Professional Documents

Culture Documents

DSE6110 MKIII DSE6120 MKIII Installation Instructions

DSE6110 MKIII DSE6120 MKIII Installation Instructions

Uploaded by

almisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DSE6110 MKIII DSE6120 MKIII Installation Instructions

DSE6110 MKIII DSE6120 MKIII Installation Instructions

Uploaded by

almisCopyright:

Available Formats

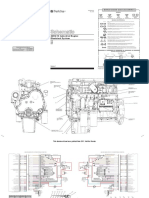

TYPICAL WIRING DIAGRAM 053-240 ISSUE 3

OUTPUT SOURCES

Output Sources

NOTE: A larger version of the typical wiring diagram is included in the 0 Not Used 77 Emergency Stop 154 Mains Load Inhibit

DEEP SEA ELECTRONICS

product’s operator manual. Refer to DSE Publication: 057-289 DSE6110 MKIII & 1 Air Flap Relay 78 Energise To Stop 155 Mains Low Freq

DSE6120 MKIII Operator Manual available from www.deepseaelectronics.com. m

2 Alar Mute 79 External Panel Lock 156 Mains Low Volts DSE6110 MKIII & DSE6120 MKIII

m

3 Alar Reset 80 Fail To Start 157 RESERVED Installation Instructions

arm 1 Due

NOTE: Terminals 33, 34, 35 and 36 are not fitted to the DSE6110 MKIII.

4 Alt Config 1 Selected 81 Fail To Stop 158 Maintenance Al

5 RESERVED 82 Fan Control 159 Maintenance Alarm 2 Due

gh Alarm Maintenance Alarm 3 Due

6 RESERVED 83 Flex Sensor A Hi 160

ACCESSING THE MAIN CONFIGURATION EDITOR

7 RESERVED 84 Flex Sensor A High Pre-Alm 161 Manual Restore Contact

8 RESERVED Flex Sensor A Low Alarm O C Ensure the engine is at rest and the module is in STOP mode by pressing the

85 162 MPU pen ircuit

Stop/Reset) button.

Flex Sensor A Low Pre-Alm

(

9 Analogue Input A 86 163 RESERVED

10 Analogue Input B 87 Flex Sensor A OC 164 Oil Pressure Sensor OC (Stop/Reset) and ( Tick) buttons simultaneously.

gh Alarm

Press the

11 Analogue Input C 88 Flex Sensor B Hi 165 Oil Pressure Switch

gh Pre-Alm

If a module security PIN has been set, the PIN number request is then shown:

12 Analogue Input D 89 Flex Sensor B Hi 166 Open Gen Output

The first ‘#’ changes to ‘0’. Press the Up) or Down

13 Arm Safety On Alar s m 90 Flex Sensor B Low Alarm 167 Open Gen Pulse

( ( ) button to adjust it to

m Flex Sensor B Low Pre-Alm

the correct value.

14 Audible Alar 91 168 Open Mains Output

15 Auto Restore Inhibit 92 Flex Sensor B OC 169 Open Mains Pulse

gh Alarm Over Current IDMT Alarm

Press the (Right) button when the first digit is correctly entered. The digit previously

W

16 Auto Start Inhibit 93 Flex Sensor C Hi 170

Flex Sensor C High Pre-Alm

entered now shows ‘#’ for security.

17 Auxiliary Mains Failure 94 171 Over Current Imm arning

18 Battery High Volts Flex Sensor C Low Alarm Over Freq Runaway

W

95 172 Left)

Flex Sensor C Low Pre-Alm

(

19 Batter Low Volts

Repeat this process for the other digits of the PIN number. If required press the

96 173 Over Freq arning button to move back to adjust one of the previous digits.

20 Call For Scheduled Run 97 Flex Sensor C OC 174 Over Speed Runaway

21 Charge Alt Fail Shutdown gh Alarm Over Speed Shutdown

W W

98 Flex Sensor D Hi 175 PIN is checked for validity when the ( Tick) button is pressed. If the number is not

22 Charge Alt Fail arning 99 Flex Sensor D High Pre-Alm 176 Over Speed arning correct, the PIN must be re- entered.

23 Close Gen Output 100 Flex Sensor D Low Alarm 177 Overspeed Delayed Alarm If the PIN has been successfully entered (or the module PIN has not been enabled),

24 Close Gen Pulse 101 Flex Sensor D Low Pre-Alm 178 Overspeed Delayed Wng the editor is displayed:

25 Close Mains Output 102 Flex Sensor D OC 179 Overspeed Overshoot Alarm

26 Close Mains Pulse 103 Fuel Level Hi gh Alarm 180 Overspeed Overshoot Wng EDITING A PARAMETER

gh Pre-Alarm

Preheat During Preheat Enter the editor as described above.

27 Combined Mains Failure 104 Fuel Level Hi 181

Timer

28 Maintenance Alm 1,2,3 105 Fuel Level Low Alarm 182 Preheat Until Crank End (Right) or (Left) buttons to cycle to the section to view/change.

Common Lo /Hi Freq Alm Low Pre-Alarm

Press the

29 106 Fuel Level 183 Preheat Until End Of Safety Press the ( Up) or Down)

( buttons to select the parameter to view/change

Lo/Hi Freq

W

Combined Preheat Until End Of within the currently selected section.

30 107 Fuel Pump Control 184

arni ng Warmin g

Lo/Hi Volt Alm 108

W

31 Combined Fuel Relay 185 Protections Disabled To edit the parameter, press the (Tick) button to enter edit mode. The parameter

32 CombinedLo/Hi Volt ng 109 Fuel Sensor OC 186 Remote Control 1 begins to flash to indicate editing.

33 Common Alarm 110 Fuel Tank Bund Level Hi gh 187 Remote Control 10 Press the ( Up) or Down)

( buttons to change the parameter to the required

34 Common E Trip 111 RESERVED 188 Remote Control 2 value.

Shutdown

W

35 Common 112 Gas Choke On 189 Remote Control 3

36 Common arning 113 Gas Ignition 190 Remote Control 4 Press the (Tick) button to save the value. The parameter ceases flashing to

37 Config CAN 1 Active 114

Gen Loading Freq Not 191 Remote Control 5

indicate that it has been saved.

Reached

Gen Loading Volts Not To exit the editor and save the changes, press and hold the ( Tick) button.

38 Config CAN 10 Active 115 192 Remote Control 6

Reached

39 Config CAN 2 Active 116 Gen Hi Freq Overshoot Alm 193 Remote Control 7

To exit the editor without saving the changes, press and hold the (Stop/Reset)

40 Config CAN 3 Active 117 Gen Hi Freq Overshoot Wng 194 Remote Control 8

button.

41 Config CAN 4 Active 118 Gen Available 195 Remote Control 9

DIMENSIONS AND MOUNTING 42 Config CAN 5 Active 119 Gen Closed Aux 196 Remote Start Off Load ACCESSING THE ‘RUNNING’ CONFIGURATION EDITOR

Parameter Specification 43 Config CAN 6 Active 120 Gen Excite 197 Remote Start On Load The ‘running’ editor can be entered while the engine is running. All protections remain

Dimensions 216 mm x 158 mm x 43 mm (8.5” x 6.2” x 1.5”) 44 Config CAN 7 Active Gen High Volts Alarm active if the engine is running while the running editor is entered.

W

121 198 Reset Maintenance 1

Panel Cutout 184 mm X 137 mm (7.2” X 5.3”) 45 Config CAN 8 Active 122 Gen High Volts arning 199 Reset Maintenance 2

0.5 kg (1.1 lb) Gen High Volts Shutdown

Press and hold the ( Tick) button to enter the running editor.

Weight 46 Config CAN 9 Active 123 200 Reset Maintenance 3

Operating Temperature -40 ºC to +70 ºC (-40 ºF to +158 ºF) 47 Coolant Cooler Control 124 Gen Load Inhibit 201 Scheduled Auto Start Inhibit

Gen Low Volts Alarm

5 ºC (-40 ºF to +185 ºF) RUNNING CONFIGURATION EDITOR PARAMETERS

W

Storage Temperature -40 ºC to +8 48 Coolant Heater Control 125 202 SCR Inducement

49 Coolant Temp

Switch 126 Gen Low Volts arning 203 Screensaver Active Section

Parameter As Shown On

Section

Parameter As Shown On

Gen High Freq Alarm

Display Display

OUTPUT SOURCES CONTINUED 50 Cooling Down 127 204 Shutdown Blocked Contrast

Gen High Freq Delayed Alm

Module Engine Frequency Adjust

Output Sources Continued 51 Data Logging Active 128 205 Simulate Auto Button

Language Continued DPF Auto Regen Inhibit

Low Gen High Freq Delayed

63

DPF Forced Regen

140 Lamp Test 217 System In Auto Mode

52 DEF Level 129

W

arning

206 Simulate Close Gen Engine Manual Freq Trim DPF Man Regen Request

Alarm

Requested

53 DEF Level Low RESERVED Speed Bias ECU Service Mode

64 DPF Non Mission 141 Load Freq Not Reached 218 System In Man Mode 130 207 Simulate Lamp Test

65 DPF Regen Active 142 Load Volts Not Reached 219 System In Stop Mode 54 Digital Input A 131 RESERVED 208 Simulate Mains Available

Governor Gain

66 DPF Regen Interlock 143 MPU Signal 220 55 Digital Input B 132 HEST Active 209 Simulate Manual

Temp

Loss Of System In Test Mode

67 144 221 56 Digital Input C 133 High Coolant E Trip 210 Simulate Open Gen

Temp

DPTC Filter Louvre Control Telemetry Active

High Coolant Sdn NOTE: If the editor is inactive for the duration of the LCD Page Timer, it is

Low Coolant Temp

Temp W

68 Droop Enable 145 222 Telemetry Data Active 57 Digital Input D 134 211 Simulate Start

High Coolant arning 212 automatically exited to ensure security.

69 146 Low Load 223 58 Digital Input E 135 Simulate Stop

Temp

ECU (ECM) Data Fail Temp Sensor OC

Low Oil Pressure Sdn Low Freq Alarm High Inlet Shutdown 213

Temp W

70 ECU (ECM) Power 147 224 59 Digital Input F 136 Simulate Test On Load

NOTE: The PIN number is automatically reset when exiting the editor

71 ECU (ECM) Shutdown 148 Low Oil Pressure Wng 225 Low Freq Warning 60 Digital Input G 137 High Inlet arning 214 Smoke Limiting

(manually or automatically) to ensure security.

72 149 226 Low Speed Alarm 61 Digital Input H 138 Inhibit Scheduled Run 215 Start Relay

Alarm

ECU (ECM) Stop Main Config Selected

73 ECU (ECM) Warning 150 Mains Closed Aux 227 Low Speed Warning 62 HTR Fitted and ON 139 kW Overload 216 Stop And Panel Lock

74 ECU Pre-Heat 151 Mains Failure 228 Wait For Man Restore Deep Sea Electronics Ltd. Deep Sea Electronics Inc.

gh Freq Abbreviation Table Overleaf Output Sources Continued Overleaf Tel: +1 (815) 316 8706

support@deepseaelectronics.com

75 EJP 1 152 Mains Hi 229 Water in Fuel Tel:+44 (0)1723 890099

Mains High Volts

Fax: +1 (815) 316 8708

76 EJP 2 153

www.deepseaelectronics.com USAsupport@deepsea electronics .com

www.deepseaelectronics.com

Abbreviation Table Overleaf Output Sources Continued Overleaf

MAIN CONFIGURATION EDITOR PARAMETERS Section Parameter As Shown On Display Section Parameter As Shown On Display Section Parameter As Shown On Display

Engine Battery Under Voltage Warning Delay Timers Start Delay Mains Fail Schedule Bank 1 Schedule 1 to 8

Continued Battery Over Voltage Warning [Enable] Continued Start Delay Telemetry Continued Schedule Period Bank 2

Battery Over Voltage Warning Return Mains Transient Delay Bank 2 Schedule 1 to 8

NOTE: Comprehensive module configuration is possible

using the DSE Configuration Suite PC Software, refer to DSE Battery Over Voltage Warning Cranking

publication 057-290 DSE61xx MKIII Configuration Suite PC Charge Alternator Failure Warning [Enable] Cranking Rest ABBREVIATION KEY TABLE

Software Manual available from www.deepseaelectronics.com. Charge Alternator Failure Warning Smoke Limiting

Abbreviation Meaning

Charge Alternator Failure Warning Delay Smoke Limiting Off

Alm Alarm

Charge Alternator Failure Shutdown [Enable] DPF Ramp

Wng Warning

Section Parameter As Shown On Display

Module Contrast

Charge Alternator Failure Shutdown Safety On Delay

Sdn Shutdown

Charge Alternator Failure Shut down Delay Warming E Trip Electrical Trip

Language

Current Date and Time

Low Battery Start [Enable] ECU Override

OC Open Circuit

Fast Loading

Low Battery Run On Load [Enable] Mains Transfer Time

Lo Low/Under

Low Battery Start Threshold Breaker Close Pulse

Hi High/Over

Warnings Latched

Lamp Test At Start Up

Low Battery Start Delay Breaker Trip Pulse

Alt Alternative

Low Battery Run Time Return Delay

Freq Frequency

Power Save Mode

Magnetic Pickup [Enable] Cooling Gen Generator

Backlight Power Saving

Flywheel Teeth Cooling At Idle

Ph Phase

Event Log Display Format

Maintenance Pin Protect

Generator AC System ETS Solenoid Hold Grey Coloured Item DSE6120 MKIII Only

Alternator Fitted Fail To Stop Delay

Cool Down In Stop Mode

Alternator Poles LCD Page Delay

Hold Start Button To Crank

REQUIREMENTS FOR UL CERTIFICATION

Under Voltage Alarm [Enable] LCD Scroll Delay

Power Up In Mode Specification Description

Under Voltage Alarm [Trip] Backlight Timer

Audible Alarm Timer Screw Terminal

Under Voltage Pre-Alarm [Enable] Sleep Timer

Suppress Instrument Gen erator Voltage Tightening 4.5 lb-in (0.5 Nm)

erator Frequency

Under Voltage Pre-Alarm [Trip] Audible Alarm

Torque

Suppress Instrument Gen

Under Voltage Delay CAN ECU Alternate Engine Speed

Conductors Terminals suitable for connection of conductor

Loading Voltage

Suppress Instrument Mains Voltage

ECU Data Fail

Suppress Instrument Mains Freq uency Nominal Voltage ECU Data Fail Action

size 13 AWG to 20 AWG (0.5 mm² to 2.5 mm²).

Conductor protection must be provided in

Suppress Instrument Current

Over Voltage Pre-Alarm [Enable] ECU Data Fail Delay accordance with NFPA 70, Article 240.

Suppress Instrument kW

Over Voltage Pre-Alarm Return Use Module Oil Pressure Low voltage circuits (35 V or less) must be

Suppress Instrument kvar

Over Voltage Pre-Alarm [Trip] Use Module Coolant Temp supplied from the engine starting battery or an

Suppress Instrument kVA

Over Voltage Shutdown [Trip] Use Module Engine Hours isolated secondary circuit.

Suppress Instrument Power Factor

Over Voltage Delay Use Module RPM The communication, sensor, and/or battery

Suppress Instrument kWh derived circuit conductors shall be separated

Under Frequency Alarm [Enable] Use Module Charge Alt

Suppress Instrument kvarh

Under Frequency Alarm [Trip] Maintenance Maintenance Alarm 1 [Enable] and secured to maintain at least ¼” (6 mm)

Maintenance Alarm 1 Action

Suppress Instrument kVAh separation from the generator and mains

Under Frequency Pre-Alarm [Enable] Alarms

Suppress Instrument Charge Alt ernator Under Frequency Pre-Alarm [Trip] Maintenance Alarm 1 Engine Hours

connected circuit conductors unless all

Alt Config Alternate Configuration

Under Frequency Delay Maintenance Alarm 1 On Due Date

conductors are rated 600 V or greater.

Engine Start Attempts

Loading Frequency Maintenance Alarm 1 Interval

Current Inputs Must be connected through UL Listed or

Recognized isolating current transformers with

Maintenance Alarm 2 [Enable]

Gas Engine Choke (Gas Engine Only)

Nominal Frequency

the secondary rating of 5 A max.

Maintenance Alarm 2 Action

Gas Engine Delay (Gas Engine Only)

Over Frequency Pre-Alarm [Enable]

Communication Must be connected to communication circuits of

Maintenance Alarm 2 Engine Hours

Circuits

Ignition off Delay (Gas Engine Only)

Over Frequency Pre-Alarm Return

UL Listed equipment.

Maintenance Alarm 2 On Due Date [Enable]

Crank Disconnect Oil Pressure

Over Frequency Pre-Alarm [Trip]

DC Output Pilot

Maintenance Alarm 2 Interval

Oil Pressure Check Prior to Starting 0.5 A

Over Frequency Shutdown [Trip]

Duty

Maintenance Alarm 3 [Enable]

Crank Disconnect Frequency

Over Frequency Delay

Mounting Suitable for flat surface mounting in Type 1

Maintenance Alarm 3 Action

Crank Disconnect Engine Speed

Frequency Overshoot Shutdown Enclosure Type rating with surrounding air

Crank Disconnect Oil Pressure

Frequency Overshoot Delay Maintenance Alarm 3 Engine Hours temperature -22 ºF to +122 ºF (-30 ºC to +50

Oil Pressure Low Shutdown

CT Location Maintenance Alarm 3 On Due Date [Enable] ºC).

Maintenance Alarm 3 Interval

Oil Pressure Low Pre-Alarm

CT Primary Suitable for pollution degree 3 environments

Coolant Temp Low Warning

Full Load R ating Outputs Digital Output A Source when voltage sensing inputs do not exceed 300

Coolant Temp High Pre-Alarm

Immediate Over Current [Enable] Digital Output A Polarity V. When used to monitor voltages over 300 V

Coolant Temp High Electrical Trip

Delayed Over Current [Enable] Digital Output B Source device to be installed in an unventilated or

Coolant Temp High Shutdown filtered ventilation enclosure to maintain a

Delayed Over Current Digital Output B Polarity

Fuel Usage Running Rate

Full Load kW Rating Digital Output C Source pollution degree 2 environment.

Fuel Usage Stopped Rate Operating

kW Overload Alarm [Enable] Digital Output C Polarity -22 ºF to +122 ºF (-30 ºC to +50 ºC)

Specific Gravity Temperature

kW Overload Alarm Action Digital Output D Source

Pre-Heat Temp

kW Overload Alarm Return Digital Output D Polarity

Pre-Heat Timer

kW Overload Alarm Trip Digital Output E Source

Post-Heat Temp kW Overload Alarm Delay Digital Output E Polarity

Post-Heat Timer Mains Mains Failure Detection Digital Output F Source

Droop [Enable]

DSE6120 Immediate Mains Dropout Digital Output F Polarity

Droop [Control] MKIII Only Under Voltage [Enable] Digital Output G Source

Under Speed Shutdown [Enable] Under Voltage Trip Digital Output G Polarity

Under Speed Shutdown [Trip] Under Voltage Return Digital Output H Source

Under Speed Warning [Enable] Over Voltage [Enable] Digital Output H Polarity

Under Speed Warning Over Voltage Return Digital Output I Source

Under Speed Delay Over Voltage Trip Digital Output I Polarity

Over Speed Warning [Enable]

Under Frequency [Enable] LCD Indicator 1 Source

Over Speed Warning

Under Frequency Trip LCD Indicator 1 Polarity

Over Speed Shutdown [Trip]

Under Frequency Return LCD Indicator 2 Source

Over Speed Delay

Over Frequency [Enable] LCD Indicator 2 Polarity

Overspeed Overshoot

Over Frequency Return LCD Indicator 3 Source

Overspeed Overshoot [Delay]

Over Frequency Trip Polarity

LCD Indicator 3

Battery Under Voltage Warning [Enable]

Timers Start Delay Off Load Schedule Schedule Enable

Battery Under Voltage Warning Start Delay On Load Schedule Period Bank 1

Battery Under Voltage Warning Return

You might also like

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- New DLL Physical ScienceDocument55 pagesNew DLL Physical ScienceGirl from the NorthNo ratings yet

- Murphy Autostart 700 PDFDocument2 pagesMurphy Autostart 700 PDFBEN100% (1)

- Aux101 Service ManualDocument98 pagesAux101 Service ManualKaiser lqbalNo ratings yet

- Leroy Somer AVR R250Document12 pagesLeroy Somer AVR R250Drago TuljNo ratings yet

- Esquema Electrico Perkins 2200 PDFDocument2 pagesEsquema Electrico Perkins 2200 PDFDaniel Graterol100% (9)

- GU610A Genset ControllerDocument33 pagesGU610A Genset ControllerNay SoeNo ratings yet

- HGM410 HGM420 V1.6 enDocument44 pagesHGM410 HGM420 V1.6 enDante Marcelo Obinu HidalgoNo ratings yet

- SDG25S-150S-6A Series Service ManualDocument109 pagesSDG25S-150S-6A Series Service ManualGoolshan BhugalooNo ratings yet

- Kubota SQ1120.SQ1150.SQ3140.SQ3200.SQ3300Document63 pagesKubota SQ1120.SQ1150.SQ3140.SQ3200.SQ3300Khaled Kamel100% (2)

- Operation Manual Dse 5220Document32 pagesOperation Manual Dse 5220Prudz75% (8)

- GU320Acontrol Panel Operation Manual - EN - A4Document23 pagesGU320Acontrol Panel Operation Manual - EN - A4presertec100% (3)

- Power Wizard 1.1 & 1.1+.xlsx: Download NowDocument5 pagesPower Wizard 1.1 & 1.1+.xlsx: Download NowFulgence Randrianirina67% (3)

- Avr As-440 Denyo PDFDocument1 pageAvr As-440 Denyo PDFRusmiyanto Yanto100% (1)

- WEG Automatic Voltage Regulator Grt7 Th4 r2 10001284109 Manual EnglishDocument78 pagesWEG Automatic Voltage Regulator Grt7 Th4 r2 10001284109 Manual Englisht8823pcNo ratings yet

- Power Command Digital Generator Set Control PCC1302: Cummins (Onan) Harness-Control 327-1617-01 0338-4978Document2 pagesPower Command Digital Generator Set Control PCC1302: Cummins (Onan) Harness-Control 327-1617-01 0338-4978Javier MongeNo ratings yet

- InteliCompact NT 1.4 Reference Guide r2Document272 pagesInteliCompact NT 1.4 Reference Guide r2Gustavo PereiraNo ratings yet

- Wiring Diagram DSE 7320 AMFDocument1 pageWiring Diagram DSE 7320 AMFIPS RSSK0% (2)

- SA - Separation System - Operating Instructions - 2002Document30 pagesSA - Separation System - Operating Instructions - 2002Centrifugal SeparatorNo ratings yet

- Deep Sea 4420 ManualDocument55 pagesDeep Sea 4420 ManualBara100% (1)

- InteliCompact NT 1.4r3 ManualDocument273 pagesInteliCompact NT 1.4r3 ManualYuri Da Gama Santos100% (4)

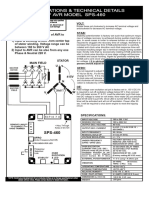

- Sps 460Document1 pageSps 460BrianHazeNo ratings yet

- Owner's Manual: Series 165 Automatic Transfer SwitchesDocument8 pagesOwner's Manual: Series 165 Automatic Transfer Switchespevare100% (1)

- Controlador ASM18G GrupoDocument16 pagesControlador ASM18G GrupowillyederccNo ratings yet

- Deep Sea 701 - 702Document2 pagesDeep Sea 701 - 702Anamul HoqueNo ratings yet

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFKo Thet100% (5)

- Governor Controller (GAC ESD5111) - DatasheetDocument5 pagesGovernor Controller (GAC ESD5111) - Datasheetazhan77No ratings yet

- Kit 8923-1061 - Woodward - 26272 - New PDFDocument3 pagesKit 8923-1061 - Woodward - 26272 - New PDFAlexandre100% (1)

- Emko Trans AMFDocument69 pagesEmko Trans AMFRahmat Nur IlhamNo ratings yet

- Multi-Instrument With Control and Protection Device For Genset Unit TYPE SPG-120/20Document12 pagesMulti-Instrument With Control and Protection Device For Genset Unit TYPE SPG-120/20lejocolsaNo ratings yet

- R448 Manual From Mac Far Lane GeneratorsDocument14 pagesR448 Manual From Mac Far Lane Generatorstocanh1990No ratings yet

- WOODWARD SPEED SW. ESSE-2 OnlyDocument24 pagesWOODWARD SPEED SW. ESSE-2 OnlyAnkit RedkarNo ratings yet

- Gencon II Pro FeaturesDocument6 pagesGencon II Pro FeaturesJessica Tatiana Muñoz OrtizNo ratings yet

- Avr Conversion InstructionsDocument2 pagesAvr Conversion InstructionsJose PirulliNo ratings yet

- HGM6110N 6120N 6110NC 6120NC 6110CAN 6120CAN En-1Document11 pagesHGM6110N 6120N 6110NC 6120NC 6110CAN 6120CAN En-1Marcos LunaNo ratings yet

- 8.1 Parameters Set List: KP310V1.0 Controller Operation ManualDocument5 pages8.1 Parameters Set List: KP310V1.0 Controller Operation ManualConstru Roca RentalNo ratings yet

- Figure 9: Powerwizard 2.0 Control Electrical ConnectionsDocument1 pageFigure 9: Powerwizard 2.0 Control Electrical ConnectionsAhsen EjazNo ratings yet

- InteliLite AMF20-25Document2 pagesInteliLite AMF20-25albertooliveira100% (2)

- Wiring Diagram DSE 7320 AMFDocument1 pageWiring Diagram DSE 7320 AMFIvan Alves100% (1)

- Dse5510 Diagram PDFDocument1 pageDse5510 Diagram PDFRodrigo ObregonNo ratings yet

- DSE6110 MKIII DSE6120 MKIII PC Software Manual PDFDocument184 pagesDSE6110 MKIII DSE6120 MKIII PC Software Manual PDFاحمدحسنالملاخضرNo ratings yet

- Deep Sea Electronics LTD.: Typical Wiring Diagram Output SourcesDocument2 pagesDeep Sea Electronics LTD.: Typical Wiring Diagram Output SourcesLuis Montagne100% (1)

- General Information: Drilling Template (MM)Document4 pagesGeneral Information: Drilling Template (MM)Bruno MarianoNo ratings yet

- Gu601a En0507 PDFDocument30 pagesGu601a En0507 PDFChhoan Nhun100% (3)

- P 704Document2 pagesP 704presertec67% (3)

- Wiring Diagram Dse 7320 Amf PDF FreeDocument1 pageWiring Diagram Dse 7320 Amf PDF FreeSemih GençNo ratings yet

- Auto Start & Auto Mains Failure Control Modules: GensetDocument3 pagesAuto Start & Auto Mains Failure Control Modules: Gensetalexander3233No ratings yet

- Lixise lxc6310Document33 pagesLixise lxc6310Hector CabreraNo ratings yet

- ME AGS N Hardy Diesel HDYW Series Generators With M6 Contol Panel Rev 8 19 2011 PDFDocument1 pageME AGS N Hardy Diesel HDYW Series Generators With M6 Contol Panel Rev 8 19 2011 PDFAyub WaskitoNo ratings yet

- Powerwizard 2.0: Total ControlDocument2 pagesPowerwizard 2.0: Total Controliko57No ratings yet

- DSE6110 MKII DSE6120 MKII Installation InstructionsDocument2 pagesDSE6110 MKII DSE6120 MKII Installation InstructionsBJNE01100% (1)

- DYN110794 Technical BulletinDocument4 pagesDYN110794 Technical BulletinGolbert GolbiNo ratings yet

- GU304 Device: ManualDocument27 pagesGU304 Device: ManualRODRIGO_RALONo ratings yet

- 8610 AxfDocument6 pages8610 Axfbruno magalhãesNo ratings yet

- Akai 265dDocument2 pagesAkai 265dVagabundi GackenholzNo ratings yet

- 11 AlarmsDocument62 pages11 AlarmsvaldoNo ratings yet

- SG770 WSM-3200 Control PanelDocument13 pagesSG770 WSM-3200 Control Panelrkss100% (1)

- TC Ka3esDocument72 pagesTC Ka3esChen FrankNo ratings yet

- DTC P0325 Knock Sensor 1 Circuit MalfunctionDocument3 pagesDTC P0325 Knock Sensor 1 Circuit MalfunctionErln LimaNo ratings yet

- Image For Illustrative Purposes Only..: Generating Set Model (Pm165)Document2 pagesImage For Illustrative Purposes Only..: Generating Set Model (Pm165)Anamta KhanNo ratings yet

- Amf Relay CatalogDocument2 pagesAmf Relay CatalogShoeb ShaikhNo ratings yet

- Automático Schneider Ic60 - A9F44340Document2 pagesAutomático Schneider Ic60 - A9F44340jorgeNo ratings yet

- Allen Bradley AB 1763 L16BWA PDFDocument4 pagesAllen Bradley AB 1763 L16BWA PDFjorgeNo ratings yet

- Industrial Cellular VPN Router NR500 Pro User Manual: Guangzhou Navigateworx Technologies Co, LTDDocument79 pagesIndustrial Cellular VPN Router NR500 Pro User Manual: Guangzhou Navigateworx Technologies Co, LTDjorgeNo ratings yet

- DSE4610 DSE4620 Installation Instructions PDFDocument2 pagesDSE4610 DSE4620 Installation Instructions PDFjorge100% (1)

- DSE892 Data Sheet (USA) PDFDocument2 pagesDSE892 Data Sheet (USA) PDFjorgeNo ratings yet

- Annotation and Back AnnotationDocument3 pagesAnnotation and Back AnnotationFirdaus AlamNo ratings yet

- Rapport Fra UL International GermanyDocument32 pagesRapport Fra UL International GermanyIngenioerenNo ratings yet

- Xiaomi MI4c SchematicDocument39 pagesXiaomi MI4c SchematicArifinNo ratings yet

- How My FXC Camera Works?Document2 pagesHow My FXC Camera Works?malileoNo ratings yet

- IEEE STD 259-1999 PDFDocument18 pagesIEEE STD 259-1999 PDFEdwin CapdepomtNo ratings yet

- Siemens Air Cooled Generators Sgen 100a 4p Brochure PDFDocument4 pagesSiemens Air Cooled Generators Sgen 100a 4p Brochure PDFEduar Andres Orozco CardenasNo ratings yet

- School: SMK Methodist (Acs) Ipoh Name:Bawen S/O Muralitharan Class: 2B Teacher: en Nik Syzuan Title: Computer SystemDocument19 pagesSchool: SMK Methodist (Acs) Ipoh Name:Bawen S/O Muralitharan Class: 2B Teacher: en Nik Syzuan Title: Computer SystemBawen MuralitharanNo ratings yet

- Ec8691 Unit Iv - PPTDocument49 pagesEc8691 Unit Iv - PPTVinothkumar UrumanNo ratings yet

- 9 - MEP Works Expertise - Design and Interface Management - HVAC, FPS, LSP, OHT CraneDocument2 pages9 - MEP Works Expertise - Design and Interface Management - HVAC, FPS, LSP, OHT CraneYass AhmedNo ratings yet

- Verilog Basics Simple Things Coding Examples: Lazanyi@mit - Bme.huDocument1 pageVerilog Basics Simple Things Coding Examples: Lazanyi@mit - Bme.hurasagna sarangaNo ratings yet

- f16 Module 7 Optical AmplifiersDocument43 pagesf16 Module 7 Optical AmplifiersGuillermo Castillo MarmolNo ratings yet

- Teledyne - Junction FETs Theory and Applications PDFDocument96 pagesTeledyne - Junction FETs Theory and Applications PDFDomenico BarillariNo ratings yet

- Specifications Audio Power Specifications EspecificacionesDocument4 pagesSpecifications Audio Power Specifications EspecificacionesRobertoTealdiNo ratings yet

- Chapter 3c X Ray DiffractionDocument40 pagesChapter 3c X Ray DiffractiondhandametNo ratings yet

- Omd E-M1 Mark II Quick Guide enDocument12 pagesOmd E-M1 Mark II Quick Guide engepallNo ratings yet

- Medidor Caudal Kobold BGFDocument6 pagesMedidor Caudal Kobold BGFBase SistemasNo ratings yet

- Current Transport Studies of N-Zno/P-Si Hetero-Nanostructures Grown by Pulsed Laser DepositionDocument9 pagesCurrent Transport Studies of N-Zno/P-Si Hetero-Nanostructures Grown by Pulsed Laser DepositionInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- BSNL 3G Setting GujaratDocument24 pagesBSNL 3G Setting GujaratDr. Rakshit SolankiNo ratings yet

- Opacimetro Sensors LCS2400 PDFDocument2 pagesOpacimetro Sensors LCS2400 PDFvictorino044No ratings yet

- Full Chapter Operational Amplifiers Theory and Design 3Rd Edition Johan Huijsing Auth PDFDocument53 pagesFull Chapter Operational Amplifiers Theory and Design 3Rd Edition Johan Huijsing Auth PDFtony.harrell377No ratings yet

- Was Shown As: Was Shown As: Was Shown As: Was Shown AsDocument17 pagesWas Shown As: Was Shown As: Was Shown As: Was Shown AsDharamvir Singh Choudhari67% (3)

- Cutler-Hammer Instructions For Installation, Operation and Maintenance of Type DHP-VR Vaccum Replacement Circuit Breakers For DHP SwitchgearDocument49 pagesCutler-Hammer Instructions For Installation, Operation and Maintenance of Type DHP-VR Vaccum Replacement Circuit Breakers For DHP Switchgearfafejaya13No ratings yet

- Compliance 34Document4 pagesCompliance 34midhunvarNo ratings yet

- Note: L: Lecture, P: Practical, ESE: End Semester ExaminationDocument30 pagesNote: L: Lecture, P: Practical, ESE: End Semester ExaminationAditya NisalNo ratings yet

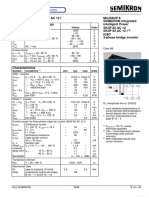

- SKIIP82AC12 SemikronDocument5 pagesSKIIP82AC12 SemikronMuhammad azeemNo ratings yet

- ZQX600 桥式抓斗卸船机 用户手册 ZQX600 Bridge-type Grab ship Unloader Users' ManualDocument29 pagesZQX600 桥式抓斗卸船机 用户手册 ZQX600 Bridge-type Grab ship Unloader Users' ManualArnold StevenNo ratings yet

- I/O Basics: Ports Data, Control, and Status BitsDocument11 pagesI/O Basics: Ports Data, Control, and Status BitsNikhil GobhilNo ratings yet

- Hardware & Software InterruptsDocument33 pagesHardware & Software InterruptsShubham BakshiNo ratings yet

- Trihal TransformerDocument4 pagesTrihal Transformerhino_kaguNo ratings yet