Professional Documents

Culture Documents

Optimization of Gate Leaf of Automatic O

Uploaded by

Wanderson WadjôCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization of Gate Leaf of Automatic O

Uploaded by

Wanderson WadjôCopyright:

Available Formats

IJIRST –International Journal for Innovative Research in Science & Technology| Volume 2 | Issue 03 | August 2015

ISSN (online): 2349-6010

Optimization of Gate Leaf of Automatic Outflow

Regulating Gate System

Anushree Sunil Waikar P.G. Mehar

PG Student Assistant Professor

Department of Mechanical Engineering Department of Mechanical Engineering

K.D.K. college of Engineering, Nagpur, Maharashtra, India K.D.K. college of Engineering, Nagpur, Maharashtra, India

Abstract

The main objective in the “Optimization of gate leaf of Automatic outflow regulating gate system” is to achieve suitable design

for Gate leaf proper. Finite element analysis of Gate leaf proper is taken for the study. Structural systems of Gate leaf can be

easily analyzed using Finite Element techniques. So firstly a proper Finite Element Model is developed using Cad software Creo

1.0. Then static analysis is done to determine the Equivalent stresses, shear stress & total deformations etc in the present design

for the given loading conditions in gate close position as well as gate open position using Finite Element Analysis Software

ANSYS v 12. The analysis of gate leaf shows that stresses under both loading conditions are well below permissible limit. The

new designed & optimized gate leaf is also analyzed to determine the von Misses stress, shear stress etc. Compared to existing

design of gate leaf, new designed gate leaf has 30.38% less in weight while satisfying the permissible stress condition.

Keywords: Automatic Outflow Regulating Gate, Design Analysis, Optimization, Ansys Workbench

_______________________________________________________________________________________________________

I. INTRODUCTION

Automation in hydraulic gates is employed to regulate the flow of water through a reservoir or canal, without any human

interference.

The automatic outflow regulating gate [1] is a water pressure operated gate, which does not need electricity for its operation. It

is unique invention, which can decide by itself the timing as well as extent of opening & thus regulate the discharge flowing

through it, by sensing water levels on Upstream &/or Downstream side.

The gate system [2] consists of 2 parts;

Rotating gate leaf &

A pair of supporting fulcrum assemblies & embedded parts fixed in supporting structures

The rotating gate leaf assembly consists of;

The supporting fulcrum assemblies & embedded parts consists of rolling surfaces, link brackets, trunnion girder, seal anchors

etc. The components of rotating gate leaf account for more than 60% of total weight of gate system. Hence if this portion is

optimized, it will result in saving in weight as well as cost of Automatic outflow regulating gate system.

All rights reserved by www.ijirst.org 142

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

II. CONSTRUCTION OF GATE LEAF PROPER OF AUTOMATIC OUTFLOW REGULATING GATE SYSTEM

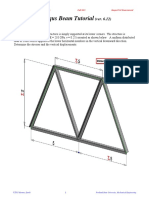

Fig. 1: Construction

Table - 1

Sr. Number of components used in

Name of component Sections used Material

No. gate leaf assembly

1 Upstream Skin plate 1 12mm plate Structural steel

2 Downstream Skin plate 1 12 mm plate Structural steel

3 Horizontal members 10 ISMB 600 Structural steel

4 Bottom end angle 1 ISA 90 X 90 X 12 Structural steel

5 Top end channel 1 ISMC 250 Structural steel

6 Stiffeners for bottom portion of gate leaf 8 12 mm plate Structural steel

7 Stiffeners for bottom portion of gate leaf 8 12 mm plate Structural steel

III. OBJECTIVES

This research pertains to optimize the gate leaf part of Automatic outflow regulating gate system. By using analysis software for

gate leaf structure we check the results for minimum weight with respect to height of the gate. It is highly desirable to do this

analysis and optimization for creating most economical gate leaf structure.

The working stress method which is presently used for computing stresses as described above is quite conservative. Today

many computer based tools & methods of indeterminate structural analysis like FEM are available. It is therefore proposed to use

these modern methods for design of components of rotating gate leaf for proposed optimization work.

The optimization of Gate leaf can result in reduction of weight of gate leaf & hence cost reduction. Hence, the need of

proposed work.

All rights reserved by www.ijirst.org 143

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

IV. PROBLEM FORMULATION

The gate leaf consists of upstream skin plate, downstream skin plate & horizontal members. The water load is transferred by

upstream skin plate to the horizontal members, which subsequently transfer it to the end girders. Structurally, the upstream skin

plate acts as a one-way slab spanning over horizontal members. The slab stresses in upstream skin plate in various panels are

calculated from this consideration. The horizontal members and Upstream and Downstream skin plates co-act as a composite

section. The effective width of co-acting flanges (Upstream & Downstream skin plates) for the intermediate composite sections

is taken as 40*t + B, while that for top most & bottom most composite section is taken as 20t+b, where t=thickness of skin plate

(after considering 1.5 mm corrosion allowance) and B=width of flange of horizontal member. The composite sections consisting

of horizontal members along with co-acting skin plates are checked for bending stresses and shear stresses. The combined action

of skin plates and horizontal members produces beam stresses in the skin plates, which act at right angles to the slab stresses.

Hence the Upstream skin plate is also checked for combined stresses. The horizontal members transfer load to the end girder.

Normally, box sections are provided for End girders of gate leaf. Since the end girders are substantially rigid & stiff compared

to horizontal members & skin plate (as shown in Fig-2), it is presumed in this analysis that the horizontal members are rigidly

fixed to the end girders on both sides.

As the Gate leaf part of the system i.e. Assembly of Horizontal members, upstream skin plate & downstream skin plate is in

the range of 60% - 70% of weight of total Automatic outflow regulating gate system, we will concentrate on analyzing the gate

leaf part only. The gate leaf part will be analyzed in gate close position where the loading is maximum in bottom portion of gate

leaf & also in gate open position where top portion of gate will face maximum loading.

In this research, we are going to analyze the gate leaf of size 10.0m wide & 6.0 m height (nominal). As the gate is tilted 30

degrees in gate close position, to store water up to 6m of height we have to construct gate leaf of height [(1.155 X Height of

water column to be stored) + free board of 0.5m] i.e. total height of gate is 7.48m. The width of gate is [(Width of clear span

between two piers) – (2 X width of rubber seal) – (2 X width of seal seats) - (2 X width of End girders)] i.e total width of gate is

8.75 m. Thus the size of gate leaf which is to be analyzed is of size 8.75m wide & 7.48m height. For this gate leaf the two

extreme loading conditions are as follows;

Gate fully closed and upstream water level up to top lip of gate, at 6.544m above gate sill

Gate fully open with upstream water level i.e., at 6.544 m above gate sill level. The height of water column is 3.32 m

above the upstream skin plate in this condition. The spans & thicknesses of skin plates as well as section details of

various Horizontal members are shown in Fig 5A (sectional side view) & 5B (plan view).

A. Permissible Stresses

The permissible stresses for different gate components are determined as per annexure B of IS: 4622-1992. The permissible

stresses under "wet and accessible” conditions have been considered for all structural steel components of gate.

For structural steel corresponding to IS: 2062, minimum guaranteed yield point stress, Yp = 2550 kg/cm2. Hence after

considering factor of safety we get permissible stresses as,

Permissible compressive/tensile stress in bending = 45% Yp

= 0.45 * 2550 = 1145 kg/cm2 = 112.5 Mpa

Permissible combined stress = 60% * Yp

= 0.60 * 2550 = 1530 kg/cm2 = 150 Mpa

Permissible shear stress = 35% * Yp

= 0.35 * 2550 = 890 kg/cm2 = 87.5 Mpa

Also, Maximum deflection of gate under normal condition of loading shall be limited to L/800 (L=length of gate leaf) of the

span.

The load intensities at different points on gate leaf when gate is in closed position, for this loading condition are shown in Fig.

3.

All rights reserved by www.ijirst.org 144

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

Fig. 3: Load Intensities On Gate Leaf In Gate Close Position

The load intensities at different points on gate leaf when gate is in open position, for this loading condition are shown in Fig. 4.

Fig. 4: Load Intensities On Gate Leaf In Gate Open Position

V. ANALYSIS & INTERPRETATION

The model of existing design of gate leaf shown in Fig. 1 was created in Creo parametric 1.0 & analyzed for gate close & gate

open loading condition in Ansys Workbench [3] giving the results as follows in Table-2;

All rights reserved by www.ijirst.org 145

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

Table - 2

Gate leaf proper of existing design

Solution information

Gate closed position Gate open position

Equivalent Stress (Mpa) 56.513 36.417

Maximum Shear stress (Mpa) 31.115 20.969

Deformation (mm) 1.8172 1.3939

Weight of gate leaf proper (kg) 24842

From above table we can see that all the stresses well are below permissible (Permissible Equivalent stress = 150Mpa,

Permissible shear stress = 87.5Mpa & Maximum deflection of L/800 (L=length of gate leaf) of the span = (8750/800) = 10.9375

mm as mentioned above).

The Stresses are found to be much below permissible limit & hence possibilities are there to optimize the existing design for

economical design.

VI. OPTIMIZATION

Optimization is defined as a maximization of wanted properties and minimization of unwanted properties. In case of structural

optimization the gate leaf; Desired Properties are: Strength, Stiffness & Deflection etc & Undesired Properties are Material, Cost,

and Weight etc.

In the case of gate leaf we can reduce the weight by reducing thickness of skin plate, but it will increase the deflection as well

as the shear stress. Also we can reduce depth of horizontal members etc. Some of the design combinations are analyzed below to

get optimized weight of gate leaf with all the desired properties within permissible limits.

The cases considered for optimization are as follows;

Table - 3

Parameters Existing CASE I CASE II CASE III

Skin plate thickness 12mm 10mm 8mm 8mm

Depth of ISMB Girder 600mm 550mm 550mm 500mm

No. of bottom & top stiffeners 8 6 6 6

B. Static structural Analysis of CASE-I (Gate close loading condition)

The above model for Case I is prepared in the Creo parametric & analyzed giving the results as follows;

Applying the water pressure for gate close position on new model of gate leaf, we get the following results of Equivalent stress

is shown in figure 5.

Fig. 5: Equivalent Stresses

All rights reserved by www.ijirst.org 146

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

Fig. 6: Maximum shear stress

Fig. 7: Total Deformations

The maximum equivalent stress comes out to be 71.364 Mpa. The maximum Shear stress is shown in figure 6. The Maximum

shear stress comes out to be 39.539Mpa which is less than permissible stress. The weight of the new designed gate leaf comes

out to be 19552 Kg.

All rights reserved by www.ijirst.org 147

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

C. Static structural analysis of CASE-I (Gate open loading condition)

Applying the water pressure for gate open position on new model of gate leaf, we get the following results of Equivalent stress is

shown in figure 8.

Fig. 8: Equivalent Stresses

Fig. 9: Maximum shear stress

All rights reserved by www.ijirst.org 148

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

Fig. 10: total Deformations

The Maximum Equivalent stress developed in gate when gate is in open position is 43.865Mpa i.e well below permissible

stresses. Now in Figure 9 Maximum shear stress in gate is 23.831 Mpa.

Similarly Case-II & Case-III are analyzed in Ansys workbench. Stresses & deformation comes out to be in permissible limits.

The results of all the three cases

VII. RESULTS OF ANALYSIS

The results of analysis for all the 3 cases are tabulated in following table 4

Table – 4

Results of analysis

CASE-I CASE-II CASE-III

Water loading condition – (a) Gate closed position &

Solution Information

(b) Gate open position

a b a b a b

Equivalent Stress (Map) 71.36 43.86 80.73 49.37 94.69 58.42

Maximum Shear Stress (Mpa) 39.54 23.83 44.87 25.86 52.67 31.88

Total Deformation (mm) 2.557 2.399 3.095 3.086 3.808 3.546

Weight of gate leaf proper (kg) 19552 17547 16052

From above table we can see that all the stresses are below permissible (Permissible Equivalent stress = 150Mpa, Permissible

shear stress = 87.5Mpa & Maximum deflection of L/800 (L=length of gate leaf) of the span = (8750/800) = 10.9375 mm as

mentioned above).

Also, we can see that there is difference of 8790 Kg (24842 – 16052) in existing designed gate leaf (TABLE-2) & optimized

gate leaf (TABLE-4 & CASE-III). The existing design of gate leaf is optimized by 30.38% in terms of weight of gate leaf &

hence cost.

VIII. CONCLUSION

It was found that the components of gate leaf proper with modification in thickness of plates & depth of horizontal

member gives sufficient reduction in the existing weight of gate without exceeding in permissible stresses.

All rights reserved by www.ijirst.org 149

Optimization of Gate Leaf of Automatic Outflow Regulating Gate System

(IJIRST/ Volume 2 / Issue 03/ 022)

The Stresses are found maximum on downstream skin plate & minimum on horizontal girders in all the cases.

The Deformation is found to be maximum on upstream skin plate & minimum on Horizontal members in all the cases.

The weight of gate leaf proper was reduced to 16052 Kg from 24842 Kg i.e by 30.38% which is significant.

Optimization was performed by changing sections of various components also by reducing number of stiffeners of top &

bottom.

REFERENCES

[1] An Automatic outflow regulating gate – Prabhakar Damodar Godbole : Indian patent no. 183493

[2] The Godbole gate system – Information brochure for Automatic outflow regulating gate by Godbole gates Pvt Ltd, 2B Buty plots, Dharampeth, Nagpur

440010

[3] Anushree Sunil Waikar, P G Mehar, “ Structural Analysis of Gate leaf of Automatic Outflow Regulating Gate System” in IJSRD - International Journal for

Scientific Research & Development, Vol. 3, Issue 04, 2015, ISSN (online): 2321-0613, Page no. 1145 – 1151

[4] Operational behaviour of Automatic outflow regulating gate system - Information broacher for Automatic outflow regulating gate by Godbole gates Pvt

Ltd, 2B Buty plots, Dharampeth, Nagpur 440010

[5] Godbole P.P., Dr. Ingle R.N., Dr. Porey P.D.; “The Automatic tilting gate – A powerful tool for development of water resources”, The institute of

Engineers 12th Indian engineering Congress, Nagpur, 9-13 January 1998, Page 176

[6] Godbole P.P., “Achieving automation in hydraulic gates without electricity by moving fulcrum type automatic gate”, Seminar on Hydraulic gates & their

control in water resources projects Nangal township, Punjab, Organised by Central board of irrigation & power, Bhakra Beas Management Board, 12-14

October, 1998, Page.93

[7] Litrico Xavier; Belaud Gilles; Baume Jean-Pierre; and Ribot-Bruno José, “Hydraulic Modeling of an Automatic Upstream Water-Level Control Gate”

JOURNAL OF IRRIGATION AND DRAINAGE ENGINEERING © ASCE / MARCH/APRIL 2005

[8] Amir Khosrojerdi, “Hydraulic studies of pressure distribution around vertical lift gates” Indian Journal of Science and Technology Vol. 5 No. 3 (Mar 2012)

ISSN: 0974- 6846, Page.2268

[9] Brett C. Commander, Jeff X. Schulz, George G. Goble, Bridge Diagnostics, Inc. Cameron P. Chasten, “Field Testing and Structural Analysis of Vertical

Lift Lock Gates”

[10] Mahesh P. Sharma, Denish S. Mevawala, Harsh Joshi, Devendra A. Patel, “Static Analysis of Steering Knuckle and Its Shape Optimization”. IOSR Journal

of Mechanical and Civil Engineering (IOSR-JMCE) E-ISSN: 2278-1684, P-ISSN: 2320-334X, Pg 34-38.

[11] Kuldeep B, Arun L.R, Mohammed Faheem, “Analysis and optimization of connecting rod using alfasic composites”. International Journal of Innovative

Research in Science, Engineering and Technology, Vol. 2, Issue 6, June 2013, ISSN: 2319-8753.

[12] Rehan H Zuberi, Dr. Long Kai, Prof. Zuo Zhengxing, “Design Optimization of EOT Crane Bridge”. EngOpt 2008 - International Conference on

Engineering Optimization Rio de Janeiro, Brazil, 01 - 05 June 2008.

[13] Hirak Patel, Khushbu C. Panchal, Chetan S. Jadav, « Structural Analysis of Truck Chassis Frame and Design Optimization for Weight Reduction”.

International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249 – 8958, Volume-2, Issue-4, April 2013, Pg 665-668.

[14] F. Faluyi, C. Arum, “Design Optimization of Plate Girder Using Generalized Reduced Gradient and Constrained Artificial Bee Colony Algorithms”.

International Journal of Emerging Technology and Advanced Engineering, ISSN 2250-2459, Volume 2, Issue 7, July 2012, Pg 304-312

[15] Indian Standard “RECOMMENDATIONS FOR STRUCTURAL DESIGN OF FIXED-WHEEL GATES” (Third Revision) Bureau of Indian Standards,

Manak bhavan, 9 Bahadur shah zafar marg, New Delhi.

All rights reserved by www.ijirst.org 150

You might also like

- 机械设计英文版 PDFDocument390 pages机械设计英文版 PDFArifa Jamal100% (1)

- Solid Works Video Tutorial by MagnitudeDocument3 pagesSolid Works Video Tutorial by MagnitudehariridkNo ratings yet

- Design and Analysis of Floor Hydraulic JDocument28 pagesDesign and Analysis of Floor Hydraulic JabebawalemkerNo ratings yet

- Solidworks 3d CadDocument2 pagesSolidworks 3d CaddjgiumixNo ratings yet

- Gate Leaf - SIDocument100 pagesGate Leaf - SIbambang satryojatiNo ratings yet

- Selecting the Right Water Control GateDocument132 pagesSelecting the Right Water Control GatesaishankarlNo ratings yet

- Sundriyal (2015) - Stress Analysis of Crane Hook With Different Cross Sections Using ANSYSDocument6 pagesSundriyal (2015) - Stress Analysis of Crane Hook With Different Cross Sections Using ANSYSGogyNo ratings yet

- SAP Basics - Modelling, Analysis, Design (Autosaved) PDFDocument97 pagesSAP Basics - Modelling, Analysis, Design (Autosaved) PDFinam ullahNo ratings yet

- Autodesk Inventor 80-Hour Training CourseDocument7 pagesAutodesk Inventor 80-Hour Training Coursearaz_1985No ratings yet

- Indian Standard Radial GateDocument8 pagesIndian Standard Radial GateMirza FadlulahNo ratings yet

- Sluice GateDocument2 pagesSluice GateMadusha TisseraNo ratings yet

- Coefficient of Friction Equation and Table ChartDocument3 pagesCoefficient of Friction Equation and Table Chartspamalstublieft1832No ratings yet

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Nptel: Design of Offshore Structures - Web CourseDocument2 pagesNptel: Design of Offshore Structures - Web CourseSuman.SNo ratings yet

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDocument5 pagesDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsNo ratings yet

- Graitec Com en Ad Steel Connection Design ASPDocument7 pagesGraitec Com en Ad Steel Connection Design ASPpatrickNX9420No ratings yet

- Abaqus Beam Tutorial: Problem DescriptionDocument29 pagesAbaqus Beam Tutorial: Problem Descriptionpedro paivaNo ratings yet

- WRC 297 RWE NODE 6340 25febDocument4 pagesWRC 297 RWE NODE 6340 25febnamasralNo ratings yet

- Optimizing Hydropower Trashrack Design Saves MoneyDocument4 pagesOptimizing Hydropower Trashrack Design Saves MoneypicottNo ratings yet

- BS - 3601 - (Carbon Steel Pipes and Tubes With Specified Room Temperature Properties For Pressure Purposes)Document23 pagesBS - 3601 - (Carbon Steel Pipes and Tubes With Specified Room Temperature Properties For Pressure Purposes)Aditya Jane100% (1)

- Chapter 3 - Case Studies of Static AnalysisDocument80 pagesChapter 3 - Case Studies of Static AnalysisJCavalcanti de OliveiraNo ratings yet

- Sontek Acoustic Doppler Velocity Meter Site RequirementsDocument38 pagesSontek Acoustic Doppler Velocity Meter Site RequirementsBASHAMOHUDDIN SHEIKNo ratings yet

- Work Bench VerificationDocument220 pagesWork Bench Verificationchkarthiksai0% (1)

- VAG RETO-STOP Non-Return Valve: Operating and Maintenance InstructionsDocument7 pagesVAG RETO-STOP Non-Return Valve: Operating and Maintenance Instructionswinston11No ratings yet

- HG - Flap - Gates ArmcoDocument20 pagesHG - Flap - Gates ArmcoJorge Alberto Veramendi SilvaNo ratings yet

- Mitcalc 1.74 X86/X64: Download at Maximum Speed and Remove 503 ErrorDocument4 pagesMitcalc 1.74 X86/X64: Download at Maximum Speed and Remove 503 ErrorEjaz MughalNo ratings yet

- Vector Adhesive Spray ApplicatorDocument2 pagesVector Adhesive Spray ApplicatorITWDynatecNo ratings yet

- Sluice Gate With Manual Gearbox - Sereco S.R.LDocument2 pagesSluice Gate With Manual Gearbox - Sereco S.R.LMuhammad EhtshamNo ratings yet

- MECH2400 2015 Semester 2 StudentDocument3 pagesMECH2400 2015 Semester 2 StudentSam SmithNo ratings yet

- AB Valves Manufacturer Industrial Valves EquipmentsDocument4 pagesAB Valves Manufacturer Industrial Valves EquipmentsRoger Labra LlanoNo ratings yet

- Calculation of web weld size in steel connectionsDocument4 pagesCalculation of web weld size in steel connectionsperdhana2000No ratings yet

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Lab 3Document7 pagesLab 3jisteeleNo ratings yet

- Solidworks Student Book Lesson 1 SketchesDocument144 pagesSolidworks Student Book Lesson 1 Sketcheswilddragon07100% (4)

- Penstock Butterfly Valves StandardDocument12 pagesPenstock Butterfly Valves StandardAmjath PallasNo ratings yet

- Inventor spline data calculation under 40 charsDocument3 pagesInventor spline data calculation under 40 charsUfuk KılıçNo ratings yet

- #160 Lifting Fixture 38tons 020807Document14 pages#160 Lifting Fixture 38tons 020807halder_kalyan9216No ratings yet

- Design Horizontal Pressure Vessel - 1Document2 pagesDesign Horizontal Pressure Vessel - 1evrim77100% (1)

- Assembly GateDocument1 pageAssembly GateSuranga C.DadallageNo ratings yet

- Haufe GISSMODocument48 pagesHaufe GISSMOGoncharik DmitryNo ratings yet

- Hitachi skd61 PDFDocument12 pagesHitachi skd61 PDFHieu Nguyen MinhNo ratings yet

- Lectures Week 8 - Viscoelastic MaterialsDocument6 pagesLectures Week 8 - Viscoelastic MaterialschrihiNo ratings yet

- Lab Report EetDocument4 pagesLab Report EetMuhd HaidharNo ratings yet

- Abaqus CAE Self Contact Tutorial: Problem DescriptionDocument23 pagesAbaqus CAE Self Contact Tutorial: Problem DescriptionMohammed Abu SufianNo ratings yet

- ME080 Section 8 - Other Hydraulic ComponentsDocument101 pagesME080 Section 8 - Other Hydraulic ComponentsAhmed FaragNo ratings yet

- Import Revit Into SAP2000 - SAP2000 - CSIDocument1 pageImport Revit Into SAP2000 - SAP2000 - CSIsmartcad60No ratings yet

- Box Type Annealing Furnace QuotationDocument5 pagesBox Type Annealing Furnace QuotationdantecbNo ratings yet

- Eccentric Column BucklingDocument10 pagesEccentric Column BucklingMukeshChopraNo ratings yet

- VT Program Rotary Screw Compressors 40-75HPDocument6 pagesVT Program Rotary Screw Compressors 40-75HPQco MyNo ratings yet

- WEG Roller Table 50040456 Brochure EnglishDocument12 pagesWEG Roller Table 50040456 Brochure EnglishjmartinezmoNo ratings yet

- Weld StressDocument9 pagesWeld StressArvindNo ratings yet

- Catia V5 Bending Torsion Tension Shear TutorialDocument18 pagesCatia V5 Bending Torsion Tension Shear Tutorialrankx001No ratings yet

- Two Dimensional Truss: Practical No.-01Document68 pagesTwo Dimensional Truss: Practical No.-019897856218No ratings yet

- Fresnel CSP Technology: State of The Art and Market OverviewDocument56 pagesFresnel CSP Technology: State of The Art and Market OverviewWanderson WadjôNo ratings yet

- CSP in Non-Electrical Application: Ministério DaDocument28 pagesCSP in Non-Electrical Application: Ministério DaWanderson WadjôNo ratings yet

- Inspection of Steel Penstocks & Pressure Conduits Vol2-8Document43 pagesInspection of Steel Penstocks & Pressure Conduits Vol2-8Manmohit Singh67% (3)

- Speeduino ManualDocument169 pagesSpeeduino ManualLeonardo DaviNo ratings yet

- 2014 Buck Tower CSP Techology 0Document88 pages2014 Buck Tower CSP Techology 0Wanderson WadjôNo ratings yet

- Welded Steel Pipe American Iron and Steel InstituteDocument80 pagesWelded Steel Pipe American Iron and Steel Institutemaminu1100% (1)

- Penstock ManualDocument159 pagesPenstock Manualstudent_bl95% (21)

- 12 Water ConveyanceDocument24 pages12 Water Conveyance박래건No ratings yet

- 10 11648 J Ijepe 20150404 14 PDFDocument11 pages10 11648 J Ijepe 20150404 14 PDFbacuoc.nguyen356No ratings yet

- Hydropower Waterway With Air Cushion Surge ChamberDocument8 pagesHydropower Waterway With Air Cushion Surge ChamberWanderson WadjôNo ratings yet

- Support Design PDFDocument42 pagesSupport Design PDFbalramkinageNo ratings yet

- AISI - Buried Steel PenstocksDocument96 pagesAISI - Buried Steel Penstocksmbra63100% (2)

- Engineering Guidelines For The Evaluation Penstocks TypicalDocument23 pagesEngineering Guidelines For The Evaluation Penstocks TypicalWanderson WadjôNo ratings yet

- Inspection of Steel Penstocks & Pressure Conduits Vol2-8Document43 pagesInspection of Steel Penstocks & Pressure Conduits Vol2-8Manmohit Singh67% (3)

- Lista de Publicações Sobre CondutoDocument8 pagesLista de Publicações Sobre CondutoWanderson WadjôNo ratings yet

- European Small Hydropower HandbookDocument266 pagesEuropean Small Hydropower HandbookXiao Yang100% (1)

- 10 11648 J Ijepe 20150404 14 PDFDocument11 pages10 11648 J Ijepe 20150404 14 PDFbacuoc.nguyen356No ratings yet

- Friction Factors For Large Conduits Flowing FullDocument77 pagesFriction Factors For Large Conduits Flowing FullJean BattellNo ratings yet

- Water NicollaDocument31 pagesWater NicollaNikola BoskovicNo ratings yet

- Chaminés Tipos PDFDocument163 pagesChaminés Tipos PDFWanderson WadjôNo ratings yet

- Civil Penstocks Tunnels Best PracticeDocument19 pagesCivil Penstocks Tunnels Best PracticeJenny Cecilia Ureña ZuriNo ratings yet

- Chaminés PressurizadasDocument8 pagesChaminés PressurizadasWanderson WadjôNo ratings yet

- Design of Penstock Pipe For A HydroelectDocument21 pagesDesign of Penstock Pipe For A HydroelectWanderson WadjôNo ratings yet

- Development of Surrogate Reservoir Models (SRM) For Fast Track Analysis of Complex ReservoirsDocument23 pagesDevelopment of Surrogate Reservoir Models (SRM) For Fast Track Analysis of Complex ReservoirsWanderson WadjôNo ratings yet

- Chaminé de Equilíbrio - Estudo de CasoDocument7 pagesChaminé de Equilíbrio - Estudo de CasoWanderson WadjôNo ratings yet

- Surge Tank Functions and Water Surface OscillationsDocument27 pagesSurge Tank Functions and Water Surface OscillationsArup K HazraNo ratings yet

- Discharge Ratings For Tainter Gates and Roller Gates at Lock and Dam No. 7 On The Mississippi River, La Crescent, MinnesotaDocument21 pagesDischarge Ratings For Tainter Gates and Roller Gates at Lock and Dam No. 7 On The Mississippi River, La Crescent, MinnesotaWanderson WadjôNo ratings yet

- S19DsgnGdln PDFDocument23 pagesS19DsgnGdln PDFmohanrajNo ratings yet

- Design Analysis of Water Control Gate For Diversion Dams: June 2018Document12 pagesDesign Analysis of Water Control Gate For Diversion Dams: June 2018Wanderson WadjôNo ratings yet

- BizHub 450i Parts ListDocument182 pagesBizHub 450i Parts ListDomenico Di CristofaroNo ratings yet

- Robots quietly infiltrate our livesDocument10 pagesRobots quietly infiltrate our liveschipchip1910No ratings yet

- AS LG Solar 6 Page Brochure - CS6 - CompressedDocument2 pagesAS LG Solar 6 Page Brochure - CS6 - CompressedMayur HiwarkarNo ratings yet

- Associate JD - CL 10Document3 pagesAssociate JD - CL 10Chandan AnandNo ratings yet

- Maintenance IndicatorsDocument12 pagesMaintenance IndicatorssatfasNo ratings yet

- AttachmentDocument33 pagesAttachmentAnkit JaiswalNo ratings yet

- Type of Websites AssignmentDocument12 pagesType of Websites AssignmentJallani GujjarNo ratings yet

- Weathering Steel Information, A588, A242, Corten Unique PropertiesDocument2 pagesWeathering Steel Information, A588, A242, Corten Unique Propertiesvijayarangam1984No ratings yet

- New Holland TM 175 Service Manual GuideDocument6 pagesNew Holland TM 175 Service Manual GuideH50% (2)

- Ccna NotesDocument127 pagesCcna NotesRajumallepoola93% (14)

- Dairy Farm Group Case StudyDocument5 pagesDairy Farm Group Case Studybinzidd007No ratings yet

- QB Unit 1Document6 pagesQB Unit 1Gaurav GadhesariaNo ratings yet

- 4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactDocument48 pages4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactAlfred TsuiNo ratings yet

- Grand Impianti Washer ExtractorDocument124 pagesGrand Impianti Washer ExtractorredvalorNo ratings yet

- Types PF BechmarkingDocument5 pagesTypes PF Bechmarkingshivangi dubeyNo ratings yet

- ABSTRACTDocument8 pagesABSTRACTMark Benecito BoñgolNo ratings yet

- Detroit Ds Pf12v149tDocument2 pagesDetroit Ds Pf12v149tMuhammad rizkiNo ratings yet

- Elster Rotary Gas Meter: I Connected IndustrialDocument6 pagesElster Rotary Gas Meter: I Connected IndustrialAlvaro Joel Quinteros RochaNo ratings yet

- Trainning and DevelopmentDocument33 pagesTrainning and DevelopmentDeepika BrejaNo ratings yet

- Chapter10 Test BankDocument8 pagesChapter10 Test Bankapi-250771617No ratings yet

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- SKODA ASN-ig enDocument14 pagesSKODA ASN-ig enqingpingleNo ratings yet

- Serpentine Pavilion Press PackDocument21 pagesSerpentine Pavilion Press PackAlvaro RosaDayerNo ratings yet

- Turbo RamjetDocument16 pagesTurbo RamjetDhana JayanNo ratings yet

- End Mill Series: Newly Developed "Impact Miracle Coating"Document32 pagesEnd Mill Series: Newly Developed "Impact Miracle Coating"Deepak ShekarNo ratings yet

- Facility Location and LayoutDocument26 pagesFacility Location and LayoutSameer KhanNo ratings yet

- Review - Panasonic AG-HPX370Document56 pagesReview - Panasonic AG-HPX370arthur_8No ratings yet

- BG Katalog Na BanknotiDocument133 pagesBG Katalog Na BanknotiGoroSoftNo ratings yet

- Ama Research Revise 2Document23 pagesAma Research Revise 2Gabriel YcoNo ratings yet

- MY ResumeDocument3 pagesMY ResumebbcemkeceNo ratings yet