Professional Documents

Culture Documents

Three Phase Meter:CMC/ENQ/ASG/KM/005: Section - V

Uploaded by

cahyoelektroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Three Phase Meter:CMC/ENQ/ASG/KM/005: Section - V

Uploaded by

cahyoelektroCopyright:

Available Formats

SECTION – V:

TECHNICAL SPECIFICATION(TS)

Three Phase Meter:CMC/ENQ/ASG/KM/005

Dated : 29.11.2010

The detailed meter specification No. : I-10-3A of

Three Phase Meter is enclosed

Page 1 SEAL & SIGNATURE OF THE BIDDER

CONTENTS

SECTION – V:......................................................................................................................................... 1

TECHNICAL SPECIFICATION(TS) ....................................................................................................... 1

THREE PHASE METER:CMC/ENQ/ASG/KM/005................................................................................. 1

DATED : 29.11.2010............................................................................................................................... 1

THE DETAILED METER SPECIFICATION NO. : I-10-3A OF ............................. 1

THREE PHASE METER IS ENCLOSED ................................................. 1

......................................................................................................................... 1

1.0 SCOPE.............................................................................................................................................. 3

2.0 STANDARDS .................................................................................................................................. 3

3.0 TECHNICAL SPECIFICATION........................................................................................................ 3

5.0 TAMPER & ANTI-FRAUD DETECTION/EVIDENCE FEATURES................................................... 6

6.0 COMPONENT SPECIFICATIONS................................................................................................... 7

7.0 GENERAL REQUIREMENTS........................................................................................................... 9

8.0 ANNEXURE 1: DISPLAY SEQUENCE FOR THE PARAMETERS ............................................... 10

Page 2 SEAL & SIGNATURE OF THE BIDDER

1.0 SCOPE

This specification covers the design, manufacture, testing and supply of Three-phase Four-wire Static

LT Whole Current Energy Meters of Accuracy Class 1.0, 20-100 A, 3 x 240 volts for measurement of

energy for power factor range from zero lag-unity-zero lead.

2.0 STANDARDS

IS: 13779, IEC 1036 & CBIP Technical report no.88 and its latest amendment along with BSES

specifications.

The meter shall be ISI marked (vendor shall be BIS certified) and conform to CEA metering regulation.

3.0 TECHNICAL SPECIFICATION

Sr. Parameters Technical Requirements

No.

3.1 Voltage Reference Voltage 240 volt (P-N), +20% to -40% Vref.

However the meter should withstand the maximum system voltage.

3.2 Display a) LCD (Seven digits) b) Height: 10 mm X 5 mm min.

c) Pin Type d) Viewing angle min. 120 degrees

3.3 Display a) Display parameters:

parameters LCD test, date & time, cumulative KWH, cumulative KVAH & RKVAH,

MD in KW & KVA, PF, V, I (All the energies are without decimal.)

b) Display order shall be as per Annexure-1

3.4 Power factor Zero lag –unity- zero lead

range

3.5 Power Less than 1 Watt & 4VA per phase in voltage circuit, 2 VA in current

Consumption circuit

3.6 Starting 0.2 % of Ib

current

3.7 Frequency 50 Hz with (+ or -) 5% variation

3.8 Test Output Flashing LED visible from the front

Device

3.9 Billing data a) Meter serial number, Date and time, KWH, KVAH, RKVAH, MD in

KW and KVA, No. of tamper counts, tamper occurrence with date &

time, tamper restoration date & time with snap shots. History of KWH,

KVAH, RKVAH & MD with occurrence details for last 6 months along

with TOD readings.

Page 3 SEAL & SIGNATURE OF THE BIDDER

Sr. Parameters Technical Requirements

No.

b) All the above parameters (namely KWH, KVAH, RKVAH, MD in KW

and KVA) are meter readings.

c) All these data shall be accessible for reading, recording and spot

billing by downloading through optical port with MRI (both Analogic &

SANDS) or Laptop computers at site.

3.10 MD a) Meter shall store MD in every 15/30 min. period along with date &

Registration time. At the end of every 15/30 min, new MD shall be compared with

previous MD and store whichever is higher and the same shall be

displayed.

3.11 Auto Reset of Auto reset date for MD shall be indicated at the time of finalizing GTP

MD and provision shall be made to change MD reset date through MRI

even after installation of meter on site. Defaut re-setting date is 00:00

Tariff

hrs, Timings

1st of every month.

3.12 TOD metering 1 00:00 to 6:00 Meter shall

2 06:00 to 09:30 be capable

3 09:30 to 12:00 of doing

4 12:00 to 18:00 TOD

5 18:00 to 23:00 metering

6 23:00 to 24:00 for KWH,

KVARH,

KVAH and MD in KW and KVA with 6 time zones (programmable on

site through CMRI). Following are the defaut TODs:-

3.13 Load survey 15/30 min integration period, load profile of KW, RKVA and KVA phase

wise voltage and current, for min. 50 days (with 15/ 30 minutes

integration period).

3.14 Time required Meter data consisting of all parameters and 50 days load survey for all

for data parameters (Refer 3.13) shall be read by CMRI (both Analogic &

reading from SANDS) and downloaded on desktop PC in minimum possible time (not

meter and more then 5 minutes) and it shall be indicated at the time of finalizing

downloading GTP.

on desktop PC

3.15 Diagnostic Self diagnostic for time, calendar, RTC battery all display segments and

feature NVM.

3.16 Security Programmable facility to restrict the access to the information recorded

feature at different security level such as read communication, communication

write etc

3.17 Software & a) Optical port with RS 232 compatible to transfer the data locally

communicatio through CMRI & remote through PSTN / Optical fiber / GSM / CDMA /

n compatibility RF / any other technology to the main computer.

Page 4 SEAL & SIGNATURE OF THE BIDDER

Sr. Parameters Technical Requirements

No.

b) The Supplier shall supply Software required for CMRI (both for

Analogic & SANDS make )& for the connectivity to AMR modules. The

supplier shall also provide training for the use of software. The software

should be compatible to Microsoft Windows systems menu. The

software should have polling feature with optional selection of

parameters to be downloaded for AMR application.

c) The data transfer (from meter to CMRI / AMR equipment) rate should

be minimum 1200 bps.

d) The Supplier shall provide meter reading protocols. Vendor to jointly

work with BSES IT team to develop CMRI software for meter

downloading and further uploading on computer. The vendor has to

give an undertaking in this regards.

e) Communication protocols will be either of following two types.

• Same as previous supplied meter to BSES, minimum for 10000

Nos OR

• As per IEC 62056/ DLMS protocol. Other protocols shall not be

acceptable.

3.18 Memory Non volatile memory independent of battery backup, memory should be

retained up-to 10 year in case of power failure

3.19 Climatic a) The meter should function satisfactorily in India with temperature

conditions ranging from 0 - 60ºC and humidity upto 96%.

b) Also refer IS: 13779 for climatic conditions.

3.20 Calibration Modification in calibration shall not be possible at site by any means.

3.21 Battery In case battery removal or total discharge same should not effect the working

& memory of the meter.

3.22 KVAh KVAh is computed based on KVArh and KWH value. If PF=1, or leading, then

defination KVAh = KWH. At no instance KVAh < KWh

4.0 CONSTRUCTIONAL FEATURES

Sr. Parameters Technical Requirements

No.

4.1 Body of Meter a) Top transparent and base opaque material polycarbonate of LEXAN

143A/943AA or equivalent grade having properties of V0 inflammability

level and UV stabilized.

b) Front cover & base should be ultrasonically welded and should be

provided with the brass sealing screws.

4.2 Terminal Block Made of polycarbonate of grade 500 R or equivalent grade and shall

form Integral part of the meter base, brass or copper current terminals

with flat-head brass screws.

4.3 Terminal cover Transparent terminal cover with provision of sealing through sealing

screw.

4.4 Diagram of Diagram of external connections to be shown on terminal cover

connections

Page 5 SEAL & SIGNATURE OF THE BIDDER

Sr. Parameters Technical Requirements

No.

4.5 Marking on Meter should have clearly visible, indelible and distinctly name plate

name plates marked in accordance with IS & Reliance Energy Ltd specifications.

4.6 Meter Sealing As per IS 13779 and CEA Metering Regulation 2006, Supplier will fix its

seal on meter. In addition, supplier shall affix Buyer seal(s) on side of

Meter body as advised by buyer and record should be forwarded to

Buyer.

4.7 Guarantee / 5 Years.

Warranty

4.8 Insulation A meter shall withstand an insulation test of 4 KV and impulse test at 8

KV

4.9 Resistance of The terminal block and Meter case shall have safety against the spread

heat and fire of fire. They shall not be ignited by thermal overload of live parts in

contact with them as per the relevant IS 13779.

5.0 TAMPER & ANTI-FRAUD DETECTION/EVIDENCE FEATURES

The meter shall log minimum 200 tamper events (ensuring atleast 20 events for each tamper)

compartment wise division of each event and their persistence time shall be indicated in GTP.

The Meter shall not be affected by any remote control device & extra high voltage/ field, shall continue

recording energy under any one or combinations of the following conditions:

5.1 Phase sequence reversal: The meters shall work accurately irrespective of the phase sequence

of the supply.

5.2 Detection of missing potential: In case someone intentionally takes out a potential lead, the

date and time of such occurrence shall be recorded by the Meter. The restoration of normal

supply shall also be similarly recorded. The threshold for the voltages should be

programmable.

5.3 Reversal of C.C. (Current Coil) Polarity: Meter shall record the reversal of C.C. polarity with time

and date, and also the time of restoration. Meter shall however register the energy consumed

correctly with any one, two or all three phase c.c. reversal.

5.4 C.C. Shorting: Meter shall record C.C. Terminal shorting with time and date and time of

restoration. The threshold of the current should be programmable.

5.5 Power On / Off: Meter shall detect power OFF (minimum power off period 5 minutes) if all of

phase voltages are not present. This event shall be recorded at the time of each power OFF.

At the same time power ‘ ON ‘ event shall be recorded. This logging shall be available in

Tamper details along with cumulative time of failure.

5.6 Recording of Neutral disturbance: - Meter shall log all events when AC/DC/ Pulsating voltage is

injected in neutral circuit escpially when same can disturb the recording of energy.

Page 6 SEAL & SIGNATURE OF THE BIDDER

5.7 Snap-on parameters: Meter shall log all three phase voltage, current, power factor etc. at the

time of tamper attempt for all such occurrence.

5.8 External Magnetic tampers: Meter should log on the events of attempt of tampering by external

magnetic field as mentioned in the relevent IS.

The Meter shall record as per actual load once the external abnormal magnetic field is

removed. In such conditions the Meter shall log the event for presence of abnormal external

magnetic field and its restoration.

5.9 Protection against HV spark/ ESD: Meter shall continue to record energy or log the event, incase

it is disturbed externally using a spark gun/ ignition coil. Upto 35 KV meter should be

immuned.

5.10 Influence Quantities: The Meter shall work satisfactorily with guaranteed accuracy limit

under the presence of the following influence quantities as per IS 13779, IEC-1036, and CBIP

Technical Report No.88 with latest amendment.

The influence quantities are:

a) External Magnetic field – 0.2 tesla ( with log on feature)

b) Electromagnetic field induction,

c) Radio frequency interference,

d) Unbalanced load,

e) Vibration etc,

f) Wave form 10% of 3rd harmonics,

g) Phase sequence,

h) Voltage unbalance,

i) Electro Magnetic H.F. Field, and

j) D.C. Immunity test.

5.11 Manufacturing Detail in memory :- Meter shall have manufacturing month and year in the

memory and should come in data downloading.

5.12 Neutral current measurement :– Meter shall have feature of Neutral current measurement

and display along with phase currents.

5.13 Low voltage event :- Meter shall have feature to log an event in case any of phase voltage is

<180 voltage.

5.14 2Phase connection :- Meter shall have feature to log an event in case only two phase are

connected i.e. remaining one phase & Neutral are absent.

5.15 Top cover open: The meter shall have top cover opening detection mechanism. The top

cover opening event shall be indicated display continuously in auto scroll mode with kWh or

through additional LED and shall be logged in memory. The detection and logging mechanism

shall work even when meter is not energized. In case of indication of display, meter display

shall get reset in 150 days.

• Additional feature other than mentioned above will be preferred.

6.0 COMPONENT SPECIFICATIONS

Page 7 SEAL & SIGNATURE OF THE BIDDER

Sl. Component Requirement Makes and Origin

No Function

6.1 Current The Meters should be with the The current transformer

Transformers current transformers as should withstand for the

measuring elements. clauses under 5.9.j

The current transformer should

withstand for the clauses under

5.9.j

6.2 Measurement or The Measurement or USA: Anolog Devices,

computing chips computing chips used in the Cyrus Logic, Atmel,

Meter should be with the Phillips, Texas

Surface mount type along with Instruments.

the ASICs. South Africa: SAMES

Japan: NEC

6.3 Memory chips The memory chips should not USA: Atmel, National

be affected by the external Semiconductors, Texas

parameters like sparking, high Instruments, Phillips,

voltage spikes or electrostatic ST,Microchip

discharges. Japan: Hitachi or Oki

6.4 Display modules a) The display modules should Truly semiconductor,

be well protected from the Tianma/ Haijing

external UV radiations. Electronics, China

b) The display visibility should

be sufficient to read the Meter

mounted at height of 0.5 meter

as well as at the height of 2

meters (refer 3.2.d for Viewing

angle).

c) The construction of the

modules should be such that

the displayed quantity should

not disturbed with the life of

display (PIN Type).

d) It should be trans-reflective

HTN or STN type industrial

grade with extended

temperature range minimum 70

ºC.

6.5 Optical port Optical port should be used to Everlight, Osram, Agillent,

transfer the meter data to NFC

meter reading instrument.

The mechanical construction of

the port should be such to

facilitate the data transfer

easily.

6.6 Power Supply The power supply should be SMPS Type

with the capabilities as per the

relevant standards. The power (It should take care of

Page 8 SEAL & SIGNATURE OF THE BIDDER

Sl. Component Requirement Makes and Origin

No Function

supply unit of the meter should clause 3.1 and 3.5)

not be affected in case the

maximum voltage of the

system appears to the

terminals due to faults or due to

wrong connections.

6.7 Electronic The active & passive USA: National

components components should be of the Semiconductors, Atmel,

surface mount type & are to be Phillips, Texas

handled & soldered by the Instruments,ST,Onsemi

state of art assembly Japan: Hitachi, Oki,

processes. The PTH AVX or Ricoh

components should be Korea: Samsung

positioned such a way that the EPCOS,Vishay

leads of components should

not be under stress and not

touching the internal wires.

LED Everlight, Agillent

6.8 Mechanical parts a) The internal electrical

components should be of

electrolytic copper & should be

protected from corrosion, rust

etc.

b) The other mechanical

components should be

protected from rust, corrosion

etc. by suitable plating/painting

methods.

6.9 Battery Lithium with guaranteed life of Texcell, SAFT, Varta

10 years

6.10 RTC & Micro The accuracy of RTC shall be USA: Philips, Dallas

controller as per relevant IEC / IS Atmel, Motorola,

standards Microchip

Japan: NEC or Oki

6.11 P.C.B. Glass Epoxy, fire resistance

grade FR4, with minimum

thickness 1.6 mm

Note:1) The components used by manufacturer shall have “Minimum Life” more than the 10 years.

2) Incase vendor want to use other make components; same shall be approved by BSES before use.

Deviation of component make is not allowed without prior approval.

3) Even for existing/ par suppliers – frest approval is needed for all deviations.

7.0 GENERAL REQUIREMENTS

7.1 On the meter name-plate:

a) meter serial number should be of 8 digits

b) size of the digit of the meter serial number should be minimum 5mm X 3mm.

c) bar code should be printed next to / below / above the meter serial number

Page 9 SEAL & SIGNATURE OF THE BIDDER

d) BIS registration mark ( ISI mark)

7.2 Meter Sr. Nos. to be printed in black on the name plate, instead of embossing.

7.3 Buyer’s Serial Number sticker should be fixed on window glass from inside or on Meter front cover of

minimum digit size 6 mm X 3 mm.

7.4 The supplier should seal meters on both sides. The Buyer shall approve the method of sealing.

7.5 The internal potential links should be in closed position or link less Meters will be preferred and there shall

not be any external link.

7.6 The internal potential links should be in closed position or link less Meters will be preferred. There shall

not be any external link.

7.7 Delivarable with Meters.

1. Individual meter accuracy test report.

2. Terminal cover

3. Consolidated report of routine test report & seal & initial reading record. (soft copy as per BRPL

format)

7.8 Box number, Meter serial number, type, rating should be mentioned on cases / cartons.

7.9 Meters shall be suitably packed with environmental friendly material in order to avoid damage or

disturbance during transit or handling and to prevent in grace of moisture and dust. Also refer CEA

Metering Regulation 2006.

7.10 In case battery removal/ total discharge same should not effect the working & memory of the meter .

8.0 ANNEXURE 1: DISPLAY SEQUENCE FOR THE PARAMETERS

1. 8.1 Default Display:

Display Parameters:

Default Display (Auto Mode)

1. Lamp test

2. Real time

3. Date

4. Cumulative kWh

5. Cumulative kvarh Lag

6. Cumulative kvarh lead

7. Cumulative kVah

8. Current Max. demand in kW & Kva

9. Inst. Avg. Power Factor (3 phase)

10. Inst. Voltage R,Y,B (Phase- Neutral)

11. Inst. Line current R,Y, B

12. Neutral Current.

Page 10 SEAL & SIGNATURE OF THE BIDDER

8.2 On-demand Display:

After using pushbutton the following parameters should be displayed.

1. LCD test

2. Date

3. Real Time

4. Cumulative RKVAH

5. Cumulative KVAH

6. Current MD in KW

7. Current MD in KVA

8. Instantaneous Power factor

9. Instantaneous voltage R phase

10. Instantaneous voltage Y phase

11. Instantaneous voltage B phase

12. Instantaneous current R phase

13. Instantaneous current Y phase

14. Instantaneous current B phase

15. Last month billing Date

16. Last month billing KWH reading

17. Last month billing RKVAH reading

18. Last month billing KVAH reading

19. Last month billing Maximum Demand in KW

20. Last month billing Maximum Demand in KW occurrence Date

21. Last month billing Maximum Demand in KW occurrence Time

22. Last month billing Maximum Demand in KVA

23. Last month billing Maximum Demand in KVA occurrence Date

24. Last month billing Maximum Demand in KVA occurrence Time

25. Neutral Current.

Note: The meter display should return to Default Display mode (mentioned above) if the ‘push button’ is not

operated for more than 6 seconds.

Page 11 SEAL & SIGNATURE OF THE BIDDER

Page 12 SEAL & SIGNATURE OF THE BIDDER

You might also like

- Position Sensing: Angle and Distance Measurement for EngineersFrom EverandPosition Sensing: Angle and Distance Measurement for EngineersNo ratings yet

- KWH MeterDocument17 pagesKWH MeterSURJIT SINGHNo ratings yet

- Sem Hand BookDocument118 pagesSem Hand BookrajuwithualwaysNo ratings yet

- Group Metering System: Technical SpecificationsDocument10 pagesGroup Metering System: Technical SpecificationsAmit Kumar SinghNo ratings yet

- Metering Manual: North Easrtern Regional Load Despatch CentreDocument96 pagesMetering Manual: North Easrtern Regional Load Despatch Centreamankhurana1602No ratings yet

- 38tmss06r0-Dynamic System MonitorDocument11 pages38tmss06r0-Dynamic System MonitorshabeerNo ratings yet

- Manual Electric MotorDocument17 pagesManual Electric Motorm,.100% (1)

- Abt ManualDocument39 pagesAbt ManualAbhinav Tewari100% (1)

- Metering Manual - PgcilDocument93 pagesMetering Manual - PgcilKrishna Venkataraman100% (1)

- Sem Hand Book PDFDocument118 pagesSem Hand Book PDFAnonymous wl7fgzivPNo ratings yet

- Alcatel BSS - B9 Telecom Parameters Dictionary (209240000e04)Document936 pagesAlcatel BSS - B9 Telecom Parameters Dictionary (209240000e04)dmkhalid451No ratings yet

- E6000 InstructionManual v27Document42 pagesE6000 InstructionManual v27rommel76No ratings yet

- Cole Parmer 08212Document6 pagesCole Parmer 08212Lincolyn MoyoNo ratings yet

- CMRIDocument6 pagesCMRIatnu_chowdhuryNo ratings yet

- WCDMA / HSDPA Signalling Mode: R&S CMU300 Radio Communication Tester For 2G/3G Base StationsDocument17 pagesWCDMA / HSDPA Signalling Mode: R&S CMU300 Radio Communication Tester For 2G/3G Base StationsRahul KumarNo ratings yet

- AmrDocument18 pagesAmrJHON MILLANo ratings yet

- Anritsu CMA3000 Field Tester Data SheetDocument8 pagesAnritsu CMA3000 Field Tester Data SheetJuan Mendez100% (1)

- Al-Bader 13213.8KV SubstationDocument18 pagesAl-Bader 13213.8KV SubstationfarhanyazdaniNo ratings yet

- Haryana Vidyut Prasaran Nigam LimitedDocument6 pagesHaryana Vidyut Prasaran Nigam LimitedasdfghjklNo ratings yet

- Parameter DictDocument192 pagesParameter DictPuneet YadavNo ratings yet

- Charge Intergraion - Analog Vs DigitalDocument8 pagesCharge Intergraion - Analog Vs DigitalKen BuiNo ratings yet

- CSC IiDocument30 pagesCSC Iiramakrishnan.tlmrvtc.eleNo ratings yet

- Trans-Cal Industries, IncDocument23 pagesTrans-Cal Industries, IncjackcastelNo ratings yet

- 00698atDocument37 pages00698atYazan Sosnak MahmoudNo ratings yet

- E7000 - Instruction Manual - v10Document38 pagesE7000 - Instruction Manual - v10edcooNo ratings yet

- M A C R F D TV (DTV) A O S: Odulation ND Oding Equirements OR Igital Pplications VER AtelliteDocument33 pagesM A C R F D TV (DTV) A O S: Odulation ND Oding Equirements OR Igital Pplications VER AtelliteTanzim TajNo ratings yet

- HP 37722A Telecom Analyzer HP 37732A Telecom/datacom AnalyzerDocument8 pagesHP 37722A Telecom Analyzer HP 37732A Telecom/datacom Analyzermisael392No ratings yet

- Technical Specification: of A.C. Single Phase, Whole Current, Static, 240volt, 10-60amps, Class 1.0Document17 pagesTechnical Specification: of A.C. Single Phase, Whole Current, Static, 240volt, 10-60amps, Class 1.0prajith555No ratings yet

- HS Systems Table of ContentsDocument8 pagesHS Systems Table of ContentsGrimmjow JaegerjaquezNo ratings yet

- Calibration and Testing of Phasor Measurement UnitDocument13 pagesCalibration and Testing of Phasor Measurement UnitSalvador ArcosNo ratings yet

- Seatel 09Document41 pagesSeatel 09Organis AlelxisNo ratings yet

- 3) +DGA Pre-Read TelemetryDocument22 pages3) +DGA Pre-Read TelemetryyuriiNo ratings yet

- Jitter-Wander Measurements GuideDocument30 pagesJitter-Wander Measurements GuidegercruNo ratings yet

- Tech Specs of ABT Meter 25 11 20111Document50 pagesTech Specs of ABT Meter 25 11 20111Ramdas TaloleNo ratings yet

- 7SR242 - Duobias Technical Manual Chapter 07 Applications GuideDocument56 pages7SR242 - Duobias Technical Manual Chapter 07 Applications GuideVishwanath TodurkarNo ratings yet

- Measuring EDGE SignalsDocument3 pagesMeasuring EDGE SignalsKien TranNo ratings yet

- Wandel Goltermann DLA-9D PDFDocument6 pagesWandel Goltermann DLA-9D PDFTorrevadoNo ratings yet

- Grid Meter For Power ExchangeDocument4 pagesGrid Meter For Power ExchangeRichard SyNo ratings yet

- Manual TelemobileDocument36 pagesManual TelemobileEmerson Pedroso de MoraesNo ratings yet

- BSC6900 - T200 and N200Document5 pagesBSC6900 - T200 and N200Debraj DasNo ratings yet

- Measuring The Picosecond Rise Time PF GaN DeviceDocument4 pagesMeasuring The Picosecond Rise Time PF GaN Devicebinayaks248No ratings yet

- GTP - Prometer 100Document2 pagesGTP - Prometer 100MASUD RANANo ratings yet

- Release Notes: NivergeDocument17 pagesRelease Notes: NivergeUdayanga Sanjeewa WickramasingheNo ratings yet

- 2423 SpecDocument50 pages2423 SpecAssistant EngineerNo ratings yet

- Submission of Vendor Proposal For AWSDocument5 pagesSubmission of Vendor Proposal For AWSSakshi SemwalNo ratings yet

- Agilent Technologies - RFDocument64 pagesAgilent Technologies - RFeloyx3xNo ratings yet

- Digital Instruments and Measuring TransducersDocument36 pagesDigital Instruments and Measuring TransducersAnas BasarahNo ratings yet

- GSM BSC6000 Performance StatisticsDocument72 pagesGSM BSC6000 Performance StatisticsAli AlshwalNo ratings yet

- GQ GCM-300EPlus ManualDocument19 pagesGQ GCM-300EPlus ManualHugo WilkinsonNo ratings yet

- Construction Installation & Management PlanDocument47 pagesConstruction Installation & Management PlanSaurabh DwivediNo ratings yet

- Practical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsFrom EverandPractical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsRating: 5 out of 5 stars5/5 (6)

- Advanced Multicarrier Technologies for Future Radio Communication: 5G and BeyondFrom EverandAdvanced Multicarrier Technologies for Future Radio Communication: 5G and BeyondNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Video and Multimedia Transmissions over Cellular Networks: Analysis, Modelling and Optimization in Live 3G Mobile CommunicationsFrom EverandVideo and Multimedia Transmissions over Cellular Networks: Analysis, Modelling and Optimization in Live 3G Mobile CommunicationsNo ratings yet

- Engineering ThermodynamicsDocument24 pagesEngineering Thermodynamicsapi-26570979100% (2)

- Analysis of Vertical Axis Wind Turbine: Mini Project Work Report Submitted ToDocument47 pagesAnalysis of Vertical Axis Wind Turbine: Mini Project Work Report Submitted ToSanketNo ratings yet

- Sample Test Using Auto-ChekerDocument3 pagesSample Test Using Auto-ChekerJhon Aliangan MayuyoNo ratings yet

- 0625 w15 Ms 33Document7 pages0625 w15 Ms 33Hany ElGezawyNo ratings yet

- Physics HL Answers Chris Hamper Second Edition Pearson 2014pdfDocument52 pagesPhysics HL Answers Chris Hamper Second Edition Pearson 2014pdfDeepika DevarajNo ratings yet

- Lab Report: Rocket Experiment 2017Document20 pagesLab Report: Rocket Experiment 2017api-343596257No ratings yet

- 08 EPG Climate ControlDocument58 pages08 EPG Climate ControlRobNo ratings yet

- ACS 2000 ServiceMan 3BHS344169 E01 RevDocument78 pagesACS 2000 ServiceMan 3BHS344169 E01 Revadrianahouki100% (2)

- Bliss Anand America - Magnetic Level Gauges - NewDocument25 pagesBliss Anand America - Magnetic Level Gauges - NewNikhil WadhwaNo ratings yet

- ASTM F2412 FootwearDocument15 pagesASTM F2412 FootwearmonizrNo ratings yet

- Wall Mounted: Split Type Room Air Conditioner TypeDocument18 pagesWall Mounted: Split Type Room Air Conditioner TypeDavid Lemos Sanchez100% (1)

- TestDocument361 pagesTestJake Sy100% (1)

- ABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHADocument5 pagesABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHAjavedsmg1No ratings yet

- Chapter 5 Protection Coordination-Objectives and Methodology PDFDocument13 pagesChapter 5 Protection Coordination-Objectives and Methodology PDFRyan Anthony UmaliNo ratings yet

- Thermal ExpansionDocument5 pagesThermal ExpansionParis ParyNo ratings yet

- Turbo, Cad, Auto QPDocument25 pagesTurbo, Cad, Auto QPvarshitha srinivasNo ratings yet

- Power System Protection Power System Stability: Substation Automation ProductsDocument15 pagesPower System Protection Power System Stability: Substation Automation ProductsRobert Mihayo100% (1)

- Motor Thermal Capacity Used - How Does The Relay Know PDFDocument14 pagesMotor Thermal Capacity Used - How Does The Relay Know PDFdusktodawnNo ratings yet

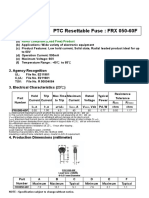

- Radial Leaded 3PTC Resettable Fuse: FRX 050-60F: 1. SummaryDocument7 pagesRadial Leaded 3PTC Resettable Fuse: FRX 050-60F: 1. SummaryАнатолий ДонецкNo ratings yet

- How To Size A ThickenerDocument5 pagesHow To Size A ThickenerRodrigo GarcíaNo ratings yet

- SENTRON Residual Current Protective Devices AFDDs Complete English 10 2014 201502111453105536Document50 pagesSENTRON Residual Current Protective Devices AFDDs Complete English 10 2014 201502111453105536Alvaro Coy H.No ratings yet

- Battery LeadAcidDesulfator DirectDrive Type3Document6 pagesBattery LeadAcidDesulfator DirectDrive Type3kokiskoNo ratings yet

- Calculation SpreadsheetDocument48 pagesCalculation SpreadsheetDimitrios MilionisNo ratings yet

- Module 4 Work Energy PowerDocument7 pagesModule 4 Work Energy PowerGreen BrainNo ratings yet

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- Power Chain Tool - v2.1Document75 pagesPower Chain Tool - v2.1ErdincNo ratings yet

- Appendix - Properties of FluidDocument5 pagesAppendix - Properties of FluidM Syafiq SamadNo ratings yet

- Abb RVPDocument4 pagesAbb RVPanandeieNo ratings yet

- Growatt Min 5000tlxDocument2 pagesGrowatt Min 5000tlxMatheus FariasNo ratings yet

- Technical Manual - UP Range - 03Document51 pagesTechnical Manual - UP Range - 03Emad Othman0% (1)