Professional Documents

Culture Documents

Swage Optional Fase Wahlweise Optional Wahlweise: 04MAY2016 22SEP2016 21OCT2017 24SEP2018 3 4 5

Uploaded by

Usama TwabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swage Optional Fase Wahlweise Optional Wahlweise: 04MAY2016 22SEP2016 21OCT2017 24SEP2018 3 4 5

Uploaded by

Usama TwabCopyright:

Available Formats

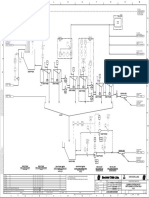

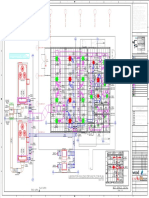

8 7 6 5 4 3 2 1

THIS DRAWING IS UNPUBLISHED. RELEASED FOR PUBLICATION 2011

REVISIONS

ALL RIGHTS RESERVED.

C COPYRIGHT2015 -

P LTR DESCRIPTION DATE DWN APVD

A18 ECR-16-006173 04MAY2016 MB JK

B CONTACTS FOR FLR-CABLE

A A19 ECR-16-009404 22SEP2016 MB JK

3

Kontakte fuer FLR-Leitung A20 ECR-17-005648 21OCT2017 MB PSt

A21 ECR-18-014391 24SEP2018 SCK RP

C

DRAWING:7 8

4

2

B DRAWING:6 8

DRAWING:17 8

5

A

0.15

1

DRAWING:5 8

DRAWING:24 8

5.7+0.05

0.7

-0.15

DESIGN 963898 / 963900 / 963904

FORM A Ausfuehrung 963898 / 963900 / 963904

12

FORM B

DRAWING:15 8

0.1

2.6+0.05

-0.15

1.6

D D

11

DRAWING:14 8

0.5 max.

0.7 # 0.15

0.8

9 6

CUT-OFF

DRAWING:16 8

0.03

B

DRAWING:26 8

A

X10CrNi188 8

0.32

DRAWING:18 8

10

7

DRAWING:23 8

22.4 0.5

DRAWING:25 8

0.15

0.4

15

DRAWING:50 8

SWAGE OPTIONAL

CUTS OPTIONAL 4x Fase wahlweise

Schnitte wahlweise 4x OPTIONAL

wahlweise 20

min. 1 31

DRAWING:29 8

1.1 min.

963900:25 8

28

DRAWING:20 8

2.2+0.05

-0.15

0.8+0.05

-0.20

0.6+0.07

21

0.8 max.

DRAWING:27 8

25

3.8+0.05

1.2+0.05

-0.20

0.15

-0.20

DRAWING:32 8

26

27 DRAWING:30 8

30

23

SERRATIONS

DRAWING:19 8

963900:25 8

SERRATIONS

0.6

DRAWING:22 8

C 22

DESIGN 1 DESIGN 2 C

02

24

0.

DRAWING:21 8

DRAWING:31 8

11.6

2

0.

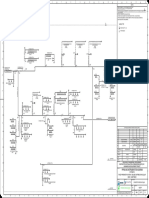

DESIGN 963902

CONTACTS FOR SINGLE WIRE SEALING SYSTEM: Ausfuehrung 963902

FLR- AND FLK-CABLE

Kontakte fuer Einzeldichtung-System:

FLR- und FLK-Leitung

DIMENSIONS SEE FIGURE CONTACTS FOR FLR-CABLE

Masse siehe Darstellung der Kontakte fuer FLR-Leitung C

0.15

42

C DRAWING:38 8

0.4

45

B 41

DRAWING:51 8

DRAWING:37 8

B B

A 40 DRAWING:36 8

FORM C

min. 1.25 50 963900:25 8

43

0.3 max. DRAWING:38 8

C CUT-OFF

OPTIONAL

CUTS OPTIONAL 4x

Wahlweise

1.2+0.05

-0.25

Schnitte wahlweise 4x

51

963900:25 8

SERRATIONS

DESIGN 3

A A

5:1 THIS DRAWING IS A CONTROLLED DOCUMENT.

DWN 11JUN1997

T.Bersch

CHK 11JUN1997 TE Connectivity

DIMENSIONS: TOLERANCES UNLESS

U.Muenk

OTHERWISE SPECIFIED: APVD 02MAR2011 NAME

mm M.Bleicher

PRODUCT SPEC

PRODUCT GROUP DRAWING

-

0 PLC

1 PLC - TAB 1.6 x 0.6

108-18331

2 PLC

3 PLC

-

- APPLICATION SPEC

Flachstecker 1.6 x 0.6

4 PLC - SIZE CAGE CODE DRAWING NO RESTRICTED TO

ANGLES - 114-18082

MATERIAL

SEE TABLE sheet 2

FINISH

SEE TABLE sheet 2

WEIGHT

- A1 00779 1355055

A21

SCALE SHEET OF REV

siehe Tabelle siehe Tabelle CUSTOMER DRAWING 10:1 1 2

4805 (3/13)

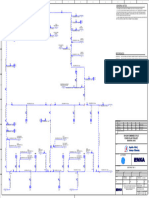

8 7 6 5 4 3 2 1

THIS DRAWING IS UNPUBLISHED. RELEASED FOR PUBLICATION 2011

REVISIONS

ALL RIGHTS RESERVED.

C COPYRIGHT2011 -

P LTR DESCRIPTION DATE DWN APVD

- SEE SHEET 1 - - -

SECTION C-C

FORM C

Schnitt C-C

SECTION B-B FORM A

SECTION A-A Schnitt B-B FORM B 57 DRAWING:39 8

X # 0.3

Schnitt A-A 54

H # 0.3

DRAWING:11 8

51

DRAWING:10 8

E # 0.3

# 0.3

# 0.3

# 0.3

D D

53

DRAWING:12 8

56

DRAWING:58 8

50

L

DRAWING:9 8

K

G

DD 52 DI 55

DI 58

so 1 CONTACT AREA SELECTIVE GOLD 0.8µm MIN. OVER NICKEL.

DRAWING:13 8

DRAWING:59 8

so

DRAWING:8 8

r

WIRE CRIMP AREA ELECTRO TIN PLATED 1µm MIN. OVER NICKEL

Kontaktzone selectiv vergoldet 0.8µm min. ueber Ni

Drahtcrimpbereich gal. verzinnt 1µm min. ueber Ni

2 FOR DOUBLE- AND SINGLE TERMINATION

fuer Doppel- und Einzelanschlaege

3 SINGE WIRE SEAL TO BE SELECTED ACCORDING TO INSULATION-DIA

ACCODING TO APPLICATION SPECIFICATION 114-18082

SEE / siehe SEE / siehe Auswahl der Eubzeldichtung entsprechend dem Isolationsdurchmesser nach

SECTION A-A SECTION B-B / C-C Verarbeitungsspezification 114-18082

Schnitt A-A Schnitt B-B / C-C

4 TIN PLATED

1703278-5 A 1 CuSn4 E = 2.8 C

5 L = 4.9 vorverzinnt

1.5 1.95 - 2.4 G = 3.0 - 3.0 4.4 6.4 3.6

D ISO = 2.9

1703278-2 A 1 CuFe2 4 D Dr = 1.4

5 CONTACT AREA SELECTIVE SILVER 3µm MIN. OVER NICKEL.

2-964269-2 A 1 CuFe2 C

5 WIRE CRIMP AREA ELECTRO TIN PLATED 1.5µm MIN. OVER NICKEL

964269-5 A 1 CuSn4 5

E = 2.5

L = 4.8

Kontaktzone selectiv versilbert 3µm min. ueber Ni

G = 2.7 539612-1

0.5 - 1.0 1.4 - 2.1 D ISO = 2.7 539663-2

3.0 4.4 6.4 3.3 Drahtcrimpbereich gal. verzinnt 1.5µm min. ueber Ni

964269-3 E 1 CuSn4 1 D Dr = 1.2

3

964269-2 D 1 CuFe2 6 DIFFERENT TOOL DETAILS

4

C FUNCTION AND HANDLING WITH ALL DETAILS CONTINUOUSLY C

Einzeldichtungssystem

963904-3 G 1 CuSn4 1 A SUPPLY AFTER AVAILABILITY

E = 2.6 H = 4.5

SINGLE WIRE SEAL /

963904-2 F 1 CuFe2 0.5 - 1.0 1.4 - 2.1 G = 2.8 K = 4.8 539651-2 3.0 4.6 7.0 - Verschiedene Werkzeugausfuehrungen

4

D Dr = 1.2 D ISO = 2.7 Funktion und Handhabung bei allen Ausfuehrungen gleich

963904-1 F 1 CuSn4 4 Lieferung nach Verfuegbarkeit

2141884-5 A 2 CuSn4 5 C

2141884-3 B 2 CuSn4 E = 2.4

1 L = 4.8

0.35 1.15 - 1.6 G = 2.3 539663-2 2.5 4.4 6.4 3.3

D ISO = 2.6

2-2141884-2 A 2 CuFe2 5 D Dr = 1.0

2141884-2 A 2 CuFe2 4

969028-5 A 3 CuSn4 5 C

E = 2.1 X = 4.3

539612-1

siehe Verarbeitungsspezifikation 114-18082

969028-3 E 3 CuSn4 1 0.2 - 0.5 1.15 - 1.6 G = 2.1 L = 4.8 2.5 4.4 6.4 3.3

539663-2

SEE APPLICATION SPECIFICATION 114-18082

D Dr = 0.8 D ISO = 2.6

969028-2 D 3 CuFe2 4

963902-3 E 3 CuSn4 1 A

E = 2.1 H = 4.5

963902-2 D 3 CuFe2 4 0.2 - 0.5 1.15 - 1.6 G = 2.1 K = 4.8 539651-2 2.5 4.6 7.0 -

D Dr = 0.8 D ISO = 2.7

963902-1 D 3 CuSn4 4

1241846-5 A 1 CuSn4 5 A

539960-1

1241846-3 B 1 CuSn4 E = 2.8 H = 3.5

1

1.5 2.2 - 2.4 G = 3.0 K = 3.9 169400-0 - 3.0 4.4 6.4 -

1241846-2 A 1 CuFe2 4 D Dr = 1.4 DISO = 1.9 539635-1

1241846-1 A 1 CuSn4 4

B 969079-3 C 1 CuSn4 1 B B

E = 2.5 H = 3.7

0.5 - 1.0 1.4 - 2.1 G = 2.8 K = 3.9 - 3.0 4.6 6.2 -

969079-2

B 1 CuFe2 4 D Dr = 1.2 DISO = 1.8

2

964267-4 A 1 CuSn4 5 A

964267-3 D 1 CuSn4 E = 2.5 H = 3.2

1 539612-1

0.5 - 1.0 1.4 - 2.1 G = 2.7 K = 3.4 3.0 4.4 6.4 -

964267-2 C 1 CuFe2 D Dr = 1.2 DISO = 1.8 539663-2

4

ungedichtet

UNSEALED /

964267-1 C 1 CuSn4 4

963900-4 E 1 CuSn4 1 A

963900-3 E 1 CuSn4 E = 2.6 H = 3.2

1

0.5 - 1.0 1.4 - 2.1 G = 2.8 K = 3.4 539651-2 3.0 4.6 7.0 -

963900-2 D 1 CuFe2 4 D Dr = 1.2 D ISO = 1.8

963900-1 D 1 CuSn4 4

963898-3 E 3 CuSn4 1 A

E = 2.1 H = 2.9

963898-2 D 3 CuFe2 0.2 - 0.5 1.15 - 1.6 G = 2.1 K = 2.9 539651-2 2.5 4.6 7.0 -

4

D Dr = 0.8 DISO = 1.4

963898-1 D 3 CuSn4 4

2141882-3 B 2 CuSn4 A21 E = 2.4 A H = 2.9

1

0.22 - 0.35 1.15 - 1.6 G = 2.3 K = 2.9 539633-2 2.5 4.4 6.4 -

2141882-2 A 2 CuFe2 4 D Dr = 1.0 DISO = 1.4

964265-5 A 3 CuSn4 5 A

E = 2.1 H = 2.9

G = 2.1 K = 2.9 539612-1

A 964265-3 D 3 CuSn4 1 0.2 - 0.35 1.15 - 1.6 2.5 4.4 6.4 - A

D Dr = 0.8 DISO = 1.4 539663-2

964265-2 C 3 CuFe2 4 THIS DRAWING IS A CONTROLLED DOCUMENT.

DWN 11JUN1997

T.Bersch

CHK 11JUN1997 TE Connectivity

STRIP FORM TE U.Muenk

CRIMP DATA DIMENSIONS: TOLERANCES UNLESS

WIRE CRIMP INSUL. CRIMP ORDER-NO. OTHERWISE SPECIFIED: APVD 02MAR2011 NAME

DESIGN INSULATION n A B C X AND mm M.Bleicher PRODUCT GROUP DRAWING

SERRATIONS MATERIAL SURFACE DGB Drahtcrimp Isolationscrimp HAND TOOL INSERT CRIMP TOOL

0 PLC - PRODUCT SPEC

TAB 1.6 x 0.6 TYPE A

-

TE Bandware EXTRACTION 1 PLC

108-18331

Flachstecker 1.6 x 0.6 Typ A

REV Isolations n 2 PLC -

ORDER-NO. TOOL 3 PLC - APPLICATION SPEC

Ausfuehrung WerkstoffOberflaeche mm² Handzange Matrize Crimpdaten 4 PLC

ANGLES

-

- 114-18082

SIZE CAGE CODE DRAWING NO RESTRICTED TO

CRIMP DIMENSION mm DIMENSION mm

Serrations mm

Crimpabmessungen mm Abmessung mm Ausdrueck-

und Crimp-

werkzeuge

MATERIAL

SEE TABLE sheet 2

FINISH

SEE TABLE sheet 2

WEIGHT

- A1 00779 1355055

werkzeug siehe Tabelle siehe Tabelle CUSTOMER DRAWING

SCALE

10:1

SHEET

2

OF

2 A21

REV

4805 (3/13)

You might also like

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- 426-5051-00 - Turck Breakout & BoxRemote ModuleDocument6 pages426-5051-00 - Turck Breakout & BoxRemote ModulejNo ratings yet

- 2S6T 14a464 Ub PDFDocument3 pages2S6T 14a464 Ub PDFKemmerly ErazoNo ratings yet

- Site Plan: R 0 A D 60' (34C)Document1 pageSite Plan: R 0 A D 60' (34C)BatWing ZNo ratings yet

- Enq-439-Drainage R01Document6 pagesEnq-439-Drainage R01abdullah sahibNo ratings yet

- BC-6800 Fluidic DiagramDocument24 pagesBC-6800 Fluidic DiagramFENGNo ratings yet

- Schematics Xt1965 LaDocument66 pagesSchematics Xt1965 LasetrabporciunculaNo ratings yet

- XC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18Document1 pageXC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18percyctba FilhoNo ratings yet

- Pim1013 Pim1014 Pim1013 Pim1014: Piq101 Piq101Document1 pagePim1013 Pim1014 Pim1013 Pim1014: Piq101 Piq101Alexsei BordaNo ratings yet

- Xstrata Bechtel Alliance: A. Gonzalez A. GonzalezDocument1 pageXstrata Bechtel Alliance: A. Gonzalez A. GonzalezjhonNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- WD Centre Line PlanDocument1 pageWD Centre Line PlanRaj GuptaNo ratings yet

- PID Turbcompr Desc1raEtapaDocument1 pagePID Turbcompr Desc1raEtapaJholman SanchezNo ratings yet

- WWW .Cpu 999: Tdïîä¿Óãsky77594 Wcdmïîä¿Óãsky77592-21Document11 pagesWWW .Cpu 999: Tdïîä¿Óãsky77594 Wcdmïîä¿Óãsky77592-21Desert EagleNo ratings yet

- 25635-220-M6-0210-00001-R2 Chancadora 1Document1 page25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNo ratings yet

- Rub 170Document1 pageRub 170Deepak SinghNo ratings yet

- Coo 4Document1 pageCoo 4Jok PrasNo ratings yet

- Analisi Triadi E Rivolti: Esercizio 2Document2 pagesAnalisi Triadi E Rivolti: Esercizio 2televisioneNo ratings yet

- 5802002614_WIRING_GENSET_WITHOUT_BOX_TIER_4B_B_13_NO_20_Document1 page5802002614_WIRING_GENSET_WITHOUT_BOX_TIER_4B_B_13_NO_20_cesar saavedra saavedraNo ratings yet

- 144095-2 DWGDocument1 page144095-2 DWGheronNo ratings yet

- 000 Arturia MiniBrute DigitalBoard MAESTRODocument18 pages000 Arturia MiniBrute DigitalBoard MAESTROCristobal NicolásNo ratings yet

- LLC Multiple VoltageDocument2 pagesLLC Multiple VoltageDanut StanciuNo ratings yet

- Site Plan Vicinity Map List of Drawings: StudioDocument1 pageSite Plan Vicinity Map List of Drawings: StudioBatWing ZNo ratings yet

- Roadmap ColorDocument2 pagesRoadmap Colortkhan2001No ratings yet

- 640-0762 (Inversora) - SURT7500,8000,10000Document7 pages640-0762 (Inversora) - SURT7500,8000,10000Helder RizziNo ratings yet

- 26-D-103a - Ground Floor Plan 1 of 3 (Low Level)Document1 page26-D-103a - Ground Floor Plan 1 of 3 (Low Level)Jhonson PintoNo ratings yet

- A-812 13TH Floor Rcp-Erga - Ttb-A0Document1 pageA-812 13TH Floor Rcp-Erga - Ttb-A0shahul hameedNo ratings yet

- 3rd Storey Plumbing Layout Plan Rev 0 (Color, Revit)Document1 page3rd Storey Plumbing Layout Plan Rev 0 (Color, Revit)ZenChanNo ratings yet

- Issue For Relay Panel Construction PDFDocument119 pagesIssue For Relay Panel Construction PDFallanng30No ratings yet

- Legend: Project Name: LPIC EPC1 SCUDocument1 pageLegend: Project Name: LPIC EPC1 SCUjeswinNo ratings yet

- 1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMDocument12 pages1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMShilu GhoshNo ratings yet

- ZONING_REV1_25-AUG-20Document1 pageZONING_REV1_25-AUG-20ahmed yaqoobNo ratings yet

- Paras Ventures - (Ground Floor)Document1 pageParas Ventures - (Ground Floor)AriyanNo ratings yet

- Schematic Diagram of P300 - 4800105M301 - P3 - V1 - 20130123Document10 pagesSchematic Diagram of P300 - 4800105M301 - P3 - V1 - 20130123Riza VirsadaNo ratings yet

- 22 06 VCS de de Duc 03 2Document1 page22 06 VCS de de Duc 03 2MARCELO ALEJANDRO CUEVAS ALBORNOZNo ratings yet

- Plano Esquemático Huawei Y320Document9 pagesPlano Esquemático Huawei Y320Gonzalo CastañedaNo ratings yet

- IQ360-000-M6-SG-00003 Rev03Document1 pageIQ360-000-M6-SG-00003 Rev03mustafa1989ocNo ratings yet

- FinalDocument1 pageFinalredNo ratings yet

- Diagrama Celular ChinoDocument19 pagesDiagrama Celular ChinoWilinton Pisso33% (3)

- Wd11y021s10Document28 pagesWd11y021s10cages48160No ratings yet

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaNo ratings yet

- PS0121-DWG-B-003 Sheet 5 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 4 R.5Document1 pagePS0121-DWG-B-003 Sheet 5 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 4 R.5yusak adi setiawanNo ratings yet

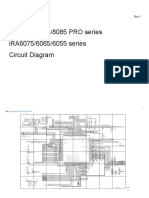

- Ira6000 8000 Series-CdDocument427 pagesIra6000 8000 Series-Cdluongnam100% (1)

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirNo ratings yet

- B Side: N7Tw - Power.Pcb 1LG4B10Y04300Document2 pagesB Side: N7Tw - Power.Pcb 1LG4B10Y04300Dario EzequielNo ratings yet

- To Control Unit OCS, See Circuit Diagram 2081507Document1 pageTo Control Unit OCS, See Circuit Diagram 2081507andrestkaNo ratings yet

- Top View Section X-X: Design DataDocument1 pageTop View Section X-X: Design DatakishoreNo ratings yet

- Fuga A 5 Pro Organo Pleno BachDocument12 pagesFuga A 5 Pro Organo Pleno BachSilva BielsilvaNo ratings yet

- A B C D E: Laboratory Building Ground Floor PlanDocument1 pageA B C D E: Laboratory Building Ground Floor PlanEmre ÇilNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Jaime A Restrepo: Sanitary Level 1 - Residential BuildingDocument1 pageJaime A Restrepo: Sanitary Level 1 - Residential BuildingSrijon BrahmacharyNo ratings yet

- Eec Serie KDocument1 pageEec Serie KmiltonNo ratings yet

- Detailed Design 16 MAY 2022: Mandai Rainforest Park North SingaporeDocument12 pagesDetailed Design 16 MAY 2022: Mandai Rainforest Park North SingaporeJawNo ratings yet

- GT A GT B GT D GT F GT G GT E GT C: 400Kv Switchyard EquipmentDocument1 pageGT A GT B GT D GT F GT G GT E GT C: 400Kv Switchyard EquipmentS Rao CheepuriNo ratings yet

- Sample MDRDocument4 pagesSample MDRchristi SNo ratings yet

- 0210-CRB-0002 0210-CNJ-0002 0210-ZMH-0015: Rock Breaker Hydraulic PowerDocument1 page0210-CRB-0002 0210-CNJ-0002 0210-ZMH-0015: Rock Breaker Hydraulic Powernestor159357No ratings yet

- Peavey Electronics IncDocument3 pagesPeavey Electronics IncTrevor Washburn0% (1)

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet