument6 pagesBasic Aircraft Maintenance Training - Aircraft Maintenance Practices Course - EASA Part-66 - EASA PART-147 - FL Technics TrainingPhil ZimbNo ratings yet

- Asco Keystone CompatibilityDocument2 pagesAsco Keystone CompatibilityalexmontellNo ratings yet

- Tube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Document5 pagesTube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Jit BNo ratings yet

- Painting of Piping and Equipments The Piping Engineering WorldDocument9 pagesPainting of Piping and Equipments The Piping Engineering WorldMinMinNaingNo ratings yet

- Twin Seal Submersible Pump Packer: Product Family H78540Document7 pagesTwin Seal Submersible Pump Packer: Product Family H78540Mehdi Norouzi100% (1)

- Design and Performance of Buried PVC Pipe SystemsDocument57 pagesDesign and Performance of Buried PVC Pipe Systems이동욱100% (1)

- 70180-2530-HRSG-RFQ-FT1 Rev.01 PDFDocument75 pages70180-2530-HRSG-RFQ-FT1 Rev.01 PDFluis marcelino chuquimango muñozNo ratings yet

- YMA BrochureDocument9 pagesYMA Brochurenairam2003No ratings yet

- Steel Structure 1Document15 pagesSteel Structure 1Febriono AdiNo ratings yet

- Summary of Differences PSL 1 and PSL 2 (Based On API 5L Edition 43)Document1 pageSummary of Differences PSL 1 and PSL 2 (Based On API 5L Edition 43)Buddy EkoNo ratings yet