Professional Documents

Culture Documents

Fosroc Conplast AEA: Constructive Solutions

Uploaded by

SeychellesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fosroc Conplast AEA: Constructive Solutions

Uploaded by

SeychellesCopyright:

Available Formats

Fosroc Conplast AEA constructive solutions

Air entraining agent

Uses Typical Properties

To produce air entrained concrete for increased durability, Appearance : Brown liquid

resistant to damage by frost and de-icing salts, and to improve Chloride content : Nil to BS 5075 / BS:EN934

the cohesion and workability of concrete mixes where poorly Specific gravity : 1.02 at 25°C

graded aggregates must by used, and in any situation where

The degree of air entrainment will be affected by a number of

bleeding, segregation or sand runs occur. Typical

factors:

applications include:

Sand content: The quantity of air entrained will increase with

Concrete roadways

increasing sand content - typically from 4.5 to 6.0% for a sand

Bridge decks content increase from 35% to 45%.

Airport runways and taxiways Cement fineness and content: The amount of air entrained

reduces with an increase in cement fineness. Air content

Other extensive areas of concrete exposed to potential

decreases with increasing cement content. A 1% air loss

frost damage

may be typical for a cement content increase of 90 kg/m3.

Advantages Organic impurities: Carbon can reduce the effectiveness of

Conplast AEA. This does not normally create a problem, but

Provides concrete with resistance to freezing and thawing.

care may have to be taken when using PFA, certain pigments

Improves cohesion, reduces segregation and bleeding. or lignite bearing sands.

Gives dense, uniform, close textured surface to concrete. Concrete temperature: A temperature increase will reduce

air content, e.g. a rise from 10°C to 32°C may halve the amount

Excellent air bubble stability.

of air entrained. In practice, daily fluctuations are much smaller

Consistent performance, even with changes in aggregate and do not cause significant variations.

quality and ambient temperature.

Mixing and pumping: Variations of mixer type and transit time

Effective in low workability concrete. will change the level of air entrainment. Small losses of air

may occur during pumping. With long pipelines, air content

Suitable for use in Middle East conditions.

in excess of 5% may seriously reduce the efficiency of the

pump.

Standards compliance

Compaction of concrete: Entrained air will not be lost by normal

Conplast AEA conforms with BS 5075, BS:EN 934-2 and with

vibration, though prolonged vibration is best avoided.

ASTM C260 as an air entraining agent.

Low workability concrete: i.e. slumps of less than 25 mm or

Description compacting factors between 0.80 to 0.85 may require an

increased dosage of Conplast AEA in order to achieve the

Conplast AEA is a chloride-free admixture based on

normal required air content.

neutralised vinsol resin and is supplied as a dark brown

solution. Conplast AEA acts on the interface of the cement/ Setting time: Negligible effect at normal dosage rates.

aggregate particles and mixing water to produce microscopic

Compatibility: Conplast AEA is compatible with other Fosroc

air bubbles evenly distributed throughout the concrete.

Conplast admixtures, but it is recommended that all

Technical support admixtures be added to concrete separately.

Fosroc provides a technical advisory service for on-site Conplast AEA can be used with all types of Portland cements.

assistance and advice on admixture selection, evaluation For advice on special cements, consult the technical

trials and dispensing equipment. Technical data and department.

guidance can be provided for admixtures and other products

Conplast AEA

for use with fresh and hardened concrete.

Fosroc Conplast AEA

Instructions for use Cleaning

Dosage Spillages of Conplast AEA can be removed with water.

The optimum dosage for Conplast AEA to meet the desired

Estimating

air content in concrete is best determined by site trials using

local cement and aggregate . As a guideline a dose between Supply

0.1 to 1.0 litre / m3 of concrete may be adapted for lab trial and Conplast AEA

based on results of air content the final dosage can be 210 litre drum, 1000 litre totes or bulk

optimised.

For larger users, storage tanks can be supplied.

Overdosing

Storage

An overdose of double the recommended amount of Conplast

Conplast AEA has a minimum shelf life of 12 months provided

AEA can result in slight increase in settling time and a reduction

the temperature is kept within the range of 2°C to 50°C.

in compressive strength.

Dispensing Precautions

The correct quantity of Conplast AEA should be measured by Health and Safety

means of a recommended dispenser. The company’s

Conplast AEA is slightly toxic and must not be ingested. It is

technical department should be consulted regarding suitable

mildly alkaline and prolonged contact with the skin must be

equipment and its installation.

avoided. Splashes to the skin should be washed with water.

Conplast AEA should be added directly to the mixer and best Any splashes to eyes should immediately be flushed with

results are obtained if added at the same time as the mixing clean water and medical advice should be sought.

water.

Fire

Curing

Conplast AEA is non-flammable.

A Concure*† curing membrane should be used, or alternative

curing methods such as polythene, water spray or wet

hessian.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 6731779 fax: 6731449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4665501 fax: 4664147 email: qatar@fosroc.com

UAE/0608/10/D

You might also like

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Conplast AeaDocument2 pagesConplast AeaVincent JavateNo ratings yet

- TDS Conplast AEA India3Document4 pagesTDS Conplast AEA India3Santosh MhetreNo ratings yet

- Air entraining admixture improves concrete durabilityDocument3 pagesAir entraining admixture improves concrete durabilitytalatzahoorNo ratings yet

- Conplast PA21: Constructive SolutionsDocument3 pagesConplast PA21: Constructive SolutionstalatzahoorNo ratings yet

- Conplast Ae316 PDFDocument4 pagesConplast Ae316 PDFdipinnediyaparambathNo ratings yet

- Conplast RP200Document2 pagesConplast RP200thoryamaraghyNo ratings yet

- Conplast SP337Document4 pagesConplast SP337Anonymous VJUVtmVusNo ratings yet

- Conplast AEA: Air Entraining AdmixtureDocument4 pagesConplast AEA: Air Entraining AdmixtureVenkata Raju KalidindiNo ratings yet

- TDS Conplast SP435 Saudi ArabiaDocument3 pagesTDS Conplast SP435 Saudi ArabiaEng. Renjith SarmaNo ratings yet

- Conplast WP : High Performance Hydrophobic Waterproofing SystemDocument3 pagesConplast WP : High Performance Hydrophobic Waterproofing SystemFarah HaseenahNo ratings yet

- Conplast AE300: Air Entraining AdmixtureDocument3 pagesConplast AE300: Air Entraining AdmixtureBalasubramanian AnanthNo ratings yet

- Conplast PA21(S) Improves Concrete DurabilityDocument4 pagesConplast PA21(S) Improves Concrete DurabilityVenkata Raju KalidindiNo ratings yet

- Fosroc Conplast WP200: Appearance: Specific Gravity: Chloride Content: Nil To BS 5075 / BS:EN934Document2 pagesFosroc Conplast WP200: Appearance: Specific Gravity: Chloride Content: Nil To BS 5075 / BS:EN934Vincent JavateNo ratings yet

- Fosroc Conplast RP264: Constructive SolutionsDocument2 pagesFosroc Conplast RP264: Constructive SolutionsVincent JavateNo ratings yet

- Constructive solutions for high-strength concreteDocument2 pagesConstructive solutions for high-strength concreteBagus Rizqi KurniawanNo ratings yet

- High performance air entraining admixtureDocument4 pagesHigh performance air entraining admixturemohab hakimNo ratings yet

- Pds Conplast RDocument4 pagesPds Conplast RilhamNo ratings yet

- Data Sheet - Fosroc - Conplast WP AdmixtureDocument3 pagesData Sheet - Fosroc - Conplast WP AdmixtureLau Yenn YennNo ratings yet

- 4 Conplast RP 264Document4 pages4 Conplast RP 264racingspirit80No ratings yet

- Fosroc Conplast WP200: Constructive SolutionsDocument2 pagesFosroc Conplast WP200: Constructive SolutionsVincent JavateNo ratings yet

- Conplast SP431R TDSDocument2 pagesConplast SP431R TDSBiruckNo ratings yet

- Conplast sp495Document2 pagesConplast sp495Vincent JavateNo ratings yet

- Performance Analysis of Air-Entrained Concrete: Strength, Workability and DurabilityDocument27 pagesPerformance Analysis of Air-Entrained Concrete: Strength, Workability and DurabilityHazbullah ShajiNo ratings yet

- Conplast R Retarding Concrete AdmixtureDocument2 pagesConplast R Retarding Concrete AdmixtureHemaNo ratings yet

- Performance Analysis of Air-Entrained ConcreteDocument26 pagesPerformance Analysis of Air-Entrained ConcreteHazbullah ShajiNo ratings yet

- TDS Conplast SP430 G8 IndiaDocument2 pagesTDS Conplast SP430 G8 IndiaZeeshaan BhattNo ratings yet

- Conplast SP430: High-performance superplasticizer for concreteDocument2 pagesConplast SP430: High-performance superplasticizer for concreteKarthik TumuluriNo ratings yet

- Fosroc Conplast SP2000: Constructive SolutionsDocument2 pagesFosroc Conplast SP2000: Constructive SolutionsVincent JavateNo ratings yet

- Pds Conplast Wp500Document3 pagesPds Conplast Wp500ilhamNo ratings yet

- Fosroc Conplast RP264: Retarding Water Reducing AdmixtureDocument2 pagesFosroc Conplast RP264: Retarding Water Reducing AdmixtureShaik QutubuddinNo ratings yet

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocument2 pagesConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaNo ratings yet

- Conplast W: Accelerating Admixture For Unreinforced Cement Concrete/mortarDocument3 pagesConplast W: Accelerating Admixture For Unreinforced Cement Concrete/mortaraashish patidarNo ratings yet

- TechBrief Air Entraining AdmixturesDocument2 pagesTechBrief Air Entraining AdmixturesgayathriNo ratings yet

- 1 Conplast P211Document3 pages1 Conplast P211racingspirit80No ratings yet

- Conplast X421 - DataSheetDocument2 pagesConplast X421 - DataSheetmido_20067581No ratings yet

- 5 Conplast SP 335Document2 pages5 Conplast SP 335racingspirit80No ratings yet

- Conplast SP500 KL: High Perfor Mance Water Reducing and Superplasticising AdmixtureDocument2 pagesConplast SP500 KL: High Perfor Mance Water Reducing and Superplasticising AdmixtureSankar VNo ratings yet

- Fosroc Conplast SP335 Multi-Range Water Reducing AdmixtureDocument2 pagesFosroc Conplast SP335 Multi-Range Water Reducing AdmixtureVincent JavateNo ratings yet

- Fosroc Conplast NC: Constructive SolutionsDocument4 pagesFosroc Conplast NC: Constructive SolutionsVincent JavateNo ratings yet

- A. Duran-HerreraDocument13 pagesA. Duran-HerreraPurandhar ReddiNo ratings yet

- Fosroc's Calcium Nitrite Corrosion InhibitorDocument2 pagesFosroc's Calcium Nitrite Corrosion InhibitorVincent JavateNo ratings yet

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocument2 pagesConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsPrasantaNo ratings yet

- Usage of Flywash As Replacement of Cement in High Strength ConcreteDocument27 pagesUsage of Flywash As Replacement of Cement in High Strength ConcretececoordinatorsNo ratings yet

- 2 Conplast P509Document2 pages2 Conplast P509racingspirit80No ratings yet

- Conplast PA21 Air Entraining AdmixtureDocument3 pagesConplast PA21 Air Entraining AdmixtureTori SmallNo ratings yet

- Fosroc Conplast SP470: Constructive SolutionsDocument2 pagesFosroc Conplast SP470: Constructive SolutionsVincent JavateNo ratings yet

- CAPENTRAINDocument2 pagesCAPENTRAINMedrar TareqNo ratings yet

- Conplast WP 421 PDFDocument2 pagesConplast WP 421 PDFharsoNo ratings yet

- 7 Conplast SP 1000Document2 pages7 Conplast SP 1000racingspirit80No ratings yet

- Fosroc Conplast SP335: Multi-Range Water Reducing AdmixtureDocument2 pagesFosroc Conplast SP335: Multi-Range Water Reducing AdmixtureVincent JavateNo ratings yet

- 3 Conplast RP 244Document3 pages3 Conplast RP 244racingspirit80No ratings yet

- Brochure Product Summary Guide BFL PDFDocument33 pagesBrochure Product Summary Guide BFL PDFTanvir Ahmed KhanNo ratings yet

- Air Entrained ConcreteDocument10 pagesAir Entrained ConcreteanushaNo ratings yet

- Conplast Sp430saDocument3 pagesConplast Sp430sathoryamaraghyNo ratings yet

- 21 AdmixtureDocument21 pages21 AdmixtureKrutaganasinh KathiyaNo ratings yet

- 8 Conplast SP 1000RDocument2 pages8 Conplast SP 1000Rracingspirit80No ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Physics ProjectDocument12 pagesPhysics ProjectDanish SharmaNo ratings yet

- Factors Affecting Selection of FoundationDocument4 pagesFactors Affecting Selection of FoundationRoy JariNo ratings yet

- Lecture 3: Operation Involving Particulate MatterDocument25 pagesLecture 3: Operation Involving Particulate MatterTaytoNo ratings yet

- GhostPeaks Part1Document4 pagesGhostPeaks Part1Raga Bima100% (1)

- Welding Processes and TechniqueDocument49 pagesWelding Processes and TechniqueRanendraNo ratings yet

- Unconsolidated Undrained Triaxial Test On ClayDocument16 pagesUnconsolidated Undrained Triaxial Test On Claygrantyboy8450% (2)

- Produced WatersDocument87 pagesProduced WatersrakicbgNo ratings yet

- INWQSDocument3 pagesINWQSLabibaNo ratings yet

- 6.product Tech Slide PresentationDocument158 pages6.product Tech Slide PresentationHadi MuchlisNo ratings yet

- PRESTRESSED CONCRETE 03 Rev00Document4 pagesPRESTRESSED CONCRETE 03 Rev00Hussein MuslihNo ratings yet

- Leaching Spent Batteries Powder Sodium Carbonate CO2Document6 pagesLeaching Spent Batteries Powder Sodium Carbonate CO2Boulos NassarNo ratings yet

- RAN Chemicals - Products - Powder Paint - Pure Polyster - For 93:7 - Carboxylated Polyester (R-3930)Document3 pagesRAN Chemicals - Products - Powder Paint - Pure Polyster - For 93:7 - Carboxylated Polyester (R-3930)crplzNo ratings yet

- The Hermes Wide Belt Product Family For Sanding Particleboard and FiberboardDocument8 pagesThe Hermes Wide Belt Product Family For Sanding Particleboard and FiberboardFlavioNo ratings yet

- SUS316 Compression Fitting SafetyDocument7 pagesSUS316 Compression Fitting SafetysunanNo ratings yet

- Julius BlumDocument141 pagesJulius Blumjuneenho MattosNo ratings yet

- Product Data Sheet OK 92.18: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 92.18: E 'Manual Metal-Arc Welding'Cesar ObesoNo ratings yet

- Magnetic Float Level Switch Specifications and ApplicationsDocument29 pagesMagnetic Float Level Switch Specifications and ApplicationsWidhi ImranovichNo ratings yet

- Engineering Booklet QuestionsDocument9 pagesEngineering Booklet QuestionsCosmin CretuNo ratings yet

- EXPERIMENT No.1 TemplateDocument6 pagesEXPERIMENT No.1 TemplateAthos FajardoNo ratings yet

- CorrLube VpCI Lithium EP GreaseDocument2 pagesCorrLube VpCI Lithium EP GreaselyanagustNo ratings yet

- Dyeing DefectsDocument12 pagesDyeing DefectsHARRY1765No ratings yet

- 1 s2.0 S1364032117308250 MainDocument27 pages1 s2.0 S1364032117308250 MainMohan KumarNo ratings yet

- "Hot Topics": Effect of Carbon in Ductile IronDocument4 pages"Hot Topics": Effect of Carbon in Ductile IronAdeel BhattiNo ratings yet

- Carbon Steel GradesDocument4 pagesCarbon Steel GradesKiky IchanafiNo ratings yet

- 2011, Ippolito, Drinking Water Treatment Residuals A Review of RecDocument13 pages2011, Ippolito, Drinking Water Treatment Residuals A Review of RecAfranio Neves JrNo ratings yet

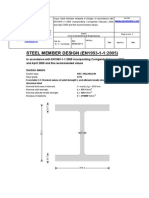

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Win ThanNo ratings yet

- Flute Care and Maintenance: AssemblyDocument2 pagesFlute Care and Maintenance: AssemblyJean VictorNo ratings yet

- Potassium-metaBisulphite 12 3Document25 pagesPotassium-metaBisulphite 12 3Prakash SwainNo ratings yet

- r050211802 Thermodynamics and KineticsDocument8 pagesr050211802 Thermodynamics and KineticsSrinivasa Rao GNo ratings yet

- Sachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Document6 pagesSachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Costas SachpazisNo ratings yet