Professional Documents

Culture Documents

(Taken From EN ISO 10077-2: 2003) : Thermal Conductivities of Materials

Uploaded by

Cao Nguyên0 ratings0% found this document useful (0 votes)

33 views4 pagesOriginal Title

Thermal-conductivities-of-materials-EN-ISO10456

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views4 pages(Taken From EN ISO 10077-2: 2003) : Thermal Conductivities of Materials

Uploaded by

Cao NguyênCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

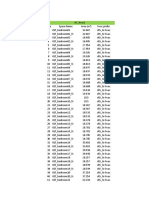

Thermal conductivities of materials

(taken from EN ISO 10077-2: 2003)

Group Material Density kg/m³ Thermal

conductivity

W/(m·K)

Frame Copper 8900 380.0

Aluminium (Si Alloys) 2800 160.0

Brass 8400 120.0

Steel 7800 50.0

Stainless steel 7900 17.0

PVC (polyvinylchloride), rigid 1390 0.17

Hardwood 700 0.18

Softwood (typical construction timber) 500 0.13

Fibreglass (UP-resin) 1900 0.40

Glass Soda lime glass 2500 1.0

PMMA (polymethylmethacrylate) 1180 0.18

Polycarbonates 1200 0.20

Thermal Polyamid (nylon) 1150 0.25

break Polyamid 6.6 with 25% glass fibre 1450 0.30

Polyethylene HD, high density 980 0.50

Polyethylene LD, low density 920 0.33

Polypropylene, solid 910 0.22

Polypropylene with 25% glass fibre 1200 0.25

PU (polyurethane), rigid 1200 0.25

PVC (polyvinylchloride), rigid 1390 0.17

Weather PCP (polychloroprene), eg Neoprene 1240 0.23

Stripping EPDM (ethylene propylene diene monomer) 1150 0.25

Silicone, pure 1200 0.35

PVC, flexible (PVC-P) 40% softener 1200 0.14

Mohair (polyester) sweep 0.14

Elastomeric foam, flexible 60 to 80 0.05

Sealant and PU (polyurethane), resin 1200 0.25

glass edge Butyl (isobutene), solid/hot melt 1200 0.24

material Polysulfide 1700 0.40

Silicone, pure 1200 0.35

Polyisobutylene 930 0.20

Polyester resin 1400 0.19

Silica gel (desiccant) 720 0.13

Molecular sieve (desiccant) 650 to 750 0.10

Silicone foam, low density 750 0.12

Silicone foam, medium density 820 0.17

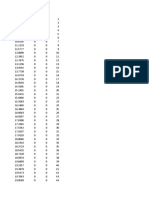

Design thermal values for materials in general building applications

(taken from BS EN ISO 10456: 2007)

Material group or application Density kg/m³ Thermal

conductivity

W/(m·K)

Asphalt 2100 0.70

Bitumen Pure 1050 0.17

Felt/sheet 1100 0.23

Concrete a Medium density 1800 1.15

2000 1.35

2200 1.65

High density 2400 2.00

Reinforced (with 1% of steel) 2300 2.30

Reinforced (with 2% of steel) 2400 2.50

Floor Rubber 1200 0.17

coverings Plastic 1700 0.25

Underlay, cellular rubber or plastic 270 0.10

Underlay, felt 120 0.05

Underlay, wool 200 0.06

Underlay, cork <200 0.05

Tiles, cork >400 0.065

Carpet / textile flooring 200 0.06

Linoleum 1200 0.17

Gases Air 1.23 0.025

Carbon dioxide 1.95 0.014

Argon 1.70 0.017

Sulphur hexafluoride 6.36 0.013

Krypton 3.56 0.009

Xenon 5.68 0.0054

Glass Soda lime glass (including “float glass”) 2500 1.00

Quartz glass 2200 1.40

Glass mosaic 2000 1.20

Water Ice at -10ºC 920 2.30

Ice at 0ºC 900 2.20

Snow, freshly fallen (<30mm) 100 0.05

Snow, soft (30 to 70m) 200 0.12

Snow, slightly compacted (70 to 100mm) 300 0.23

Snow, compacted (<200mm) 500 0.60

Water at 10ºC 1000 0.60

Water at 40ºC 990 0.63

Water at 80ºC 970 0.67

Metals Aluminium alloys 2800 160.0

Bronze 8700 65.0

Brass 8400 120.0

Copper 8900 380.0

Iron, cast 7500 50.0

Lead 11300 35.0

Steel 7800 50.0

b

Stainless steel , austenitic or austenitic-ferritic 7900 17.0

Stainless steel b, ferritic or martensitic 7900 30.0

Zinc 7200 110.0

Plastics, Acrylic 1050 0.20

solid Polycarbonates 1200 0.20

Polytetrafluoroethylene (PTFE) 2200 0.25

Polyvinylchloride (PVC) 1390 0.17

Polymethylmethacrylate (PMMA) 1180 0.18

Polyacetate 1410 0.30

Polyamide (nylon) 1150 0.25

Polyamide 6.6 with 25% glass fibre 1450 0.30

Polyethylene/polythene, high density 980 0.50

Polyethylene/polythene, low density 920 0.33

Polystyrene 1050 0.16

Polypropylene 910 0.22

Polypropylene with 25% glass fibre 1200 0.25

Polyurethane (PU) 1200 0.25

Epoxy resin 1200 0.20

Phenolic resin 1300 0.30

Polyester resin 1400 0.19

Rubber Natural 910 0.13

Neoprene (polychloroprene) 1240 0.23

Butyl (isobutene), solid/hot melt 1200 0.24

Foam rubber 60 - 80 0.06

Hard rubber (ebonite), solid 1200 0.17

Ethylene propylene diene monomer (EPDM) 1150 0.25

Polyisobutylene 930 0.20

Polysulfide 1700 0.40

Butadiene 980 0.25

Sealant Silica gel (desiccant) 720 0.13

materials, Silicone, pure 1200 0.35

weather Silicone, filled 1450 0.50

stripping

Silicone foam 750 0.12

and thermal

breaks Urethane/polyurethane (thermal break) 1300 0.21

Polyvinylchloride (PVC), flexible with 40% 1200 0.14

softener

Elastomeric foam, flexible 60 – 80 0.05

Polyurethane (PU) foam 70 0.05

Polyethylene foam 70 0.05

Gypsum Gypsum 600 0.18

“ 900 0.30

“ 1200 0.43

“ 1500 0.56

Gypsum plasterboard c 700 0.21

“ 900 0.25

Plasters Gypsum insulating plaster 600 0.18

and renders Gypsum plastering 1000 0.40

“ 1300 0.57

Gypsum, sand 1600 0.80

Lime, sand 1600 0.80

Cement, sand 1800 1.00

Soils Clay or silt 1200 – 1800 1.50

Sand and gravel 1700 – 2200 2.00

Stone Natural, crystalline rock 2800 3.50

Natural, sedimentary rock 2600 2.30

Natural, sedimentary rock, light 1500 0.85

Natural, porous, eg lava 1600 0.55

Basalt 2700 – 3000 3.50

Gneiss 2400 – 2700 3.50

Graphite 2500 – 2700 2.80

Marble 2800 3.50

Slate 2000 – 2800 2.20

Limestone, extra soft 1600 0.85

Limestone, soft 1800 1.10

Limestone, semi hard 2000 1.40

Limestone, hard 2200 1.70

Limestone, extra hard 2600 2.30

Sandstone (silica) 2600 2.30

Natural pumice 400 0.12

Artificial stone 1750 1.30

Tiles Clay 2000 1.00

(roofing) Concrete 2100 1.50

Tiles (other) Ceramic/porcelain 2300 1.30

Plastic 1000 0.20

d

Timber 450 0.12

500 0.13

700 0.18

e

Wood Plywood 300 0.09

based “ 500 0.13

d

panels “ 700 0.17

“ 1000 0.24

Cement-bonded particleboard 1200 0.23

Particleboard 300 0.10

“ 600 0.14

“ 900 0.18

Oriented strand board (OSB) 650 0.13

f

Fibreboard, including MDF 250 0.07

“ 400 0.10

“ 600 0.14

“ 800 0.18

a

The density for concrete is the dry density.

b

EN 10088-1 contains extensive lists of properties of stainless steels which may be used when the precise composition of the

stainless steel is known.

c

The thermal conductivity includes the effect of the paper liners.

d

The density for timber and wood-based products is the density in equilibrium with 20ºC and 65% relative humidity, including

the mass of hygroscopic water.

e

As an interim measure and until sufficient significant data for solid wood panels (SWP) and laminated veneer lumber (LVL)

are available, the values given for plywood may be used.

f

MDF: Medium density fibreboard, dry process.

You might also like

- Embodied Energy - TilesDocument13 pagesEmbodied Energy - TilesfakemasterkgpNo ratings yet

- Thermal component heat transfer analysisDocument1 pageThermal component heat transfer analysiscan gulerNo ratings yet

- Daikin Load Calculation Report for Building PROBADocument4 pagesDaikin Load Calculation Report for Building PROBAUROCIONo ratings yet

- Water Insulating ProjectDocument47 pagesWater Insulating Projectcan gulerNo ratings yet

- Thermal component heat transfer and heat lossDocument1 pageThermal component heat transfer and heat losscan gulerNo ratings yet

- Recap ThermalDocument8 pagesRecap ThermalGunnerZedNo ratings yet

- Properties of SolidsDocument10 pagesProperties of SolidsdhruvNo ratings yet

- Input Parameters: Compartment With Thermally Thick/Thin BoundariesDocument3 pagesInput Parameters: Compartment With Thermally Thick/Thin BoundariesJohn ANo ratings yet

- Ultrasonic Wall Thickness Gauge Measurement: All Velocities Are ApproximationsDocument6 pagesUltrasonic Wall Thickness Gauge Measurement: All Velocities Are ApproximationsAvijit DebnathNo ratings yet

- Table of Fruit PropertiesDocument2 pagesTable of Fruit PropertiesRoberto JacintoNo ratings yet

- Emissivity Table of Various Surfaces For Infrared ThermometryDocument19 pagesEmissivity Table of Various Surfaces For Infrared Thermometryntiiac201No ratings yet

- 3Document1 page3can gulerNo ratings yet

- DENSITY VALUES OF PLASTICSDocument4 pagesDENSITY VALUES OF PLASTICSAbdullah Al AsikNo ratings yet

- Properties of Nonmetals.: Temperature 10 Substance C W/M C KG/M KJ/KG C M /s Structural and Heat-Resistant MaterialsDocument3 pagesProperties of Nonmetals.: Temperature 10 Substance C W/M C KG/M KJ/KG C M /s Structural and Heat-Resistant MaterialsMalik Mohammad AsifNo ratings yet

- Thermophysicl propeties of common materials (structural building materials)Document2 pagesThermophysicl propeties of common materials (structural building materials)Buchule NtlabatiNo ratings yet

- AcosutiPLus V Fibreglass Absorption and NRCsDocument2 pagesAcosutiPLus V Fibreglass Absorption and NRCsHamzeh TarteerNo ratings yet

- Insulation ThicknessDocument1 pageInsulation ThicknessHamza KhanNo ratings yet

- Thermal Conductivity Guide - 40 Materials & GasesDocument10 pagesThermal Conductivity Guide - 40 Materials & GasesrickyNo ratings yet

- Part I - Multiphase Pipeline & Slug Catcher Design GuideDocument1 pagePart I - Multiphase Pipeline & Slug Catcher Design GuideamoghimiNo ratings yet

- Thermal Conductivity of Common MaterialsDocument4 pagesThermal Conductivity of Common MaterialsYash AjmeraNo ratings yet

- U Value CalculatorDocument1 pageU Value CalculatorBillieNo ratings yet

- Chapter 2 - The Price and Availability of Materia - 2012 - Engineering MaterialsDocument12 pagesChapter 2 - The Price and Availability of Materia - 2012 - Engineering MaterialsDavidNo ratings yet

- Resin Shrinkage Values Chart Under 40 CharactersDocument2 pagesResin Shrinkage Values Chart Under 40 CharactersandreathomeNo ratings yet

- Velocity of Sound PDFDocument1 pageVelocity of Sound PDFFaizalFaizNo ratings yet

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdDocument10 pagesSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourNo ratings yet

- Sound Velocity Chart PDFDocument1 pageSound Velocity Chart PDFIman NutnumNo ratings yet

- Sound Velocity Chart PDFDocument1 pageSound Velocity Chart PDFSrinivasan MechNo ratings yet

- Sound Velocity Chart PDFDocument1 pageSound Velocity Chart PDF1339979No ratings yet

- Sound Velocity Chart PDFDocument1 pageSound Velocity Chart PDFmamillapalli sri harshaNo ratings yet

- Sound Velocity ChartDocument1 pageSound Velocity ChartNikolaos OrfanoudakisNo ratings yet

- Ultrasonic Sound Velocity Chart for Common MaterialsDocument1 pageUltrasonic Sound Velocity Chart for Common Materialsrajat kumar JenaNo ratings yet

- Sound Velocity Chart PDFDocument1 pageSound Velocity Chart PDFJamesNo ratings yet

- Building Element Layer Current Number Layer'S Name Thickness (M) Density (Dan/MDocument3 pagesBuilding Element Layer Current Number Layer'S Name Thickness (M) Density (Dan/MFaeria20No ratings yet

- GSR 2015 (Building Works) For PrintingDocument262 pagesGSR 2015 (Building Works) For PrintingNayan FataniaNo ratings yet

- Sound Velocity ChartDocument1 pageSound Velocity Charttarık100% (2)

- Thermal Conductivity of Lagged PipeDocument17 pagesThermal Conductivity of Lagged PipeInzamamul HaqueNo ratings yet

- Chapter 2 - Price and Availability of Materials - 2019 - Engineering Materials 1Document14 pagesChapter 2 - Price and Availability of Materials - 2019 - Engineering Materials 1Juan Camilo AlarconNo ratings yet

- K - W/ (M.K) : Thermal ConductivityDocument15 pagesK - W/ (M.K) : Thermal ConductivityschuberthjoseNo ratings yet

- NanoPore VIPDocument2 pagesNanoPore VIPbooter_bewareNo ratings yet

- Thermal Conductivity For Different MaterialsDocument5 pagesThermal Conductivity For Different MaterialsLalit SolankiNo ratings yet

- Conductive Epoxy Field Joint Recipe for Tangguh Project PipelinesDocument6 pagesConductive Epoxy Field Joint Recipe for Tangguh Project Pipelinesnoto.sugiartoNo ratings yet

- 02-Ducting SmacnaDocument4 pages02-Ducting SmacnaSonghengNo ratings yet

- Lamination Kit DN200Document1 pageLamination Kit DN200Mohammad IqbalNo ratings yet

- Specific Gravity Materials GuideDocument1 pageSpecific Gravity Materials Guideck19654840No ratings yet

- SWD Trench CalculationDocument8 pagesSWD Trench Calculationsalmaan mastanNo ratings yet

- Community Market Standard BoQDocument4 pagesCommunity Market Standard BoQAF Dowell MirinNo ratings yet

- Walls ConstructionDocument2 pagesWalls Constructioncomekib310No ratings yet

- U ValueDocument61 pagesU Valueزين ال عابدينNo ratings yet

- Energy Efficiency in Green BuildingDocument22 pagesEnergy Efficiency in Green Buildingavyn89No ratings yet

- Material Density ListingDocument1 pageMaterial Density ListingElmer VillegasNo ratings yet

- E SolDocument7 pagesE SolPeter ZubarikNo ratings yet

- Cryogel Z: Flexible Industrial Insulation With Vapor Barrier For Sub-Ambient and Cryogenic ApplicationsDocument4 pagesCryogel Z: Flexible Industrial Insulation With Vapor Barrier For Sub-Ambient and Cryogenic ApplicationsValdemar OjedaNo ratings yet

- COMMUNITY MARKETDocument8 pagesCOMMUNITY MARKETracing.phreak100% (1)

- Latitude Deg SI US /G: Table 2: Engineering Constants A) Acceleration of GravityDocument6 pagesLatitude Deg SI US /G: Table 2: Engineering Constants A) Acceleration of GravityASIM KUMAR SRIVASTAVANo ratings yet

- Database of Embodied Energy and Water Values For MaterialsDocument3 pagesDatabase of Embodied Energy and Water Values For MaterialsMax Yanac TelleriaNo ratings yet

- Global Polymer Industries, Inc. Dielectric Constant Dielectric StrengthDocument10 pagesGlobal Polymer Industries, Inc. Dielectric Constant Dielectric StrengthJair Fajrdo LopezNo ratings yet

- Own Catalogue - Norton LeaDocument2 pagesOwn Catalogue - Norton LeaRobenNo ratings yet

- Polymer Production Capacity Projections for 2009Document27 pagesPolymer Production Capacity Projections for 2009RaviNo ratings yet

- Orphanage: Concept DesignDocument12 pagesOrphanage: Concept DesignCao NguyênNo ratings yet

- Hvac ProfileDocument36 pagesHvac ProfileCao NguyênNo ratings yet

- Layer Zone Area (m2) Total capacity (kW) % Chênh lệch Edeec simulation's case Current designDocument12 pagesLayer Zone Area (m2) Total capacity (kW) % Chênh lệch Edeec simulation's case Current designCao NguyênNo ratings yet

- EquationsDocument60 pagesEquationsNileshPawarNo ratings yet

- Cooling CapDocument45 pagesCooling CapCao NguyênNo ratings yet

- TCVN 232-1999Document28 pagesTCVN 232-1999Trần HuyNo ratings yet

- HCM Velocity - 12msDocument8 pagesHCM Velocity - 12msCao NguyênNo ratings yet

- Load Calc A307 Aug 2020Document6 pagesLoad Calc A307 Aug 2020Cao NguyênNo ratings yet

- Energy Survey Analysis for Commercial BuildingsDocument31 pagesEnergy Survey Analysis for Commercial BuildingsCao NguyênNo ratings yet

- Future of Design The Sustainable Engineering StudioDocument10 pagesFuture of Design The Sustainable Engineering StudioCao NguyênNo ratings yet

- LOTUS NC V3 Technical Manual 30.12.2019Document278 pagesLOTUS NC V3 Technical Manual 30.12.2019Cao NguyênNo ratings yet

- LEED v4.1 IDC 190725 CleanDocument94 pagesLEED v4.1 IDC 190725 CleanCao NguyênNo ratings yet

- Catalog Daikin Ftxs Ftks SeriesDocument11 pagesCatalog Daikin Ftxs Ftks SeriesCao NguyênNo ratings yet

- Introduction To Computational Fluid Dynamics: December 2010Document15 pagesIntroduction To Computational Fluid Dynamics: December 2010kishorebabubhumulaNo ratings yet

- dc18 03 Annex ADocument7 pagesdc18 03 Annex ACao NguyênNo ratings yet

- LOTUS Buildings in Operation V1 Scorecard: Total Total TotalDocument1 pageLOTUS Buildings in Operation V1 Scorecard: Total Total TotalCao NguyênNo ratings yet

- LEED v4.1 Residential Single Family Rating System 1.2020Document69 pagesLEED v4.1 Residential Single Family Rating System 1.2020Azzreiz AzzarainNo ratings yet

- LEED v4.1 Residential BD C MF Homes Core and Shell 190402 CleanDocument93 pagesLEED v4.1 Residential BD C MF Homes Core and Shell 190402 CleanCao NguyênNo ratings yet

- LEED Version 4 For Building Design and Construction (IMPORTANTE)Document154 pagesLEED Version 4 For Building Design and Construction (IMPORTANTE)Carlos L. Oyuela100% (1)

- Leed v4.1 BD C GuideDocument257 pagesLeed v4.1 BD C GuideJose David SanchezNo ratings yet

- LOTUS NC V3 Technical Manual 30.12.2019Document278 pagesLOTUS NC V3 Technical Manual 30.12.2019Cao NguyênNo ratings yet

- LEED v4.1 For Building Design and Construction 1 PAGE PrintableDocument11 pagesLEED v4.1 For Building Design and Construction 1 PAGE PrintableCao NguyênNo ratings yet

- LEED v4.1 Residential Single Family Rating System 1.2020Document69 pagesLEED v4.1 Residential Single Family Rating System 1.2020Azzreiz AzzarainNo ratings yet

- Basis of Design (BOD) ExampleDocument4 pagesBasis of Design (BOD) Exampleusebio6433% (3)

- 17-Chillers Level 2 Air-Cooled (TDP-622)Document52 pages17-Chillers Level 2 Air-Cooled (TDP-622)Hany Rifaat100% (2)

- Nioec SP 50 59Document9 pagesNioec SP 50 59aminNo ratings yet

- Lecture 21Document24 pagesLecture 21jnmanivannanNo ratings yet

- Composites C: Open AccessDocument8 pagesComposites C: Open AccessLiran KatzNo ratings yet

- Assignment For Mid 1Document9 pagesAssignment For Mid 1Vũ Thị Hà TrangNo ratings yet

- Concrete Beam Design Based On ACI 318-99Document3 pagesConcrete Beam Design Based On ACI 318-99Michele SimmonsNo ratings yet

- Pressure Distribution Over CylinderDocument7 pagesPressure Distribution Over CylinderArunSutharNo ratings yet

- VRV IV - Leaflet - HA - FINAL LR - tcm582-400473 PDFDocument36 pagesVRV IV - Leaflet - HA - FINAL LR - tcm582-400473 PDFDhirendra Singh RathoreNo ratings yet

- ELEMENT 10 Fire1Document13 pagesELEMENT 10 Fire1Aaquil RaziNo ratings yet

- Appendix C Steam TablesDocument8 pagesAppendix C Steam TablesWin Alfalah Nasution100% (1)

- Technical SpecificationDocument334 pagesTechnical SpecificationKiran VenkataNo ratings yet

- SPECIAL CONCRETES GUIDEDocument30 pagesSPECIAL CONCRETES GUIDECésar HuamánNo ratings yet

- Ib Tutorial 4 (12 13) Sem 2Document5 pagesIb Tutorial 4 (12 13) Sem 2omarnasriNo ratings yet

- 01-15-14 Concrete Damaged Plasticity ModelDocument13 pages01-15-14 Concrete Damaged Plasticity ModelatchzytNo ratings yet

- Lesson 4 Analysis and Design For Axial Tension (Part 2)Document3 pagesLesson 4 Analysis and Design For Axial Tension (Part 2)EJ Dela CruzNo ratings yet

- Elastocrete P8J Waterproofing Kit Technical Data SheetDocument3 pagesElastocrete P8J Waterproofing Kit Technical Data SheetZèlia FláviaNo ratings yet

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- 3RD Term S2 Technical DrawingDocument30 pages3RD Term S2 Technical DrawingDada RasheedNo ratings yet

- Design File Type RUBDocument116 pagesDesign File Type RUBAbilaash VNo ratings yet

- Piston Stress AnalysisDocument13 pagesPiston Stress Analysisducatiss900100% (3)

- Toa Exit Exam QnA-1Document26 pagesToa Exit Exam QnA-1anonuevo.chloe14No ratings yet

- Mini ProjectDocument58 pagesMini ProjectDeepak Varma50% (2)

- Fundiciones Nardo Presentation LetterDocument2 pagesFundiciones Nardo Presentation LetterEnrique PGNo ratings yet

- Đĩa Phân Phối Khí TinhDocument2 pagesĐĩa Phân Phối Khí TinhVu DongNo ratings yet

- MD Reading 3 4Document96 pagesMD Reading 3 4asapamoreNo ratings yet

- 6 Deviation of Actual Cycle From Ideal CycleDocument5 pages6 Deviation of Actual Cycle From Ideal CyclecaptainhassNo ratings yet

- Eaton Panelboards Lighting Controls Product Guide Ca014005en CADocument119 pagesEaton Panelboards Lighting Controls Product Guide Ca014005en CAchristian de leonNo ratings yet

- Example of Wind Load Determination - Asce 7-10Document3 pagesExample of Wind Load Determination - Asce 7-10Oscar Wong ChongNo ratings yet

- Seam Weld Fatigue Analysis Femfat PDFDocument17 pagesSeam Weld Fatigue Analysis Femfat PDFaminNo ratings yet

- MDS5738 Door Assembly (Control Panel)Document4 pagesMDS5738 Door Assembly (Control Panel)Bruno AdroverNo ratings yet