Professional Documents

Culture Documents

Installation Manual ESGI 2 ENG

Uploaded by

Nana Tabi GyekyeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual ESGI 2 ENG

Uploaded by

Nana Tabi GyekyeCopyright:

Available Formats

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Installation manual of

ESGI 2 LPG supply system

Part I

Strona 1 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

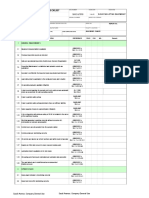

CONTENTS

page

1. ESGI SYSTEM 3

1.1. Control Unit 3

1.2. Reducer 4

1.3. RAIL Injectors 4

1.4. Gas filter of volatile phase integrated and gas temperature sensor 5

1.5. Wires 5

1.6. Switch and control kit sachet 5

1.7. P1/MAP Sensor 6

1.8. Copper pipes and rubber hoses 6

1.9. Additional accessories 6

1.10. Gas tank 6

1.11. Multivalve of the LPG tank 7

1.12. Refueling valve 7

2. LPG system installation procedures 8

2.1. Starting. 8

2.2. Fitting the Reducer 8

2.3. Connecting reducer’s water circulation 8

2.4. Installing injector nozzles in the suction manifold 8

2.5. Injector rail installation 10

2.6. Connecting injector rail to the injectors in the suction manifold 10

2.7. Connecting gas reducer to the injector rail 11

2.8. Installing gas filter and P1/MAP sensor in the arrangement: reducer – filter – injector 11

rail

2.9. LPG tank installation (extract from regulation 67R 01) 12

2.9.1. LPG tank installation - toroidal 13

2.9.2. LPG tank installation - cylindrical 15

2.10. Multivalve 17

2.11. Gas level indicator: 17

2.12. Gas-tight casing: 18

2.13. Rigid and flexible gas pipes: 18

2.14 Connections between components of LPG system: 19

2.15 Electronically controlled power valve: 20

2.16. Thermal safety valve 20

2.17 Tank inlet 20

2.18. Installing control unit (ECU) 21

2.19. Connecting electric wires to the battery 21

2.20. Connecting electric wires of the gas reducer temperature sensor to the vehicle electric 22

system.

2.21. Connecting the switch and buzzer 22

2.22. Connecting reducer’s electrovalve and multivalve at the gas tank 23

2.23. Connecting electric installation bundles 23

2.23.1. Connecting 12 V power supply through ignition 24

2.23.2. Connecting RPM signal 24

2.23.3. Connecting the lambda sensor 24

2.23.4. Connecting the gas level sensor 24

2.23.5. Electric connections of the petrol injectors 24

2.23.6. Careful examination of the quality of electrical connections 25

2.23.7. Connecting power supply (battery) 25

2.24. Starting the engine and making installation adjustments 25

2.25. Completing installation 25

Strona 2 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

1. The ESGI sequential gas injection system

The ESGI sequential gas injection

system complies with the strict EURO-4 exhaust emission standard and is fully

compatible with EOBD. A unique algorithm controls the gas injectors by processing the

signals received from the engine’s ECU, which makes fuel map programming much

easier. Users of ESGI only need to set the basic engine parameters and run a short

adaptation test. Regardless of the engine type it takes only a few minutes to program the

whole system. You simply check if the system works correctly and, if necessary, make a few

minimal adjuments. A great advantage of the ESGI system is its full compatibi-lity with the

available reducers and gas injectors. The universal nature of the controller and software

allows you to install the ESGI system in almost every vehicle, no matter if the engine uses

sequential, semisequential or full-group injection. You can also install any type of multi-valve

with a fuel level gauge and adjust the software accordingly.

1.1.Control Unit

The control unit reads data from various sensors and

controls the various system functions. It controls the gas

injection timing based on the petrol injection timing and the

engine rpm signals. The aluminum casing of the control unit

is hermetically sealed and heat-resistant. It protects the

electronic components housed inside it against atmospheric

agents and mechanical stress. The ca-sing also protects the

control unit against electromagnetic radiation emitted by

electrical elements of the engine or by other sources

(transmitters, relays, cellular phones, etc.). If any of the sensors are disconnected or

damaged the control unit displays corresponding error codes in the software application.

Signals are transmitted through wires bundled in a single airtight FCI harness.

1.2. Reducer

Reducer to ESGI 2 is a single stage regulator, with variable

outlet pressure at the level of 1.2 bar of the suction manifold

pressure. Inside the reducer, the liquid gas vaporizes in

result of thermal exchange with engine cooling agent. The

outlet pressure is regulated by the mechanism: spring –

membrane – gland, and a special vibration damping system.

It must be noted that one side of the membrane is affected

by gas pressure and the other side is affected by the

pressure from the suction manifold, connected by a rubber

hose. As a result, the output gas pressure is not fixed, but it

varies according to the suction manifold pressure. For

example, when running engine at low speed, the suction

manifold pressure may reach -0.6 bar and the outlet pressure +0.6 bar. However, when

pressing acceleration pedal whole way down, the manifold pressure will be around 0 bar

(atmospheric pressure), and the gas pressure around +1 bar. In the reducer, there is a

Strona 3 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

temperature sensor, which is responsible for transmitting to ESGI control unit all data

necessary for proper flow stream control. Switching from petrol to gas also depends on the

temperature of the reducer, what prevents from switching when the gas temperature is too

low. Depending on the configuration, different types of reducers may be used.

1.3. Injectors

The rail injectors are of bottom feed type. Gas from the rail

gets to the bottom part of the injector and when the

electromagnet shifts the pivot with the valve, the gas is

injected into the suction manifold. The vulcanized rubber on

the pivot assures tightness and silent operation of the

injector. Difference in pressure affecting the valve keeps the

valve closed when the coil is not powered, and the gas does

not get into the suction manifold. In order to achieve proper

operation of injectors, the right exhaust nozzles must be used according to engine power.

1.4. Gas filter of volatile phase integrated and gas temperature sensor

Owing to its small dimensions the inte-grated LPG gas filter is

very easy to install. It is equipped with high quality filter

cartridge manfactured using state- of-the-art filtering

materials. It is recommended to replace the cartridge

every 10 000 - 15 000 km.

1.5. Wires

The wires of ESGI system are arranged into one bundle of

power cables, cables for controlling electrovalves and

injectors, and signal cables for sensors and the switch. The

bundle of cables is connected to the gas control unit via an

airtight FCI wire harness. All cables have appropriate plugs

for gas injectors, temperature sensor and P1/MAP sensor,

which simplifies the wiring procedure. To prevent wiring

errors the cables are color-coded as indicated in the

diagram.

Strona 4 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

1.6. Switch

The switch unit has an aesthetic appeal and can be easily installed

inside the vehicle compartment. It acts as a 2-position gas/petrol

selector switch with a gas mode indicator and incorporates a fuel

gauge. New model of switch included buzzer inside

You will find the switch unit inside the control kit bag with

all the elements that are needed to install the system:

temperature sensor, reducer, buzzer, P1/MAP sensor

adapter and bands and connectors.

1.7. P1/MAP Sensor

An integrated pressure sensor measures gas pressure and

negative pressure in the MAP suction manifold. Based on

the gas and MAP pressure readings, which are the engine

load reference, the main unit calculates the best LPG

amount for optimal driving quality and fuel consumption.

1.8. Copper and PVC pipes and rubber hoses

An integrated pressure sensor measures gas pressure and

negative pressure in the MAP suction manifold. Based on

the gas and MAP pressure readings, which are the engine

load reference, the main unit

calculates the best LPG amount for

optimal driving quality and fuel consumption.

.

Strona 5 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

1.9. Additional accessories

The set includes assembly sachet with all clips, bands,

adapters and nozzles. Each set is supplied with assembly

diagram, abbreviated installation manual and system

programming manual.

1.10. Gas tank

System ESGI/115 includes toroidal tank for LPG, which is

mounted in the spare wheel well with the provided clamping

screws. Air-tight chamber of the tank is closed with a

hermetic cover. The chamber has a ventilating hole which

leads out of the vehicle. The ventilating hole is also used to

conduct copper pipes and electric wires through it.

Depending on the system configuration, different types of

tanks may be used.

1.11. Multivalve

The multivalve installed in the tank opening is a combined

device comprising of a valve limiting tank refill up to 80%, a

remotely controlled working valve with a device preventing

from efflux, a safety-valve preventing from excessive

increase of gas pressure in the tank, a thermal protection

and a gas level gauge. Gas level is indicated on the

gas/petrol switch installed in the vehicle cab. Depending on

the configuration, different types of multi-valves may be

used.

1.12. Refueling valve

Refueling valve assures tight connection with dispenser

nozzle at the LPG refueling station, and enables safe

refilling of the tank with liquid gas. The refueling valve is

equipped with a non-return valve, which prevents from

uncontrolled efflux of the gas when disengaged from a

dispenser nozzle. Additionally, the set includes hole plug

securing the refueling valve from impurities. Depending on

the configuration, different types of refueling valves may

be used.

Strona 6 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

INSTALLATION

START-UP

Install ESGI

Disconnect the Install Connect the

control unit Start the engine

battery the LPG tank wires to the

gas injector

rail

Fit the reducer

in the engine Install Refuel

Install the

compartment fuse box the LPG tank

multivalve in

the tank Connect the

Connect wires to the

reducer’s water ESGI control Perform initial

Connect the unit

circulation control of the

Install the electric wires

system

refueling valve to the reducer

tightness

Fit the with the cap and

electrovalve electrovalve Connect

electric wires

in the battery Insert the gas

Connect the system system fuses

Install the refueling valve to Install the

nozzles in the the multivalve petrol/gas

suction switch in the

manifold vehicle cab Check the Start the engine

correctness of on LPG

the electric

Connect the connections

Install the supply pipe

Connect the

injector rail with wiring to Check

wires to the

the multivalve tightness of

petrol/gas

Connect the the LPG system

switch

battery

Connect the Conduct

silnikathe

electrovalve to supply pipe with ESGI system

the reducer wiring under adjustments

the chassis to Connect the and exhaust

the engine wires to the analysis

compartment multivalve and

Connect fuel the LPG level

pipe to the gauge

electrovalve Final control of

the installation

correctness

Disconnect and the LPG

Install the gas petrol injector system

filter of volatile circuits; operation

phase connect

emulation

bundle

Connect Installation

reducer to the completion,

filter and filling in and

injector rail issuing the

documentation,

instructing the

user

Strona 7 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2. LPG system installation procedures

2.1. Starting.

Before starting the process of installation, the battery must be unconditionally disconnected.

2.2. Fitting the reducer

- Mount the reducer to the solid part of the body or frame.

- Locate the reducer in a place that would allow for future inspections and adjustments.

- To mount the reducer use brackets and screws designed for the purpose.

- Follow the instructions for reducer installation

Mount the reducer and connect wire to EV Mount copper pipe and rubber hose to

cooling system and to LPG

2.3. Connecting reducer’s water circulation

- Connect water pipes to engine cooling system in series, or parallel to vehicle cab heating

circulation (Fig.1 and 2).

- When fitting the reducer into the water circulation, pay attention to tightness of the

couplings.

- Secure the couplings with metal band clips.

Strona 8 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.4. Installing injector nozzles in the suction manifold

- Drill and tap the holes for nozzles in the suction manifold only

on a suction manifold that has been dismantled and removed

from the engine. The suction manifold nozzles should be

installed in the manifold at the angle of not less than 45

degrees in the direction of the gas flow (suction). Optimum

angle is 45-50 degrees.

- Screw the nozzles into the suction manifold with gap filling adhesive.

It is acceptable to install injector nozzles on an assembled suction manifold. In that case it is

especially important to clean the manifold from all filings.

- Drill the holes close to the engine suction valves and screw stub pipes (nozzles) in it,

through which the gas will flow. The nozzles should incline towards the valves.

- Connect all the fitted nozzles to the electrovalves stub pipes of the injector rail with the use

of high-pressure rubber hoses.

- Secure the connections with metal band clips. Make sure that the length of the rubber

hoses is identical and possibly the shortest.

- Connect the power and control wires from the control unit to the injector rail coils.

- For V-type engines apply the same procedures remembering to fit gas nozzles close to the

petrol injectors, close to inlet valves in both heads of the V engine.

Strona 9 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.5. Injector rail installation

- Install the injector rail on the engine casing as close to the suction manifold as possible.

- Secure the connections with metal band clips. Make sure that the length of the rubber

hoses is identical and possibly the shortest.

- Connect the power and control wires from the control unit to the injector rail coils.

- Installing the injector rail with the outlets upwards is unacceptable.

- For V-type engines, you may use two identical rails arranged symmetrically according to

the principles presented above.

All connection secure with metal clips

Strona 10 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.6. Connecting injector rail to the injectors in the suction manifold

- Connect the injector rail to the nozzles in the suction manifold by means of a rubber hose

of the diameter appropriate for the nozzles. The hose should meet the standard E 67 R 01

Class 2 for LPG, and it should not be longer than 250 mm. After connecting the rail with the

stub pipes, check carefully the quality and air-tightness of the connections.

2.7. Connecting gas reducer to the injector rail

- Connect the injector rail to gas reducer by means of a gas hose of 12 mm in diameter, that

complies with the standard E 67 R 01 Class 2 for LPG.

- After connecting, check carefully the quality and air-tightness of the connections.

2.8. Installing gas filter and P1/MAP sensor in the arrangement: reducer – filter –

injector rail

- Install gas filter between the gas reducer and injector rail on the rubber hose of 12 mm in

diameter. Secure the connections with metal band clips and check the quality and air-

tightness of the connections.

- Install the temperature sensor before injection rail In rubber hose 12 mm

- Connect the temperature sensor to the bundle of electric wires.

- Install the gas filter as close to the injector rail as possible, in a place that is easily

accessible for check-up or replacement.

Strona 11 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

- The gas filter is supplied along with the control set and constitutes its integral whole. You

must not use a substitute not originating from the ESGI set.

- Mount MAP sensor to the body.

- Connect stub pipe of the P1 sensor to the stub pipe in the tee of temperature sensor of

volatile phase by means of a hose.

- Secure the connections with the supplied CLICK bands.

- Connect the MAP stub pipe to the high-pressure hose connecting reducer with the suction

manifold.

- Connect P1-MAP sensor to do the gas bundle.

2.9. LPG tank installation (extract from regulation 67R 01)

LPG tank:

- cannot be located in the engine compartment

- should be safely mounted to the vehicle

- should be mounted in the correct position, according to the instructions designed by the

tank manufacturer and in accordance with R67 and R115.

LPG tank should have fixed points of installation to the vehicle, or should be mounted to the

vehicle only by means of screws, washers and nuts or special frame and clamping rings

supplied in the set by the tank manufacturer. The LPG tank should be installed so that there

is no other contact of metal with metal than in the fixed points of installation designed by the

manufacturer.

When the vehicle is fully loaded, the LPG tank should not be lower than 200 mm above the

road surface, unless it is appropriately secured at the front and at both sides and no part of

the tank stands out below the protective structure.

Strona 12 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.9.1. Installation Toroidal Tank

Step 1

Step 2

Step 3

Strona 13 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Step 4 Step 5

Strona 14 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.9.2. Installation Cylindrical Tank

Step 1

Step 2

Step 3

Strona 15 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Step 4

Step 5

Step6

Strona 16 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Step 7

2.10. Multivalve:

Should be suitable for particular LPG tank and installed in conformity with the standard 67R

01.

2.11. Gas level indicator:

Indicator should be suitable for particular multivalve and installed in the right position

assuring its proper operation.

Strona 17 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.12. Gas-tight casing:

Gas-tight casing should be installed over the LPG tank accessories, unless the tank is

installed outside the vehicle and its accessories are sheltered against impurities and water.

The gas-tight casing should be vented through a ventilation pipe leading outside the vehicle.

The ventilation pipe should be downward at the outlet. However, it should not exit into the

wheel housing or aim at a heat source, such as exhaust system.

The internal cross-sectional area of the ventilation pipe should be at least 450 mm2 .

If a gas pipe, a hose or electric wires are placed inside the ventilation pipe, the clear area of

the ventilation pipe should also be 450 mm2 . The ventilation pipe should be well fastened to

secure its tight connection with the gas-tight casing.

2.13. Rigid and flexible gas pipes:

Rigid gas pipes, made of mild steel, should have anticorrosion protective coating.

Weldless rigid gas pipes, made of copper, should have rubber or plastic protective casing.

Using flexible gas pipes is also acceptable.

Fasten the metal pipes in such a manner that they are not exposed to excessive vibrations or

stresses.

Gas pipes should have protective casing in places of fastening to prevent damages resulting

from abrasion.

Gas pipes should never be located in the vicinity of the jack points in the car.

Gas pipes should be fastened by means of clamping rings to the main vehicle structure or to

the elements rigidly joined to the main vehicle structure.

Strona 18 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Holes in the vehicle body, through which rigid or flexible gas pipes are conducted, should be

secured with fairleads. Diameter of the holes should be at least 1.5 of the diameter of the

rigid or flexible pipe passing through that hole.

2.14 Connections between components of LPG system:

Soldered or welded connections are unacceptable.

Connect rigid gas pipes with appropriate connectors made of the same material as the pipe.

Design pressure should be the same as the pressure specified for the gas pipe, or higher.

Multiple joins should be made of corrosion resistant material.

Number of the connections should be possibly the smallest and they should be located in

places where they may be inspected. Rigid or flexible gas pipe in the passenger

compartment or in the closed luggage compartment should not be longer than it is necessary

for safe installation.

There should be no connections in the passenger compartment or in the closed luggage

compartment, except:

- connections inside the gas-tight casing or on it,

- connections between gas pipe and fuel inlet, if the connection is covered with LPG resistant

material with ventilation going directly outside the vehicle.

If the LPG installation requires a return conductor, its connection with LPG tank should be

equipped with a check valve.

Flexible pipes for LPG under pressure should be equipped with mechanical connection

suitable for multiple usage.

Additional accessories, others than those required by PN-EN 12806, which are necessary for

proper engine operation, should be installed only to those components of LPG system, where

pressure is

lowered than 20 kPa.

Strona 19 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.15 Electronically controlled power valve:

Electronically (remotely) controlled power valve should be installed on a rigid gas pipe,

between the LPG tank and the reducer/vaporiser, as close to the reducer/vaporiser as

possible. The valve should be of such a type that its normal position is closed.

If a fuel return system is applied between the reducer and the LPG tank, the electronically

controlled power valve should be installed in the engine compartment, in the place indicated

by the manufacturer of LPG system.

The electronically controlled power valve may be integrated with the reducer.

The electronically controlled power valve should operate in such a manner that the fuel

intake is shut when:

- the ignition is off

- other type of fuel was selected in dual-fuel vehicles.

2.16. Thermal safety valve:

Termiczny zawór bezpieczeństwa jest montowany przez producenta zbiorników do tych

zbiornikach, w których jest wymagane jego uŜycie. W trakcie montaŜu instalacji do pojazdu

nie przewiduje się montaŜu termicznego zaworu bezpieczeństwa do zbiornika.

2.17 Tank inlet:

Tank inlet should be secured against twisting and protected against water.

Tank inlet should be located outside the vehicle in accordance with the current regulations.

Strona 20 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Strona 21 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.18. Installing control unit (ECU)

- Install the control unit in an easily

accessible place, away from heat sources

and not exposed to humidity.

- Take utmost attention to make good

electric insulation of the wires.

- Secure connections and wires at full length

against damage and moisture.

The manufacturer shall not be liable for any

damage resulting from improper installation

of the system or from the use of

inappropriate materials or components.

2.19. Connecting electric wires to the battery

- Remove the main fuse.

- Connect the power leads (red and brown with a loop Φ8) according to the electrical

diagram directly to the battery clamps using ready installation elements.

2.20. Connecting electric wires of the gas reducer temperature sensor to the

vehicle electric system.

- The temperature sensor installed in the reducer should be connected to the wires (yellow

and black) of the gas control unit according to the supplied diagram.

Strona 22 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.21. Connecting the switch and buzzer

- Install the switch inside the vehicle in a place well visible for the

driver – drill Φ14 hole.

- While installing the indicator, carefully fit it by pushing it

delicately into the drilled Φ14 hole.

- Gas level indicator works with a sensor 0 to 90 ohm.

- Install the buzzer in such a place that its alarm is audible for the

driver, and connect the wires (red and black) observing polarity.

- After installing the switch, connect the bundle of wires to it

(green, blue, white, grey and black). The black wire is the

common earth for the switch and the buzzer.

Strona 23 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.22. Connecting reducer’s electrovalve and multivalve at the gas tank

- Connect wires (blue and black) which supply power for electrovalve at reducer and

multivalve at the tank.

2.23. Connecting electric installation bundles

Electric components of the LPG system should be protected against overload. Installation is

equipped with fuses, whose minimal value after change should be identical with value

specified in the supplied documentation.

Locate the main fuse in a visible place accessible without the use of any tools.

Electric wires should be appropriately protected against damage. Electric connections inside

the boot or in passenger compartment should comply with protection type IP40 according to

EN 60529. All the other electric connections should comply with protection type IP54

according to EN 60529.

Electric components and their connections located inside the gas-tight casing should have

construction that do not produce any sparks.

Electrical connections, except earth connection, should be insulated. Using uninsulated wires

is unacceptable. Never install any fuses inside the gas-tight casing.

2.23.1. Connecting 12 V power supply through ignition:

Connect appropriate wire (red) to the place where supply voltage appears after turning the

key into the ignition position. It may be feeding petrol injectors or feeding injection module.

2.23.2. Connecting RPM signal:

To determine rotational speed of the engine crankshaft, the control unit uses RPM signal

sent by ignition module (ignition coil WN or an integrated ignition module DIS) or from the

engine ECU. Use impulse probe or oscilloscope to find the electric wire with the signal.

Strona 24 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

Connect the brown wire from the gas control unit bundle to the wire. The frequency of

impulses sent to the petrol control unit increases as the engine rpm increases, therefore the

frequency of the signal on the screen of the oscilloscope also increases.

2.23.3. Connecting the lambda sensor:

To connect the lambda sensor, first find the sensor wire, remove the insulation and solder

the control unit wire to it (purple – sensor 1, grey – sensor 2).

2.23.4. Connecting the gas level sensor

Solder the signal wires from the gas tank level sensor to the wires (grey and black) of the

gas control unit.

2.23.5. Electric connections of the petrol injectors

- Version with plugs:

Disconnect petrol injector plugs. Connect the plugs of the gas control unit to the petrol

injectors and to the control wires from the engine ECU according to the installation diagram

and the markings on the gas bundle.

- Version “with cutting”

Remove insulation from the petrol injector wires. Cut the wires linking petrol injectors with

the engine ECU. Solder appropriate wires from the gas bundle according to the diagram.

Connect the single-colour wire from the injector’s side, and solder the wire with the black

stripe to the wire from the engine ECU’s side. After soldering and checking the right

sequence of the wires, carefully insulate the connections.

NOTE

With full-group and half-sequential systems, disconnect circuits of petrol injectors and

connect them to appropriate wires from the gas bundle according to the installation diagram.

Never connect joined wires from the gas bundle to the common control wires of the petrol

injectors from the engine ECU. Such connection makes proper adaptation impossible, blocks

sequential switching from petrol to gas and does not allow switching between particular

cylinder injectors for diagnosis.

2.23.6. Careful examination of the quality of electrical connections

All the wire connections must be permanently soldered and properly insulated and checked

before connecting to the power supply (battery).

Check the quality of electrical connections, their protection and conformity with the

installation diagram.

2.23.7. Connecting power supply (battery)

Having performed all the procedures of checking installation and being assured that the

connections are appropriate in terms of quality of wire connections, connectors, etc. and in

accordance with the wiring diagram, switch on the battery by inserting the main fuse in the

socket.

Strona 25 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

Development and manufacturing of

control and gas systems for

automotive

Installation manual

2.24. Starting the engine and making installation adjustments

- After checking all the connections and fastenings, and connecting battery, but before

inserting fuses into the gas system fuse socket, you may start the engine on petrol.

- After filling the gas tank with LPG that complies with gas quality standard, check tightness

of all connections in reducer’s water circulation and, in particular, of the connections in

gas system (connections in the tank, connections in the engine compartment, connections

on flexible hoses) with the use of a tightness tester.

- Appropriately adjust LPG system according to the procedures listed in the ESGI preparation

and programming manual enclosed below.

- Perform final examination of exhaust composition by means of 4-gas analyser and make

necessary adjustments.

2.25. Completing installation

- Perform final visual examination for the conformity of the installation with R67 and R115

- Remove any contamination produced during installation from the inside of the vehicle, the

engine compartment and the boot.

- Stick the rating plate of the additional LPG supply system in the place indicated in the

manual.

- Fill in the guarantee book and documents necessary for proper vehicle registration.

Strona 26 z 26

EKO ALMA SP.J.

POLAND 55-010 Radwanice ul. Grafitowa 2

Tel. +48 0 71 311 73 97 – Email: info@autogas.pl

You might also like

- Practical Power System and Protective Relays CommissioningFrom EverandPractical Power System and Protective Relays CommissioningRating: 4.5 out of 5 stars4.5/5 (10)

- Edwards InstallDocument51 pagesEdwards Installrodrigo seguelNo ratings yet

- 005 enDocument64 pages005 ensam tariqNo ratings yet

- Remeha 'Gas - 3002 - EcoDocument36 pagesRemeha 'Gas - 3002 - EcodunveganNo ratings yet

- Lambdatronic S 3200Document87 pagesLambdatronic S 3200Nicolas JerezNo ratings yet

- IM SM Avanta Plus ENDocument64 pagesIM SM Avanta Plus ENDániel TóthNo ratings yet

- RD 532 CombiDocument80 pagesRD 532 Combijeff gNo ratings yet

- BSS Essential Guide: Permanently Installed Fuel Systems and Fixed EnginesDocument2 pagesBSS Essential Guide: Permanently Installed Fuel Systems and Fixed EnginesCostin RotaruNo ratings yet

- MP Hydraulic Lift Equipment 1 " 1 ": Bvin / Bvin A3Document43 pagesMP Hydraulic Lift Equipment 1 " 1 ": Bvin / Bvin A3Coil98No ratings yet

- QSV91G Containerized SpecificationDocument26 pagesQSV91G Containerized SpecificationmackyyoNo ratings yet

- Installation & Service Manual: Remeha Avanta RangeDocument72 pagesInstallation & Service Manual: Remeha Avanta RangePEB14No ratings yet

- TD2365 - VeitDocument31 pagesTD2365 - VeitRATSITOHARA EricNo ratings yet

- Lectrocount : Standard Bulk Truck System Standard Bulk Truck System Installation Procedures Installation ProceduresDocument44 pagesLectrocount : Standard Bulk Truck System Standard Bulk Truck System Installation Procedures Installation ProceduresPhilip HoferNo ratings yet

- Components and Installation HandbookDocument52 pagesComponents and Installation HandbookOmar Enrique ContrerasNo ratings yet

- Product - Files - 2020 04 07 - 11 44 353Document47 pagesProduct - Files - 2020 04 07 - 11 44 353Nabil KhNo ratings yet

- محطات التعبئة في هونغ كونغDocument68 pagesمحطات التعبئة في هونغ كونغمحمود من فارس للبترولNo ratings yet

- Eh Blower ManualDocument44 pagesEh Blower Manualterry.defaut9764100% (1)

- Greenstar He System: Installation and Servicing InstructionsDocument44 pagesGreenstar He System: Installation and Servicing InstructionsMattForrestNo ratings yet

- P3 MkIII Auto Manifold Type 2R O&M Manual Rev 7Document25 pagesP3 MkIII Auto Manifold Type 2R O&M Manual Rev 7anfalapNo ratings yet

- M&C EC30C Instruction Manual PDFDocument78 pagesM&C EC30C Instruction Manual PDFindraNo ratings yet

- Avanta Plus 35cDocument153 pagesAvanta Plus 35cAurel SteclearNo ratings yet

- Turbomax Vuw 242/1 E Turbomax Vuw 282/1 E Instructions For Installation and ServicingDocument60 pagesTurbomax Vuw 242/1 E Turbomax Vuw 282/1 E Instructions For Installation and ServicingsivsorNo ratings yet

- Mynute 10e 14e 20e Installation and Servicing InstructionsDocument44 pagesMynute 10e 14e 20e Installation and Servicing InstructionsJavaid ArshadNo ratings yet

- LPG Dispenser: User's GuideDocument16 pagesLPG Dispenser: User's Guidesam tariqNo ratings yet

- Bechtel Corporation Engineering - Control Systems Engineering Design Guide Control Valves 3DG-J51-00001, Revision 002, 2002 August 5Document40 pagesBechtel Corporation Engineering - Control Systems Engineering Design Guide Control Valves 3DG-J51-00001, Revision 002, 2002 August 5Alvis JeffreyNo ratings yet

- Operation and Maintenance Instructions Hydraulic Aggregate Type BZGF6-silentDocument59 pagesOperation and Maintenance Instructions Hydraulic Aggregate Type BZGF6-silentVO DUC ThaoNo ratings yet

- Compresor Sullair ES-8-15-30HP-02250117-368Document86 pagesCompresor Sullair ES-8-15-30HP-02250117-368pabloNo ratings yet

- Restek Methanizer For Agilent GCS: Instruction/ Operation ManualDocument44 pagesRestek Methanizer For Agilent GCS: Instruction/ Operation Manualginga716No ratings yet

- S 1500Document158 pagesS 1500vm8119No ratings yet

- GeneralAire DS25LC Owners ManualDocument32 pagesGeneralAire DS25LC Owners ManualJigga mannNo ratings yet

- Baxi Eco3 User ManualDocument32 pagesBaxi Eco3 User ManualnebanuitNo ratings yet

- Manual WG10, 20 458-GB-10-99Document27 pagesManual WG10, 20 458-GB-10-99trpac100% (4)

- Motan Kober Manual c33gc24Document28 pagesMotan Kober Manual c33gc24Tibor BrassaiNo ratings yet

- Chemist 500 Manuale ENGDocument198 pagesChemist 500 Manuale ENGRenan AguiarNo ratings yet

- Tvis p15Document66 pagesTvis p15Mihir007123456No ratings yet

- Manual: Installation and Operating InstructionsDocument90 pagesManual: Installation and Operating InstructionsDidi MoacaNo ratings yet

- Installation and Servicing InstructionsDocument128 pagesInstallation and Servicing InstructionsAsad GhaffarNo ratings yet

- Design Guide: VLT HVAC Drive FC 102Document228 pagesDesign Guide: VLT HVAC Drive FC 102Yusef Nome C.No ratings yet

- Vokera Riello Compact 25 A - EnGDocument40 pagesVokera Riello Compact 25 A - EnGluismontoy.pNo ratings yet

- 01 31462-01-02-01 - Inst - Manual - Rev2Document120 pages01 31462-01-02-01 - Inst - Manual - Rev2pRADEEP sNo ratings yet

- Manual GWH2400ES - English - 10 - 2007Document56 pagesManual GWH2400ES - English - 10 - 2007MatiasNo ratings yet

- Attachment ReportDocument63 pagesAttachment ReportSajeed RahmanNo ratings yet

- Manual GesanDocument70 pagesManual Gesanradupetrache82% (11)

- SR200 Manual Revision 05Document91 pagesSR200 Manual Revision 05mheshimiwaNo ratings yet

- Industrial Attachment - 1701099Document63 pagesIndustrial Attachment - 1701099Omar Bin Harun TalhaNo ratings yet

- LR Omegas GPL 5 6 8 Cil GBDocument48 pagesLR Omegas GPL 5 6 8 Cil GBYacine KhazeneNo ratings yet

- User Manual GNS 3200-4200 2006 enDocument103 pagesUser Manual GNS 3200-4200 2006 enEvaldas NarmontasNo ratings yet

- CLS CLH BassaDocument342 pagesCLS CLH Bassaapi-3769211100% (1)

- Gas 610 Eco Technical InformationDocument56 pagesGas 610 Eco Technical InformationPedro QuintalNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument38 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- MMPX Separation System, Automatic - Installation - 1995Document47 pagesMMPX Separation System, Automatic - Installation - 1995Centrifugal SeparatorNo ratings yet

- Installation and Operating Instructions Weishaupt Gas Burners Sizes 1 To 11Document46 pagesInstallation and Operating Instructions Weishaupt Gas Burners Sizes 1 To 11abuMalak75% (4)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument25 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Manuale Glup HT-HTLP v2.1 0315 enDocument92 pagesManuale Glup HT-HTLP v2.1 0315 engabrieleshlNo ratings yet

- Soft Copy - Technical Submittal - Booster PumpsDocument240 pagesSoft Copy - Technical Submittal - Booster Pumps721917114 47No ratings yet

- Installation, Maintenance and User Manual For Fm200 Fire Extinguishing SystemsDocument175 pagesInstallation, Maintenance and User Manual For Fm200 Fire Extinguishing Systemsozer100% (1)

- Optoelectronic Level SwitchDocument40 pagesOptoelectronic Level SwitchArpan Trivedi100% (2)

- Acf Ayf S50Document54 pagesAcf Ayf S50ELDUVINA RIBASNo ratings yet

- C2500 ЭлектросхемыDocument32 pagesC2500 ЭлектросхемыЕвгений ГубаревNo ratings yet

- M47D20 VP44: Seminar Working MaterialDocument69 pagesM47D20 VP44: Seminar Working MaterialIongornistu67% (6)

- Techinical GPLDocument33 pagesTechinical GPLAlex RaduNo ratings yet

- CNG System Installation ManualDocument38 pagesCNG System Installation ManualmarjanchoNo ratings yet

- The Rodenticidal Effect of Indomethacin: Pathogenesis and PathologyDocument12 pagesThe Rodenticidal Effect of Indomethacin: Pathogenesis and PathologyNana Tabi GyekyeNo ratings yet

- LFF EDocument260 pagesLFF EJessica Viera HernándezNo ratings yet

- 205-01 Driveshaft - Removal and Installation - Front DriveshaftDocument5 pages205-01 Driveshaft - Removal and Installation - Front DriveshaftCARLOS LIMADANo ratings yet

- Passive-voice#1901010030#Muhammad Ziad AlfianDocument3 pagesPassive-voice#1901010030#Muhammad Ziad Alfianyusuf hijriahNo ratings yet

- HETRONIC MEC-HL C INSTALLATION MANUAL (Eng) PDFDocument26 pagesHETRONIC MEC-HL C INSTALLATION MANUAL (Eng) PDFAndzej Lazovskij100% (1)

- Technical Service Information: Isuzu & BMWDocument5 pagesTechnical Service Information: Isuzu & BMWMario MastronardiNo ratings yet

- Price Bridgestone FebruariDocument13 pagesPrice Bridgestone FebruariAbdurrohman Ahmad RofiqNo ratings yet

- Checkball Book Import Volume IDocument103 pagesCheckball Book Import Volume IEryk NowickiNo ratings yet

- Cycle Innovations GL1000Document32 pagesCycle Innovations GL1000CaptainMidnight85100% (1)

- MD4 CalibrationDocument25 pagesMD4 CalibrationPalm House CoffeeNo ratings yet

- Case # 3 .-Patrimonio HoyDocument3 pagesCase # 3 .-Patrimonio HoyDavid Enrique Gaona GarcíaNo ratings yet

- PBL345 R 01Document5 pagesPBL345 R 01danhproNo ratings yet

- Iseki TH4295 4335 4365 Parts Manual 1Document350 pagesIseki TH4295 4335 4365 Parts Manual 1Вячеслав ШапочкаNo ratings yet

- Ariel JGE JGH JGK JGT Manual - 231029 - 233805Document203 pagesAriel JGE JGH JGK JGT Manual - 231029 - 233805Daniel LatorreNo ratings yet

- PMT YO EFB Press - 1Document20 pagesPMT YO EFB Press - 1eko cienkNo ratings yet

- PG Course Descriptions 2017Document13 pagesPG Course Descriptions 2017LungisaniNo ratings yet

- ICE (CH 1)Document41 pagesICE (CH 1)xyonieNo ratings yet

- Catalogo Grua Grove Rt600eDocument20 pagesCatalogo Grua Grove Rt600e-Raul-No ratings yet

- Unit VIII Reciprocating PumpsDocument16 pagesUnit VIII Reciprocating PumpsRICHARD VALIENTENo ratings yet

- Gas TurbineDocument86 pagesGas Turbinerahul_choubey_9100% (2)

- Saic-U-7010 - Side Boom Tractor-Cranes-2023Document8 pagesSaic-U-7010 - Side Boom Tractor-Cranes-2023محمد ممدوحNo ratings yet

- M325D MH M325D LMH: Material HandlerDocument20 pagesM325D MH M325D LMH: Material HandlerGoran MatovicNo ratings yet

- Manual de Mecánica Ssangyong Korando C200 Del 2010 Al 2019Document1,162 pagesManual de Mecánica Ssangyong Korando C200 Del 2010 Al 2019kevin andres marimon vega100% (2)

- Murder Crime Scene TranscriptDocument2 pagesMurder Crime Scene TranscriptLowell AlfonsoNo ratings yet

- Cessna: Where This Catalog Refers To ADocument458 pagesCessna: Where This Catalog Refers To AFábio FariaNo ratings yet

- Car Concept 1 - Study and Design LanguageDocument52 pagesCar Concept 1 - Study and Design LanguageJay SoniNo ratings yet

- 05-737-800 Ramp & Transit FuelDocument90 pages05-737-800 Ramp & Transit FuelNicolas SalNo ratings yet

- Dokumen - Tips - Cambio Automatico Citroen ZF 4hp20Document250 pagesDokumen - Tips - Cambio Automatico Citroen ZF 4hp20Razvan DragomirNo ratings yet

- Engine Immobiliser System: RegistrationDocument7 pagesEngine Immobiliser System: Registrationdima65No ratings yet

- Notes Session 1&2 - Business To Business - Introduction: Definition of Industrial MarketingDocument150 pagesNotes Session 1&2 - Business To Business - Introduction: Definition of Industrial Marketingantima shardaNo ratings yet

- Technical Specifications: 2021 FORD F-150Document12 pagesTechnical Specifications: 2021 FORD F-150Attchu HunNo ratings yet

- Annual ReportDocument132 pagesAnnual ReportANUBHAV NARWALNo ratings yet