Professional Documents

Culture Documents

Diesel and LPG Forklift Trucks for 1200, 1600, 1800 and 2000 kg Capacities

Uploaded by

ErissonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diesel and LPG Forklift Trucks for 1200, 1600, 1800 and 2000 kg Capacities

Uploaded by

ErissonCopyright:

Available Formats

Diesel and LPG Forklift Trucks

1200, 1600, 1800 and 2000 kg

H 12

H 16

H 18

H 20

350-03

Introduction changing gear. Linde central control lever Transmission

Developed with the aid of the latest design operates all lifting mast functions (lift, lower, Hydrostatic transmission, made by Linde

methods, these trucks offer the following tilt). Automatic adjustment of engine speed and flange-mounted direct to the engine,

outstanding features: to the power output required for lifting and provides sensitive, infinitely variable con-

● Exceptional economy, due to minimised other functions. Operator’s overhead guard trol of vehicle speed, while also serving as

servicing costs and long service intervals forms an integral unit with the drivers the operating braking system. The integral,

● High productivity and low fuel compartment and can be fitted with addi- trouble-free, multiple-disc brake acts only

consumption through the use of tional equipment up to fully enclosed cab as a parking brake. Automatically engaged

high-torque engines combined configuration. when engine switched off. Oil supplied by

with hydrostatic transmission control the hydrostatic pump is separated and

systems Chassis directed to the two fixed-displacement

● Outstanding environmental friendliness, Designed for maximum strength by the motors mounted in the semi-compact axle,

arising from: finite element method (FEM). Enclosed eliminating the need for a differential and

– optimised engine designs in terms all round to reduce noise and protect affording smooth, progressive travel, both

of exhaust gases and noise internally mounted sub-assemblies from forwards and in reverse.

– LP gas version with two-way damage.

catalytic converter as standard Steering

– low noise levels for operator and Engine Hydrostatic system providing light operation,

surrounding environment alike Liquid cooled diesel or LPG engine, precise control, free of play and low steering

● Ergonomically designed cab and specially adapted for use with this series effort (20 N), thus allowing a steering wheel

controls, with: of trucks. High torque rating at low engine of only 300 mm diameter.

– Linde double pedal drive control rpm not only reduces fuel consumption,

system exhaust emissions and noise levels but Masts

– Linde central control lever also prolongs durability. Smoke emissions Clear-view lifting masts in standard, duplex

– operator’s compartment, insulated from the diesel engine are exemplary or triplex configuration. Masts are con-

from vehicle itself. below 2.5 Bosch under all operating con- structed of double-T profiles, interleaved

ditions. Linde Hydraulic Control (LHC) to provide a high section modulus. Lifting

Driver’s position for engine, transmission and hydraulic cylinders are accommodated in the outer

Optimised layout, based on the latest ergo- system. recesses of the mast profiles to provide

nomic principles, for operators in the 5–95 maximum visibility for the operator. Power-

percentile. Considerably reduced vibration Automatic speed control ful lifting system ensures high lifting

and noise, through insulating the operator’s The automatic engine speed control speeds. The mast assembly is flange-

compartment from the vehicle itself by system, exclusive to Linde, ensures that mounted direct to the reduction gearbox

means of shock absorbers. Seat adjustable the engine and hydrostatic system are on the drive axle. Duplex and triplex masts

to operator’s height and weight, as well as constantly operating at the lowest possible are equipped with a free-lift cylinder.

being spring suspended and hydraulically rpm or pump output ratio, thus saving fuel

damped. Linde double pedal drive control and reducing toxic emissions and noise

system offers accurate reversing without levels.

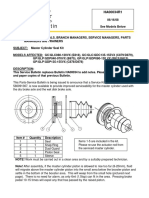

LINDE Forklift trucks Data sheet for

April 2001

Designation VDI 2198 material handling equipment

1.1 Manufacture) Linde Linde

1.2 Model designation H 12 D H 12 T H 16 D H 16 T

Characteristics

1.3 Power unit: battery, diesel, petrol, LP gas, mains power Diesel LPG Diesel LPG

1.4 Operation: manual, pedestrian, stand-on, seated, order picker Driver seated Driver seated

1.5 Load capacity Q (kg) 1200 1600

1.6 Load centre c (mm) 500 500

1.8 Axle centre to fork face x (mm) 375 375

1.9 Wheelbase y (mm) 1460 1460

2.1 Service weight kg 2525 2660

Weight

2.2 Axle load with load, front / rear kg 3116 / 609 3693 / 567

2.3 Axle load without load, front / rear kg 1222 / 1303 1167 / 1493

3.1 Tyres, front / rear (SE = CS superelastic, L = pneumatic) L (SE) L (SE)

Wheels and tyres

3.2 Tyre size, front 18 x 7–8 / 16 PR 2) 18 x 7–8 / 16 PR 2)

3.3 Tyre size, rear 18 x 7–8 / 16 PR 2) 18 x 7–8 / 16 PR 2)

3.5 Wheels, number front / rear (x = driven) 2x / 2 2x / 2

3.6 Track width, front b10 (mm) 910 910

3.7 Track width, rear b11 (mm) 874 874

4.1 Mast / fork carriage tilt, forward / backward a/b (°) 6 / 10 6 / 10

4.2 Height of mast, lowered h1 (mm) 2095 / 2070 / 2070 1) 2095 / 2070 / 2070 1)

4.3 Free lift h2 (mm) 150 150

4.4 Lift h3 (mm) 3050 / 3070 / 4470 1) 3050 / 3070 / 4470 1)

4.5 Height of mast, extended h4 (mm) 3658 / 3678 / 5078 1) 3658 / 3678 / 5078 1)

4.7 Height of overhead guard (cabin) h6 (mm) 2070 2070

4.8 Height of seat / stand-on platform h7 (mm) 1000 1000

4.12 Towing coupling height h10 (mm) 560 560

4.19 Overall length l1 (mm) 3074 3119

Dimensions

4.20 Length to fork face l2 (mm) 2174 2219

4.21 Overall width b1/b2 (mm) 1087 1087

4.22 Fork dimensions s/e/l (mm) 40 x 80 x 900 40 x 80 x 900

4.23 Fork carriage to DIN 15173, class /Form A, B 2A 2A

4.24 Width of fork carriage b3 (mm) 1040 1040

4.31 Ground clearance, mast m1 (mm) 90 90

4.32 Ground clearance, centre of wheelbase m2 (mm) 127 127

4.33 Aisle width with pallets 1000 x 1200 across forks Ast (mm) 3523 3565

4.34 Aisle width with pallets 800 x 1200 along forks Ast (mm) 3723 3765

4.35 Turning radius Wa (mm) 1948 1990

4.36 Maximum between the centres of rotation distance b13 (mm) 590 590

5.1 Travel speed, with / without load km/h 18 / 18.5 18 / 18.5

5.2 Lifting speed, with / without load m/s 0.57 / 0.58 0.57 / 0.58

Performance

5.3 Lowering speed, with / without load m/s 0.58 / 0.47 0.58 / 0.47

5.5 Tractive force, with / without load, 60 minute rating N 14200 / 9220 14200 / 9220

5.7 Climbing ability, with / without load, 30 minute rating % 42 / 30 34 / 26

5.9 Acceleration time, with / without load (first 10 m) s 4.5 /4.0 4.8 /4.2

5.10 Service brake hydrostatic hydrostatic

7.1 Manufacturer of engine / type VW / ADG VW / ADF VW / ADG VW / ADF

IC-engine

7.2 Engine rated power to ISO 1585 kW 28 27 28 27

7.3 Rated rpm min –1 2200 2300 2200 2300

7.4 Number of cylinders / Displac. ccm cm3 4 / 1900 4 / 1800 4 / 1900 4 / 1800

7.5 Fuel consumption to VDI l/h 2.2 2.2 2.3 2.3

8.1 Type of drive control hydr. / infinitely variable hydr. / infinitely variable

8.2 Working pressure for attachments bar 175 215

Others

8.3 Oil quantity for attachments l/min 18 18

8.4 Mean noise level at driver’s ear dB (A) 76 72 76 72

8.5 Towing coupling, design / type DIN, no – –

All data based on standard-equipment with Standardmast 3050.

1) Figures Standard/Duplex/Triplex with 150 mm free lift.

2) Optional SE-tyres.

3) Figures in brackets with SE-tyres 200/50-10.

DFG

Abbreviation to VDI 3586

VDI 2198

Linde Linde

H 18 D H 18 T H 20 D H 20 T

Diesel LPG Diesel LPG

Driver seated Driver seated

1800 2000

500 500

380 384

1500 1560

2890 3108

4063 / 628 4370 / 738

1243 / 1648 1274 / 1834

L (SE) SE

18 x 7–8 / 16 PR 2) 200 / 50 –10

18 x 7–8 / 16 PR 2) 18 x 7–8

2x / 2 2x / 2

910 945

874 874

6 / 10 6 / 10

2095 / 2070 / 2070 1) 3003 / 2078 / 2078 1)

150 150

3050 / 3070 / 4470 1) 3050 / 3070 / 4470 1)

3658 / 3678 / 5078 1) 3658 / 3678 / 5078 1)

2070 2070

Safety distance a = 200 mm

1000 1000

560 560 Lifting capacity diagrams:

3160 3246 H 12 H 16

1200 mm 1600 mm

2260 2346 1100 1500

1000 1400

1087 (1168) 3 ) 1168 900 1300

800 1200

45 x 100 x 900 45 x 100 x 900 5200

700 1100

5500 1000 4300

2A 2A 600

5800 900 5000

1040 1040 500 6000 5200

800 5400

400 6220

90 (98) 3 ) 98 700 5650

127 135 300 600

500 600 700 800 900 1000 500 600 700 800 900 1000

3606 3690 kg mm kg mm

3806 3890

2026 2105 H 18 H 20

1800 mm 2000 mm

605 630 1600 1800

18 / 18.5 18 / 18.5 1400 1600

1300

0.57 / 0.58 0.57 / 0.58 1400

1200 1300 4700

4500

0.59 / 0.47 0.59 / 0.47 1200

1100 5000 5000

1100

14200 / 9220 14200 / 9220 1000 5200

5300 1000

900 5400

31 / 26 31 / 26 900

5650

800 5650 800

4.9 / 4.4 5.0 / 4.5 500 600 700 800 900 1000 500 600 700 800 900 1000

hydrostatic hydrostatic kg mm kg mm

VW /ADG VW / ADF VW / ADG VW / ADF

Lifting capacity diagrams are valid for Standard- and Duplexmasts

28 27 28 27 without integrated sideshift with SE-tyres.

2200 2300 2200 2300

Figures for other equipments and triplex masts on request.

4 / 1900 4 / 1800 4 / 1900 4 / 1800

2.3 2.3 2.4 2.4 Overall height and lift heights (in mm) Standard

hydr. / infinitely variable hydr. / infinitely variable Lift heights h3 2850 3050 3850 4250 4850

Overall height mast retracted h1 # 2000 2100 2500 2700 3000

230 250 (with 150 mm free lift – standard)

18 18 Overall height mast extended h4 3458 3658 4458 4858 5458

76 72 76 72

– – Overall height and lift Duplex Triplex

heights (in mm)

Lift heights h3 2770 3070 3770 4020 4470 5470 5920 6220

Overall height mast h1 1925 2075 2425 1925 2075 2475 2625 2725

retracted

Overall height h4 3378 3678 4378 4628 5078 6078 6528 6828

mast extended

Special free lift h2 1318 14 68 1818 1318 1468 1868 2018 2118

Equipment

lIlustrations and technical details not binding for actual construction. All dimensions subject to customary tolerances.

Subject to modification in the interests of progress.

Safety ● Multidisplay instrument with operating hydraulics for all types of lifting mast,

● Outstanding ergonomics to lessen hours meter and indicator lamps for all operating in conjunction with

fatigue the important vehicle functions automatic engine speed control

● Drive train braking – smooth transition ● Uniformly sized tyres front and rear ● Non-standard fork lengths

from driving to brake application (fully interchangeable) ● Additional equipment for operator’s

● Automatic engagement of the parking ● Standard mast, lift height h3 = 3050 mm overhead guard up to full cab with

brake when the engine is switched off ● Fork carriage width b1 = 1040 mm enclosed roof, front and rear windows

● Low noise level so that warning fork length l = 900 mm. and doors with sliding windows

signals etc. can be heard easily ● Comfort seat

● These forklift trucks naturally also offer Optional equipment ● Front and rear windscreen wipers

– high stability ● Standard mast, lift height ● Heating

– good visibility from 2850 to 5650 mm ● Vehicle lighting, working lamps

– hydraulic power steering. ● Duplex mast, lift height ● High-level exhaust

from 2770 to 3770 mm ● Equipment for use on public roads

Standard equipment ● Triplex mast, lift height ● LPG tank for volumetric refuelling

Printed in Germany · 062 · e · ? · 0104 · A&P · Ind. C

● Combination dry air filter downward from 4020 to 6220 mm ● Superelastic tyres

exhaust ● Higher-lift masts on request ● Special paint finish

● Two-way catalytic converter for ● Integral sideshift ● Special low container-version

LP gas version ● Single or dual supplementary (Height of overhead guard h6 = 1980 mm)

● Vacuum filter for hydraulic system ● Warning markings

hydraulic power steering ● Controlled catalytic converter (LPG)

● Particle filter (diesel).

Additional equipment on request.

Linde AG, Linde Material Handling Division

Postfach 10 0136, 63701 Aschaffenburg, Germany

Phone +49-60 21- 99-0, Fax +49-60 21-99 -1570

www.linde-forklifts.com, info@linde-forklifts.com

You might also like

- Truck Stop Business PlanDocument40 pagesTruck Stop Business PlanBy Gibran Roman71% (7)

- Brochure HYSTER H2.5 TX-25T PDFDocument8 pagesBrochure HYSTER H2.5 TX-25T PDFFrancisco MoncayoNo ratings yet

- GD535-5 CEN00731-01 English PDFDocument20 pagesGD535-5 CEN00731-01 English PDFPachacuticCartuche67% (3)

- Hyundai 250D-7E Diesel Forklift Trucks Power and PerformanceDocument7 pagesHyundai 250D-7E Diesel Forklift Trucks Power and Performanceharshal161987100% (1)

- Diagrams and Schematics 1 - (04-2014) - Us-EnDocument102 pagesDiagrams and Schematics 1 - (04-2014) - Us-EnErisson100% (1)

- Allison Transmissions Operating Manual 2002 SmallDocument42 pagesAllison Transmissions Operating Manual 2002 SmallleoscazNo ratings yet

- FG WilsonDocument2 pagesFG WilsonMohammad Hazbehzad50% (4)

- IAB Passenger Handling Training 1Document31 pagesIAB Passenger Handling Training 1sir peter0% (1)

- Hydrostatic Drive Diesel/LPG Trucks 5,000 - 7,000 Lbs. Capacity H25D/T H30D/T H35D/TDocument6 pagesHydrostatic Drive Diesel/LPG Trucks 5,000 - 7,000 Lbs. Capacity H25D/T H30D/T H35D/Tahmed zhranNo ratings yet

- 1533717485ficha Técnica H8Document6 pages1533717485ficha Técnica H8XXX YYYNo ratings yet

- Linde EN Ds 139 l12r l16r 1103 BDocument4 pagesLinde EN Ds 139 l12r l16r 1103 BNadeem AhmedNo ratings yet

- Serie 391 H16-20 BROCHUREDocument8 pagesSerie 391 H16-20 BROCHUREOlvil MovilNo ratings yet

- Linde N20vi, N20vliDocument4 pagesLinde N20vi, N20vliATILLANo ratings yet

- Linde H40 45 50Document6 pagesLinde H40 45 50Lucas IbañezNo ratings yet

- Linde H40D/T, H45D/T, H50D/T Material Handling Forklifts - Manual & SpecificationsDocument6 pagesLinde H40D/T, H45D/T, H50D/T Material Handling Forklifts - Manual & Specificationssvinche43546No ratings yet

- Linde H70D 15000 LBDocument6 pagesLinde H70D 15000 LBhadi abdollahiNo ratings yet

- 16510Document12 pages16510DenNo ratings yet

- Linde Brochure 387-388 DR PDFDocument12 pagesLinde Brochure 387-388 DR PDFSohailAhmadNo ratings yet

- Lion's ChassisDocument2 pagesLion's ChassisPhilippine Bus Enthusiasts SocietyNo ratings yet

- G-Series Wheel Loaders Stage V 721G & 821G ModelsDocument20 pagesG-Series Wheel Loaders Stage V 721G & 821G ModelsGoran MatovicNo ratings yet

- Linde Series 5195 Reach Truck Spec SheetDocument8 pagesLinde Series 5195 Reach Truck Spec SheetYogitha Sarah BabyNo ratings yet

- Bro ShureDocument52 pagesBro Shurezio.jean01No ratings yet

- 899-Kompressor Atlas Copco Xats 347 CD SLDocument2 pages899-Kompressor Atlas Copco Xats 347 CD SLEng. Badawy IbrahimNo ratings yet

- Hitachi ZW550Document12 pagesHitachi ZW550ForomaquinasNo ratings yet

- glp060 070Document6 pagesglp060 070Edinson FlorianoNo ratings yet

- Wa200 5Document7 pagesWa200 5Richi Munez100% (2)

- ZF Cambio 2Document3 pagesZF Cambio 2J GNo ratings yet

- Volvo L150 F, L180 F, L220 F BrochureDocument36 pagesVolvo L150 F, L180 F, L220 F Brochuresixin93551No ratings yet

- NEUS Dump 1601 eDocument1 pageNEUS Dump 1601 eJamal HabbasNo ratings yet

- Technical Data: Neuson Fourwheel Drive DumperDocument1 pageTechnical Data: Neuson Fourwheel Drive DumperJamal HabbasNo ratings yet

- With New Hi-Line Versions: Traditionally InnovativeDocument16 pagesWith New Hi-Line Versions: Traditionally InnovativemiminiweweNo ratings yet

- Caterpillar 990H BrochureDocument20 pagesCaterpillar 990H BrochureEugene MalinowskiNo ratings yet

- Komatsu Gd555-5 eDocument8 pagesKomatsu Gd555-5 eRobert Lowe100% (2)

- Komatsu WA320 5Document7 pagesKomatsu WA320 5cristi_ama100% (2)

- D20 CR EnginesDocument4 pagesD20 CR EnginesxristinaNo ratings yet

- AT2412 Eng 02 324355777Document3 pagesAT2412 Eng 02 324355777bandanyimba738No ratings yet

- Technical Data: Neuson Fourwheel Drive DumperDocument1 pageTechnical Data: Neuson Fourwheel Drive DumperJamal HabbasNo ratings yet

- D85-18 WH PDFDocument20 pagesD85-18 WH PDFSBNo ratings yet

- J30 40XN XNTDocument24 pagesJ30 40XN XNTWalter LlanosNo ratings yet

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 pagesSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezNo ratings yet

- Dumper Specification PDFDocument4 pagesDumper Specification PDFravimutyamNo ratings yet

- 2 Series 2 Series: 45 - 50 - 60 STD / GEDocument8 pages2 Series 2 Series: 45 - 50 - 60 STD / GEГаврило ПринципNo ratings yet

- Specifications: Benefits Features and Advanced TechnologiesDocument3 pagesSpecifications: Benefits Features and Advanced TechnologiesRobertoGomezNo ratings yet

- Volvo D16 Engine Family: SpecificationsDocument3 pagesVolvo D16 Engine Family: SpecificationsJicheng PiaoNo ratings yet

- L550 - L580 2plus2 Stufe III-B - enDocument28 pagesL550 - L580 2plus2 Stufe III-B - ensanches pita100% (2)

- Wheel Loader L 586: Product InformationDocument16 pagesWheel Loader L 586: Product InformationcraigNo ratings yet

- Cummins Westport ISX12 G Brochure - 4971420 - 0313Document6 pagesCummins Westport ISX12 G Brochure - 4971420 - 0313noeing02No ratings yet

- IC Forklift X Series 4.0-Mini 5.0TDocument6 pagesIC Forklift X Series 4.0-Mini 5.0TNKG1001No ratings yet

- ZW 310 Wheel Loader: Top-Class Production with Amazing MobilityDocument20 pagesZW 310 Wheel Loader: Top-Class Production with Amazing MobilitySohibul AminNo ratings yet

- Specifications: Benefits Features and Advanced TechnologiesDocument8 pagesSpecifications: Benefits Features and Advanced TechnologiesESCC OfficeNo ratings yet

- DP80N - DP90N - DP100N - DP120N DP135N - DP150N - DP160N: SpecificationsDocument6 pagesDP80N - DP90N - DP100N - DP120N DP135N - DP150N - DP160N: SpecificationsBiniyam12100% (1)

- Hyundai H 1 BrochureDocument3 pagesHyundai H 1 BrochureMpho Daniel PuleNo ratings yet

- t3 50f Brochure Uk enDocument4 pagest3 50f Brochure Uk enDejan PanticNo ratings yet

- l110g, l120g: Volvo Wheel LoadersDocument32 pagesl110g, l120g: Volvo Wheel LoadersRalle RadioNo ratings yet

- Linde EN Ds n20cb n2025c n25chp br4587 en A 0419 ViewDocument6 pagesLinde EN Ds n20cb n2025c n25chp br4587 en A 0419 ViewNadeem AhmedNo ratings yet

- Hyundai Heavy Industries: Diesel Counterbalance TrucksDocument16 pagesHyundai Heavy Industries: Diesel Counterbalance TrucksLucasDiezNo ratings yet

- Series: Sit-Down, Counterbalanced IC, Pneumatic Tire LineDocument20 pagesSeries: Sit-Down, Counterbalanced IC, Pneumatic Tire LineOmar OVNo ratings yet

- GP060-070VX Spec SheetDocument6 pagesGP060-070VX Spec SheetNeil DesaiNo ratings yet

- Lotus Range Extender EngineDocument23 pagesLotus Range Extender Enginestefan.vince536No ratings yet

- Diesel and LPG Forklift Trucks Capacity 5000 - 8000 KGDocument2 pagesDiesel and LPG Forklift Trucks Capacity 5000 - 8000 KGwill wuNo ratings yet

- A04 12 02Document4 pagesA04 12 02Marius Babei100% (1)

- AT2812 Eng 01 331482018Document5 pagesAT2812 Eng 01 331482018AbelNo ratings yet

- 2TG20 30.140Document4 pages2TG20 30.140Achmad GunawanNo ratings yet

- Em-256 - Capacidades e Especificãoes-4121189-8000srm1732 - (05-2017) - Us-EnDocument14 pagesEm-256 - Capacidades e Especificãoes-4121189-8000srm1732 - (05-2017) - Us-EnErissonNo ratings yet

- Outriggers: 3500 PSI ReliefDocument2 pagesOutriggers: 3500 PSI ReliefErissonNo ratings yet

- LBCE process standardsDocument4 pagesLBCE process standardsErissonNo ratings yet

- Periodic Maintenance: PART NO. 4121195 8000 SRM 1734Document94 pagesPeriodic Maintenance: PART NO. 4121195 8000 SRM 1734Erisson100% (1)

- Parts 4121225 (D222) H PM US EN (07 2019)Document1,102 pagesParts 4121225 (D222) H PM US EN (07 2019)Erisson100% (1)

- 107A RED: Lbce Process StandardsDocument7 pages107A RED: Lbce Process StandardsErissonNo ratings yet

- Notes:: Trans Serv DRY WETDocument2 pagesNotes:: Trans Serv DRY WETErissonNo ratings yet

- Calibration Procedures - (04-2014) - Us-EnDocument66 pagesCalibration Procedures - (04-2014) - Us-EnErisson0% (1)

- Cooling System - (03-2013) - Us-EnDocument70 pagesCooling System - (03-2013) - Us-EnErissonNo ratings yet

- Linde H20T - 03Document591 pagesLinde H20T - 03Wagner Dalla Bernardine100% (1)

- Capacities and Specifications - (02-2014) - Us-EnDocument22 pagesCapacities and Specifications - (02-2014) - Us-EnErissonNo ratings yet

- 0900766b803b14a0.pdf DOUGLASDocument11 pages0900766b803b14a0.pdf DOUGLASErissonNo ratings yet

- LBCE Process Standards Relief Valve SettingsDocument2 pagesLBCE Process Standards Relief Valve SettingsErissonNo ratings yet

- 2100 BrochureDocument2 pages2100 BrochureErissonNo ratings yet

- 7Iggm×R 4vsgihmqmirxswhitvyifew 7Iggm×R: 4Vyifehipegsqtviwm×RhipqsxsvDocument20 pages7Iggm×R 4vsgihmqmirxswhitvyifew 7Iggm×R: 4Vyifehipegsqtviwm×RhipqsxsvErissonNo ratings yet

- Cylinder Repair (Mast SN A513, A514, A613, A614, B513BB514) - (02-2014) - Us-EnDocument66 pagesCylinder Repair (Mast SN A513, A514, A613, A614, B513BB514) - (02-2014) - Us-EnErissonNo ratings yet

- Seltec AC Compressor Catalog 2010Document39 pagesSeltec AC Compressor Catalog 2010Erisson100% (1)

- 7iggm (R - Rjsvqegm×Rkirivep 7iggm (R:, IvveqmirxewhiwivzmgmsDocument20 pages7iggm (R - Rjsvqegm×Rkirivep 7iggm (R:, IvveqmirxewhiwivzmgmsErissonNo ratings yet

- Kubota ManualDocument38 pagesKubota ManualRODRIGO_RALO50% (4)

- View All Qtys A: 580080176 and 580095355 B: 580050701 and 580095356Document2 pagesView All Qtys A: 580080176 and 580095355 B: 580050701 and 580095356ErissonNo ratings yet

- Parts Manual ERP040DH, ERP050DH, ERP060DH (D216) : Yale Materials Handling CorporationDocument280 pagesParts Manual ERP040DH, ERP050DH, ERP060DH (D216) : Yale Materials Handling CorporationErisson100% (1)

- Sistema Elétrico Gp-155Document194 pagesSistema Elétrico Gp-155ErissonNo ratings yet

- G65QSDocument4 pagesG65QSSamuel ZaragozaNo ratings yet

- Sistema Elétrico Gp-155Document194 pagesSistema Elétrico Gp-155ErissonNo ratings yet

- HA00034R01YDocument2 pagesHA00034R01YErissonNo ratings yet

- DSE 4510 Dse4520 Operator ManualDocument64 pagesDSE 4510 Dse4520 Operator ManualPedro100% (5)

- 2001 Series: Standard SpecificationDocument2 pages2001 Series: Standard SpecificationErissonNo ratings yet

- A5S 390R Transmission Catalogue - Automatic Choice 1Document9 pagesA5S 390R Transmission Catalogue - Automatic Choice 1Ivaylo GeorgievNo ratings yet

- Alternate SponsorshipsDocument4 pagesAlternate Sponsorshipsbigkev73100% (1)

- JCB 360 SpecyfikacjaDocument1 pageJCB 360 SpecyfikacjaAlicja PopielNo ratings yet

- Table With Trend (1) * Chép bài mẫu (không cần chép phần Vietnamese) - Ghi question tương ứng trong tập đề Example 1Document6 pagesTable With Trend (1) * Chép bài mẫu (không cần chép phần Vietnamese) - Ghi question tương ứng trong tập đề Example 1Vân Anh NguyễnNo ratings yet

- Pavement Design Guide - A Short CourseDocument325 pagesPavement Design Guide - A Short CourseEloy Jimenez OntiverosNo ratings yet

- MG HSDocument5 pagesMG HSVed DomaNo ratings yet

- LRT Feasibility StudyDocument30 pagesLRT Feasibility StudyBhagyashri KulkarniNo ratings yet

- UAZ PROFI Original Accessories CatalogueDocument19 pagesUAZ PROFI Original Accessories Cataloguetrasnochador77No ratings yet

- Producto: TRUCK Modelo: 793F TRUCK SSP Configuración: 793F Off-Highway Truck SSP00001-UP (MACHINE) POWERED BY C175-16 EngineDocument2 pagesProducto: TRUCK Modelo: 793F TRUCK SSP Configuración: 793F Off-Highway Truck SSP00001-UP (MACHINE) POWERED BY C175-16 EnginemanuelNo ratings yet

- GAD Major Bridge Cum VUP LVUP SVUP 4.50m ClearanceDocument9 pagesGAD Major Bridge Cum VUP LVUP SVUP 4.50m ClearanceVipin cNo ratings yet

- Operations Management Sustaina Chain Management 12th EditionDocument1 pageOperations Management Sustaina Chain Management 12th Editionomer asgharNo ratings yet

- Electronic Control System 1. General: Chassis - A750E and A750F Automatic Transmissions CH-50Document14 pagesElectronic Control System 1. General: Chassis - A750E and A750F Automatic Transmissions CH-50Maxi SardiNo ratings yet

- 19 Performing Underchassis Preventive PDFDocument124 pages19 Performing Underchassis Preventive PDFMujeres Virglius PabliusNo ratings yet

- Majestic Dash8 Checklists PDFDocument13 pagesMajestic Dash8 Checklists PDFDanielNo ratings yet

- Industrial Training Report SubmissionDocument49 pagesIndustrial Training Report SubmissionkannanNo ratings yet

- The Sharan: Technical DataDocument24 pagesThe Sharan: Technical DatacitalacNo ratings yet

- A Vision of NagpurDocument95 pagesA Vision of NagpurpritisakoreNo ratings yet

- Wireless Door Lock Control System Registration ProcedureDocument5 pagesWireless Door Lock Control System Registration Procedureawan wijayantoNo ratings yet

- Road Safety Crossword 1Document2 pagesRoad Safety Crossword 1Kanageswary Sai0% (1)

- A2 U4 Extra Grammar Practice Reinforcement PDFDocument1 pageA2 U4 Extra Grammar Practice Reinforcement PDFVick BastinNo ratings yet

- Denim IntroductionDocument13 pagesDenim IntroductionSrinivas PatraNo ratings yet

- NHAI Environment Impact AssesmentDocument201 pagesNHAI Environment Impact AssesmentVinay Raj100% (1)

- (Forensic) Criminalistic Study Materials..Document59 pages(Forensic) Criminalistic Study Materials..Bernabe Fuentes Jr.No ratings yet

- Torque Bull Gear Pv729-Pi0759Document6 pagesTorque Bull Gear Pv729-Pi0759Patricio Alejandro Castro LopezNo ratings yet

- LJ 50 QTDocument54 pagesLJ 50 QTverkacktNo ratings yet

- Summary Destiantio TGL 08 - 09 SeptemberDocument3 pagesSummary Destiantio TGL 08 - 09 SeptemberDicky ArdiansyahNo ratings yet

- Audi SSP 438 Audi The Advanced Maintenance ConceptDocument4 pagesAudi SSP 438 Audi The Advanced Maintenance Conceptjonathan100% (45)

- Vehicle Impact Protection ResearchDocument12 pagesVehicle Impact Protection ResearchDianna LambertNo ratings yet