Professional Documents

Culture Documents

370D4 2F 6RStandards

370D4 2F 6RStandards

Uploaded by

Alejandro Parrado0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

370D4-2F-6RStandards

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 page370D4 2F 6RStandards

370D4 2F 6RStandards

Uploaded by

Alejandro ParradoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

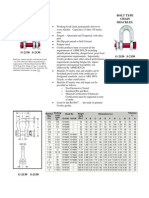

DYNASEAL ®

370D4 TRUNNION BALL VALVES DYNASEAL ®

370D4 TRUNNION BALL VALVES

CLASS 150 THROUGH 2500 & 5000# MOP

2 in. - 6 in. x 4 in. (50 mm - 150 mm x 100 mm)

FEATURES AND BENEFITS

Lever Handle FIRE TESTED FOR SAFETY

• DynaSeal 370D4 valves are

qualified under API 6FA

and API 607 4th Edition standards.

Stem Retainer Rings ACTUATION-FRIENDLY BI-DIRECTIONAL FLOW

Body Stem Stop • A variety of actuator types can be

Stop Plate

easily installed.

Stem O- Rings • Cooper Cameron Valves can

Stem Seal provide a total package of valves,

actuators or worm gear mounting

Stem Stem

Stud plates to accommodate actuation.

Injection

Fitting END CONNECTIONS

BI-DIRECTIONAL FLOW

Stem Bearing Flanged, weld, weld-by-flange This valve uses pressure-actuated seats with locked-in non-metallic

BODY STYLES face seals.

Two-piece To assure sealing at low pressure, special wave springs force the

Ball

Check Valve seats against the ball. At higher pressures, the upstream seat is

Seat Assembly (Consists of Seat Ring and STANDARD MATERIALS forced against the ball by the pressure working across the

Grease Fitting Seat Face Seal in Material List) differential area between the seat insert and the seat O-Ring.

Carbon Steel, Stainless Steel,

Seat O-Rings Seat Spring NACE MR0175 (Rev. 2002) The higher the pressure, the tighter the seal.

Body/ Tailpiece O-Ring OPTIONAL MATERIALS

Grounding Spring Nut Special trims available upon request.

Trunnion Bearing

DOUBLE BLOCK AND BLEED OPERATION

Tailpiece

Trunnion The pressure-actuated seats and

Trunnion O-Ring bleed fittings allow double block

and bleed operation. SEAT INJECTION FITTING

Check Valve

Lower Cover Plate

When used for block and bleed,

Stud this feature may permit the valve

Nut to take the place of two valves.

Bleed and Drain Fitting Grease Fitting It also allows the operator to check

up and downstream sealing by

bleeding off the body pressure.

STANDARDS AND SPECIFICATIONS ASME/ANSI PRESSURE CLASS

SECONDARY SEAT SEAL INJECTION

DynaSeal 370D4 ball valves conform to the following SIZE CLASS In the event of damage to the valve seat, sealant can be injected to

design and testing standards: in. (mm) 150 300 600 900 1500 2500 temporarily seal the valve.

• API 6D

• ASME/ANSI B16.34 (Valves, Flange End) 2 (50) • • • • • •

• ASME/ANSI B16.5 (Steel Pipe Flanges and Flange Fitting) 3x2 (75 x 50) • •

• MSS-SP-6 (Standard Finishes for Pipe Flanges)

• MSS-SP-25 (Standard Marking System for Valves) 3 (75) • • • • • •

• MSS-SP-55 (Quality Standards for Steel Castings) 4 x 3 (100 x 75) • •

• API 6FA (Fire Test Specification)

In addition DynaSeal 370D4 ball valves can be supplied 4 (100) • • • • • •

to comply with these standards: 6 x 4 (150 x 100) • • • • • •

• ASME/ANSI B31.1 (Power Piping)

• API 598 (Valve Inspection and Testing) SIZE

• ASME/ANSI B31.3 (Chemical Plant and Petroleum Refinery Piping) in. (mm) 5000# MOP

• MSS-SP-61 (Pressure Testing of Steel Valves) EXCESS BODY PRESSURE

• ASME/ANSI B16.104 (Valve Seat Leakage) 2 1/16 (52) •

• NACE MR0175 (Rev. 2002)

3 1/8 (79) •

• API 607 4th Edition (Fire Test Specification) AUTOMATIC BODY PRESSURE RELIEF

4 1/16 (103) • Seats will internally relieve excess body pressure.

14 12/03 TC1777-NP-5M 12/03 TC1777-NP-5M 23

You might also like

- Tubular Running Services Tech InfoDocument32 pagesTubular Running Services Tech InfoAlejandro Parrado100% (3)

- General Biology 2: 2 Semester - Module 1Document16 pagesGeneral Biology 2: 2 Semester - Module 1Almira Ibba100% (1)

- 1500-SSC SERIES Scorpion Service Center Manual de Operación Y ServicioDocument39 pages1500-SSC SERIES Scorpion Service Center Manual de Operación Y ServicioAlejandro ParradoNo ratings yet

- AtomDocument3 pagesAtomRich ManNo ratings yet

- Haskel Catalogo Dei Gas BoostersDocument36 pagesHaskel Catalogo Dei Gas BoosterslorytechNo ratings yet

- Stainless Steel Pressure RatingDocument1 pageStainless Steel Pressure RatingJatinder SondhiNo ratings yet

- Sea Max Manual 2010Document31 pagesSea Max Manual 2010adrian_jvNo ratings yet

- 8 - Subsea QuestionsDocument111 pages8 - Subsea QuestionssouthernorNo ratings yet

- Jetstream Pump FE Brochure.7 2016Document12 pagesJetstream Pump FE Brochure.7 2016Phit Nguyen VietNo ratings yet

- 15K 10-26-18 MainCatalog PDFDocument279 pages15K 10-26-18 MainCatalog PDFNico Jeria100% (1)

- Liquid Nitrogen DosingDocument4 pagesLiquid Nitrogen DosingBegenkzNo ratings yet

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- KREUZ SubseaDocument2 pagesKREUZ SubseaAlfredo MunarNo ratings yet

- SMD Atom - Workclass ROV PDFDocument3 pagesSMD Atom - Workclass ROV PDFredchaozNo ratings yet

- Pressure Rating A269 (Tubing)Document2 pagesPressure Rating A269 (Tubing)Michel LupienNo ratings yet

- CAD Designer or CAD TechnicianDocument1 pageCAD Designer or CAD Technicianapi-79041757No ratings yet

- RR 436Document70 pagesRR 436Jas Philip MNo ratings yet

- LARS A Frame DatasheetDocument2 pagesLARS A Frame Datasheetalexpc1988No ratings yet

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Document3 pagesDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleNo ratings yet

- Extreme Sports: Jacob Martínez EstradaDocument10 pagesExtreme Sports: Jacob Martínez EstradaJacob EstradaNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- ANSI B16.5 - Steel Pipe Flanges - Maximum Pressure and Temperature Ratings - Group 1Document3 pagesANSI B16.5 - Steel Pipe Flanges - Maximum Pressure and Temperature Ratings - Group 1jacksonbello34No ratings yet

- Material Handling and Process Improvement Using Lean Manufacturing Principles.1-4Document4 pagesMaterial Handling and Process Improvement Using Lean Manufacturing Principles.1-4SitisaifulNo ratings yet

- Pump in PlantDocument14 pagesPump in PlantGanesh MarkadNo ratings yet

- Ministry of Environment and Engery Maldives: Consultant: Riyan PVT LTD., MaleDocument2 pagesMinistry of Environment and Engery Maldives: Consultant: Riyan PVT LTD., MalePrem Kumar0% (1)

- Haskel Liquid Pumps v16Document24 pagesHaskel Liquid Pumps v16Carl Moritz50% (2)

- Pumps and Industrial ApplicationDocument19 pagesPumps and Industrial Applicationdevasree reddyNo ratings yet

- Subsea 7 FleetDocument34 pagesSubsea 7 FleetTord MartinsenNo ratings yet

- Calibration of Pressure GaugeDocument5 pagesCalibration of Pressure GaugeVarun SinghNo ratings yet

- Crosby Shackle Cotter Pin GuideDocument2 pagesCrosby Shackle Cotter Pin Guidesdb15840% (5)

- PE 3 Pump Engineer Interview PDFDocument8 pagesPE 3 Pump Engineer Interview PDFdgkmurtiNo ratings yet

- S G209 CrosbyDocument1 pageS G209 CrosbyJS168No ratings yet

- Mechanical Engineering 2 PDFDocument15 pagesMechanical Engineering 2 PDFHardikDevdaNo ratings yet

- Water Cooled Flooded Vertical Screw ChillersDocument96 pagesWater Cooled Flooded Vertical Screw ChillersaftabNo ratings yet

- NTPC Project ReportDocument31 pagesNTPC Project ReportDeepak Ranjan ParidaNo ratings yet

- Crosby Catalog 2008 - Page 76 To 88Document13 pagesCrosby Catalog 2008 - Page 76 To 88Prejit RadhakrishnaNo ratings yet

- Crossby Shackles Catalog G-2130 PDFDocument1 pageCrossby Shackles Catalog G-2130 PDFSam LowNo ratings yet

- Capacitive Level Meters For Cryogenic Liquids With Continuous Read-OutDocument7 pagesCapacitive Level Meters For Cryogenic Liquids With Continuous Read-OutMohamed Amine ChakrounNo ratings yet

- Auto CAD 2011 CommandsDocument7 pagesAuto CAD 2011 CommandsRaja RathinamNo ratings yet

- Alzamil Chiller - SeriesDocument13 pagesAlzamil Chiller - SeriesRAZA MEHDINo ratings yet

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800No ratings yet

- Plate Type Heat Exchangers: Operation & Maintenance ManualDocument24 pagesPlate Type Heat Exchangers: Operation & Maintenance ManualasjkhjshdjkashdashNo ratings yet

- ASME Flange & PN RatingDocument7 pagesASME Flange & PN Ratinggetz_meNo ratings yet

- Haskel Pump SelectionDocument3 pagesHaskel Pump Selectionsondk2100% (1)

- Pressure Rating PDFDocument4 pagesPressure Rating PDFMohamed AdelNo ratings yet

- Liquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFDocument30 pagesLiquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFHidroil Neuquen SrlNo ratings yet

- TOTAL Calculation SheetDocument22 pagesTOTAL Calculation SheetMd. Abdulla Al MamunNo ratings yet

- Pipe Support CatalogueDocument21 pagesPipe Support Cataloguejuber shikalgarNo ratings yet

- Nitrogen TankDocument9 pagesNitrogen TankVirnando NainggolanNo ratings yet

- Catalyst Loading MethodDocument3 pagesCatalyst Loading Methoderwan_exe0% (1)

- Instruction Sheet: W-Series Hydraulic Torque WrenchesDocument40 pagesInstruction Sheet: W-Series Hydraulic Torque WrenchesShag Shaggy100% (1)

- Study Skills GuideDocument46 pagesStudy Skills GuideStefannyAgnesSalimNo ratings yet

- Kaizen Quality ProductivityDocument20 pagesKaizen Quality ProductivitygurunathnkulkarniNo ratings yet

- Abnt NBR 15514Document20 pagesAbnt NBR 15514Andre alexander dos santosNo ratings yet

- WKM 370d5 Trunnion Mounted Ball Valves BrochureDocument12 pagesWKM 370d5 Trunnion Mounted Ball Valves BrochureAnonymous qhVGVpNo ratings yet

- MA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsDocument8 pagesMA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsFawn DixonNo ratings yet

- Abz Valve 400Document9 pagesAbz Valve 400John Harry RamirezNo ratings yet

- 05.2. - Valvula de Bola Montada Sobre Muñon PDFDocument24 pages05.2. - Valvula de Bola Montada Sobre Muñon PDFalquimista203No ratings yet

- WKM 370d4 Trunnion Mounted Ball Valves Brochure PDFDocument40 pagesWKM 370d4 Trunnion Mounted Ball Valves Brochure PDFAdhie WaelacxhNo ratings yet

- CT WKM Ball Trun 370d4 02Document40 pagesCT WKM Ball Trun 370d4 02Andersson Benito HerreraNo ratings yet

- Apollo-HP 215L-215WDocument16 pagesApollo-HP 215L-215WDaniel SanNo ratings yet

- Vertex Hose ClampDocument8 pagesVertex Hose ClampRamasamy PNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Cameron Flexpacker-Nr (Narrow Range) Ram PackerDocument1 pageCameron Flexpacker-Nr (Narrow Range) Ram PackerAlejandro ParradoNo ratings yet

- Tc1324 Mp13 Pneum Piston ActDocument36 pagesTc1324 Mp13 Pneum Piston ActAlejandro ParradoNo ratings yet

- Tc148 FL & FLS Op and MaintDocument24 pagesTc148 FL & FLS Op and MaintAlejandro ParradoNo ratings yet

- TC1201 Valvulas de CompuertaDocument16 pagesTC1201 Valvulas de CompuertaAlejandro ParradoNo ratings yet

- Blowout Preventers Rental: 21 1/4" - 2K Psi Bop StackDocument1 pageBlowout Preventers Rental: 21 1/4" - 2K Psi Bop StackAlejandro ParradoNo ratings yet

- NTPC & Group - D: RAILWAY - 2019Document8 pagesNTPC & Group - D: RAILWAY - 2019Vineeth RavindhranNo ratings yet

- MRP Lot For LotDocument43 pagesMRP Lot For LotAmin ShafanezhadNo ratings yet

- Breech Births & Cesarean Sections - Diana Rose VillamorDocument31 pagesBreech Births & Cesarean Sections - Diana Rose VillamorDaniel TomnobNo ratings yet

- Tensile Strength of Untwisted Blended Cotton/Flax Fibre StreamsDocument4 pagesTensile Strength of Untwisted Blended Cotton/Flax Fibre StreamsJarin JuthiNo ratings yet

- List of Toxic Chemical Registered in CaragaDocument49 pagesList of Toxic Chemical Registered in Caragamyreen20No ratings yet

- Math 201 Spring 2021 SyllabusDocument4 pagesMath 201 Spring 2021 SyllabusPoyraz EmelNo ratings yet

- MIM1186.500 HAZARD COMMUNICATION PROGRAM (HCP), Jan2016 PDFDocument8 pagesMIM1186.500 HAZARD COMMUNICATION PROGRAM (HCP), Jan2016 PDFGrenoite GrenoiteNo ratings yet

- St. Paul University SurigaoDocument3 pagesSt. Paul University SurigaoJoenetha Ann ApariciNo ratings yet

- Gas Condensate PVT Analysis Workbook: Written by Robert Mott, August 2003Document43 pagesGas Condensate PVT Analysis Workbook: Written by Robert Mott, August 2003Mario HuasasquicheNo ratings yet

- SSADocument10 pagesSSAAnkush KumarNo ratings yet

- Cscro VIII HR Training Center Building - Phase 1 Plans PDFDocument10 pagesCscro VIII HR Training Center Building - Phase 1 Plans PDFJohn Laurence Crucena VillaNo ratings yet

- Satellite P55T B5340Document4 pagesSatellite P55T B5340Marcelino SalazarNo ratings yet

- BHU PET M.SC Applied Microbiology Exam Question PaperDocument22 pagesBHU PET M.SC Applied Microbiology Exam Question PaperDivya SolankiNo ratings yet

- Quiz 1: Massachusetts Institute of Technology 6.042J/18.062J, Fall '05 Prof. Albert R. Meyer Prof. Ronitt RubinfeldDocument9 pagesQuiz 1: Massachusetts Institute of Technology 6.042J/18.062J, Fall '05 Prof. Albert R. Meyer Prof. Ronitt RubinfeldAlireza KafaeiNo ratings yet

- The Effect of Temperature and Concentration On Galvanic Cells PDFDocument12 pagesThe Effect of Temperature and Concentration On Galvanic Cells PDFPrashant JaitlyNo ratings yet

- Original Article: Clinical and Histopathological Correlation of Cutaneous TuberculosisDocument6 pagesOriginal Article: Clinical and Histopathological Correlation of Cutaneous Tuberculosisderil ridwanNo ratings yet

- Solid Mensuration Module 1Document9 pagesSolid Mensuration Module 1Azha Clarice Villanueva100% (2)

- Which Windows Do I Choose?: Comparing The Operating SystemsDocument4 pagesWhich Windows Do I Choose?: Comparing The Operating Systemswez99No ratings yet

- Previews 2016437 PreDocument7 pagesPreviews 2016437 Preenvista servicesNo ratings yet

- INFORM September 2018.4Document52 pagesINFORM September 2018.4irajNo ratings yet

- MIPI/DSI Receiver With HDMI Transmitter: Data SheetDocument12 pagesMIPI/DSI Receiver With HDMI Transmitter: Data SheetRobert GrabekNo ratings yet

- Principles For Layout Plans and Sectioning Diagrams For 25 KV Ac TractionDocument4 pagesPrinciples For Layout Plans and Sectioning Diagrams For 25 KV Ac TractionPragati SrivastavaNo ratings yet

- Cen-Ts 14778-1Document25 pagesCen-Ts 14778-1A Toca do FuinnhaNo ratings yet

- RULE 9 of PD1096Document5 pagesRULE 9 of PD1096Janna Victoria CayasanNo ratings yet

- Imm Toacs Feb 2023Document57 pagesImm Toacs Feb 2023rehan hayderNo ratings yet

- Ged108 ReviewerDocument8 pagesGed108 Reviewerley janaNo ratings yet

- Manuscript SpecificationsDocument3 pagesManuscript SpecificationsPreda AndreiNo ratings yet

- Cruise Control Izusu CamionesDocument12 pagesCruise Control Izusu CamionesAnonymous KOtSfT6qNo ratings yet