Professional Documents

Culture Documents

X11 Construction Chemical

Uploaded by

aamir kalimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X11 Construction Chemical

Uploaded by

aamir kalimCopyright:

Available Formats

X11 Non-Chloride hardening

accelerator for concrete

PROPERTIES FIELDS OF APPLICATION X11

• Ready to use liquid accelerator • Precast / prestressed concrete production

• Reduce setting time in general and • Concrete pavement repairs

specially under cold weather

• Repairs of the industrial floors

• Leading to early high and ultimate

increased strength • Repairs of concrete slabs and flat

members

• It reduce bleed and segregation while

improves workability • Cold weather concreting

• Does not contain any added chloride ions

• Early de-stripping in cold weather

ensuring that the product does not

contribute to the corrosion of reinforcing

steel

• Reduction of chloride attack

• Reduced segregation

• Faster setting times – accelerated

construction

• During cold climate

• High early strength – early de-shuttering

• Early stiffening – quicker finishing

operations

• Facilitates concreting even below 5°C

SPECIAL SURFACE WATER

ADMIXTURE SHOTCRETE GROUTS

ADMIXTURE IMPROVEMENT PROOFING

CRACK

FLOORING COATING JOINT SEALANT REPAIR TILING

INJECTION

Non-Chloride hardening accelerator for concrete

TECHNICAL DATA

X11 DIRECTION OF USE

TYPE X-11

X11 is a ready-to-use liquid which is dispensed into

Color color less free flowing liquid the concrete together with the mixing water. The

Nitrate content Nil dispersing of admixture shall be more uniform if the

admixture is added to the damp concrete after 50 to

Specific gravity 1.26 @ 25°C

70% of the mixing water has been added. The

PH value >6 addition of X11 to dry aggregate or cement is not

Chloride content to BS5075 :1982 < 0.2% recommended.

3

Consumption with m

COMPATIBILITY:

Concrete 2 - 5 Liter X11, is compatible with most admixtures used in the

production of quality concrete including normal, other

mid-range and high-range water-reducing

admixtures, air entertainers, accelerators, retarders,

extended set control admixtures, corrosion inhibitors,

STANDARDS: and shrinkage reducers. X11 is also compatible with

slag and Pozzolans such as fly ash and silica fume.

ASTM C-494 Type C

EN 934-2: T6 & T7 CAUTION:

IS 9103: 1999 The effect of X11is dependent upon the cement

properties and the type of plasticizers used in the

PACKAGING: concrete mix. The setting time and early strength gain

may be affected if strong retarders are used in the

Supplied in: 250 kg drum mix.

Storage: Dry; Frost free, out of direct sunlight RATE OF HARDENING:

The temperature of the concrete mix and the ambient

Shelf life: 24 months, when stores as above temperature (forms, earth, reinforcement, air, etc.)

affect the hardening rate of concrete. At higher

Hazard class: No dangerous goods, Observe temperatures, concrete hardens more rapidly which

Material Safety datasheet. may cause problems with placing and finishing. One

of the functions of X 11 admixture is to accelerate the

DOSAGE: set of concrete. Within the normal dosage range, it

will generally reduce the setting times of concrete

Optimum dosage of X11 should be determined with containing normal Portland cement approximately by

trial mixes. As a guide, a dosage range of 2 Liter to 5 1 hour to 3 hours compared to a plain concrete mix,

Liter per cubic meter of concrete is recommended at depending on materials at site and temperatures. Trial

normal temperatures. mixes should be made with site materials &

approximating the job site conditions to determine

Higher dosages may be required when certain the dosage required. It is strongly recommended that

combinations of materials and conditions are present concrete should be properly cured particularly in

or acceleration is required at colder climatic windy and dry climates.

conditions.

The use of PAGEL, Curing Compound, evaporation

reducer to prevent quick moisture loss from the

surface of the flat works such as pavements in the

dry and windy climates is highly recommended.

The information provided in this leaflet, is supplied by our consulting service and is the end result of exhaustive research work and extensive experience. They are, however, without

liability on our part, in particular with regard to third parties proprietary rights, and do not relieve the user of the responsibility for verifying that theproducts and processes are suitable

for the intended application. The data presented was derived from tests under normal climate conditions according to DIN 50014 and mean average values and analysis. Deviations

are possible when delivery takes place. Given that recommendations may differ from those shown in this leaflet written confirmation should be sought. It is the responsibility of the

purchaser to ensure they have the latest leaflet issue and that its contents are current. Our customer service staff will be glad to provide assistance at any time. We appreciate the

interest you have shown in our products. This technical data sheet supercedes pre viously issued information.

PAGEL PAKISTAN (PVT.) LTD.

1-A, MISC. ZONE, VALUE ADDITION CITY Phone: +92-41-850-7212-13

SAHIANWALA ROAD, KHURRIANWALA. Fax: +92-41-850-7214

FAISALABAD Email: info@pagelpakistan.com Technical Ref. Sheet 2.16 PK

Website: www.pagelpakistan.com QS-Formblatt 01/14 Rev. 02

SPECIAL SURFACE WATER

ADMIXTURE SHOTCRETE GROUTS

ADMIXTURE IMPROVEMENT PROOFING

CRACK

FLOORING COATING JOINT SEALANT REPAIR TILING

INJECTION

You might also like

- ASTM D5084-16a Standard Test Methods For Measurement of Hydraulic Conductivity of Saturated Porous Materials Using A Flexible Wall PermeameterDocument24 pagesASTM D5084-16a Standard Test Methods For Measurement of Hydraulic Conductivity of Saturated Porous Materials Using A Flexible Wall PermeameterDerly Gómez100% (2)

- Maintenance and Inspection - ChiczanDocument9 pagesMaintenance and Inspection - ChiczanIngenius TeamNo ratings yet

- Pipe Support Span CalculationsDocument2 pagesPipe Support Span CalculationsktejankarNo ratings yet

- Well Control Methods PDFDocument89 pagesWell Control Methods PDFDanny Dukeran100% (2)

- Rock Proof: Liquid Water Integral WaterproofDocument2 pagesRock Proof: Liquid Water Integral Waterproofimran jamalNo ratings yet

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocument2 pagesConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsPrasantaNo ratings yet

- Naphthaplast F 707 LDocument2 pagesNaphthaplast F 707 LAnonymous AO4q022cUxNo ratings yet

- Rockproof X2P PDFDocument2 pagesRockproof X2P PDFSyed AyazNo ratings yet

- Naphthaplast F 707 UlDocument2 pagesNaphthaplast F 707 UlÖmer ErcanNo ratings yet

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocument2 pagesConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaNo ratings yet

- Fosroc Conplast SP561: High Performance Superplasticiser For Slump Retention and High Strength ConcreteDocument2 pagesFosroc Conplast SP561: High Performance Superplasticiser For Slump Retention and High Strength ConcreteVincent JavateNo ratings yet

- Conplast X421IC PDFDocument2 pagesConplast X421IC PDFShaik QutubuddinNo ratings yet

- Xtreme WR30Document2 pagesXtreme WR30central labNo ratings yet

- 2 HPS PlusDocument2 pages2 HPS PlusAhmed MamdouhNo ratings yet

- Data Sheet - Fosroc - Conplast WP AdmixtureDocument3 pagesData Sheet - Fosroc - Conplast WP AdmixtureLau Yenn YennNo ratings yet

- X-Mix X500: Set Retarding / High Range Water-Reducing /super Plasticizing AdmixtureDocument2 pagesX-Mix X500: Set Retarding / High Range Water-Reducing /super Plasticizing Admixturediaa mohamedNo ratings yet

- Conplast RP264Document4 pagesConplast RP264Jitendra BridgemohanNo ratings yet

- Xtreme WR55Document2 pagesXtreme WR55central labNo ratings yet

- CEMFLEX ULTRA - TDS Cementitious WaterproofingDocument2 pagesCEMFLEX ULTRA - TDS Cementitious WaterproofingAnoop ShankarNo ratings yet

- Conplast WP : High Performance Hydrophobic Waterproofing SystemDocument3 pagesConplast WP : High Performance Hydrophobic Waterproofing SystemFarah HaseenahNo ratings yet

- Conplast WP 421 PDFDocument2 pagesConplast WP 421 PDFharsoNo ratings yet

- Conplast SP500 KL: High Perfor Mance Water Reducing and Superplasticising AdmixtureDocument2 pagesConplast SP500 KL: High Perfor Mance Water Reducing and Superplasticising AdmixtureSankar VNo ratings yet

- Conplast WLDocument2 pagesConplast WLady999No ratings yet

- AdmixtureDocument4 pagesAdmixtureElaMazlanNo ratings yet

- En RMC13 Concrete HandbookDocument7 pagesEn RMC13 Concrete HandbookSrikar AvrNo ratings yet

- Cebex 112Document2 pagesCebex 112mohab hakimNo ratings yet

- Conplast W: Accelerating Admixture For Unreinforced Cement Concrete/mortarDocument3 pagesConplast W: Accelerating Admixture For Unreinforced Cement Concrete/mortaraashish patidarNo ratings yet

- Sika Air Mix - PDSDocument4 pagesSika Air Mix - PDSRonnie NdozirehoNo ratings yet

- Auracast 200 Dec20Document3 pagesAuracast 200 Dec20binausahagadaNo ratings yet

- Brushbond RFX PDFDocument2 pagesBrushbond RFX PDFDeep GandhiNo ratings yet

- Product Summary Catalogue: Creating Solutions For ConstructionDocument46 pagesProduct Summary Catalogue: Creating Solutions For Constructionpiyu114No ratings yet

- Fosroc Conplast WLDocument2 pagesFosroc Conplast WLRanganath NagargojeNo ratings yet

- Chemical Admixtures For ConcreteDocument7 pagesChemical Admixtures For ConcreteFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Conplast WL XtraDocument2 pagesConplast WL XtrapankajsinghNo ratings yet

- Renderoc S2Document4 pagesRenderoc S2R.ThangarajNo ratings yet

- Conplast SP495 CXDocument2 pagesConplast SP495 CXm.basim.technitalNo ratings yet

- Construction Chemicals: Total Solution ofDocument4 pagesConstruction Chemicals: Total Solution ofdwijNo ratings yet

- Delvo Stabiliser: Cement Hydration Control AdmixtureDocument2 pagesDelvo Stabiliser: Cement Hydration Control AdmixtureDoby YuniardiNo ratings yet

- Pds Conplast RDocument4 pagesPds Conplast RilhamNo ratings yet

- MYKSavemixSP111 PDFDocument2 pagesMYKSavemixSP111 PDFRanaware NandkishorNo ratings yet

- Consol SS 74 NDocument2 pagesConsol SS 74 NreginaulfahNo ratings yet

- HINCOL Rapid Setting Modified Emulsion (Bond Coat) A4 (Web)Document2 pagesHINCOL Rapid Setting Modified Emulsion (Bond Coat) A4 (Web)Tk SubhashNo ratings yet

- Fosroc Renderoc HB: Technical Data SheetDocument4 pagesFosroc Renderoc HB: Technical Data SheetRJNo ratings yet

- TDS - Conplast SP430 - IndiaDocument2 pagesTDS - Conplast SP430 - IndiaKarthik TumuluriNo ratings yet

- DCP - Product SummeryDocument36 pagesDCP - Product SummeryMina RemonNo ratings yet

- Auramix 350 DIS: High Range Water Reducing and Retarding Type Admixture For Wide Range of Concrete GradeDocument2 pagesAuramix 350 DIS: High Range Water Reducing and Retarding Type Admixture For Wide Range of Concrete GradeABHI MITRANo ratings yet

- Conplast sp430Document2 pagesConplast sp430sethuNo ratings yet

- Premcrete Hydroseal FX - TDSDocument3 pagesPremcrete Hydroseal FX - TDSSorin TantauNo ratings yet

- Conmix SP4Document2 pagesConmix SP4albarajeel forwarding001No ratings yet

- Fosroc Data Sheet 350 DISDocument2 pagesFosroc Data Sheet 350 DISKUNAL SHAHNo ratings yet

- Dynamon NRG1022Document4 pagesDynamon NRG1022yaw shuNo ratings yet

- RENDEROCLADocument5 pagesRENDEROCLAm.elsanee.cubicNo ratings yet

- Rheomac 707 PDFDocument3 pagesRheomac 707 PDFMohamed KhanNo ratings yet

- Millennium Product DataDocument15 pagesMillennium Product DataAnonymous ZizCrNlQkpNo ratings yet

- TDS Conplast SP430ES2 India3Document2 pagesTDS Conplast SP430ES2 India3H.b. DawudNo ratings yet

- Rock Seal Acrylic Reinforced Cementitious, Fle-Xible Waterproof CoatingDocument2 pagesRock Seal Acrylic Reinforced Cementitious, Fle-Xible Waterproof Coatingimran jamalNo ratings yet

- TDS Conplast WL India3Document2 pagesTDS Conplast WL India3rajni phNo ratings yet

- Concure RB90Document4 pagesConcure RB90m.elsanee.cubicNo ratings yet

- 21 AdmixtureDocument21 pages21 AdmixtureKrutaganasinh KathiyaNo ratings yet

- Fosroc Conplast AEA: Constructive SolutionsDocument2 pagesFosroc Conplast AEA: Constructive SolutionsSeychellesNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Factors Affecting The Success of Construction Projects in Khyber Pakhtunkhwa, PakistanDocument6 pagesFactors Affecting The Success of Construction Projects in Khyber Pakhtunkhwa, Pakistanaamir kalimNo ratings yet

- POINTS ON HYDRAULICS OF RUN-OF-RIVER STRUCTUREsDocument2 pagesPOINTS ON HYDRAULICS OF RUN-OF-RIVER STRUCTUREsaamir kalimNo ratings yet

- Engineer CivilDocument1 pageEngineer Civilaamir kalimNo ratings yet

- Current Trendsand Modernizationof Construction Industryin PakistanDocument15 pagesCurrent Trendsand Modernizationof Construction Industryin Pakistanaamir kalimNo ratings yet

- The Law of ContractsDocument1 pageThe Law of Contractsaamir kalimNo ratings yet

- University of Engineering and Technology, Taxila Department of Civil EngineeringDocument3 pagesUniversity of Engineering and Technology, Taxila Department of Civil Engineeringaamir kalimNo ratings yet

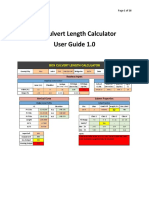

- Box Culvert Length Calculator User Guide 1.0Document16 pagesBox Culvert Length Calculator User Guide 1.0aamir kalimNo ratings yet

- Submittal Patterson Bombs PDFDocument77 pagesSubmittal Patterson Bombs PDFFred GarciaNo ratings yet

- Advert - 31.10.23-1Document19 pagesAdvert - 31.10.23-1Isaac GisoreNo ratings yet

- Price List: Supplier Cost I. Steel Unit SGIDocument4 pagesPrice List: Supplier Cost I. Steel Unit SGIBords MoralesNo ratings yet

- Chapter A8-Prestressed Concrete Cylinder Pipe (PCCP) and Fittings PDFDocument19 pagesChapter A8-Prestressed Concrete Cylinder Pipe (PCCP) and Fittings PDFRoel RicamaraNo ratings yet

- DimensionsDocument11 pagesDimensionsAsavela NotshwelekaNo ratings yet

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsChidi OkoloNo ratings yet

- Basic Guide To Calculating Falls and Gradients For Drainage - Basic Guide To Calculating Falls and Gradients For Drainage - Wyre CouncilDocument6 pagesBasic Guide To Calculating Falls and Gradients For Drainage - Basic Guide To Calculating Falls and Gradients For Drainage - Wyre Councilvenkateswara rao pothinaNo ratings yet

- Effect of Bracing On Regular and Irregular RCC (G+10) Frame Structure With Different Types of Bracings Under Dynamic LoadingDocument13 pagesEffect of Bracing On Regular and Irregular RCC (G+10) Frame Structure With Different Types of Bracings Under Dynamic LoadingIJRASETPublicationsNo ratings yet

- Powerpoint Presentation Road Pavement Failure (Coren Assembly) Revised FinalDocument110 pagesPowerpoint Presentation Road Pavement Failure (Coren Assembly) Revised FinalAdegboyega AdeyemiNo ratings yet

- Instant Download Ebook PDF 2018 International Building Code Illustrated Handbook by International Code PDF ScribdDocument41 pagesInstant Download Ebook PDF 2018 International Building Code Illustrated Handbook by International Code PDF Scribdfred.rivera82998% (49)

- Group 1-6 HvacDocument22 pagesGroup 1-6 Hvacryan bhinogNo ratings yet

- Soporte Antisísmico Fig825ADocument1 pageSoporte Antisísmico Fig825AMichael IturraNo ratings yet

- WVA Consulting Engineers PVT LTD: Analsyis and Design of Steel Watch TowerDocument23 pagesWVA Consulting Engineers PVT LTD: Analsyis and Design of Steel Watch TowerRomyMohanNo ratings yet

- Lee Jeeho ThesisDocument163 pagesLee Jeeho Thesisclam2014No ratings yet

- Material Calculator (Building)Document7 pagesMaterial Calculator (Building)Kumbie MadzekeNo ratings yet

- Bridge Technical Note 2001 - 005 Approach SlabsDocument3 pagesBridge Technical Note 2001 - 005 Approach SlabsChen YishengNo ratings yet

- Mat FoundationDocument38 pagesMat FoundationDinarWahyuNo ratings yet

- Oe4625 Dredge Pumps and Slurry Transport: Vaclav MatousekDocument27 pagesOe4625 Dredge Pumps and Slurry Transport: Vaclav MatouseknawajhaNo ratings yet

- Structural Design Offshore - Lecture 1 IntroDocument26 pagesStructural Design Offshore - Lecture 1 IntrobaharmarineNo ratings yet

- 04 Part 2-Desain Bangunan Sipil Pada PLTADocument30 pages04 Part 2-Desain Bangunan Sipil Pada PLTANovi AndrianyNo ratings yet

- Use of Glass Powder For Soil StabilisationDocument75 pagesUse of Glass Powder For Soil StabilisationKaushal RijalNo ratings yet

- TOPIC 1: Air-Conditioning Systems: Subtopic: Types of HVAC SystemsDocument32 pagesTOPIC 1: Air-Conditioning Systems: Subtopic: Types of HVAC SystemsMuhammad Fadhil Hilmi NasutionNo ratings yet

- RDSO GuidelineDocument57 pagesRDSO GuidelineSyed Nizam ElahiNo ratings yet

- 05 - Flex ADocument40 pages05 - Flex ANathan MolongwanaNo ratings yet

- CMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736Document1 pageCMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736steepa22No ratings yet

- Association For Preservation Technology International (APT) Association For Preservation Technology International (APT)Document10 pagesAssociation For Preservation Technology International (APT) Association For Preservation Technology International (APT)To CoNo ratings yet