Professional Documents

Culture Documents

019061-InstallationGuide

Uploaded by

hadrian lucifer0 ratings0% found this document useful (0 votes)

21 views1 pageinstallation guide

Original Title

13303_019061-InstallationGuide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstallation guide

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 page019061-InstallationGuide

Uploaded by

hadrian luciferinstallation guide

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

R

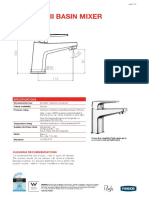

ACQUA - BASIN MIXER (CAST)

WATER EFFICIENT TAPWARE

1

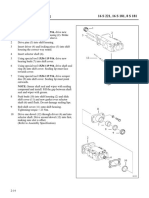

PLUMBERS INSTALLATION INSTRUCTIONS

Important Information

* Not suitable for gravity feed systems.

* Mixer is fitted with a flow regulated aerator insert.

IMPORTANT

Pressure & Temperature Requirements.

2 3 4 5

This low flow rate may not be suitable for connection to

some Instantaneous Gas Water Heaters, some Tempering Hot and cold water inlet pressures should be equal.

Valves, some Solar Water Heaters & some Thermostatic Static Inlet pressure range : 150-1000 kPa 6

Mixing Valves. New Regulation:- 500 kPa maximum static pressure

Check with the manufacturers of these products. at any outlet within a building.

Note:-An aerator insert kit (Part No. SP2001), is (Ref. AS/NZS 3500.1-2003, Clause 3.3.4)

available if required.

Maximum hot water temperature : 80 C.

* Isolating stop taps must be fitted to the hot & cold water

supply connections. (Part No. 842018C - Mini cistern 1/4T) Deck Requirements

* All pipework must be thoroughly flushed prior to

installation, as foreign materials may block the

Deck thickness : 45mm maximum

Tap body hole (in deck) : 33-35mm

7

flow regulating device and reduce the flow of water.

Note: Aerator insert housing must be retightened

to prevent removal by hand. Replacing Cartridge

Installation 1) Turn off hot and cold water supplies at isolating stop taps.

1) From fixing pack fit 'O'ring (9) into groove in underside 2) Remove indicator plug (2). Using 2.5mm allen key (3)

of mixer body (8). Screw studs (10) into underside of loosen screw (4) and remove handle (1). Unscrew cap (5) 8

mixer body (8). taking care not to damage the decorative finish. Unscrew

nut (6) then lift out old cartridge (7).

2) Flexible Tail Mixer Connections: Apply suitable lubricant to 18

'O'rings (11). Fit flexible tail (19) (with red indication) into 3) Ensure inside face of mixer body (8) is clean. Fit new

hole marked 'H' in underside of mixer body (8). cartridge (7) into mixer body, taking care that two lugs on

Hand tighten the tail, ensuring the 'O'ring (11) has fully base of cartridge (7) fit into mating holes in mixer body (8). 17

entered the sealing bore to provide a watertight joint.

Fit other flexible tail (with blue indication) into remaining

4) Screw on nut (6). Important:- Nut (6) should be tightened 9

to a torque of 12 Nm.

hole in a similar manner.

5) Replace cap (5), tightening by hand. Fit handle (1) taking 16

3) Insert the inlet connection end (15) of each flexible tail (19) 10

care that it is pushed fully down, tighten screw (4) and

through the hole in the deck. Place mixer over deck replace indicator plug (2), position with red to the left.

hole, fit gasket (12) and fixing plate (13) over studs (10) then

screw on fixing nuts (14). Position mixer as required then 6) Turn on isolating stop taps and check operation.

tighten fixing nuts (14) using a suitable spanner.

Replacing Aerator Insert Mixer 12

4) Flexible Tail Inlet Connections: Connect the flexible tails (19) Connection End 11

1) Carefully remove aerator housing (16) from mixer body (8),

to the hot and cold isolating stop taps, hand tighten the

connecting nut (15) until rubber cone contacts the sealing

taking care not to damage the decorative finish. 13

face of the connection end, then tighten a further one turn 2) Remove seal (18) & aerator insert (17) from aerator

to provide a watertight joint. housing. Check that aerator housing is clean. Deposits of 19

Important: Flexible tails must not be kinked, twisted or in lime can be removed by washing in a vinegar solution. 14

tension when installed. (Minimum Bend Radius:- 50mm) 3) Fit new aerator insert (17) into aerator housing (16) followed

Do not install flexible tails where subject to ultra violet light. by seal (18) then screw assembly into mixer body (8)

Inlet

and tighten securely(to prevent removal by hand).

Connection End 15

Fig. 1 IS569F(10/14)

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Install Sink Mixer Instructions DorfDocument2 pagesInstall Sink Mixer Instructions DorftestnationNo ratings yet

- 134649-InstallationGuide PDFDocument1 page134649-InstallationGuide PDFthadNo ratings yet

- 480 QuadrigageInstructionsDocument2 pages480 QuadrigageInstructionsjohn deereNo ratings yet

- Assembling Shift Housing ComponentsDocument2 pagesAssembling Shift Housing ComponentsThylaneNo ratings yet

- Group 7 RCV Lever Removal and InstallationDocument15 pagesGroup 7 RCV Lever Removal and InstallationRafał DworakNo ratings yet

- 6567 905A BK File InstallationGuidelines 151313 Ori 2016sep20132637Document1 page6567 905A BK File InstallationGuidelines 151313 Ori 2016sep20132637Suresh ChajjedNo ratings yet

- Amt Owner's ManualDocument8 pagesAmt Owner's ManuallrolindoNo ratings yet

- 43.88UK Mechanical Seal Replacement Instructions TCDocument4 pages43.88UK Mechanical Seal Replacement Instructions TCMohammed Mostafa El HaddadNo ratings yet

- 43 88 - Mechanical - Seal - Replacement - Instructions - TCDocument4 pages43 88 - Mechanical - Seal - Replacement - Instructions - TCAlan MercesNo ratings yet

- Posh Solus Mkii Basin Mixer 9502635 Tech WarrantyDocument3 pagesPosh Solus Mkii Basin Mixer 9502635 Tech WarrantymainpersonNo ratings yet

- B2-01 Booster Gun: Instruction ManualDocument2 pagesB2-01 Booster Gun: Instruction ManualJod RichNo ratings yet

- Sopras Sub Jupiter Diaphragm First Stage: Maintenance InstructionsDocument13 pagesSopras Sub Jupiter Diaphragm First Stage: Maintenance InstructionscesarecontoNo ratings yet

- Group 4 Disassembly and Assembly: 1. Main PumpDocument23 pagesGroup 4 Disassembly and Assembly: 1. Main PumpPriscila RodriguesNo ratings yet

- 7. اذرعت التحكم (العصيان)Document14 pages7. اذرعت التحكم (العصيان)المهندسوليدالطويلNo ratings yet

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- GF 200 1st Stage Re-AssemblyDocument16 pagesGF 200 1st Stage Re-Assemblyneoprenebearyahoo.comNo ratings yet

- Manual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066Document2 pagesManual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066marklaforestNo ratings yet

- Wags Grout Pump ManualDocument14 pagesWags Grout Pump ManualDavidMarulandaCardozoNo ratings yet

- Rci 400 Series Installation & Maintenance InstructionsDocument2 pagesRci 400 Series Installation & Maintenance InstructionsSandro MartinezNo ratings yet

- 5 Pierburg SingleDocument8 pages5 Pierburg Singlevanapeer100% (4)

- Piper Seneca II Magneto Service ManualDocument9 pagesPiper Seneca II Magneto Service ManualTríade MusicNo ratings yet

- Inspeção de MagnetoDocument9 pagesInspeção de MagnetoTríade MusicNo ratings yet

- Ultramat Plus Pneumo UFM PDocument6 pagesUltramat Plus Pneumo UFM PIsraelNo ratings yet

- GR - WRDSP - Tech LiteratureDocument7 pagesGR - WRDSP - Tech LiteratureDigger Downhole ToolsNo ratings yet

- Western RV Pressure Relief Setting Fan Drives: PurposeDocument3 pagesWestern RV Pressure Relief Setting Fan Drives: PurposessinokrotNo ratings yet

- ls400 TrannyDocument3 pagesls400 TrannyDohc MasterNo ratings yet

- Airvac Portable Vacuum Recovery SystemDocument8 pagesAirvac Portable Vacuum Recovery SystemEngTamerNo ratings yet

- Baker A-5 SemidisassenblyDocument7 pagesBaker A-5 SemidisassenblyabodolkuhaaNo ratings yet

- Adjusting Shift Fork 16 S 221, 16 S 181, 8 S 181Document3 pagesAdjusting Shift Fork 16 S 221, 16 S 181, 8 S 181ThylaneNo ratings yet

- Ni-252 GBDocument4 pagesNi-252 GByacineonlineNo ratings yet

- OsmaDrain Jointing Quick GuideDocument2 pagesOsmaDrain Jointing Quick GuideHatem AbdelnabiNo ratings yet

- AEROMATIC LTD. Fluid Bed Dryer PDFDocument13 pagesAEROMATIC LTD. Fluid Bed Dryer PDFManuel Molina KorsNo ratings yet

- Fpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsDocument1 pageFpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsServicios y Repuestos Jeremy Azhael 2320 C.ANo ratings yet

- Roatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5ADocument7 pagesRoatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AtungNo ratings yet

- A 1020Document16 pagesA 1020Pong KrubNo ratings yet

- Section 8012: Hydraulic Backhoe Quick CouplerDocument12 pagesSection 8012: Hydraulic Backhoe Quick CouplerMichel BayardelleNo ratings yet

- Fluid FaucetDocument2 pagesFluid Faucetmember1000No ratings yet

- Service Documentation: Market Release 4/97Document6 pagesService Documentation: Market Release 4/97Eprom ServisNo ratings yet

- Instruction Manual 1800CPB2 RegulatorsDocument4 pagesInstruction Manual 1800CPB2 RegulatorsCentro De Belleza Rizos EstiloNo ratings yet

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- LZWSM8 (D) (P)Document7 pagesLZWSM8 (D) (P)marinanagy211No ratings yet

- Operation and Maintenance: Model 873-400 RegulatorDocument2 pagesOperation and Maintenance: Model 873-400 Regulatorilham rusdyNo ratings yet

- Lm-827 Maintenance ManualDocument25 pagesLm-827 Maintenance ManualElmer VillegasNo ratings yet

- Assembling Clutch Housing and Centre HousingDocument3 pagesAssembling Clutch Housing and Centre HousingThylaneNo ratings yet

- RG5100 XT1 Manual 2018.1Document43 pagesRG5100 XT1 Manual 2018.1Pablo Serrano86% (7)

- Hutchride 2000: Completion Kit Parts & InstallationDocument4 pagesHutchride 2000: Completion Kit Parts & InstallationMario RodríguezNo ratings yet

- HD 7700 Manual Setup Heavy Duty PunchDocument31 pagesHD 7700 Manual Setup Heavy Duty PunchSantos MoralesNo ratings yet

- 320dl Joystick AssemblingDocument6 pages320dl Joystick AssemblingDaniel Rhasty-ghee AhmanorNo ratings yet

- Compressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveDocument3 pagesCompressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveThylaneNo ratings yet

- Compressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveDocument3 pagesCompressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveThylaneNo ratings yet

- Pacific Water - Utah - Series 960 Manual WMDocument24 pagesPacific Water - Utah - Series 960 Manual WMGreg ReynekeNo ratings yet

- Overhaul: Heater & Air ConditionerDocument4 pagesOverhaul: Heater & Air ConditionerIcaro FerreiraNo ratings yet

- Overhaul: Heater & Air ConditionerDocument4 pagesOverhaul: Heater & Air ConditionerCoco LinoNo ratings yet

- Torque Converter Clutch Case: Automatic TransmissionDocument4 pagesTorque Converter Clutch Case: Automatic TransmissionAnton FortovNo ratings yet

- 873 400 Regulator Operation and Maintenance ManualDocument2 pages873 400 Regulator Operation and Maintenance ManualHassan KhattabNo ratings yet

- Manual - Filtru AQUAPHOR - CrystallDocument28 pagesManual - Filtru AQUAPHOR - Crystallgeta_danilaNo ratings yet

- Aquaphor Crystall Product ManualDocument28 pagesAquaphor Crystall Product ManualChrisNo ratings yet

- Transdcer Replacement ProcedureDocument6 pagesTransdcer Replacement ProcedurefleetfixNo ratings yet

- GF 200 1st Stage DisassemblyDocument13 pagesGF 200 1st Stage Disassemblyneoprenebearyahoo.comNo ratings yet

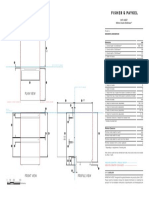

- Plan View: Data Sheet 600Mm Double Dishdrawer™Document1 pagePlan View: Data Sheet 600Mm Double Dishdrawer™hadrian luciferNo ratings yet

- Renzel Gabriel Rogacion TimesheetDocument6 pagesRenzel Gabriel Rogacion Timesheethadrian luciferNo ratings yet

- Toaz - Info Afinalproposal 1 PRDocument57 pagesToaz - Info Afinalproposal 1 PRhadrian luciferNo ratings yet

- RHE249 - Rheem Combined Brochure - 01 March 2019 WebDocument20 pagesRHE249 - Rheem Combined Brochure - 01 March 2019 WebJeromeNo ratings yet

- RHE249 - Rheem Combined Brochure - 01 March 2019 WebDocument20 pagesRHE249 - Rheem Combined Brochure - 01 March 2019 WebJeromeNo ratings yet

- User SOA330X1 User ManualDocument40 pagesUser SOA330X1 User Manualhadrian luciferNo ratings yet

- Pid - 1 Design in ArchitectureDocument61 pagesPid - 1 Design in ArchitectureDesign MommaNo ratings yet

- User SOA330X1 User ManualDocument40 pagesUser SOA330X1 User Manualhadrian luciferNo ratings yet

- Swimming Pool Calculation for Family Tube PoolDocument63 pagesSwimming Pool Calculation for Family Tube Poolwanroy80% (5)

- 2023.05 Heat Pump Specs - SplitDocument4 pages2023.05 Heat Pump Specs - SplitPrabin BhattaraiNo ratings yet

- Lab Report Shell N TubeDocument21 pagesLab Report Shell N Tuberidzuwan rahimi100% (6)

- Freshwater Generator AQUA Type HWDocument156 pagesFreshwater Generator AQUA Type HWHennadiy80% (5)

- Familiarize!!!! Part 1Document16 pagesFamiliarize!!!! Part 1James Carlo Maderazo CamarinesNo ratings yet

- Eci Water Ion Exchange Fiberglass Tanks Twobeddi 999430a 20091Document51 pagesEci Water Ion Exchange Fiberglass Tanks Twobeddi 999430a 20091Nelson Costa JrNo ratings yet

- Anexo 2 - Ficha Chiller de Absorción LGDocument17 pagesAnexo 2 - Ficha Chiller de Absorción LGSicologo CimeNo ratings yet

- 1.lecture 1 IntroductionDocument41 pages1.lecture 1 IntroductionVirak LachNo ratings yet

- Angus Orligno 100 Boiler Instruction ManualDocument60 pagesAngus Orligno 100 Boiler Instruction ManualAmândio PintoNo ratings yet

- Swimming Pool CalculationsDocument62 pagesSwimming Pool Calculationssuri422010No ratings yet

- Crown Oil Boilers BrochureDocument2 pagesCrown Oil Boilers Brochuree-ComfortUSANo ratings yet

- Water Coolers CatalogDocument34 pagesWater Coolers CatalogSinergroup Water Filters Water Purifiers Water SoftenersNo ratings yet

- Baxi MainEco Combi and System User GuideDocument32 pagesBaxi MainEco Combi and System User GuidePindiNo ratings yet

- GeasorDocument14 pagesGeasor786 RecordsNo ratings yet

- SP1 ManualDocument13 pagesSP1 ManualAnonymous RCPxaonfvNo ratings yet

- Series 100: Grundfos Data BookletDocument44 pagesSeries 100: Grundfos Data BookletadionicelNo ratings yet

- Qnergy The PCK80 Brochure Spec SheetDocument2 pagesQnergy The PCK80 Brochure Spec SheetDanny DurhamNo ratings yet

- TK 2Document32 pagesTK 2eveswan2008No ratings yet

- A112 Standards DescriptionDocument6 pagesA112 Standards Descriptionsmupy_122No ratings yet

- Types of Electrical Installations and ComponentsDocument58 pagesTypes of Electrical Installations and Componentsrobpeter2425No ratings yet

- Boiler-Manual-Cb-Cbw 100 To 400Document132 pagesBoiler-Manual-Cb-Cbw 100 To 400CayixNo ratings yet

- Service Diagnostic Manual: Top Load Washing Machine Cleansmart™ Fabricsmart™ Washsmart Eco™ Washsmart™ Quicksmart™Document33 pagesService Diagnostic Manual: Top Load Washing Machine Cleansmart™ Fabricsmart™ Washsmart Eco™ Washsmart™ Quicksmart™David100% (1)

- LG Therma V Split Rukovodstvo PolzovatelyaDocument30 pagesLG Therma V Split Rukovodstvo Polzovatelyagheorghe tabaraNo ratings yet

- Manual Tehnic Interfata PAC IF051B E - 6Document76 pagesManual Tehnic Interfata PAC IF051B E - 6boghdanNo ratings yet

- 15400Document27 pages15400uddinnadeemNo ratings yet

- Carriage 2001 Carri Lite RV Owners Manual enDocument46 pagesCarriage 2001 Carri Lite RV Owners Manual enRichard RoperNo ratings yet

- Instruction and warning book for Immergas IE MINI EOLO 24 3E boilerDocument36 pagesInstruction and warning book for Immergas IE MINI EOLO 24 3E boilerBlanaru BogdanNo ratings yet

- Hydronic Piping SystemsDocument2 pagesHydronic Piping SystemsNestor S. ReEyesNo ratings yet

- Solar Thermal Final ReportDocument173 pagesSolar Thermal Final ReportRahul TripathiNo ratings yet

- THERMA V R32 Monobloc Leaflet - 20180810Document14 pagesTHERMA V R32 Monobloc Leaflet - 20180810Muhidin KozicaNo ratings yet