Professional Documents

Culture Documents

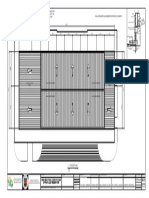

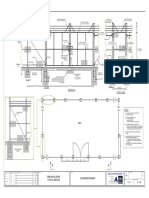

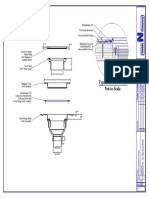

Reference Layout & Details of Tank Farm Foundations & Dyke Wall Ana-A1

Uploaded by

Lalith VasudevOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reference Layout & Details of Tank Farm Foundations & Dyke Wall Ana-A1

Uploaded by

Lalith VasudevCopyright:

Available Formats

33° 700 Tank Shell

Ring Wall Foundatioin

75 thk Anticorrosive Layer

Plant North

Schedule of Tank Foundation Ring Wall Reinf. Reinf.

Tank Tag No BCD Foundation A B C D E F Horizontal steel Vertical steel Top Reinf Bottom Reinf Foundation F 75 thk anticorrosive layer of compacted 150

Actual North 200 thk Solid

Bolts Bolts crushed stone screening,fine gravelclean

CK TK 001-002-003 16200 36 Nos(56Ø) 900 400 2200 450 16 0 @125 c/c 12 0 @100 c/c 16 0 @150 c/c 16 0 @150 c/c Block Masonry send or simillar materialmixed in 80/100 75

478 88

grade hot asphalt 8 to 10 percent by

400

BAR MARKING MRK-07, 08 MRK-05, 06 MRK-04 MRK-03 volume and rolled compacted

CK TK 004-005 14220 24 Nos(56Ø) 750 400 1900 400 484 100 16 0 @150 c/c 12 0 @125 c/c 12 0 @100 c/c 12 0 @100 c/c 12 Thk Plaster Slope 1:100

E

75 Thk 50 Thk. Anticorrosive Layer (MRK-34)

BAR MARKING MRK-15, 16 MRK-13, 14 MRK-12 MRK-11

PCC (1:4:8) 150 From center of Tank

°

C

45

CK TK 006-007, 100@ 100 c/c

150 Thk Vertical Reinf.

RBD TK 001 to 006 12200 20 Nos(48Ø) 500 350 1300 350 478 92 12 0 @125 c/c 10 0 @100 c/c 10 0 @100 c/c 10 0 @100 c/c

PCC (1:4:8) Inside

1000

BAR MARKING MRK-23, 24 MRK-21, 22 MRK-20 MRK-19 50

75 thk PCC(1:4:8) (MRK-33) 80@ 200 c/c (MRK-35, 36)

RBD TK 007 & 008 8200 14 Nos(36Ø) 450 350 1200 350 450 92 10 0 @150 c/c 80 @100 c/c 10 0 @150 c/c 10 0 @150 c/c Horizontal Reinf.

100@ 150 c/c

BAR MARKING MRK-31, 32 MRK-29, 30 MRK-28 MRK-27 Vertical Reinf. 200x200 Fillet

1000

C

Well compacted Out side

2 See Layout FFL EL +100.200

Sect. C-C Sand filling up to

95% proctor dry 40thk IPS

1:20 density FGL EL +100.00

Detail-1 ( Sump) FFL EL +100.200

230thk Rubble

1:20 400 solling

F

1000 Lap (Staggered)

A

FGL EL +100.00 2 NGL

Well compacted

75Thk earth filling up to

200

PCC(1:4:8) 95% proctor dry

density

NGL 700

(MRK-39, 40)

F

750

5° 10° 10° 7.5° 15° 300 80@ 200 c/c

5° 10° 10° 15 Hold Wall Horizontal Steel Top & Bottom

10400

° (MRK-37, 38)

80@ 150 c/c

100 300

Top & Bottom

Detail-1

A

(Typ)

R3

1000

9499 15601 13600 6400 Wall Vertical Steel

Sump R 6350

Sump

Future PCC(1:4:8)

CK TK 004 Well compacted earth

R735 R735 Sump

0 CK TK 001 0

175 17

5

Sect. A-A

2000

R3 R3

175

6400

26°

25 9° 18° 9° 18° 1:20

8400

18 18 Sump

26

° Detail-1 °

°

(Typ) R33

5 0

R3 (MRK-17, 18 & 25, 26)

R3

16600

RBD TK 007 Foundation Top

R 5350 R 5350 0 Steel 80@ 200 c/c

15 Top & Bottom

18600

RBD TK 001 Sump Sump

7.5° 15° 150 RBD TK 004

15 450

10600

D

° 0 Dyke Wall

5° 10° 1 5° 10° 1 15

0° 0°

100

R3 7.5° 26°

Sump Foundation Bottom

R 6350

26

Steel

14600

500x500x450deep

°

R33 A B PCC(1:4:8)

50 Drain Pit

CK TK 005

3000

Sump Sump Sump C 75Thk

150 FFL EL +100.20

Future 9° 18° 9° 18° RBD TK 008 FFL PCC(1:4:8)

18 18 FGL EL +100.00

R735 R735

Details of Tank Foundation (Ring Wall)

0 0 ° °

CK TK 002 5

17

250 Widex400 Deep

1:20 (CK TK 006-007,RBD TK 001 to 006

R3 R3 R3 RBD TK 007 & 008)

R3

10576

5

17 R 5350

150

R 5350 100

Drain Trench

R6

5

17

15600

7

NGL

50

450

RBD TK 002 25 thk FRP

Drain Trench

Sump Sump RBD TK 005 7.5° 26° 150

150 150

Grating RCC Coping

Sump 100@ 150 c/c

26

50

°

9° 18° R33 FFL +100.200 80@ 200 c/c Top & Bottom

50 Slope

250 Widex400 Deep

18 Floor Finish ( IPS)

°

18600

250 Widex400 Deep

100

Laid in slope (25mm Min.)

Future 2-10 0

Varies

0

Drain Trench

depth

R3

400

15 200

14600

Drain Trench

Solid Block Masonry

5° 10° 1 5° 10° 1 R 5350 Screeding 1:2:4

0° 0° Laid in Slope Sect. E-E

CK TK 006 100 300 (200mm to 350mm)

10598

Sump 9° 18° 9° 18° 1:20

18 18

100

° °

6000

0

15 7.5° 26° PCC(1:4:8)

Sump Sump R3 R3 Sump

26

Future

R 5350

°

R 5350 R33

5 0

R735 R735

0 0

Sect. B-B

14599

CK TK 003 150

Sump Sump RBD TK 006 Future 1:20

R3 R3 RBD TK 003 150 15

0

5

17

9° 18°

8599

5

17 18

°

10598

R3

14600

R 5350 7.5° 26°

Sump

26

CK TK 007

Sump 9° 18° 9° 18°

°

R33

150 18 18 5 0

° °

Future

R3 R3 0

15

R 5350 R 5350 TANK FARM

Future Sump 150 Future

Sump

150 Key Plan

19600 9675 8780 9035 250

Note:

8400

E

E

1. All dimensions are in millimetres and levels are in metres unless specified otherwise

F

F

2. All concrete grade shall be M25 machine mixed and machine vibrated

A

A

9575 7716 250 7635 7722 250 5628 3. All reinforcement shall be Fe 415 TMT bars

4. Layout dimension to be checked with GA drawing 908- G-ST-001 & if any ambiguity

is there, contact engineer In-charge prior to proceed

5. Clear cover to Main Reinforcement :

1000 3900 a) RCC Wall = 20mm

650 1000

A

A

b) Footing = 50mm

E

F

F

E

1:200

You might also like

- 7Document1 page7Modasser NewazNo ratings yet

- R Dis GR 01Document1 pageR Dis GR 01Constantin ConstantaNo ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- C.3-141-Temporary Fence H.5MDocument1 pageC.3-141-Temporary Fence H.5MYudi CasanovaNo ratings yet

- 1TB02011 011C44 Amp FC R1 SDW Ar 30001Document1 page1TB02011 011C44 Amp FC R1 SDW Ar 30001Sher DilNo ratings yet

- Miniature Linear Guides: - Wide RailsDocument1 pageMiniature Linear Guides: - Wide Railsphatdang1996No ratings yet

- Typical Roof Detail Duct Thru Roof Detail Vent Thru Roof Detail Concrete Pad On Roof DetailDocument1 pageTypical Roof Detail Duct Thru Roof Detail Vent Thru Roof Detail Concrete Pad On Roof DetailAdel KhalilNo ratings yet

- Retaining Wall Formwork Double Sided-B-001Document1 pageRetaining Wall Formwork Double Sided-B-001Ahmed Salah El DinNo ratings yet

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréNo ratings yet

- 230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Document1 page230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Mateen JawreNo ratings yet

- Bus ShelterDocument1 pageBus ShelterCHVN NH173No ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- GA-150027-1 (003) Ffetbigbore1750 PDFDocument1 pageGA-150027-1 (003) Ffetbigbore1750 PDFriinNo ratings yet

- Gutter Detail: Eva Mae V. Parrenas Romeo Andig Raul N. Banias M.D.,Mpa Atty. Suzette A. Mamon Arthur R. Defensor JRDocument1 pageGutter Detail: Eva Mae V. Parrenas Romeo Andig Raul N. Banias M.D.,Mpa Atty. Suzette A. Mamon Arthur R. Defensor JRalezandro del rossiNo ratings yet

- J3BGDF02BR012 01 01Document1 pageJ3BGDF02BR012 01 01saleem naheedNo ratings yet

- 089 - Pagar Depan SignedDocument5 pages089 - Pagar Depan Signedhansen 97No ratings yet

- Gad 2Document1 pageGad 2Aerotide InfrastructuresNo ratings yet

- Disassembly and Assembly Procedures For Rollers With Inverted Duo-Cone SealsDocument1 pageDisassembly and Assembly Procedures For Rollers With Inverted Duo-Cone Seals----No ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- 10END30BR001Document1 page10END30BR001Valesh MonisNo ratings yet

- Profile Di Roofing 5 2 1 6: Assy Rangka Dinding 4 - 1310Document12 pagesProfile Di Roofing 5 2 1 6: Assy Rangka Dinding 4 - 1310joseNo ratings yet

- Conatianer Layout Details Rev0Document1 pageConatianer Layout Details Rev0Mike MatshonaNo ratings yet

- 05 - Second Floor Beam & Slab Layout Details - r2 (05.08.21) - Sheet-1Document1 page05 - Second Floor Beam & Slab Layout Details - r2 (05.08.21) - Sheet-1PackiarajNo ratings yet

- EN-02, PANEL Fan & Feeding (EMY-301681-01) - 05Document1 pageEN-02, PANEL Fan & Feeding (EMY-301681-01) - 05M Arifur RahmanNo ratings yet

- Aisin AW TF-80SCDocument1 pageAisin AW TF-80SCJesus Alejandro Miranda Palacios100% (1)

- ROFC065330w ADocument1 pageROFC065330w AchetanbakkerNo ratings yet

- F003 76-10526-Detail DesignDocument1 pageF003 76-10526-Detail DesignMazen IsmailNo ratings yet

- Oil Cooler - As Built-ModelDocument1 pageOil Cooler - As Built-ModelbasvkaranNo ratings yet

- 3hac042305 044Document1 page3hac042305 044Hwigeun KangNo ratings yet

- 22.5 KL Check PrintDocument1 page22.5 KL Check PrintparveshNo ratings yet

- Asi 810 05 R1Document1 pageAsi 810 05 R1manoj_structureNo ratings yet

- Off R1Document1 pageOff R1Josphat benzNo ratings yet

- Fencing & Gates Typical Details Standard Drawing: Section A - A Option 1 DoorDocument1 pageFencing & Gates Typical Details Standard Drawing: Section A - A Option 1 DoorsumitanuragNo ratings yet

- General Detail Abut & WWDocument1 pageGeneral Detail Abut & WWUmesgNo ratings yet

- Pipe Ring Product Selector: Light-Duty Galvanized Pipe RingsDocument1 pagePipe Ring Product Selector: Light-Duty Galvanized Pipe RingsReem Ahmed KhalilNo ratings yet

- 04.DECK STEEL-Deck SteelDocument1 page04.DECK STEEL-Deck Steeldivision4 designsNo ratings yet

- S1Document1 pageS1Hailley DensonNo ratings yet

- PB 1 SFD (Panic Barr)Document1 pagePB 1 SFD (Panic Barr)edo artisaeNo ratings yet

- 307 2022 - Addendum - 2 Drawing - CS 01 R1Document1 page307 2022 - Addendum - 2 Drawing - CS 01 R1Danny NguyenNo ratings yet

- 33kV Standard DrawingDocument15 pages33kV Standard DrawingsheshidharrajubNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- 15 000-Bcl2000414-El-Dr-1 - AfcDocument1 page15 000-Bcl2000414-El-Dr-1 - AfcYousab JacobNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 1TB02011 011C44 Amp FF R1 SDW Ar 30001Document1 page1TB02011 011C44 Amp FF R1 SDW Ar 30001Sher DilNo ratings yet

- 01.MBT-RCC OHT-5 Lakh-DK-Model PDFDocument1 page01.MBT-RCC OHT-5 Lakh-DK-Model PDFArun NesamNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- OMSHS4-R-SNWPCL-SN - SL - 4909 - Electrical Pole Layout Plan Rev A AFCDocument1 pageOMSHS4-R-SNWPCL-SN - SL - 4909 - Electrical Pole Layout Plan Rev A AFCshihabNo ratings yet

- Typical Install Detail: (Socket Bottom)Document1 pageTypical Install Detail: (Socket Bottom)D MNo ratings yet

- GAD of Structure - A-13 - 2 PDFDocument30 pagesGAD of Structure - A-13 - 2 PDFmayank007aggarwal0% (1)

- Installation Procedure T5MaxDocument2 pagesInstallation Procedure T5MaxCarlos Alberto RuedaNo ratings yet

- Pm-Drg-Ly26 11092-M-01 Isometric Drawing Rev. D 2010 - Internal Painting Option - A3 Discharge LineDocument1 pagePm-Drg-Ly26 11092-M-01 Isometric Drawing Rev. D 2010 - Internal Painting Option - A3 Discharge LineLEE JHONNo ratings yet

- Crate V33H SchematicDocument2 pagesCrate V33H SchematicDanielo ErréNo ratings yet

- Crate V33H Schematic 1Document2 pagesCrate V33H Schematic 1Danielo ErréNo ratings yet

- Welding LOG / Dziennik SpawaniaDocument1 pageWelding LOG / Dziennik SpawaniaarissaNo ratings yet

- HV-CONNEX Separable - Data Sheet Connex Size 6S - ConnectorDocument3 pagesHV-CONNEX Separable - Data Sheet Connex Size 6S - ConnectorGlenys MuñozNo ratings yet

- A (44) SeriesDocument4 pagesA (44) SeriesSsenyonjo EricNo ratings yet

- 2 Section A: Al Jazeera EnterprisesDocument1 page2 Section A: Al Jazeera Enterprisessalmaan khanNo ratings yet

- Ret Wall Report 04.12.23Document5 pagesRet Wall Report 04.12.23Lalith VasudevNo ratings yet

- Work AssessmentDocument2 pagesWork AssessmentLalith VasudevNo ratings yet

- Slab DesignDocument3 pagesSlab DesignLalith VasudevNo ratings yet

- MDL - Plant InfraDocument2 pagesMDL - Plant InfraLalith VasudevNo ratings yet

- Security CabinDocument1 pageSecurity CabinLalith VasudevNo ratings yet

- E004 - Walkway PlanDocument1 pageE004 - Walkway PlanLalith VasudevNo ratings yet

- TFL TonnageDocument3 pagesTFL TonnageLalith VasudevNo ratings yet

- Here's Your Guide To End Digital Burnout!Document1 pageHere's Your Guide To End Digital Burnout!Lalith VasudevNo ratings yet

- 17C1 - ColumnDocument1 page17C1 - ColumnLalith VasudevNo ratings yet

- 1 Challenges in Projects Under Uncertain Environment Ans Strategic Project ManagementDocument31 pages1 Challenges in Projects Under Uncertain Environment Ans Strategic Project ManagementLalith VasudevNo ratings yet

- UACEG Anchors Chairs ENDocument10 pagesUACEG Anchors Chairs ENLalith VasudevNo ratings yet

- Equipment Catalogue EditDocument19 pagesEquipment Catalogue EditAfandi AnasNo ratings yet

- Mathios & BiopietraDocument26 pagesMathios & BiopietraDinesh GuptaNo ratings yet

- Final BOQ - Sky Pool Project 19 Feb 2023Document8 pagesFinal BOQ - Sky Pool Project 19 Feb 2023Hebatallah NassarNo ratings yet

- Louver Windows As A Passive Cooling StrategyDocument10 pagesLouver Windows As A Passive Cooling StrategyjlnederNo ratings yet

- Architecture Floor Plan Abbreviations AnDocument11 pagesArchitecture Floor Plan Abbreviations AnGraphitti Koncepts and DesignsNo ratings yet

- Tle-Ia-Carpentry: Observe Good Formworks RequirementsDocument10 pagesTle-Ia-Carpentry: Observe Good Formworks RequirementsTitser RamcaNo ratings yet

- Supreme Beam and Block FloorDocument7 pagesSupreme Beam and Block FloorhemendraengNo ratings yet

- Debris House Kerala: Submitted By: Priti Kocheta 5 SemDocument15 pagesDebris House Kerala: Submitted By: Priti Kocheta 5 Sempriti kochetaNo ratings yet

- 12.Form-11-Structural Design Basis ReportDocument6 pages12.Form-11-Structural Design Basis ReportPrem KumarNo ratings yet

- NBK CladdingDocument12 pagesNBK Claddingkeerthi EngineeringNo ratings yet

- FPT P3 Block E Apartment 12B FloorDocument48 pagesFPT P3 Block E Apartment 12B FloorHong Lan TranNo ratings yet

- Hong Kong BankDocument17 pagesHong Kong BankZtWy100% (1)

- Design A Slab For A Room of Size 5mX4m Which Carries A Live Load of 4 KN/m2. Use M20 Concrete QND Fe 415steel For The Design. Take Bearing 300mmDocument3 pagesDesign A Slab For A Room of Size 5mX4m Which Carries A Live Load of 4 KN/m2. Use M20 Concrete QND Fe 415steel For The Design. Take Bearing 300mmK N RASHMI 2127960No ratings yet

- Reinforced Concrete Flat RoofDocument3 pagesReinforced Concrete Flat RoofDiana Zuhairi40% (5)

- General PresentationDocument53 pagesGeneral PresentationKARIM GARAHNo ratings yet

- Delhi Building ByelawsDocument169 pagesDelhi Building ByelawsArun NaikNo ratings yet

- Nudra Villas A3-A4 - Id Concept PDFDocument109 pagesNudra Villas A3-A4 - Id Concept PDFAta AtefNo ratings yet

- Design and Comparison of Flat Slab According To IS 456-2000 and ACI 318-08Document34 pagesDesign and Comparison of Flat Slab According To IS 456-2000 and ACI 318-08harishram123456No ratings yet

- Workbook Unit 7Document6 pagesWorkbook Unit 7Stalim Ravichagua QuintoNo ratings yet

- Suspended CeilingsDocument21 pagesSuspended CeilingsSohailaa MohamedNo ratings yet

- Lats-Load Icad OfficesDocument7 pagesLats-Load Icad OfficesShaikhMazharAhmedNo ratings yet

- Internship SeminarDocument28 pagesInternship Seminarkavya kruthiNo ratings yet

- Confined Masonry Workshop HandbookDocument29 pagesConfined Masonry Workshop HandbookneriahpNo ratings yet

- Report On Structural Audit of Terrace Johnson & Johnson PVT LTD, Mulund West, MumbaiDocument11 pagesReport On Structural Audit of Terrace Johnson & Johnson PVT LTD, Mulund West, MumbaiHARSHADNo ratings yet

- Pinky's Iron Doors Introduces The Pantry Door CollectionDocument4 pagesPinky's Iron Doors Introduces The Pantry Door CollectionPR.comNo ratings yet

- Worksheet 4 - Describing The HouseDocument4 pagesWorksheet 4 - Describing The Housemaria luisa gomezNo ratings yet

- Abcm Assignment Diaphragm Wall Construction PPT ExplanationDocument5 pagesAbcm Assignment Diaphragm Wall Construction PPT ExplanationdrashtiNo ratings yet

- Material Inword Outword PaymentDocument33 pagesMaterial Inword Outword PaymentMAHESH SATHENo ratings yet

- Kitchen A2Document1 pageKitchen A2branishNo ratings yet

- Pedrali Chair 3Document139 pagesPedrali Chair 3muhammadNo ratings yet