Professional Documents

Culture Documents

ALUMERO - Alloys EN AW 6060 AlMgSi0 - Web

Uploaded by

emilasanovskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALUMERO - Alloys EN AW 6060 AlMgSi0 - Web

Uploaded by

emilasanovskiCopyright:

Available Formats

EN AW-6060 | Data Sheet

The alloy EN AW-6060 is a widely used extrusion alloy, suitable for applications where no special strength properties are required. Parts

can be produced with a very good surface quality, suitable for many coating operations. Typical application fields are furniture, finishing

materials, windows and doors, carbody finishing, façade construction, lighting columns and flagpoles, architecture, and food industry.

Chemical composition according to EN573-3 (weight %, remainder Al)

Si Fe Cu Mn Mg Cr Zn Ti remarks others

each total

max. max. max. max. max.

0.30 – 0.60 0.10 – 0.30 0.35 – 0.60 max. max.

0.10 0.10 0.05 0.15 0.10

0.05 0.15

Mechanical properties according to EN755-2

Temper* Wall thickness Yield stress Tensile strength Elongation Hardness**

e*** Rp0.2 [MPa] Rm [MPa] A [%] A50mm [%] HB

T4 e ≤ 25 60 120 16 14 45

e≤5 120 160 8 6 55

T5

5 < e ≤ 25 100 140 8 6 50

e≤3 150 190 8 6 65

T6

3 < e ≤ 25 140 170 8 6 60

e≤3 160 215 8 6 70

T66

3 < e ≤ 25 150 195 8 6 65

* Temper designation according to EN515: T4-Naturally aged to a stable condition, T5-cooled from an elevated temperature forming operation and artificially aged, T6-Solution heat treated, quenched and artificially aged, T66-cooled from an elevated temperature

forming operation and artificially aged to a condition with higher mechanical properties through special control of manufacturing processes. T6 and T66 properties can be achieved by press quenching)

** Hardness values are for indication only *** For different wall thicknesses within one profile, the lowest specified properties shall be considered as valid for the whole profile cross section

Physical properties (approximate values, 20°C)

Co-efficient of thermal

Density [kg/m3] Melting range [°C] Electrical conductivity [MS/m] Thermal conductivity [W/m.K] Modulus of elasticity [GPa]

expansion 10-6/K

2700 585 – 650 28 – 34 200 – 220 23.4 ~ 70

Weldability* Machining characteristics* Corrosion resistance*

Gas: 3 TIG: 2 MIG: 2 T4 temper: 3 T5 and T6 temper: 2 General: 1 Marine: 2

Typical filler materials (EN ISO18273): AlMg5Cr(A) or AlSi5, and AlMg3 when

the product has to be anodised. Due to the heat input during welding the Coating properties* Page 2/6

mechanical properties will be reduced by approximately 50% (ref. EN1999 -1). Hard/protective anodising: 1 Decorative/bright/colour anodising: 1 Edition July 2018

You might also like

- BS 4360 specification for structural steel plates and productsDocument1 pageBS 4360 specification for structural steel plates and productsHong Rui Chong100% (1)

- ASTM A53 Data Sheet PDFDocument3 pagesASTM A53 Data Sheet PDFmarcelomaster88No ratings yet

- Sliding Mitre Saw GCM 12 Sde 164984 0601b23170Document447 pagesSliding Mitre Saw GCM 12 Sde 164984 0601b23170emilasanovskiNo ratings yet

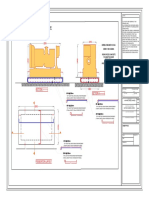

- Base Foundation of Generator: SECTION I - I SECTION II - IIDocument1 pageBase Foundation of Generator: SECTION I - I SECTION II - IIHayman AhmedNo ratings yet

- EN AW-6082 Data Sheet: High Strength Aluminum Alloy for Structural ApplicationsDocument1 pageEN AW-6082 Data Sheet: High Strength Aluminum Alloy for Structural ApplicationsemilasanovskiNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- Nedal Aluminium BV Alloy Data Sheet for EN-AW 6060 Extrusion AlloyDocument1 pageNedal Aluminium BV Alloy Data Sheet for EN-AW 6060 Extrusion Alloyankur panwarNo ratings yet

- ALUMINIUM ALLOYS FOR EXTRUDED PROFILESDocument19 pagesALUMINIUM ALLOYS FOR EXTRUDED PROFILESDon JonesNo ratings yet

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- Medium Strength Extrusion Alloy Data SheetDocument1 pageMedium Strength Extrusion Alloy Data Sheetankur panwarNo ratings yet

- Alloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)Document1 pageAlloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)CocoNo ratings yet

- Non-alloy heat resisting steel data sheetDocument4 pagesNon-alloy heat resisting steel data sheetraduonoNo ratings yet

- 50CRMO4_50CrMo4-Nr.1.7228-ENGDocument2 pages50CRMO4_50CrMo4-Nr.1.7228-ENGLuiz Antonio dos AnjosNo ratings yet

- #Kobelco Welding Hand BookDocument1 page#Kobelco Welding Hand BookIradahNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- Steel BS4360 43A PDFDocument1 pageSteel BS4360 43A PDFscmNo ratings yet

- BS 4360 specification for structural steel plates and productsDocument1 pageBS 4360 specification for structural steel plates and productsscmNo ratings yet

- Steel BS4360 43A PDFDocument1 pageSteel BS4360 43A PDFsyakiroh100% (1)

- 07 10 2019 Lamifil Aluminium Alloys For Electrical ApplicationsDocument1 page07 10 2019 Lamifil Aluminium Alloys For Electrical ApplicationscantigiNo ratings yet

- ALUMINIUM ALLOYS For Electrical ApplicationsDocument1 pageALUMINIUM ALLOYS For Electrical Applicationstwo travellerNo ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGBiaizidi Abbou SamirNo ratings yet

- Technical Card: Information OnlyDocument1 pageTechnical Card: Information OnlyBhuvnesh VermaNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- Hydro en Aw 6082Document3 pagesHydro en Aw 6082Velissarios DemetriouNo ratings yet

- 110 Pump Industry: RPM Trimming (R) : Curve No: 50 HZ SUC: 150 DISCH: 125Document4 pages110 Pump Industry: RPM Trimming (R) : Curve No: 50 HZ SUC: 150 DISCH: 125g1ann1sNo ratings yet

- Astm Standartlar 6060 6063 6082Document2 pagesAstm Standartlar 6060 6063 6082kartepe.tercumanNo ratings yet

- Alloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Document1 pageAlloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Bouchra SonsuzaNo ratings yet

- 1050 Data Sheet: Chemical CompositionDocument1 page1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaNo ratings yet

- Nature of Engineering Materials ReportDocument162 pagesNature of Engineering Materials ReportDryx LetranNo ratings yet

- 56 Si 7Document2 pages56 Si 7Bhuvanesh ShanmugamNo ratings yet

- Industrial LeafletsDocument5 pagesIndustrial LeafletsMukiara LuffyNo ratings yet

- Aluminium 1050Document2 pagesAluminium 1050Sephiwe MafilikaNo ratings yet

- ASTM A53 Data SheetDocument3 pagesASTM A53 Data Sheetmarcelomaster88No ratings yet

- DSA00260586Document6 pagesDSA00260586Msi InfotronicNo ratings yet

- Case Hardening Steel 20NiCrMo2 2 AUSADocument3 pagesCase Hardening Steel 20NiCrMo2 2 AUSAzhenyupanNo ratings yet

- High Strength Steel Tubes For Structural and Engineering ApplicationsDocument12 pagesHigh Strength Steel Tubes For Structural and Engineering ApplicationsA LettristeNo ratings yet

- TG S50 PDFDocument1 pageTG S50 PDFIvan RocoNo ratings yet

- Chemical Composition % of Steel S690QL (1.8928) : EN 10025-6-2004Document1 pageChemical Composition % of Steel S690QL (1.8928) : EN 10025-6-2004Miodrag TopalovicNo ratings yet

- Voestalpine Heavy Plate Datasheet Durostat en 20170904Document3 pagesVoestalpine Heavy Plate Datasheet Durostat en 20170904Kristy HillNo ratings yet

- SIMPLEX_MAXIDocument2 pagesSIMPLEX_MAXIJane RicoNo ratings yet

- Atlas 8620H: Colour Code: Red (Band) - WhiteDocument3 pagesAtlas 8620H: Colour Code: Red (Band) - WhiteVíctor DominguezNo ratings yet

- Corrugated Hose DatasheetDocument1 pageCorrugated Hose DatasheetSam LarismaNo ratings yet

- Taha Associates - Blade Ejector PinDocument2 pagesTaha Associates - Blade Ejector PinTaha AssociatesNo ratings yet

- P355GH boiler plate steel specsDocument1 pageP355GH boiler plate steel specsCommercial MarocNo ratings yet

- Gricon 80G: Identification Description ClassificationDocument2 pagesGricon 80G: Identification Description ClassificationSharad ShahNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument2 pagesEquivalents of Carbon Steel QualitiesmichaelNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- Technical Specification References: I! OI C UDocument30 pagesTechnical Specification References: I! OI C Uabubakar aliNo ratings yet

- Jis G3106Document1 pageJis G3106jhephe46No ratings yet

- EGT301Document2 pagesEGT301ghared salehNo ratings yet

- Tolerances - SKFDocument2 pagesTolerances - SKFZeshanNo ratings yet

- Stainless Steel 1.4571Document4 pagesStainless Steel 1.4571ANKUSH PARMARNo ratings yet

- p355n NH Nl1 Nl2 TubesDocument4 pagesp355n NH Nl1 Nl2 Tubesado31No ratings yet

- Special Steels RE60S: For Structural ProductsDocument1 pageSpecial Steels RE60S: For Structural ProductsRollpass DesignNo ratings yet

- Stainless Steels 430F: MartensiticDocument2 pagesStainless Steels 430F: MartensiticRavindra ErabattiNo ratings yet

- 34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGDocument2 pages34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGNarimane BentyNo ratings yet

- Plasma HPR130Document4 pagesPlasma HPR130Imre VarnjuNo ratings yet

- Chemical PropertiesDocument1 pageChemical PropertiesDanny TriwibowoNo ratings yet

- Ambient Vaporizers - High Pressure: Manufactured by CryovationDocument6 pagesAmbient Vaporizers - High Pressure: Manufactured by CryovationemilasanovskiNo ratings yet

- To Check The Movement NumberDocument14 pagesTo Check The Movement NumberemilasanovskiNo ratings yet

- 6M13Document1 page6M13emilasanovskiNo ratings yet

- 6305LU SingleRowRadialBallBearing SingleSealed (ContactRubberSeal)Document3 pages6305LU SingleRowRadialBallBearing SingleSealed (ContactRubberSeal)Javier RosasNo ratings yet

- Instruction Manual: Citizen Quartz Racing Combo With Electroluminescence Model No. JN7XXX Cal. No. C401Document5 pagesInstruction Manual: Citizen Quartz Racing Combo With Electroluminescence Model No. JN7XXX Cal. No. C401emilasanovskiNo ratings yet

- 2011 EU Legislation Transportable Pressure EquipmentDocument8 pages2011 EU Legislation Transportable Pressure EquipmentemilasanovskiNo ratings yet

- Aluminium Alloy en Aw 6060 Material Data Sheet AlumincoDocument1 pageAluminium Alloy en Aw 6060 Material Data Sheet AlumincoGilbertoNo ratings yet

- Aluminium Alloy en Aw 6060 Material Data Sheet AlumincoDocument31 pagesAluminium Alloy en Aw 6060 Material Data Sheet AlumincoemilasanovskiNo ratings yet

- G Shock Ga100a 7a Manual - UnlockedDocument4 pagesG Shock Ga100a 7a Manual - UnlockedSuneo DeltaNo ratings yet

- ISO IEC 17020 2012 Inspection Standard Application DocumentDocument31 pagesISO IEC 17020 2012 Inspection Standard Application Documentdaniel_avendaño_7No ratings yet

- HTC One M8s User GuideDocument199 pagesHTC One M8s User GuideemilasanovskiNo ratings yet

- ITM HydrogenConversionTableDocument1 pageITM HydrogenConversionTablepiugabiNo ratings yet

- Energetix Katalog2015Document67 pagesEnergetix Katalog2015Predrag DžodićNo ratings yet

- Design With Plastics. Focus - Injection MoldingDocument72 pagesDesign With Plastics. Focus - Injection MoldingPrithviraj Daga100% (6)

- Aluminium A380Document1 pageAluminium A380Ashokkumar VelloreNo ratings yet

- Mcqs Preparation For Engineering Competitive Exams: Peb Beam Welding SystemDocument9 pagesMcqs Preparation For Engineering Competitive Exams: Peb Beam Welding SystemMukul TiwariNo ratings yet

- High-performance Cement-based CompositesDocument44 pagesHigh-performance Cement-based CompositesWasim AbbassNo ratings yet

- Conducting Polymer LECTURE3 07012021Document27 pagesConducting Polymer LECTURE3 07012021Manteg SinghNo ratings yet

- Block Data Sheet En771Document1 pageBlock Data Sheet En771ivanNo ratings yet

- Atlas Grade Datasheet 410 Rev May 2008Document2 pagesAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNo ratings yet

- Work Schedule for External Development Drainage and Water WorksDocument15 pagesWork Schedule for External Development Drainage and Water WorksTax ProffessionalNo ratings yet

- Aci Beam Crack Width Bot ZDocument2 pagesAci Beam Crack Width Bot ZParthiban ArivazhaganNo ratings yet

- MP1 Quiz 2Document3 pagesMP1 Quiz 2Veerakumar SNo ratings yet

- Science 5 Quarter 1 Module 3 Week 3Document6 pagesScience 5 Quarter 1 Module 3 Week 3Vhacie TorresNo ratings yet

- Design of Cantilever Slab for MOI ProjectDocument6 pagesDesign of Cantilever Slab for MOI ProjectHamjaytizii Engineering TvNo ratings yet

- North Cherwell: March 2021 February 2021 January 2021Document2 pagesNorth Cherwell: March 2021 February 2021 January 2021Dung NguyễnNo ratings yet

- Anchor Designer™ Software: 1/4 BN Engineer: 2/13/2017 Date: Bakkum Noelke CompanyDocument4 pagesAnchor Designer™ Software: 1/4 BN Engineer: 2/13/2017 Date: Bakkum Noelke CompanyBao NguyenNo ratings yet

- Wire Harness Repair-2200SRM1128 - (05-2005) - US-ENDocument76 pagesWire Harness Repair-2200SRM1128 - (05-2005) - US-ENMichał BujaraNo ratings yet

- Effect of Accelerating Admixture On Properties of ConcreteDocument8 pagesEffect of Accelerating Admixture On Properties of ConcreteVictor Danny Danielo RojasNo ratings yet

- 1345 3539 1 SMDocument10 pages1345 3539 1 SMYoga PrasytioNo ratings yet

- Bs 5400 Part 7Document24 pagesBs 5400 Part 7Ivy PaulNo ratings yet

- Statically Indeterminate MembersDocument7 pagesStatically Indeterminate MembersballDISCOVERIES PHballDISCOVERIESNo ratings yet

- Hydropalat 333Document2 pagesHydropalat 333JCNo ratings yet

- PC5300NC5330 MetricDocument20 pagesPC5300NC5330 MetricSakthi VelNo ratings yet

- Project Relative Advantages and Disadvantages of UPVC, Aluminum and Wooden Doors/WindowsDocument16 pagesProject Relative Advantages and Disadvantages of UPVC, Aluminum and Wooden Doors/Windowskhan03355No ratings yet

- Sikaflex®-717 WS: Product Data SheetDocument4 pagesSikaflex®-717 WS: Product Data SheetbeerNo ratings yet

- BeamDocument23 pagesBeamMohammad YusufNo ratings yet

- Brochure - Highly Insulated Pipe-In PipeDocument2 pagesBrochure - Highly Insulated Pipe-In PipefralgiugiaNo ratings yet

- Batangas II Electric Cooperative ProjectDocument3 pagesBatangas II Electric Cooperative ProjectRamled RerrefNo ratings yet

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeDocument9 pagesAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSNo ratings yet

- Chemical Spinning Methods - Wet, Dry & MeltDocument5 pagesChemical Spinning Methods - Wet, Dry & MeltGolam SarwarNo ratings yet

- List of Construction Prices For Electrical Works Philippines - PHILCON PRICESDocument3 pagesList of Construction Prices For Electrical Works Philippines - PHILCON PRICESjohn reyesNo ratings yet