Professional Documents

Culture Documents

Adj Slack Adjuster

Adj Slack Adjuster

Uploaded by

EndraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adj Slack Adjuster

Adj Slack Adjuster

Uploaded by

EndraCopyright:

Available Formats

10:02-14

Issue 1 en

Wheel brake components brake

slack adjusters

Work Description

© Scania CV AB 2001, Sweden

1 713 016

Contents

Contents

Brake slack adjuster, manual

adjustment Removal.................................................................... 3

Fitting ....................................................................... 3

Setting....................................................................... 4

Brake slack adjuster, automatic

adjustment Removal.................................................................... 6

Fitting ....................................................................... 6

Setting....................................................................... 7

Reconditioning ......................................................... 9

© Scania CV AB 2001, Sweden

2 10:02-14

Brake slack adjuster, manual adjustment

Work Description

Brake slack adjuster, manual adjustment

Removal

1 Remove the split pin and pivot pin 3 on the

brake chamber push rod.

2 Remove bolt 2, which holds the brake slack

adjuster, and remove wear indicator 1.

3 Remove the brake slack adjuster.

Fitting

1 Fit the brake slack adjuster to the brake

eccentric shaft so that the arrow on the

adjuster shows the direction it will move

during braking.

2 Fit wear indicator 1 and bolt 2 which hold

the brake slack adjuster. With new brake

linings, the wear indicator should point hori-

zontally.

3 Fit pivot pin 3 and the split pin to the brake

chamber push rod.

4 Check push rod basic setting and, if requi-

red, adjust the brake slack adjuster, see

Adjustment.

© Scania CV AB 2001, Sweden

10:02-14 3

Brake slack adjuster, manual adjustment

Setting

Measuring push rod basic setting 6 Calculate stroke length L2 = L1 - L.

7 If the stroke length exceeds the maximum

Description

permissible, the brake slack adjuster must

1 Release the parking brake pressure by at be adjusted. See Adjusting.

least 6 bar.

2 Remove the pivot pin from the push rod link

yoke.

3 Measure basic setting L, adjust if required.

4 Fit the pivot pin.

5 Fully depress the brake pedal. Measure

brake position L1.

Cylinder size Outer diameter Basic setting L Brake Stroke

(above strap) position L1 length L2

16 165 mm 69-71 mm 94-115 mm 25-44 mm

20 176 mm 69-71 mm 94-115 mm 25-44 mm

24 186 mm 69-71 mm 94-115 mm 25-44 mm

30 210 mm 69-71 mm 99-122 mm 30-51 mm

24 at the rear of 186 mm 214-216 mm 239 - 260 mm 25 - 44 mm

HK and all

30 wheel drive 210 mm 214-216 mm 244 - 267 mm 30 - 51 mm

vehicles

24 on the second 186 mm 259-261 mm 284 - 305 mm 25 - 44 mm

rear axle on 6x4

30 heavy-duty 210 mm 259-261 mm 289 - 321 mm 30 - 51 mm

tractors

© Scania CV AB 2001, Sweden

4 10:02-14

Brake slack adjuster, manual adjustment

Adjusting

Brake slack adjusters with manual adjustment

must be adjusted as brake linings can wear.

1 Lift up the axle.

2 Check brake chamber stroke length. See

Measuring push rod basic setting.

3 Rotate the wheel whilst pressing in lock

sleeve 1 and fitting adjusting screw 2.

4 When the wheel cannot be rotated manually,

unscrew the adjusting screw a half turn so

that the brake lining comes free from the

brake drum.

Note: Ensure that lock sleeve 1 comes out and

locks the adjusting screw.

© Scania CV AB 2001, Sweden

10:02-14 5

Brake slack adjuster, automatic adjustment

Brake slack adjuster, automatic adjustment

Removal

1 Remove the split pin and pivot pin 4 on the

brake chamber push rod.

2 Remove bolt 3, which holds the brake slack

adjuster, and remove wear indicator 2.

3 Remove the nut or bolt holding guide arm 1.

Remove the brake slack adjuster.

Fitting

1 Fit the brake slack adjuster to the brake

eccentric shaft so that the arrow on the

adjuster shows the direction it will move

during braking.

2 Fit wear indicator 2 and bolt 3 which hold

the brake slack adjuster. With new brake

linings, wear indicator 2 should point hori- 1 Steering arm

zontally. 2 Wear indicator

3 Screw

3 Fit pivot pin 4 and the split pin to the brake

chamber push rod. 4 Pivot pin

4 Check push rod basic setting, see Setting,

Measuring push rod basic setting.

© Scania CV AB 2001, Sweden

6 10:02-14

Brake slack adjuster, automatic adjustment

Setting

Measuring push rod basic setting 5 Fully depress the brake pedal. Measure

brake position L1.

Description 6 Calculate stroke length L2 = L1 - L.

1 Release the parking brake pressure by at

least 6 bar.

2 Remove the pivot pin from the push rod link

yoke.

3 Measure basic setting L, adjust if required.

4 Fit the pivot pin.

Cylinder size Outer diameter Basic setting L Brake Stroke

(above strap) position L1 length L2

16 165 mm 69-71 mm 94-115 mm 25-44 mm

20 176 mm 69-71 mm 94-115 mm 25-44 mm

24 186 mm 69-71 mm 94-115 mm 25-44 mm

30 210 mm 69-71 mm 99 -122 mm 30-51 mm

24 at the rear of 186 mm 214-216 mm 239 - 260 mm 25 - 44 mm

HK and all

30 wheel drive 210 mm 214-216 mm 244 - 267 mm 30 - 51 mm

vehicles

24 on the second 186 mm 259-261 mm 284 - 305 mm 25 - 44 mm

rear axle on 6x4

30 heavy-duty 210 mm 259-261 mm 289 - 312 mm 30 - 51 mm

tractors

© Scania CV AB 2001, Sweden

10:02-14 7

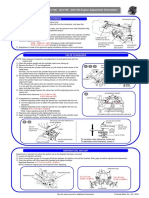

Brake slack adjuster, automatic adjustment

Adjusting

1 Raise the relevant wheel. Place chocks in

front of and behind at least two wheels and

release the parking brake.

2 Unscrew support pin 2 through the rectang-

ular hole in guide arm 1. Adjust the position

L

of the slack adjuster by turning worm screw

3 until the hole for pin 5 in the slack adjuster

coincides with push rod link yoke 4. Fit

pivot pin 5.

3 Press guide arm 1 in direction A until there 4 5

is a stop in brake direction.

Note: Check that the basic setting

(measurement L) remains unchanged during

3

adjustment.

6

1

4 Lock support pin 2 with the lock nut. 2

10 2439

5 Lock the guide arm with a washer and bolt

A

or nut.

6 Turn the eccentric shaft with worm screw 3 1 Steering arm

clockwise at the same time as the wheel 2 Support pin

spins. Turn until the lining is in contact with 3 Worm screw

the brake drum (the wheel cannot be rotated

manually). 4 Link yoke

5 Pivot pin

7 Turn the worm screw 3/4 of a turn anti- 6 Wear indicator

clockwise. The brake slack adjuster now has

its basic setting. A = Direction of rotation for steering arm

L = Basic setting

Note: The worm screw may only be turned

using a hand tool.

8 Apply the parking brake and lower the

wheel.

© Scania CV AB 2001, Sweden

8 10:02-14

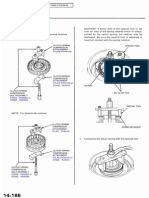

Brake slack adjuster, automatic adjustment

Reconditioning

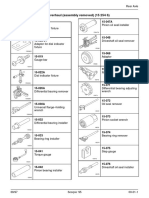

Overview, brake slack adjuster with automatic adjustment

1 Bushing 12 Rivet

2 Front cap 13 Compression springs

3 Needle bearing 14 Disc plug

4 One-way coupling 15 Rack

5 Bushing 16 O-ring

6 O-ring 17 Worm gear

7 Worm screw 18 O-ring

8 Grease nipple/plug 19 Gasket

9 Thrust washer 20 Guide plate

10 Compression spring 21 Screw

11 Rear cap 22 Steering arm

© Scania CV AB 2001, Sweden

10:02-14 9

Brake slack adjuster, automatic adjustment

Dismantling the brake slack adjuster

Special tools

No. Description Illustration Tool board

98 237 Fork spanner, included in B1

98 232

98 239 Spacer ring, included in B1

98 232

98 557 Drift, included in 98 232 B1

© Scania CV AB 2001, Sweden

10 10:02-14

Brake slack adjuster, automatic adjustment

Dismantling

1 Clean the brake slack adjuster. 2

3 4

© Scania CV AB 2001, Sweden

10:02-14 11

Brake slack adjuster, automatic adjustment

5 Remove the spring-loaded rack. 6

7 8 First remove the rivet and then unscrew and

remove the rear cap.

© Scania CV AB 2001, Sweden

12 10:02-14

Brake slack adjuster, automatic adjustment

9 10 First remove the rivet and then unscrew the

front cap. Use tool 98 237.

11 12 Press out the bushing and worm screw

© Scania CV AB 2001, Sweden

10:02-14 13

Brake slack adjuster, automatic adjustment

13 14

15 Knock out the bushing.

© Scania CV AB 2001, Sweden

14 10:02-14

Brake slack adjuster, automatic adjustment

Cleaning and checking

Specifications

Tolerances

Maximum diameter in the worm gear hole (wear limit) 62.20 mm

Minimum outside diameter of worm gear 61.87 mm

Maximum clearance for guide arm gear teeth 0.4 mm

© Scania CV AB 2001, Sweden

10:02-14 15

Brake slack adjuster, automatic adjustment

1 Clean all parts and examine them carefully. 2 Replace worn and damaged parts. Always

The oil grooves should be open and clean. replace the following parts:

3 Check the inside diameter with a dial gauge 4 The surface should be smooth, as indicated

for internal measurement. on the left.

Note: Check points 3-9 particularly carefully.

© Scania CV AB 2001, Sweden

16 10:02-14

Brake slack adjuster, automatic adjustment

5 The worm gear outside gear teeth must not 6 Check the diameter on both the upper and

be deformed. Replace with a new worm lower edge of the worm gear.

gear if the gear teeth are deformed.

7 The clearance on the guide plate gear teeth 8 Check that the guide plate arm is firmly

should not exceed 0.4 mm. secured. There should be no play.

© Scania CV AB 2001, Sweden

10:02-14 17

Brake slack adjuster, automatic adjustment

9 Rack mounting 1, which engages with guide

plate 2, should not be worn.

© Scania CV AB 2001, Sweden

18 10:02-14

Brake slack adjuster, automatic adjustment

Assembly of brake slack adjuster

Specifications

Tolerances

Maximum diameter in the worm gear hole (wear limit) 62.20 mm

Axial clearance for worm screw 0.15 -0.60 mm

Minimum tooth height of cone clutch in one-way coupling. 0.08 mm

Tightening torque

Front cap 50 Nm

Special tools

No. Description Illustration Tool board

98 075 Dial gauge D2

98 234 Accessory to dial gauge, B1

Included in 98 232

98 240 Wrench, included in 98 232 B1

99 009-2 Drift 99 009 -

115 368

99 194 99 009−2

99 009−1

98 237 Fork spanner, included in B1

98 232

© Scania CV AB 2001, Sweden

10:02-14 19

Brake slack adjuster, automatic adjustment

Assembly

1 Grease all parts with chassis lubricant. 2 The worm gear flange should face outwards.

3 4 Press in the bushing over the worm screw.

© Scania CV AB 2001, Sweden

20 10:02-14

Brake slack adjuster, automatic adjustment

5 Check that the worm gear rotates 1 turn, 6 Check that the engaging sleeve and lock

when 22 turns are made on the worm screw. sleeve are in contact with each other.

7 Tighten the front cap to 50 Nm. 8 Fit the special tool.

© Scania CV AB 2001, Sweden

10:02-14 21

Brake slack adjuster, automatic adjustment

9 If the clearance is outside the limits the one- 10

way coupling and worm screw should be

replaced.

11 Knock in the disc plug. 12

Note! Make sure that the plug goes right down

to the bottom and that it does not get twisted.

© Scania CV AB 2001, Sweden

22 10:02-14

Brake slack adjuster, automatic adjustment

13 14

15 Screw in the rear cover 4 turns. 16 Set the spring force, see Setting the brake

slack adjuster spring force.

© Scania CV AB 2001, Sweden

10:02-14 23

Brake slack adjuster, automatic adjustment

Setting the brake slack adjuster spring force

Specifications

Pretensioning

Helical spring pretensioning 3530-3730 N

Special tools

No. Description Illustration Tool board

98 236 Setting tool B1

Included in 98 232

99 214 Hexagonal grip B1

Included in 98 232

99 417 Adapter for grease filling B1

Included in 98 232

99 418 Guide plate B1

Included in 98 232

© Scania CV AB 2001, Sweden

24 10:02-14

Brake slack adjuster, automatic adjustment

Setting

1 Use setting tool 98 236 to set the spring 2

force.

3 The guide arm must be positioned facing 4 Load the adjuster until the pressure gauge

towards the pressure gauge, otherwise there reads like the sensor by the arrow in the

will not be enough space to set the brake illustration.

slack adjuster spring force. If necessary,

replace guide plate with tool 99 418. Adjust

the spring force in accordance with points

4-10. Then change back to the original

guide arm.

© Scania CV AB 2001, Sweden

10:02-14 25

Brake slack adjuster, automatic adjustment

5 Turn the guide arm so that the rack in the 6 Load the brake slack adjuster further until

slack adjuster is pushed up into its groove. the pressure gauge enters the red marking.

The guide arm should then go back to the

starting position when the cone clutch is

released. If the guide arm goes slowly, it

may be necessary to move it back with

slight pressure (with the finger).

7 If the guide arm goes back when the pres- 8 Release the pressure on the slack adjuster.

sure gauge indicator is outside the red mar-

king, the force is adjusted by tightening or

loosening the rear cap.

© Scania CV AB 2001, Sweden

26 10:02-14

Brake slack adjuster, automatic adjustment

9 Repeat points 6-8 until the correct clutch 10

force is obtained on two measurements.

11 Fill with grease until grease comes out at the 12 Install a new bushing.

point marked with an arrow. If there is no

grease nipple, use grease filling adapter

99 417

© Scania CV AB 2001, Sweden

10:02-14 27

You might also like

- Manual Oficina c4.2 c6.4 CaterpillaDocument177 pagesManual Oficina c4.2 c6.4 CaterpillaIvo Silva89% (53)

- MANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsDocument24 pagesMANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsLUIS SAENZ100% (6)

- Sherlock Holmes PuzzlesDocument132 pagesSherlock Holmes PuzzlesBabu Khan90% (10)

- Worksheet For Unsent Letter GuideDocument5 pagesWorksheet For Unsent Letter GuidesharklasNo ratings yet

- Scania HPI System EDCDocument29 pagesScania HPI System EDCnoran100% (2)

- SCANIA Suspension BT300 Work DescDocument44 pagesSCANIA Suspension BT300 Work DescHeri SuryoNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Document200 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- 2012 Components Technical Manual UkDocument154 pages2012 Components Technical Manual UkBrummerNo ratings yet

- 2 Steering Axle: Technical Manual Publ. No. 6193.007 1217Document20 pages2 Steering Axle: Technical Manual Publ. No. 6193.007 1217----100% (1)

- Boxxer Race Tuning GuideDocument11 pagesBoxxer Race Tuning GuideJorge Eduardo Jaramillo CortesNo ratings yet

- KIA Sorento ManualDocument1,349 pagesKIA Sorento ManualSteven AmadorNo ratings yet

- Part 206 Brake SystemDocument118 pagesPart 206 Brake SystemHugo DelagarzaNo ratings yet

- Clutch: Precautions and Preparation Operating CylinderDocument16 pagesClutch: Precautions and Preparation Operating CylinderGuillermo Alexamder Sanchez YbañezNo ratings yet

- 2D Задняя подвескаDocument10 pages2D Задняя подвескаtankg1000No ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: Sectiontipo3331No ratings yet

- Toyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairDocument17 pagesToyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairWenceslao Francisco Mejía EspinozaNo ratings yet

- Brake JMC CamionetaDocument63 pagesBrake JMC CamionetaRusonegroNo ratings yet

- 4 SteerDocument6 pages4 Steeryared abebeNo ratings yet

- User Manual Bos Deville 2014 EngDocument9 pagesUser Manual Bos Deville 2014 EngAndrei MosoraNo ratings yet

- FR20 3 Chassis Partie3 enDocument30 pagesFR20 3 Chassis Partie3 enEdmond MarkovitsNo ratings yet

- Service Manual Yamaha Scorpio Chapter 6 ChasisDocument50 pagesService Manual Yamaha Scorpio Chapter 6 Chasisjolang46No ratings yet

- Section 90: Pedal and Pedal Switch AdjustmentsDocument24 pagesSection 90: Pedal and Pedal Switch Adjustmentsjeffrey pelletierNo ratings yet

- Suspension PDFDocument66 pagesSuspension PDFManny AybarNo ratings yet

- HAIMA 7 Service Manual (MT) - H Clutch PDFDocument7 pagesHAIMA 7 Service Manual (MT) - H Clutch PDFjhon greigNo ratings yet

- Honda HRA214 Quick AdjustDocument1 pageHonda HRA214 Quick AdjusthicksdpNo ratings yet

- Ajuste Valvula 3176CDocument3 pagesAjuste Valvula 3176CAdelio RamirezNo ratings yet

- 4hp14 at ManualDocument52 pages4hp14 at ManualAzmi MushoffaNo ratings yet

- Kawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndDocument41 pagesKawasaki KLX110 & KLX110L Service Repair Manual - Chapter 4 - Engine Top EndbarackkNo ratings yet

- Air Suspention Work DescriptionDocument52 pagesAir Suspention Work DescriptionHari100% (1)

- The Others: Check Wear and Tear, Flab of The Bucket TeethDocument17 pagesThe Others: Check Wear and Tear, Flab of The Bucket TeethPreett Rajin MenabungNo ratings yet

- 2010 - 11 - 08 US GCV135 160 Engine Adjustment Information - Xls - 2010 - 11 - 08 General GCV135 - 160 - 190 GSV190 Engine Adjustment IDocument1 page2010 - 11 - 08 US GCV135 160 Engine Adjustment Information - Xls - 2010 - 11 - 08 General GCV135 - 160 - 190 GSV190 Engine Adjustment Ipeter smithNo ratings yet

- Manual Transmission 5 SpeedDocument12 pagesManual Transmission 5 Speedav1135100% (1)

- nrc0083-3 Aurum Suspension-Setup Document 001Document8 pagesnrc0083-3 Aurum Suspension-Setup Document 001DAVID BERJANONo ratings yet

- 6 Cylinder Head - ValveDocument14 pages6 Cylinder Head - ValveSaraNo ratings yet

- zxr400 H 04Document23 pageszxr400 H 04hugo_bikerNo ratings yet

- Secoroc FT 160BC Pusher Leg: Secoroc Rock Drilling ToolsDocument12 pagesSecoroc FT 160BC Pusher Leg: Secoroc Rock Drilling Toolsjosh1419No ratings yet

- BA STEYR EVO 10 en PDFDocument26 pagesBA STEYR EVO 10 en PDFAnwar Anwar100% (1)

- Toyota Tundra (2UZ FE) 2002Document16 pagesToyota Tundra (2UZ FE) 2002Isaac Castillo100% (1)

- 204 - 00 Suspension SystemDocument4 pages204 - 00 Suspension Systemtechnical trainer 011cNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

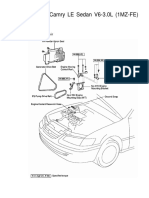

- Toyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument14 pagesToyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairEutério SilvaNo ratings yet

- Suspension AxleDocument97 pagesSuspension AxleLoc TruongNo ratings yet

- Diff OverhaulDocument22 pagesDiff Overhaul2791957No ratings yet

- Toyota Truck SequoiaDocument16 pagesToyota Truck SequoiaD3NYNo ratings yet

- Rear Drum Brakes: Section: 4E2Document12 pagesRear Drum Brakes: Section: 4E2Rafael HernandezNo ratings yet

- Engine Valve Lash - Inspect Adjust (SENR9939-32)Document3 pagesEngine Valve Lash - Inspect Adjust (SENR9939-32)Guido Emanuel SteinbachNo ratings yet

- 605 00 242 AWL Tuning Guide RevBDocument12 pages605 00 242 AWL Tuning Guide RevBJuju RafaelNo ratings yet

- Toyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairDocument15 pagesToyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairyosnielNo ratings yet

- Arranque de Patada CBFDocument23 pagesArranque de Patada CBFlau cv 97No ratings yet

- DRF400 450 WorkshopDocument173 pagesDRF400 450 Workshopraul perez100% (1)

- User Manual GazelleDocument52 pagesUser Manual GazellejeretikaNo ratings yet

- Toyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument15 pagesToyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairFrancisco Guillen-DorantesNo ratings yet

- Suspension ZF RCU Manual Final AutosavedDocument57 pagesSuspension ZF RCU Manual Final AutosavedTiago ZeferinoNo ratings yet

- 34sPACE WAGONDocument20 pages34sPACE WAGONrafaelcruzgjaNo ratings yet

- Suspension and AxleDocument127 pagesSuspension and AxledwcdiscoNo ratings yet

- Kayaba Forks Workshop Manual - Off-Road-Eng-61e529a6c44f0Document64 pagesKayaba Forks Workshop Manual - Off-Road-Eng-61e529a6c44f0Aleš ZaverlaNo ratings yet

- Monark AB 828E Ergomedic Instruction ManualDocument28 pagesMonark AB 828E Ergomedic Instruction ManualtvmNo ratings yet

- Caja Direccion 2007 Dodge RamDocument19 pagesCaja Direccion 2007 Dodge RamBSVolcanNo ratings yet

- Rear SuspensionDocument15 pagesRear SuspensionRuth Nora García IzaguirreNo ratings yet

- 2001 Boxxer Manual 4Document17 pages2001 Boxxer Manual 4Róbert ŠintajNo ratings yet

- Section 41 - Steering - Chapter 1Document34 pagesSection 41 - Steering - Chapter 1npero2No ratings yet

- Steering Your Skis - Part 1: Ski Performance Breakthrough, #2From EverandSteering Your Skis - Part 1: Ski Performance Breakthrough, #2Rating: 3 out of 5 stars3/5 (1)

- Neo CheatingDocument147 pagesNeo Cheatingxavros100% (1)

- General Instruction Manual HamiltonDocument100 pagesGeneral Instruction Manual HamiltonDonato AndriaNo ratings yet

- Pilihlah Salah Satu Jawaban Yang Paling Tepat! Questions 1 To 4. Questions 5 To 7. DirectionsDocument8 pagesPilihlah Salah Satu Jawaban Yang Paling Tepat! Questions 1 To 4. Questions 5 To 7. DirectionsAgung WidyonoNo ratings yet

- Form 2 English TIME: 15 Minutes Listening Comprehension: Levels 5 - 6 - 7Document12 pagesForm 2 English TIME: 15 Minutes Listening Comprehension: Levels 5 - 6 - 7Kom Mathi BalaNo ratings yet

- Demon God Dragon Ball Wiki FandomDocument1 pageDemon God Dragon Ball Wiki FandomJaydenNo ratings yet

- TrainspottingDocument3 pagesTrainspottingMariaSoldi0% (1)

- Renu Yarn List: Type Quality Brightness Country of Origin MOQDocument4 pagesRenu Yarn List: Type Quality Brightness Country of Origin MOQSharif0721No ratings yet

- Led TV: ServiceDocument43 pagesLed TV: ServicesunnyNo ratings yet

- HalltechDocument1 pageHalltechLeonardo Villarroel100% (1)

- Problem Set 8Document3 pagesProblem Set 8Le MoustierNo ratings yet

- 02.0 PP II IV Music Since 1900Document6 pages02.0 PP II IV Music Since 1900Marisa KwokNo ratings yet

- ICSE Computer ProjectDocument51 pagesICSE Computer ProjectManish Agarwal75% (4)

- The World Is An AppleDocument27 pagesThe World Is An AppleGeorge George100% (1)

- Chloe - TMD Diet Chart July 2022Document2 pagesChloe - TMD Diet Chart July 2022Aditya GandhiNo ratings yet

- SBG Magazine Issue 3 Digital EditionDocument48 pagesSBG Magazine Issue 3 Digital EditionAhmed Abdul100% (5)

- 99 IC Projects 1984Document98 pages99 IC Projects 1984RAUL RENDONNo ratings yet

- Future of Animation Industry in India: Presented by Nimish Pant PGDM 2010-12 BatchDocument19 pagesFuture of Animation Industry in India: Presented by Nimish Pant PGDM 2010-12 BatchThe Bhaukali GyanNo ratings yet

- Day MagicDocument8 pagesDay MagicKaushik Ram SNo ratings yet

- DataSheet XNP-6320HS 180115Document1 pageDataSheet XNP-6320HS 180115Bobby NguyenNo ratings yet

- Systemd Cheatsheet PDFDocument1 pageSystemd Cheatsheet PDFcarlesplaNo ratings yet

- Fa A201 SBB3014Document2 pagesFa A201 SBB3014Cornelius Olsa Anak OlberntNo ratings yet

- Epp 5 - 4MTDocument4 pagesEpp 5 - 4MTRaina Gail B. MercadoNo ratings yet

- viếtDocument5 pagesviếtNhư Dương Thị QuỳnhNo ratings yet

- Fujitsu LifeBook T4220 Notebook PCDocument10 pagesFujitsu LifeBook T4220 Notebook PCUchen JeffrieNo ratings yet

- Peter Wollen - The Two Avant-GardesDocument9 pagesPeter Wollen - The Two Avant-Gardesdoragreenissleepy100% (2)

- XN-10!11!20 21 E Inst ChecklistDocument5 pagesXN-10!11!20 21 E Inst ChecklistHadiNo ratings yet

- An Open Letter To My Fellow GraduatesDocument3 pagesAn Open Letter To My Fellow GraduatesAlfonso DimlaNo ratings yet

- The Elephant ManDocument32 pagesThe Elephant ManNORITA AHMADNo ratings yet