Professional Documents

Culture Documents

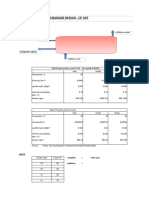

Software: Curtiss-Wright Flow Control Service Corp

Uploaded by

Raul tejadaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Software: Curtiss-Wright Flow Control Service Corp

Uploaded by

Raul tejadaCopyright:

Available Formats

Software

Control and Analysis Software for Bohlin Rheometers the lifecycle of a facility. It fulfills all OSHA CFR 29 1910.119

Designed for Malvern Bohlin documentation requirements, and integrates and stores MOC,

rheometers, version 6.40 of this PHA, maintenance and equipment records. IPRSM provides

control and analysis software instantaneous access to real-time, reliable data from any loca-

incorporates new features, tion, and is capable of evaluating any pressure relief device

including more-flexible data (e.g., valves, rupture disks, emergency vents, etc.). The soft-

analysis setup and automation, ware also includes hydraulic piping calculations, and engineer-

and a completely new test type. ing and catalog data for all major PRV manufacturers.

The new multi-wave test mode Featuring platform-independent import/export capabilities,

involves the application of multi- IPRSM utilizes a comprehensive thermo-physical property

ple frequencies for faster testing package and integrates with most other databases.

and is useful for studying rapidly Curtiss-Wright Flow Control Service Corp.

changing systems, such as ther- www.cwfc.com

mosetting resins or the gelation

of foodstuffs. Featuring a new MODES Software for Predicting Elastomer Seal Damage

template wizard, set-up and storage of analysis routines is Developed as a cost-effective alternative to physical testing for

easy, and operators can add multiple analyses to the menus for the prediction of explosive decompression (ED) in elastomer

easy re-use. Fewer than five mouse clicks are needed to per- systems, the MODES computer program is over 88% accurate

form an analysis. Improved model-fitting facilities allow at predicting the onset of ED damage in seals. It enables engi-

automation of fitting and result reporting on test completion, a neers to assess an extensive range of what-if scenarios and

function that can be enhanced by automated determination of design components and operating procedures to avoid failure.

the best fit from a user-defined list of rheological models. An The software, a result of BHR Group’s MODES project, is

advanced simplex algorithm is used to optimize convergence available to sponsoring organizations and contains extensive

to the best model fit to the data. A complete implementation data on the selected materials. It permits users to calculate safe

of Time Temperature Superposition (TTS) analysis is avail- minimum decompression times and the number of subcritical

able for application to any selected variable. Calculation of “ emergency” decompressions the seal can survive without

WLF and Arrhenius constants is included in the TTS analysis damage, as well as seal performance under user-specified con-

package, as is calculation of extrapolated viscoelastic proper- ditions. This allows engineers to optimize seal and housing

ties at any frequency and temperature. design, perform sensitivity studies and risk analyses based on

Malvern Instruments material variability and material type, and assess the effect of

www.malvern.co.uk different fluids, pressures and temperatures.

BHR Group Ltd.

Combustion Expert 3.2 Energy-Saving Software www.bhrsolutions.com/manufac/modes.htm

One of the key benefits of Combustion Expert 3.2 is its abil-

ity to perform technical and economic evaluations when con- FATE 2.0 for Design, Off-Normal and Accident Analysis

verting from oil- to natural-gas-fired furnaces or vice versa. Modeling at Nuclear and Chemical Facilities

These changes affect the flame temperature, air/fuel ratio, gas FATE 2.0 (Facility Flow, Aerosol, Thermal and Explosion

emissivity and the radiative heat transfer in the furnace. At Model) software is designed to replace computer codes current-

higher temperatures, the heat transfer is almost always driven ly used for design and safety analyses for U.S. Dept. of Energy

by radiation. These calculations are very cumbersome and projects at the Hanford site and elsewhere. These include codes

difficult to make. However, with this software, these calcula- such as HADCRT for tank farms and waste treatment plants

tions can be done with a click of a mouse in a few seconds. and WESF, PFP, HANSF MCO and HANSF for spent nuclear

The key to saving fuel is not only keeping records of what fuel, sludge and the site’s “T plant” chemical separation facility.

was paid/used for energy, which vary with production, ener- New features include the flammability and combustion of gas-

gy costs, operating hours and operating conditions, but also es, vapors and aerosols model, and entrainment of deposits to

knowing the current efficiency of the system. form aerosols modeling. Other models include thermal radia-

Combustion Software Inc tion networks, event-oriented simulation and a limited distribu-

www.combustionsoftware.com tion fire model. General capabilities include multiple-compart-

ment thermodynamics and general species analysis, facility

IPRSM for Pressure Relief System Management nodalization and flow, aerosol behavior, heat transfer determi-

IPRSM, a web-enabled software for intelligent pressure-relief- nation, sources and time-dependent conditions, and nuclear fuel

system management. has proven to be the cost-effective way to and sludge models including chemical reactions.

manage documentation for pressure-relief systems and assure Fauske & Associates, Inc.

compliance with regulatory codes and company standards over www.fauske.com

24 www.cepmagazine.org April 2005 CEP

You might also like

- MasteringPhysics ME12001 Thermodynamics Homework T5Document23 pagesMasteringPhysics ME12001 Thermodynamics Homework T5gdfeiu dionwdn75% (4)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Technical Manual - Modular SCREW ChillerDocument118 pagesTechnical Manual - Modular SCREW ChillerCesar Orlando Barria Vera100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Pro II Input ManualDocument69 pagesPro II Input ManualNareshNo ratings yet

- Mining SoftwareDocument12 pagesMining SoftwaresunilsinghmNo ratings yet

- OTC-29054-MS Qualification of New Technologies in Subsea Processing 2018Document12 pagesOTC-29054-MS Qualification of New Technologies in Subsea Processing 2018HunterNo ratings yet

- Design for Testability, Debug and Reliability: Next Generation Measures Using Formal TechniquesFrom EverandDesign for Testability, Debug and Reliability: Next Generation Measures Using Formal TechniquesNo ratings yet

- Temperature and Heat 02Document7 pagesTemperature and Heat 02Astrid AshNo ratings yet

- Chapter 07 PDFDocument268 pagesChapter 07 PDFIgor0% (1)

- Automated simulation and JHA softwareDocument1 pageAutomated simulation and JHA softwareRaul TejedaNo ratings yet

- Process Safety Related SoftwareDocument9 pagesProcess Safety Related Software3114568No ratings yet

- An Expert System For RCM in The Chemical IndustryDocument13 pagesAn Expert System For RCM in The Chemical IndustryMuhammad Rusydi AlwiNo ratings yet

- Emergency Pressure Relief Vent Sizing For Runaway ReactionsDocument2 pagesEmergency Pressure Relief Vent Sizing For Runaway ReactionsJoel OngNo ratings yet

- Best Practices in Overpressure ProtectionDocument10 pagesBest Practices in Overpressure Protectionrvkumar61No ratings yet

- FEMFAT Flyer e WebDocument8 pagesFEMFAT Flyer e Webfkaram1965No ratings yet

- Wo Whts NW in Articial LFT PDocument2 pagesWo Whts NW in Articial LFT PPedro Paulo CordeiroNo ratings yet

- An Intelligent System For Monitoring Useful Life Transformer ReductionDocument6 pagesAn Intelligent System For Monitoring Useful Life Transformer ReductionItalo ChiarellaNo ratings yet

- iPRSM Brochure 0611Document6 pagesiPRSM Brochure 0611Hardy HendraNo ratings yet

- CHEMCAD Guide for Chemical EngineersDocument13 pagesCHEMCAD Guide for Chemical EngineersVishal ThakareNo ratings yet

- Refrigerant Inventory TechNoteDocument36 pagesRefrigerant Inventory TechNotedhavaleshNo ratings yet

- Uses of ComputersDocument11 pagesUses of ComputersImtisal E NoorNo ratings yet

- Safety-Critical Systems in Rail TransportationDocument5 pagesSafety-Critical Systems in Rail TransportationRăzvan PopaNo ratings yet

- Refrigerant Inventory TechNoteDocument36 pagesRefrigerant Inventory TechNoteYutt WattNo ratings yet

- Sciencedirect: Context Driven Remaining Useful Life EstimationDocument5 pagesSciencedirect: Context Driven Remaining Useful Life EstimationBlan JoesNo ratings yet

- Automation and Data Technology Showcase: Abstract (English)Document7 pagesAutomation and Data Technology Showcase: Abstract (English)Raam WilliamsNo ratings yet

- The Calculation Sheet That Summarizes All: Psvplus - Relieving The Pressure of PSV DesignDocument5 pagesThe Calculation Sheet That Summarizes All: Psvplus - Relieving The Pressure of PSV DesignNakkolopNo ratings yet

- Contol Ebook PDFDocument71 pagesContol Ebook PDFbab_ooNo ratings yet

- Corrosion and Scaling in Industrial BoilersDocument8 pagesCorrosion and Scaling in Industrial BoilersVIBHAVNo ratings yet

- Industrial SafetyDocument7 pagesIndustrial SafetymuneebNo ratings yet

- Aspen Modelos AliviosDocument10 pagesAspen Modelos AliviossalcedopozasNo ratings yet

- HIL Testing MPDDocument4 pagesHIL Testing MPDMichael ChandraNo ratings yet

- Alspa Boiler Care Amodis HRSGDocument2 pagesAlspa Boiler Care Amodis HRSGArya AryanNo ratings yet

- Spe 210281 MsDocument23 pagesSpe 210281 MsJesus D. Arrieta GarridoNo ratings yet

- Process Perils: Protect Plants FromDocument32 pagesProcess Perils: Protect Plants FromEliécer DoriaNo ratings yet

- Relief and Blowdown System FlaringDocument5 pagesRelief and Blowdown System FlaringRicardo NapitupuluNo ratings yet

- Real Time Corrosion Prediction in The Refining Industry - Impact On Asset Integrity and Corrosion ManagementDocument14 pagesReal Time Corrosion Prediction in The Refining Industry - Impact On Asset Integrity and Corrosion ManagementHieu Phan TrongNo ratings yet

- Design of SCADA Failsafe Industrial Valves For Hazardous Chemicals From Chemical Kinetics PerspectiveDocument4 pagesDesign of SCADA Failsafe Industrial Valves For Hazardous Chemicals From Chemical Kinetics PerspectiveEditor IJTSRDNo ratings yet

- PSVPlus V7 Fact SheetDocument4 pagesPSVPlus V7 Fact SheetGhasem BashiriNo ratings yet

- Summa : of or orDocument3 pagesSumma : of or orSantiago BNo ratings yet

- Sciencedirect: Dynamic Operator Training Simulators For Sulphuric Acid, Phosphoric Acid, and Dap Production UnitsDocument10 pagesSciencedirect: Dynamic Operator Training Simulators For Sulphuric Acid, Phosphoric Acid, and Dap Production Unitsمحمد عليNo ratings yet

- Introduction To Software ModulesDocument3 pagesIntroduction To Software ModulesArif SamoNo ratings yet

- ScadaDocument13 pagesScadamdayyub40% (5)

- Refrigeration System Exhazop: Leon Breun, Mike SawyerDocument6 pagesRefrigeration System Exhazop: Leon Breun, Mike SawyerRASHEED YUSUFNo ratings yet

- TRACE Mass, Momentum, Energy Conservation EquationsDocument26 pagesTRACE Mass, Momentum, Energy Conservation EquationspolinaNo ratings yet

- Submersible Pumps DEBS 2015 PaperDocument7 pagesSubmersible Pumps DEBS 2015 PaperAnonymous yjLUF9gDTSNo ratings yet

- Vega InstrumentsDocument32 pagesVega InstrumentsamarnethaNo ratings yet

- Versadac 031658 3Document10 pagesVersadac 031658 3Ravi Kant GuptaNo ratings yet

- PIPESIM Pipeline and Facilities Modeling: Identify and Engineer The Best Pipelines and Facilities DesignDocument2 pagesPIPESIM Pipeline and Facilities Modeling: Identify and Engineer The Best Pipelines and Facilities DesignpertmasterNo ratings yet

- Gasification Process ModelingDocument6 pagesGasification Process ModelingRebeca Santamaria MedelNo ratings yet

- IPTC-17255-MS RasGas Experience With Production Optimisation System, A Success Story PDFDocument11 pagesIPTC-17255-MS RasGas Experience With Production Optimisation System, A Success Story PDFDenis GontarevNo ratings yet

- UltraPIPE ApplicationsDocument4 pagesUltraPIPE ApplicationsAlejandraNo ratings yet

- Optimising Safety Relief and Flare SystemsDocument8 pagesOptimising Safety Relief and Flare SystemsJoseph McMullenNo ratings yet

- Proces At020 - en PDocument34 pagesProces At020 - en PAhmed KhairiNo ratings yet

- Simulation: Software Used For Chemical Design and SimulationDocument3 pagesSimulation: Software Used For Chemical Design and SimulationMubasher RajputNo ratings yet

- Gea S1214Document3 pagesGea S1214Noé ChungaNo ratings yet

- Reliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisFrom EverandReliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisNo ratings yet

- Modeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideFrom EverandModeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- PowerFactory Applications for Power System AnalysisFrom EverandPowerFactory Applications for Power System AnalysisFrancisco M. Gonzalez-LongattNo ratings yet

- Reliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationFrom EverandReliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationNo ratings yet

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Model Driven Development for Embedded Software: Application to Communications for Drone SwarmFrom EverandModel Driven Development for Embedded Software: Application to Communications for Drone SwarmNo ratings yet

- Pipelined Processor Farms: Structured Design for Embedded Parallel SystemsFrom EverandPipelined Processor Farms: Structured Design for Embedded Parallel SystemsNo ratings yet

- 91 FTPDocument1 page91 FTPRaul tejadaNo ratings yet

- Front MatterDocument13 pagesFront MatterRaul tejadaNo ratings yet

- Front MatterDocument13 pagesFront MatterRaul tejadaNo ratings yet

- Functionalization of Indole and Pyrrole Cores Via Michael-Type AdditionsDocument335 pagesFunctionalization of Indole and Pyrrole Cores Via Michael-Type AdditionsRaul tejadaNo ratings yet

- Front MatterDocument11 pagesFront MatterRaul tejadaNo ratings yet

- Front MatterDocument14 pagesFront MatterRaul tejadaNo ratings yet

- 91 FTPDocument1 page91 FTPRaul tejadaNo ratings yet

- 80 FTPDocument10 pages80 FTPRaul tejadaNo ratings yet

- Front MatterDocument13 pagesFront MatterRaul tejadaNo ratings yet

- Synthesis and Antiproliferative Activity of Polysubstituted Tetrahydropyridine and Piperidin-4-One-3-Carboxylate DerivativesDocument9 pagesSynthesis and Antiproliferative Activity of Polysubstituted Tetrahydropyridine and Piperidin-4-One-3-Carboxylate DerivativesRaul tejadaNo ratings yet

- Focus Review: Carbon-Halogen Bond Formation by The Reductive Elimination of PD SpeciesDocument9 pagesFocus Review: Carbon-Halogen Bond Formation by The Reductive Elimination of PD SpeciesRaul tejadaNo ratings yet

- 80 FTPDocument10 pages80 FTPRaul tejadaNo ratings yet

- 26 FTPDocument4 pages26 FTPRaul tejadaNo ratings yet

- Synthesis and Antiproliferative Activity of Polysubstituted Tetrahydropyridine and Piperidin-4-One-3-Carboxylate DerivativesDocument9 pagesSynthesis and Antiproliferative Activity of Polysubstituted Tetrahydropyridine and Piperidin-4-One-3-Carboxylate DerivativesRaul tejadaNo ratings yet

- Communication: Tripyridyltruxenes: Thermally Stable Cathode Buffer Materials For Organic Thin-Film Solar CellsDocument4 pagesCommunication: Tripyridyltruxenes: Thermally Stable Cathode Buffer Materials For Organic Thin-Film Solar CellsRaul tejadaNo ratings yet

- Communication: Enantiomerically Enriched (4 + 3) Cycloadducts From Optically Active Epoxy EnolsilanesDocument4 pagesCommunication: Enantiomerically Enriched (4 + 3) Cycloadducts From Optically Active Epoxy EnolsilanesRaul tejadaNo ratings yet

- Process control equipment updatesDocument1 pageProcess control equipment updatesRaul tejadaNo ratings yet

- Regioselective Cross-Dehydrogenative Coupling of Chromones and Non-Activated ArenesDocument4 pagesRegioselective Cross-Dehydrogenative Coupling of Chromones and Non-Activated ArenesRaul tejadaNo ratings yet

- 38 FTPDocument5 pages38 FTPRaul tejadaNo ratings yet

- Just The: PleaseDocument1 pageJust The: PleaseRaul tejadaNo ratings yet

- Preparation of Arylbutadiyne Derivatives by Silyl Migration Inspired by The Mukaiyama ProtocolDocument4 pagesPreparation of Arylbutadiyne Derivatives by Silyl Migration Inspired by The Mukaiyama ProtocolRaul tejadaNo ratings yet

- Top-Entry Mixer Brochure Highlights QEDPlus LineDocument1 pageTop-Entry Mixer Brochure Highlights QEDPlus LineRaul tejadaNo ratings yet

- Alarm Management PDFDocument6 pagesAlarm Management PDFKalyan varmaNo ratings yet

- Books: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsDocument1 pageBooks: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsRaul tejadaNo ratings yet

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaNo ratings yet

- President Bush Honors AIChE Member and UOP for Scientific AchievementsDocument4 pagesPresident Bush Honors AIChE Member and UOP for Scientific AchievementsRaul tejadaNo ratings yet

- Solve Problems Inventively with TRIZ MethodologyDocument8 pagesSolve Problems Inventively with TRIZ MethodologyRaul tejadaNo ratings yet

- What's: Fluids HandlingDocument3 pagesWhat's: Fluids HandlingRaul tejadaNo ratings yet

- Designing Thermal Afterburners: Ask The ExpertsDocument1 pageDesigning Thermal Afterburners: Ask The ExpertsRaul tejadaNo ratings yet

- "The Premier Print and Online Resource For Che Jobs" "The Premier Print and Online Resource For Che Jobs"Document3 pages"The Premier Print and Online Resource For Che Jobs" "The Premier Print and Online Resource For Che Jobs"Raul tejadaNo ratings yet

- Ronald.E.Hamilton: 626 1/2 W 3rd Street SDocument4 pagesRonald.E.Hamilton: 626 1/2 W 3rd Street Sapi-27778945No ratings yet

- Assgn4 Iitd ThermalDocument3 pagesAssgn4 Iitd Thermalmanish199412No ratings yet

- Notes - RES Module-2 - 18EE653 - 2020-21Document34 pagesNotes - RES Module-2 - 18EE653 - 2020-21shaheed jafarNo ratings yet

- Shah SekulicDocument972 pagesShah SekulicBilge DemirelNo ratings yet

- World Highest Building (Burj Kalifa) Air DisruptionDocument40 pagesWorld Highest Building (Burj Kalifa) Air DisruptionPrabu RajaNo ratings yet

- Piston cylinder problem tutorial basicsDocument1 pagePiston cylinder problem tutorial basicsRishi Raj100% (1)

- en Iso 9346 1996 Mass Transfer PDFDocument13 pagesen Iso 9346 1996 Mass Transfer PDFWojtek GoszczyńskiNo ratings yet

- BASIC THERMODYNAMICS CONCEPTSDocument52 pagesBASIC THERMODYNAMICS CONCEPTSNur AmalinaNo ratings yet

- How To Select A Heat PipeDocument3 pagesHow To Select A Heat PipeAdrian NiżnikowskiNo ratings yet

- Experimental Study On The Thermal Performance of R600a PDFDocument9 pagesExperimental Study On The Thermal Performance of R600a PDFEdy MesinNo ratings yet

- CFD Analysis of Shell-and-Tube Heat Exchanger DesignDocument15 pagesCFD Analysis of Shell-and-Tube Heat Exchanger DesignHari SimhaNo ratings yet

- Energy Efficient Design For Hotels in The Tropical Climate Using ModelicaDocument8 pagesEnergy Efficient Design For Hotels in The Tropical Climate Using ModelicaLasandu WanniarachchiNo ratings yet

- Energy BalanceDocument69 pagesEnergy BalanceHigh HopesNo ratings yet

- The Principles of Heat Transfer and Microporous InsulationDocument26 pagesThe Principles of Heat Transfer and Microporous InsulationAbdul MajidNo ratings yet

- Cylindrical Heat Transfer CalculationsDocument5 pagesCylindrical Heat Transfer CalculationsRenny Eka DhamayantiNo ratings yet

- Drying Process MaterialDocument39 pagesDrying Process Materialsatyam guptaNo ratings yet

- RW Ti Brochure Process Manual enDocument209 pagesRW Ti Brochure Process Manual enrherdmanNo ratings yet

- Experiment 7Document8 pagesExperiment 7Hamza KhanNo ratings yet

- Heat Exchanger Design CalculationsDocument8 pagesHeat Exchanger Design Calculationskikokiko KarimNo ratings yet

- Recommended Practices For Local Postweld Heat TreatmentDocument17 pagesRecommended Practices For Local Postweld Heat TreatmentIlkin hasanovNo ratings yet

- Solid Fuel Boiler Control Standard 2: Version 1.0) Version 1.0) Version 1.0) Version 1.0)Document26 pagesSolid Fuel Boiler Control Standard 2: Version 1.0) Version 1.0) Version 1.0) Version 1.0)Ana Odzaklieska Krste SmileskiNo ratings yet

- International Journal of Thermal Sciences: Catalina V Elez, Jose M. Ortiz de Zarate, Mohamed KhayetDocument8 pagesInternational Journal of Thermal Sciences: Catalina V Elez, Jose M. Ortiz de Zarate, Mohamed KhayetNaman AgarwalNo ratings yet

- Catalogo Maquina CarrierDocument5 pagesCatalogo Maquina CarrierNelsonNo ratings yet

- Teaching Plan HT Jan 2022Document3 pagesTeaching Plan HT Jan 2022Lade VarshithaNo ratings yet

- Computer-Aided Thermofluid Analyses Usin PDFDocument184 pagesComputer-Aided Thermofluid Analyses Usin PDFJuan JerezNo ratings yet

- Smart Hvac SystemsDocument53 pagesSmart Hvac SystemsHammad ShafiqueNo ratings yet