Professional Documents

Culture Documents

722.5 - Some Tests 3

Uploaded by

Bernhard JaniszewskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

722.5 - Some Tests 3

Uploaded by

Bernhard JaniszewskiCopyright:

Available Formats

2.

1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

Test step Test scope Test connection Test condition Nominal value Possible cause/Remedy

DTC

O 1.0 Voltage supply N15/1 Wiring,

k Ground (component

1w c L 21 Igition: ON 11 – 14 V compartment) (W16),

Overvoltage protection relay

module (K1/2).

O 2.0 1) 4 Accelerator pedal signal N15/1 Ignition: ON Wiring,

k Accelerator pedal in: TB switch (S29/4),

8w c L 3 CTP <1V TCM (N15/1).

WOT <2V

CTP 2–3V

Reference voltage N15/1

k

8w c L 12 CTP <1V Wiring,

WOT <2V O 2.1.

CTP 2–3V

O 2.1 TB Switch (S29/4) S29/4x2 Ignition: OFF S29/4

3v b K1 900 – 1600 ]

S29/4x2

3v b K 2 Disconnect TB switch AP 2.0 – 3.8 k]

potentiometer connector

(S29/4x2).

1) The voltage should increase continually when bringing the accelerator pedal to WOT.

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/1

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

Test step Test scope Test connection Test condition Nominal value Possible cause/Remedy

DTC

O 3.0 Transmission range N15/1 Ignition: ON

k

1w c L 17 Selector lever Wiring,

in: P-R-N-D > 10 V O 3.2,

4-3-2 < 1 V TCM (N15/1),

Overvoltage protection relay

module (K1/2).

O 3.1 Non - USA vehicles only

O 3.2 Transmission range X22/5 Ignition: OFF Wiring,

5v b K 4 Disconnect 5-speed TR “D“ contact switch (S16/9)

AT/engine connector

(X22/5).

Selector lever

in: P-R-N-D <5]

4-3-2 > 20 k]

O 4.0 Non - USA vehicles only

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/2

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

Test step Test scope Test connection Test condition Nominal value Possible cause/Remedy

DTC

O 5.0 5 Engine speed signal TN N15/1 Wiring,

k O 5.1,

1w c L 14 Engine: at Idle 6V TCM (N15/1).

O 5.1 Control module N15/1 Engine: at Idle DI control module (N1/3),

k TCM (N15/1) disconnected. 6V Engine systems (MAS) control

1w c L 14 module (N16),

CFI control module (N3).

O 6.0 6 Vehicle speed signal (VSS) N15/1 Drive vehicle at Wiring,

k approximately 31 mph (50 Instrument cluster (A1), DM, B&A,

1w f L 16 km/h) on a dynamometer. Vol. 1, section 1.2 23,

ABS/ASR control module Combination relay (N10),

(N30/1) disconnected. 6V~ Hall-effect speed sensor (B6).

O 7.0 Digital load signal N15/1 Engine: at Idle Wiring,

k TCM (N15/1),

1w f L 13 Vacuum line on DI control DI control module (N1/3).

module connected (CTP) approx. 0.8 V ~

Vacuum line on DI control

module disconnected (WOT) > 2 V ~

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/3

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

Test step Test scope Test connection Test condition Nominal value Possible cause/Remedy

DTC

O 8.0 Kickdown switch (S16/6) N15/1 Engine: at Idle <1V Wiring.

Activation k O 8.1,

1w c L 20 Depress kickdown switch by > 10 V TCM (N15/1),

hand (behind pedal). Kickdown switch (S16/6).

O 8.1 Kickdown solenoid valve N15/1 Ignition: OFF 10 – 30 ] Wiring,

(Y3/1y1), internal resistance k TCM (N15/1) disconnected. Valve block (Y3/1).

1w b L 20

O 9.0 7 Valve block control N15/1 Engine: at Idle >5V~ Wiring

9 valve (Y3/1y2) k O 9.1,

10 Activation in 4GR 2w f L 22 Engine speed > 1000 rpm TCM (N15/1)

Activation in 5GR Drive vehicle on a

dynamometer at

approximately 50 mph O 2.0,

(80 km/h). O 5.0 – 7.0

TR “D“ <1V~

O 9.1 Coil resistance N15/1 Ignition: OFF 2 – 10 ] Valve block control valve (Y3/1y2)

k TCM (N15/1) disconnected. (see control

2w b L 22 valve resistance

table)

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/4

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

P27-2258-13 P54-2032-13 P83-2047-13B

Figure 1 Figure 2 Figure 3

S16/9 Transmission range “D” contact switch X22/2 AT/engine connector X22/5 5-speed AT/engine connector

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/5

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

P07-2020-13 P54-2067-13 P54-2043-13A

Figure 4 Figure 5 Figure 6

X30/1 Multi-function connector block X18 Interior/taillamp harness connector X11/4 Data link connector (DTC readout)

X30/1 Multi-function connector block

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/6

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

P27-2260-13 P54-2220-13 P54-2092-13

Figure 7 Figure 8 Figure 9

Y3/1x1 Valve block connector (5-speed AT) S29/4x2 AP potentiometer connector W16 Ground (component compartment)

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/7

.

2.1 Electronic Automatic Transmission Control (ETC) Model 129 with CFI

Electrical Test Program - Test

P27-0187-13 P54-2054-13

Figure 10 Figure 11

Valve block control valve (y3/1y2), temperature W1 Main ground (behind instrument cluster)

dependant resistance table

b Diagnostic Manual • Chassis and Drivetrain • 04/94 2.1 ETC 23/8

.

You might also like

- 722.5 - Some Tests 3Document8 pages722.5 - Some Tests 3Bernhard JaniszewskiNo ratings yet

- Technical Offer-00Document2 pagesTechnical Offer-00Narendra GohilNo ratings yet

- 3-A DC Motor Driver TLE 5203: SPT IcDocument18 pages3-A DC Motor Driver TLE 5203: SPT IcJavier CuraNo ratings yet

- Tle5203 Motor Driver PDFDocument18 pagesTle5203 Motor Driver PDFJavier CuraNo ratings yet

- 415V PDB CUM MCC DH - I (Revised)Document29 pages415V PDB CUM MCC DH - I (Revised)susovan bIswasNo ratings yet

- Dual Channel, Ultra-Low Resistance Load Switch: General Description ApplicationsDocument10 pagesDual Channel, Ultra-Low Resistance Load Switch: General Description ApplicationsПавелNo ratings yet

- BLA Power Pvt. LTDDocument53 pagesBLA Power Pvt. LTDBharat PathakNo ratings yet

- Switch Yard & Protection SystemDocument48 pagesSwitch Yard & Protection SystemDharmendra GargNo ratings yet

- Manual J1000Document6 pagesManual J1000Jose Luis MendozaNo ratings yet

- مثال لحسلب تيار دوار في لمحولاتDocument5 pagesمثال لحسلب تيار دوار في لمحولاتحسن هاديNo ratings yet

- FDC6329L Integrated Load Switch: FeaturesDocument4 pagesFDC6329L Integrated Load Switch: FeaturesranelcomNo ratings yet

- NCT SizingDocument5 pagesNCT SizingPradeep SinghNo ratings yet

- TL3842 5Document12 pagesTL3842 5ajit_kmsNo ratings yet

- PE MannualDocument42 pagesPE MannualSiddhaartha. RNo ratings yet

- 31 Common Radspeed Configurations-InterfacingDocument7 pages31 Common Radspeed Configurations-Interfacingkizen_5No ratings yet

- DV2002L2Document4 pagesDV2002L2DhanukaNo ratings yet

- HTP-BQPS-TP-E-01 Attach.R1 10.20Document9 pagesHTP-BQPS-TP-E-01 Attach.R1 10.20SalmanEjazNo ratings yet

- YEA KAEPS800000042K SGDV DC WiringDocument7 pagesYEA KAEPS800000042K SGDV DC WiringZon Zon GamingTMNo ratings yet

- R1283x SERIES: 2ch DC/DC For CCD & OLEDDocument26 pagesR1283x SERIES: 2ch DC/DC For CCD & OLEDarnaud.herbertNo ratings yet

- 2N60LDocument6 pages2N60LNino NinoNo ratings yet

- FDC6330L FairchildDocument5 pagesFDC6330L FairchildluisNo ratings yet

- STP 11 NM 60Document21 pagesSTP 11 NM 60ErkanNo ratings yet

- TL3842PDocument18 pagesTL3842PjoelpalzaNo ratings yet

- D D D D D D D D D D D D: TL284x, TL384x Current-Mode PWM ControllersDocument11 pagesD D D D D D D D D D D D: TL284x, TL384x Current-Mode PWM ControllersAnonymous fAL3CNtUiNo ratings yet

- R1283K001CDocument26 pagesR1283K001CdinhdtdNo ratings yet

- VCB Offer Sep2017Document6 pagesVCB Offer Sep2017AmamSivaNo ratings yet

- MT 174 CT METER InstallationDocument3 pagesMT 174 CT METER Installationاكرم الصلويNo ratings yet

- Transformer Differential Protection Relay (87T) Stability TestDocument14 pagesTransformer Differential Protection Relay (87T) Stability Testelsayed100% (1)

- STB12NM50T4, STP12NM50, STP12NM50FPDocument20 pagesSTB12NM50T4, STP12NM50, STP12NM50FPinformagicNo ratings yet

- MDD14N25C: N-Channel MOSFET 250V, 10.2A, 0.28Document6 pagesMDD14N25C: N-Channel MOSFET 250V, 10.2A, 0.28Chang ChangNo ratings yet

- 3 Training Manual of 81-PBL024-PW2印刷版 (兼容模式)Document30 pages3 Training Manual of 81-PBL024-PW2印刷版 (兼容模式)WILIAM RODRIGUEZNo ratings yet

- 6N90C Mosfet N PDFDocument10 pages6N90C Mosfet N PDFHưng HQNo ratings yet

- RT9173BDocument13 pagesRT9173BEletronica01 - BLUEVIXNo ratings yet

- Technical SubmittalDocument6 pagesTechnical SubmittalTalha FarooqNo ratings yet

- STF 13 NM 60 NDDocument12 pagesSTF 13 NM 60 NDlejojoel321No ratings yet

- 300ma Dual LDO Regulator With POR: General Description FeaturesDocument12 pages300ma Dual LDO Regulator With POR: General Description FeaturesTitán SotoNo ratings yet

- Omron - MK0607-1189905Document11 pagesOmron - MK0607-1189905Pedro Tavares MurakameNo ratings yet

- Ee694 Power Electronics Lab Manual PDFDocument24 pagesEe694 Power Electronics Lab Manual PDFSabeeh HasnainNo ratings yet

- DI93Document2 pagesDI93Erln LimaNo ratings yet

- SW2N60DC: N-Channel Enhanced Mode TO-252/TO-251 MOSFETDocument6 pagesSW2N60DC: N-Channel Enhanced Mode TO-252/TO-251 MOSFETdanielNo ratings yet

- N-Channel 650 V, 0.60 Ω Typ., 7 A Mdmesh M2 Power Mosfet In A To-220Fp PackageDocument12 pagesN-Channel 650 V, 0.60 Ω Typ., 7 A Mdmesh M2 Power Mosfet In A To-220Fp PackagejefjronNo ratings yet

- Electromagnetic Pulse (Emp) GunDocument13 pagesElectromagnetic Pulse (Emp) Gunrajmudgal100% (3)

- Speed-Up For Darlingtons: Small CircuitscollectionDocument1 pageSpeed-Up For Darlingtons: Small CircuitscollectionTariq Zuhluf100% (1)

- Do You Have An Idea For Design ForDocument6 pagesDo You Have An Idea For Design Forjvs57No ratings yet

- Flasher, 30 M Shunt, Pilot Lamp To GND or V U2043B: FeaturesDocument10 pagesFlasher, 30 M Shunt, Pilot Lamp To GND or V U2043B: FeaturesVladimirNo ratings yet

- FDC6326L Integrated Load Switch: General Description FeaturesDocument5 pagesFDC6326L Integrated Load Switch: General Description FeaturesИван АлексиевNo ratings yet

- General Purpose Relay: Ordering InformationDocument7 pagesGeneral Purpose Relay: Ordering Informationvalimorsk ltd.No ratings yet

- Pe DC 415 510 E043 R2Document9 pagesPe DC 415 510 E043 R2ankushbahaleNo ratings yet

- Technical BOQ - 2787Document2 pagesTechnical BOQ - 2787siva nunnaNo ratings yet

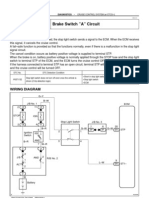

- DTC P0571/52 Brake Switch "A" CircuitDocument4 pagesDTC P0571/52 Brake Switch "A" CircuitErln LimaNo ratings yet

- 3842a DatasheetDocument8 pages3842a DatasheetVịnh DemoNo ratings yet

- Datasheet TA8428 KDocument12 pagesDatasheet TA8428 KKrum NikolovNo ratings yet

- Programmable DC/DC Controller For Advanced Microprocessors: Device Package Temp Range (T)Document6 pagesProgrammable DC/DC Controller For Advanced Microprocessors: Device Package Temp Range (T)ibrahim başderNo ratings yet

- Power Converters Lab ManualDocument89 pagesPower Converters Lab ManualHari PrasadNo ratings yet

- Zero-Voltage Switch With Adjustable Ramp T2117: FeaturesDocument15 pagesZero-Voltage Switch With Adjustable Ramp T2117: FeaturesNenad VukovicNo ratings yet

- KA3842AC/KA3842AE SMPS Controller: Features DescriptionDocument7 pagesKA3842AC/KA3842AE SMPS Controller: Features DescriptionJuan GomezNo ratings yet

- LV SystemsDocument12 pagesLV SystemsSamir AlzekriNo ratings yet

- Stp6Nk90Z - Stp6Nk90Zfp STB6NK90Z - STW7NK90ZDocument18 pagesStp6Nk90Z - Stp6Nk90Zfp STB6NK90Z - STW7NK90ZTobalElectronicaNo ratings yet

- CB 250 OldDocument5 pagesCB 250 Oldspscribd1No ratings yet

- Bentley BrochureDocument9 pagesBentley BrochureSebastian HickeyNo ratings yet

- MAZDA Transponder CatalogDocument3 pagesMAZDA Transponder CatalogKIMI GOKU YTNo ratings yet

- Turbo CatDocument9 pagesTurbo Catali4299No ratings yet

- Manual Despiece Benelli BN 302 R: Mensajes Por WhatsappDocument87 pagesManual Despiece Benelli BN 302 R: Mensajes Por Whatsapposcar cervantesNo ratings yet

- Kona Caracteristicas PDFDocument14 pagesKona Caracteristicas PDFPepe GoteraNo ratings yet

- Sizing Cylinder Tube RodDocument2 pagesSizing Cylinder Tube RodNanda PerdanaNo ratings yet

- 911 and Porsche World 03.2023Document132 pages911 and Porsche World 03.2023chairat yudhakarjkumthornNo ratings yet

- THE ALL-NEW XL6 BrochureDocument8 pagesTHE ALL-NEW XL6 BrochureAkash WadhwaNo ratings yet

- Transmission Assembly, Input Shaft, Two Wheel or Four Wheel DriveDocument4 pagesTransmission Assembly, Input Shaft, Two Wheel or Four Wheel DriveLUIS FERNANDO JOAQUINNo ratings yet

- TM 9-768 (1944)Document446 pagesTM 9-768 (1944)degardin luc100% (1)

- 1996 GEO TrackerDocument387 pages1996 GEO TrackerARTURO FLORESNo ratings yet

- Elrus Cone Plants WebDocument12 pagesElrus Cone Plants WebW MoralesNo ratings yet

- Kubota M7950DT Manual OperadorDocument71 pagesKubota M7950DT Manual OperadorcarlosNo ratings yet

- Compare and Contrast EssayDocument9 pagesCompare and Contrast EssayyesimmmNo ratings yet

- Tesla Model 3Document12 pagesTesla Model 3juanluiscrNo ratings yet

- LISTA COMPLETA MERCOMAX INTERIOR 22-04-2020 Nueva VersionDocument484 pagesLISTA COMPLETA MERCOMAX INTERIOR 22-04-2020 Nueva VersionCristian Da SilveiraNo ratings yet

- A330 Debriefing Schematic - CattsDocument22 pagesA330 Debriefing Schematic - Cattsanarko arsipelNo ratings yet

- 2017 Maverick x3 Turbo R enDocument1 page2017 Maverick x3 Turbo R enAnildo Eldivar De Oliveira SarmentoNo ratings yet

- Harimau Spare PartsDocument4 pagesHarimau Spare Partsedk34No ratings yet

- Invoice Rashid HarrierDocument3 pagesInvoice Rashid HarriermasoudmachanoNo ratings yet

- Catalog Toamna Iarna 2018 2019 VW PreviewDocument12 pagesCatalog Toamna Iarna 2018 2019 VW PreviewSorin TamasNo ratings yet

- 2011 Ford Expedition Backup Camera RemovalDocument6 pages2011 Ford Expedition Backup Camera RemovalErikNo ratings yet

- ETACS ECU Conectores VistaDocument3 pagesETACS ECU Conectores VistaSAUL MASATOSHINo ratings yet

- Audi q7 Electrical SystemDocument6 pagesAudi q7 Electrical Systemmary100% (57)

- 2003-2009 Renault Megane II Fuse Box Diagram Fuse DiagramDocument12 pages2003-2009 Renault Megane II Fuse Box Diagram Fuse Diagramwaltech2005100% (1)

- Need For Speed Shift Tuning From Shift 2Document10 pagesNeed For Speed Shift Tuning From Shift 2Ambrose WilliamsNo ratings yet

- Buku Yamaha Mio JDocument10 pagesBuku Yamaha Mio Jobenk techno50% (2)

- 930E 4SE BrochureDocument4 pages930E 4SE BrochureGregorio PerezNo ratings yet

- Astra H OwnersManual - Jan07 PDFDocument367 pagesAstra H OwnersManual - Jan07 PDFmarko23mNo ratings yet