Professional Documents

Culture Documents

V2D754026

V2D754026

Uploaded by

Salvador Reyes0 ratings0% found this document useful (0 votes)

9 views3 pagestest de marcha delco

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttest de marcha delco

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesV2D754026

V2D754026

Uploaded by

Salvador Reyestest de marcha delco

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

4-26 Starters

DELCO-REMY ENCLOSED HOUSING

emer “se tering Sod scn01

International Harvester

DESCRIPTION

12 volt, 4 pole starters of conventional design. Storters hove

solenoid pinion shaft (overrunning clutch) with entire shift

‘mechanism enclosed within drive housing, Field assembly con-

fists of four series coils or combination of series coils with one

‘or more shunt coils. Bruth assemblies ore completely enclosed

‘within field frame ot commutator end so that entre starter and

drive assembly is protected from dirt. Starter solenoid. is

flange mounted on drive end housing ond shift lever return

Spring is compression type located inside solenoid case.

Starter Application

Delco-Remy

Part No.

Application

250!

"C"& "K" Models 1108744, 1108778

Ali Other Models 1108746, 1108779

292" 1108747, 1108780

350°, 400", 4541

‘Motor Home 1108502, 1108782

Exc. Motor Home 1108748, 1108781

1108761

455° Motor Home

TESTING

STARTER CRANKING CIRCUIT TESTS

1), With engine at normal operoting temperature, ground dis

tribvtor terminal of coil 29 engine will not stort. Connect

voltmeter positive lead to motor terminal on solenoid and

‘ground negative lead, Crank engine ond read voltmeter: if

Cranking speed is normal and voltage is 9 vols or more, system

is stisfoctory. If cranking speed is below normal and voltage

is 9 volts or greater, sorter is detective.

2) starter turns engine slow with 9 volts or las, test voltage

‘across solenoid switch contacts. Connect o 12 volt meter

lead to solenoid motor terminal ond positive lead 10

terminal of switch, Crank engine and immediately turn

voltmeter switch to low scale, toke reading, then turn switch

Bock to high scale before stopping engine. Voltage drop must

rot exceed .2 volt for contacts 0 be satisfactory

SOLENOID WINDINGS TEST

NOTE — Tests are performed with all leads disconnected

Complete tes!s in minimum amount of time 10 prevent

overheating solenaid.

Hold-In Winding — Connect test equipment as shown in il

lustration. Use carbon pile to decreore bottery voltage to 10

volts. Ammeter should read 14.5 to 16.5 Amps. H amperage is

above 16.5 Amps., winding is shorted or grounded. Amperage.

drow below 14.5 Amps, indicates excessive resistance

Beth Windings In Poralel ~ Remove jumper wre trom

motor terminal of solenoid ond readjust reistonce +0

oiage 10 volts, Current draw should be 40.5:475

amperes. If not within specifications replace solencia.

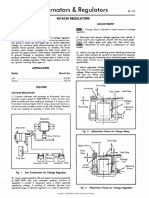

SOLENOID WINDING TEST CONNECTIONS

STARTER NO LOAD TEST

To perform test, connect starter as shown in illustration, To ob

toin voltage specified in Delco Remy Storter Specifications,

‘adjust corbon pile. Then read current draw and armoture

speed ond compare these readings with specifications

CAUTION ~ Do not apply voltage greoter than specified;

excessive voltage may couse armature 10 throw windings

becouse of excessive speed,

Ammeter

STARTER NO LOAD TEST CONNECTIONS

DELCO-REMY STARTER SPECIFICATIONS:

eral No toad Test

—rDr,rhmrmrrCOCOC

"o8s02 4595 | 750010500 | 9

"owe #80 | ‘oooesoo | 9

Moers S080 | Ssoorba00 |

rosa? 3580 | 3300-6000 |

oersa 8395 | 7i001bs00 | >

Nowra! $595 | Zs0010800 | 9

oer Soo | 5300-10300 |

Moers S080 | Ss0o.10800 | >

oszeo 5500 | 300 3

"08761 3555 | zsoo1es00 | 9

howe 4595 | 730010300 | 9

‘ipo 200 Rapa ema Campa

Starters

DELCO-REMY ENCLOSED HOUSING (Cont.)

SPECIFICATIONS

Brush Spring Tension. 35 ons

Rotation. : ockewite’ ot pinion end

jon-to-Housing Clearance. ‘O.010-.140"

© = Between pinion and pinion stop with pinion in engaged

position.

OVERHAUL

DISASSEMBLY

1)_ Disconnect field lead strap from solencid by toking out ter

minal screw. Remove two through bolts, withdraw commutator

fend frame and field frame by pulling these ports off the or

mature. Remove thrust washer from commutator end of ar

mature shaft

2) Pull out bruth holder pivot pin and remove two brush

holders and spring as on assembly. Remove brushes by toking

‘out screws attaching leads ond brushes to holder.

3) Remove two solenoid attaching screws ond remove

solenoid from drive housing. To remove solenoid cover for

switch inspection, remove nuts and insulating washers from

solenoid "S" and "BAT" terminals, remove cover

44) Remove shift lever fulerum bolt, remove shift lever, plunger,

‘and return spring from end housing. Withdraw armature

‘ossembly. Remove thrust collar from pinion end of armature

shaft

5) To remove dive assembly from armature shoft, install

piece of correct size tubing over end of shoft and against pi:

hion stop retainer, tap retoiner toward armature to uncover

snap ring. Remove snap ring from groove in shalt, then slide

Fetainer ond drive assembly off shoft

CLEANING

Clean all ports by wiping with clean cloth. Do not clean ar:

mature, field cols, or drive assembly in any type of grease dis:

solving solvent os this will damage insulation ond wash lubri

cont out of drive assembly.

PARTS REPLACEMENT & TESTING

Armature ~ Test ormature for shorted coils with a growler.

Check for grounded coils with © 110 volt test lamp. Place one

test lead on armature core or shaft, and other test lead on

commutator, Lamp should not light. flomp lights, armature is

grounded ond should be replaced. Inspect commutator. If

commutator is worn, out of round, oF has high insulation, tn

down commutator in a lathe, undercut insulation i" deep ond

Squore across entire width, sand commutator lightly with 00

grade sandpaper and clean out slots caretuly

CAUTION — Some starters have molded-type commutator,

‘ond insulation must not be undercut on these models os *his

‘may couse serious damage 40 commutotor.

Field Coils — Check with 110 volt test light. Place one test

lead on field coil terminal strap, touch other test lead to field

«oil brush lead (check series coils and shunt coils separately ot

‘oppropriote terminals). Lamp should light. If lamp does not

light, cols ore open. Check for grounds by placing one test

leod on field armature strap, touch other lead to ormature

core or shaft, CAUTION — Shunt coil ground lead mus! be

disconnected ond all field terminals insulated from frame when

‘moking ths test, If lamp lights, one or more cols are ground:

a,

‘ipo 0 200 a Rea

Brushes, Springs, & Holders — Replace brushes if worn to

one-half of original length, or if oil-soaked or pitted. Check

brush spring tension and replace springs if weak or distorted

Deformed or bent brush holders can be replaced by service un

its which are installed with screws and nuts

Drive & Pinion Assembly ~ Pinion should turn freely in

overrun direction and should not slip in drive direction. Check

Spring for correct tension and drive collar for wear (these parts

con be removed for replacement by forcing collar toward

clutch and removing lock ring from end of tube). Replace drive

cossembly if pinion teeth are worn, chipped, or cracked

Pivot Pin

ir) cor

rush Holder

Support

Brush Holder Spring

Brush Holder (Ground)

BRUSH ASSEMBLY (ONE SET SHOWN)

Armature Shaft Bushings — Inspect armature shoft bear:

ing surfaces and check for wear by noting sideploy with shaft

inserted in bushings. Drive end bushing con be replaced.

Reploce commutator end plate ossembly if bushing is worn.

Pinion Clearance ~ Connect an electrical source of 6 volts

between solenoid "S" terminal and ground. CAUTION — Do

ot use more thon & volts or motor will operate. After

tenergizing solenoid, push pinion away from stop retainer as

for as possible and use feeler gouge to check clearance

between pinion and retainer. If clearance is not within

specifications disassemble motor and check for defects

4-28 Starters

DELCO-REMY ENCLOSED HOUSING ( Cont.)

1) Lubricate armoture shaft with silicone lubricant or several

drops of SAE 10 engine oil install drive assembly on shal, in

stall retainer with cupped side out or away from pinion, instoll

lock ring in shaft groove, install thrust collar with shoulder

‘against locking. Position retainer on lack ring by using two

pliers ot opposite points to squeeze retainer and thrust collor

together against lock ring

2) Assemble brush holders ond instll brushes, connect field

leads to proper brushes, check assemblies for free movement,

3) Assemble solenoid plunger on shift. Lubricate drive housing

bushing with silicone lubricant or few drops of SAE 10 engine

cil, Install armature and drive assembly in drive housing with

Shift lever engaged in drive collar, install shift lever pin. Coot

both tides of solenoid flange which extends down between

drive housing ond field frame with suitable sealer (No.

1050026), place return spring over plunger ond install

solenoid, tighten solenoid attaching screws securely.

4) Align field frame dowel with dowel hole in drive housing.

Install field frame over armature and against end housing

CAUTION — Lift brushes up over commutator os field frame

is installed to prevent damage to brushes.

Shift Lever Assembly

Drive Assembly

Thrust Collar

Drive Housing

Armature”

mature shaft, Lubricate commutator end frame bushing with

slicane lubricant or few drops of SAE 10 engine oil install end

frame, install through bolts and tighten securely.

Plunger

3co2

0

&

SHIFT LEVER ASSEMBLY

Return Spring

Shift Lever

Drive Housing

Solenoid Assembly

Terminal

Brush Holders

End Plate

Brush Holder

Field Coils

Brush Spring

Leather Washer

cos

DELCO-REMY ENCLOSED HOUSING STARTER ASSEMBLY

‘ipo 200 Rapa ema Campa

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- V2I783002Document1 pageV2I783002Salvador ReyesNo ratings yet

- V2I803028Document1 pageV2I803028Salvador ReyesNo ratings yet

- V2I803018Document2 pagesV2I803018Salvador ReyesNo ratings yet

- V2I803029Document3 pagesV2I803029Salvador ReyesNo ratings yet

- V2I783004Document3 pagesV2I783004Salvador ReyesNo ratings yet

- V2I803032Document1 pageV2I803032Salvador ReyesNo ratings yet

- V2I803015Document2 pagesV2I803015Salvador ReyesNo ratings yet

- V2I803020Document1 pageV2I803020Salvador ReyesNo ratings yet

- V2I803023Document2 pagesV2I803023Salvador ReyesNo ratings yet

- V2I803021Document2 pagesV2I803021Salvador ReyesNo ratings yet

- V2I803017Document1 pageV2I803017Salvador ReyesNo ratings yet

- V2I803025Document1 pageV2I803025Salvador ReyesNo ratings yet

- V2I803012Document2 pagesV2I803012Salvador ReyesNo ratings yet

- V2I803010Document2 pagesV2I803010Salvador ReyesNo ratings yet

- V2I783015Document2 pagesV2I783015Salvador ReyesNo ratings yet

- V2I803004Document2 pagesV2I803004Salvador ReyesNo ratings yet

- V2I803007Document3 pagesV2I803007Salvador ReyesNo ratings yet

- V2I803003Document1 pageV2I803003Salvador ReyesNo ratings yet

- V2I803002Document1 pageV2I803002Salvador ReyesNo ratings yet

- V2I803006Document1 pageV2I803006Salvador ReyesNo ratings yet

- V2I783011Document2 pagesV2I783011Salvador ReyesNo ratings yet