Professional Documents

Culture Documents

Find the Right Cut-Off Wheel for Your Material

Uploaded by

Chris ZocOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Find the Right Cut-Off Wheel for Your Material

Uploaded by

Chris ZocCopyright:

Available Formats

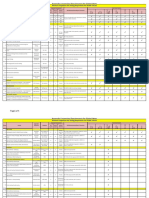

SELECTION GUIDE FOR CUT-OFF WHEELS

HV

2000

More ductile materials

More brittle materials

Mounted materials, predominately resin

Select the correct 1400

cut-off wheel

1. Go upwards on the y-axis of the overview to the right

until you find the hardness value of your material. 1000

2. Move to the right, until you cross the cut-off wheel that

fits your application. If you only have one material to cut,

find the wheel where your material’s hardness is placed 700

as close to the middle as possible. For two or more

materials, see if you can find a wheel that covers the

whole hardness range. The bars that fade out at the

bottom represent wheels that can be used for lower

500

hardness also. However, this is not a very economical

solution, and it should only be used in exceptional cases.

3. Find the number (I-XI) of the respective wheel, and see

the table below for the code of the correct wheel for your 350

cut-off machine.

250

180

120

Abrasive Bond

80

SiC Bakelite

Al2O3 Bakelite

CBN Bakelite

Diamond Bakelite

50

Diamond Metal

Diamond Metal

electro-

plated

30

I II III IV V VI VII VIII IX X XI

resins, mounted

Extremely hard

ferrous metals

ferrous metals

ferrous metals

ferrous metals

hard ceramics

Medium hard

Minerals and

Medium soft

Hard ferrous

Application

Plastics and

Non-ferrous

Soft ferrous

Very ductile

soft metals

metals (Ti)

Very hard

materials

carbides,

ceramics

Sintered

metals

metals

Cut-off machine Std. wheel size* (mm)

Magnutom-500 508 x 3.5 x 32 10S51 30A51 40A51 50A51 60A51 B0C411 B0D5117 M0D5116 E0D363

42A5110 52A5110 62A5110

Exotom-100/-150 432 x 3.0 x 32 10S43 20S43 30A43 40A43 50A43 60A43 B0C41 1

B0D35 2

M0D35 2

E0D363

Magnutom-400 42A4310 52A4310 62A4310

66A4312

Axitom-5 (1,950 rpm) 350 x 2.5 x 32 10S35 20S35 20A35 20A35 30A35 40A35 50A35 B0C356 B0D352 M0D352 E0D363

56A3512 B7D352/15

Labotom-15 (2,350 rpm) 10S35 20S35 30A35 40A35 50A35 60A35 60A35 B0C356 B0D352 M0D352 E0D363

56A3512 66A3512 66A3512 B7D352/15

Exotom/Unitom-2/-5/-50 (2,775 rpm) 10S35 30S35 20A35 30A35 40A35 50A35 60A35 B0C35 6

B0D352 M0D35 2

E0D363

56A3512 66A3512 B7D352/15

Unitom/Discotom-50/-60/-65/-100 300 x 2.0 x 32 10S30 20S30 30A30 40A30 50A30 60A30 B0C31 4

B0D314 M0D31 5

E0D315

66A3012

Discotom-5/-6/-10/ Labotom-3/-5 250 x 1.5 x 32 10S25 20S25 20A25 30A25 40A25 54A25 60A25 B0C257 B0D258 M0D258 E0D25

33A259 46A2512 50A2511 66A2512

56A2512

Discotom/Labotom 235 x 1.5 x 22 10S24 20S24 30A24 40A24 60A24 50A24

Discoplan-TS 200 x 1.0 x 22 B4D20 M4D20

1) 406 x 1.8 x 32 2) 350 x 1.5 x 32 3) 356 x 1.5 x 32 4) 305 x 1.8 x 32 5) 305 x 1.5 x 32 6) 350 x 1.8 x 32 7) Width = 1.3 8) Width = 1.1 9) Width = 0.8 10) Fibreglass reinforced

11) For hard and ductile materials, Ni-base alloys 12) 3D cut-off wheels 13) Width=0.6 14) Width=0.4 15) For sintered carbides in steel 16) Width=2.4 17) Width=3.2

Precision cut-off machine Std. wheel size* (mm)

Secotom-1/-10/-15/-50** 200 x 0.8 x 22 10S20 10S20 30A20 30A20 50A20 50A20 50A20 B0C20 B0D20 M0D2013 E1D20

M1D2013

Accutom-10/-100/-5/-50 150 x 0.5 x 12.7 10S15 10S15 40A15 40A15 50A15 50A15 50A15 B0C15 B0D15 M0D15 E0D15

SAW13 30A15 30A15 M1D15 SAW13

Accutom-2 125 x 0.5 x 12.7 30A13 30A13 30A13 30A13 50A13 50A13 50A13 B0C13 B0D13 13

M0D1314 M1D1314

M1D1314

Minitom 125 x 0.5 x 12.7 M1D1314 M1D1314 B0C1313 B0C1313 B0C1313 B0C1313 B0C1313 B0C1313 B0D1313 M0D1314 M1D1314

M1D1314

Wheels with special sizes 100 x 0.3 x 12.7 These wheels can be used on both Accutom-2/-5/-50 and Secotom-1/-10/-15/-50 for cutting of small M0D10 M1D10

specimens where high precision or minimum material loss is required. M1D10

75 x 0.15 x 12.7 M0D08 M1D08

*) Diameter x Width x Bore in mm, **) On Secotom-1 only use M0D20 + B0D20 M1D08

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Anjel Saputri (Pju)Document4 pagesAnjel Saputri (Pju)anjelsaputri75No ratings yet

- Maximized Performance with Metabo Abrasives for Angle Grinder TechnologyDocument2 pagesMaximized Performance with Metabo Abrasives for Angle Grinder TechnologyJonathan DouglasNo ratings yet

- Typical Roof Detail Duct Thru Roof Detail Vent Thru Roof Detail Concrete Pad On Roof DetailDocument1 pageTypical Roof Detail Duct Thru Roof Detail Vent Thru Roof Detail Concrete Pad On Roof DetailAdel KhalilNo ratings yet

- 3 TCP-DTRFDocument1 page3 TCP-DTRFHaevu BNo ratings yet

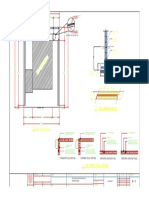

- Curtain Wall-ModelA3 PDFDocument1 pageCurtain Wall-ModelA3 PDFVinay SainNo ratings yet

- AquaTec - BR - ENDocument20 pagesAquaTec - BR - ENNashrul HakimNo ratings yet

- Corrosion TableDocument20 pagesCorrosion TableAli MuzzammilNo ratings yet

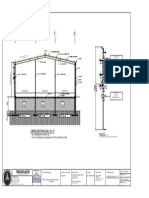

- Section Along Ma - Orosa 2Document1 pageSection Along Ma - Orosa 2Pablo PaboritoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- CV Flexible Body Filler, Light Grey: Technical InformationDocument2 pagesCV Flexible Body Filler, Light Grey: Technical InformationGoodBoi EsberNo ratings yet

- 2014MAFord CatalogCountersinksDocument25 pages2014MAFord CatalogCountersinksBeto CovasNo ratings yet

- ALS Chemical Compatibility Guide 5Document18 pagesALS Chemical Compatibility Guide 5Francisco Javier Zúñiga MontielNo ratings yet

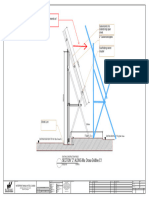

- C.3-141-Temporary Fence H.5MDocument1 pageC.3-141-Temporary Fence H.5MYudi CasanovaNo ratings yet

- Existing BLDG.: Masonry Wall DetailDocument1 pageExisting BLDG.: Masonry Wall DetailJason PeredaNo ratings yet

- Build a balsa wood gliderDocument1 pageBuild a balsa wood gliderStefan IonutNo ratings yet

- PVDF - Chemical - Resistance - ChartDocument22 pagesPVDF - Chemical - Resistance - ChartИбрагим НурмамедовNo ratings yet

- Spot Detail - 1: Exterior InteriorDocument1 pageSpot Detail - 1: Exterior InteriorByrne JobieNo ratings yet

- Schunk Carbon Technology Carbon Brush enDocument4 pagesSchunk Carbon Technology Carbon Brush enanm bNo ratings yet

- 2022 Step 1Document1 page2022 Step 1Marius NeacsuNo ratings yet

- NOMAD-CHEM-GUIDE-DIAPHRAGM-PUMPSDocument20 pagesNOMAD-CHEM-GUIDE-DIAPHRAGM-PUMPSTahaNo ratings yet

- + Cabinet Trophies Mirror PDFDocument1 page+ Cabinet Trophies Mirror PDFDiaz HamdaNo ratings yet

- Galvanic Corrosion Potential Chart Compares Metal Corrosion RatesDocument1 pageGalvanic Corrosion Potential Chart Compares Metal Corrosion RatesRamzi BEN AHMEDNo ratings yet

- BBH Boiler Plan-ModelDocument1 pageBBH Boiler Plan-Modeljohn cartagenaNo ratings yet

- 7Document1 page7Modasser NewazNo ratings yet

- Sheet D Curtain Wall DetailsDocument1 pageSheet D Curtain Wall DetailsWander LustNo ratings yet

- Right Side Elevation Isometric Viewof Fence: Proposed Perimeter Fencing and Garage Balcony RoofingDocument1 pageRight Side Elevation Isometric Viewof Fence: Proposed Perimeter Fencing and Garage Balcony RoofingRonnie Buico Conejos CENo ratings yet

- Add CorbelDocument2 pagesAdd CorbelMarielle Anne SantiagoNo ratings yet

- Reinforced concrete foundation plan and section detailsDocument1 pageReinforced concrete foundation plan and section detailsAnde BhanuNo ratings yet

- 200b Reception CounterDocument1 page200b Reception Counteraliran interiors interiorsNo ratings yet

- Appendix J Inspection Requirements For Globe ValvesDocument4 pagesAppendix J Inspection Requirements For Globe ValvesSales SES OmanNo ratings yet

- Earthpit - R4-Model 3Document1 pageEarthpit - R4-Model 3Md ShoaibNo ratings yet

- Window Shedule24Document1 pageWindow Shedule24Nehemiah KoechNo ratings yet

- Tank foundation schedule and ring wall reinforcement detailsDocument1 pageTank foundation schedule and ring wall reinforcement detailsLalith VasudevNo ratings yet

- Chemical Resistance Chart FybrocDocument22 pagesChemical Resistance Chart Fybrocshahul_2k5No ratings yet

- A2-Floor Plan, ElevationsDocument1 pageA2-Floor Plan, ElevationsRonnel John CruzNo ratings yet

- Design Guide: Sika Anchorfix®-2020Document20 pagesDesign Guide: Sika Anchorfix®-2020Myo Min ThuNo ratings yet

- Admina TableDocument1 pageAdmina TableNagi ReddyNo ratings yet

- Detail Pondasi: KontractorDocument1 pageDetail Pondasi: KontractorElgi Permana PutraNo ratings yet

- Base Plate 250Mmx250Mm: Date Rev Description ProjectDocument1 pageBase Plate 250Mmx250Mm: Date Rev Description ProjectJayaraman NNo ratings yet

- Reivew of Materials Corrosive AgentsDocument4 pagesReivew of Materials Corrosive AgentsyogkrishnaNo ratings yet

- Outdoor lamp post detailDocument1 pageOutdoor lamp post detailFRANKLYN SPENCERNo ratings yet

- Valve Chemical Compatibility Chart 4: Page 1 of 8Document8 pagesValve Chemical Compatibility Chart 4: Page 1 of 8MAHESH CHANDNo ratings yet

- structural-1Document9 pagesstructural-1manglicmotabigail11No ratings yet

- Tyra 2.0Document1 pageTyra 2.0Tín NguyễnNo ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- R0404-MT - Rev - 0 DF Da Bateria de CicloneDocument2 pagesR0404-MT - Rev - 0 DF Da Bateria de CiclonecaapasaNo ratings yet

- Productdatasheet Babsl 72 NBR 902Document2 pagesProductdatasheet Babsl 72 NBR 902narayan46No ratings yet

- Ficha Técnica FVBCDocument3 pagesFicha Técnica FVBCpereiraloraNo ratings yet

- Leave Type Safety Valve Assembly-ModelDocument1 pageLeave Type Safety Valve Assembly-ModelKevin RavenNo ratings yet

- Scheda MDS02 PDFDocument1 pageScheda MDS02 PDFThomas RiatoNo ratings yet

- MPB Arc-8Document1 pageMPB Arc-8Jay Mark GastonesNo ratings yet

- გეგმებიDocument3 pagesგეგმებიNino akhvledianiNo ratings yet

- Ceramic Wall Granito Kitchen DesignDocument1 pageCeramic Wall Granito Kitchen DesignSSM COMPANYNo ratings yet

- 400&600 Ball Valve KitzDocument1 page400&600 Ball Valve KitzSofyan CV. BLINo ratings yet

- Zinc Coating Thickness Critical for CGI Corrosion ResistanceDocument1 pageZinc Coating Thickness Critical for CGI Corrosion Resistancealezandro del rossiNo ratings yet

- Steel Truss 1 PDFDocument23 pagesSteel Truss 1 PDFMarielle CorpuzNo ratings yet

- MSS - Definitions - Coating MaterialsDocument4 pagesMSS - Definitions - Coating MaterialsIsmailEmreCanbolatNo ratings yet

- Selection Guide For Hot MountingDocument1 pageSelection Guide For Hot MountingCan ERTANNo ratings yet

- The Metallographic Examination of Archaeological Artifacts: Laboratory ManualDocument42 pagesThe Metallographic Examination of Archaeological Artifacts: Laboratory ManualArjun ArumugaswamyNo ratings yet

- Selection Guide For Hot MountingDocument1 pageSelection Guide For Hot MountingCan ERTANNo ratings yet

- Find the Right Cut-Off Wheel for Your MaterialDocument1 pageFind the Right Cut-Off Wheel for Your MaterialChris ZocNo ratings yet

- Selection of Filler Metal For WeldingDocument21 pagesSelection of Filler Metal For WeldingRegu vlogsNo ratings yet

- WeldingX80 100 ME April 2011 PDFDocument72 pagesWeldingX80 100 ME April 2011 PDFakilanrajuNo ratings yet

- 4S-02 02Document11 pages4S-02 02Claudio Hernández PobleteNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatNo ratings yet

- Portable Cabin QuotationDocument4 pagesPortable Cabin QuotationChirag DobariyaNo ratings yet

- Metallographic Specimen Preperation ReportDocument3 pagesMetallographic Specimen Preperation ReportHaqim WestWoodNo ratings yet

- Composite Structures-A Project ReportDocument60 pagesComposite Structures-A Project ReportMeenal Dutt100% (5)

- Astm 182Document15 pagesAstm 182ISABELNo ratings yet

- Alloy6013techsheet PDFDocument4 pagesAlloy6013techsheet PDFIlyasNo ratings yet

- Kumihimo With CoreDocument4 pagesKumihimo With Corehugssw2gmailcomNo ratings yet

- A1014Document3 pagesA1014malika_00No ratings yet

- Reaction TypesDocument10 pagesReaction TypesaqibazizkhanNo ratings yet

- 5070 w11 QP 12Document12 pages5070 w11 QP 12mstudy123456No ratings yet

- Misc Hetating PaperDocument14 pagesMisc Hetating PaperdhruvNo ratings yet

- EN Process Performance: Effect of Agitation, Loading and Stabilizer LevelDocument23 pagesEN Process Performance: Effect of Agitation, Loading and Stabilizer LevelStefanus Girindra WardhanaNo ratings yet

- Substation FittingsDocument12 pagesSubstation Fittingscountershadow_14No ratings yet

- Gourmet DisplayDocument44 pagesGourmet DisplayLaurenţiu MâțăNo ratings yet

- ASSAB Tool Steel Performance Comparison Chart PDFDocument1 pageASSAB Tool Steel Performance Comparison Chart PDFSophian Hakim WirajayaNo ratings yet

- Module2: Design and Calculations of Piercing & Blanking DieDocument89 pagesModule2: Design and Calculations of Piercing & Blanking DieVipul MetaNo ratings yet

- Weight Per Foot of Fillet Welds and Common Butt WeldsDocument1 pageWeight Per Foot of Fillet Welds and Common Butt WeldsDavid D'AgostinoNo ratings yet

- 2010 Catalog 1Document96 pages2010 Catalog 1ClaudiaPaggini100% (1)

- Crofer 22 HDocument27 pagesCrofer 22 HSarveshNo ratings yet

- Astm F436M-93 Reap2000Document5 pagesAstm F436M-93 Reap2000Carlos Raul Caballero LeonNo ratings yet

- Powders and Industrial Applications of Silver and Other MetalsDocument1 pagePowders and Industrial Applications of Silver and Other MetalsGabi OcheaNo ratings yet

- 121 ASTM ISO StandardsDocument3 pages121 ASTM ISO StandardsHestu Adi WicaksonoNo ratings yet

- Chisel: From Wikipedia, The Free EncyclopediaDocument5 pagesChisel: From Wikipedia, The Free EncyclopediapercydziksNo ratings yet

- Flange Dimensions Based On Tables D and E of BS 10: 1962Document6 pagesFlange Dimensions Based On Tables D and E of BS 10: 1962윤규섭No ratings yet

- CatalogDocument18 pagesCataloglangtu2011No ratings yet

- Submerged Arc WeldingDocument4 pagesSubmerged Arc WeldingAnkit BansalNo ratings yet