Professional Documents

Culture Documents

SFX 200 Technical Data Sheet Nov.18

Uploaded by

totoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SFX 200 Technical Data Sheet Nov.18

Uploaded by

totoCopyright:

Available Formats

HARMAN technology Limited

TECHNICAL INFORMATION

SFX 200

BLACK AND WHITE CAMERA FILM WITH EXTENDED RED

SENSITIVITY FOR CREATIVE PHOTOGRAPHY

ILFORD SFX 200 is a medium speed black and white camera film for creative photography. It has extended

red sensitivity (up to 740nm) and is especially suited for use with a red filter to create special effects. For

example, by using a very deep red filter, skies can be rendered almost black, and most green vegetation almost

white. Its unusual tonal rendition ensures interesting results for a range of subjects, including portraits,

landscapes, townscapes and architecture.

Best results are obtained in bright sunshine, or in the studio under tungsten lighting.

SFX also has full panchromatic sensitivity to ensure good pictorial contrast with or without the use of a filter. It

has a wide exposure latitude and is compatible with all normal developers. It has a wide tonal range.

AVAILABILITY

SFX 200 film is coated on 0.125mm/5-mil grey acetate base which gives good halation protections.

SFX 200 is available in 36 exposure DX coded cassettes, suitable for all 35mm cameras.

SFX 200 is also available as120 roll film, edge numbered 1 to 19.

EXPOSURE RATING

SFX 200 has a speed rating of ISO 200/24° to daylight.

The ISO speed rating was measured using ILFORD ID-11 developer at 20°C/68°F with intermittent agitation in

a spiral tank.

It should be noted that the exposure index (EI) range recommended for SFX 200is based on a practical

evaluation of film speed and is not based on foot speed, as is the ISO standard.

SPECTRAL SENSITIVITY

Wedge spectrogram to tungsten light (2850K)

Page 1 of 6 Nov 2018

SFX 200Technical Information

USE OF FILTERS

SFX 200 film can be used with yellow, orange or red filters, but the effect seen will depend on its transmission

characteristics. The redder the filter, the more dramatic the effect. With very dark filters, exposure times can be

very long, so the use of a tripod is recommended. Below is a guide to filter factors for various filter colours.

Filter Factors

Filter Filter Colour Filter Exposure

Kodak Wratten Factor Increase (Stops)

(or equivalent)

3 Very Light Yellow 2 1

8 Yellow 2 1 ⅓

12 Deep Yellow 2.3 1 ⅓

15 Very Deep Yellow 2.4 1 ⅓

21 Orange 2.4 1 ⅓

23a Reddish Orange 2.5 1 ⅓

25 Red 2.8 1 ½

29 Deep Red 3 1 ⅔

89B Very Deep Red 16 4

LOADING THE CAMERA

SFX 200 must be loaded in subdued light. Unlike true infra-red film, it is not necessary to load it in total

darkness.

FOCUSING

With some lenses, red light focuses at a slightly different point to other visible light. With these lenses, there

may be a shift when focusing in white light compared with red light. However, it is almost impossible to focus a

camera with a deep red filter in place.

With short to moderate focal length lenses, this difference can easily be accommodated by stopping down to

the smallest working aperture. Some lenses, particularly apochromatic (APO) designs, may need no correction.

EXPOSURE

A certain amount of experimentation is needed when first using this film. As a guide, bracket exposures by +/-

2 stops from the TTL reading with the filter in place, or the meter reading with the filter factor applied.

Note The TTL metering on some common cameras can under expose by up to 1 1/2 stops with deep red or

orange filters in place.

If you want to check the TTL metering system on your camera before starting, set the metering system of the

camera to EI 200/24, and with your filter in place – make a series of exposures up to ± 2 stops from the

indicated exposure. After processing, decide which is the best negative and re-set the camera if necessary. As

an example, the correct exposure in bright sunlight with a deep red filter is around 1/30th second at f5.6.

CHARACTERISTIC CURVE

SFX 200 film developed in ILFORD ID-11 stock for 10 minutes at 20ºC/68ºF

with intermittent agitation.

Page 2 of 6 Nov 2018

SFX 200Technical Information

PROCESSING

SFX 200 can be processed in all types of processing equipment, including spiral tanks, rotary processors, deep

tanks and automatic processors. Standard capacity figures and replenishment rates can be maintained.

SFX 200 is very robust in processing and will tolerate less than ideal processing conditions. Also, it will not

contaminate the processing chemicals.

DEVELOPMENT TIMES

The table on page 4 gives development times for both manual and machine processing. These times will

produce negatives of average contrast – suitable for printing in all enlargers.

The development times are intended as a guide and may be altered if a different result in needed.

For manual processing in spiral tanks and deep tanks, the development times are based on intermittent

agitation. Where continuous agitation is used for manual processing, and for use in rotary processors without a

pre-rinse - reduce the spiral tank development times by up to 15%.

Generally, a pre-rinse is not recommended, as it can lead to uneven processing.

CHOOSING THE BEST ILFORD DEVELOPER FOR THE JOB

Manual processing Spiral tank, dish/tray, deep tank

Including rotary processors

Liquid Powder

Best overall image quality

EI 200/24 ILFOTEC DD-X ID-11 (stock)

EI400/27 ILFOTEC DD-X ID-11 (stock)

EI800/30 ILFOTEC DD-X ID-11 (stock)

Finest grain ILFOTEC DD-X PERCEPTOL

Maximum sharpness ILFOSOL 3 (1+9) ID-11 (1+1)

Maximum film speed ILFOTEC DD-X MICROPHEN (stock)

Economy ILFOTEC LC29 (1+29) ID-11 (1+1)

MICROPHEN (1+1)

One-shot convenience ILFOSOL 3 (1+9) ID-11 (1+1)

ILFOTEC DD-X MICROPHEN (1+1)

Replenishable ILFOTEC DD-X ID-11

Machine Processing

Dip and dunk ILFOTEC DD Best overall image quality (liquid) and long tank life

ID-11 Best overall image quality (powder) and long tank life

Short leader ILFOTEC RT RAPID Rapid processing, best overall image quality and

long tank life.

Roller transport ILFOTEC RT RAPID Rapid processing

Page 3 of 6 Nov 2018

SFX 200Technical Information

35mm and Roll Film

Meter setting (EI)

ILFORD developer Dilution

200/24 400/27 800/30

Spiral tank, deep tank, dip and dunk machines (min/20°C/68°F)

ILFOTEC DD-X 1+4 10 14 −

ILFOSOL 3 1+9 6 8½ --

1+14 9 13½ −

ILFOTEC HC 1+15 5 7 10½

1+31 9 13 19

ILFOTEC LC29 1+9 5 7 10½

1+19 9 13 19

1+29 11 − −

ID-11 stock 10 14 18

1+1 17 − −

MICROPHEN stock 8½ 10½ 14½

1+1 15½ 19 −

PERCEPTOL stock 14½ − −

1+1 20 − _

Non-ILFORD Developers (min/20°C/68°F)

Developer Dilution Meter setting (EI)

200/24 400/27 800/30

Kodak D-76 stock 10 12½ 16½

1+1 14½ − −

Kodak HC-110 A 5 7 10½

B 9 13 19

Kodak T-Max 1+4 8½ 10½ 12½

Tetenal Ultrafin 1 + 10 10 13 −

Kodak Xtol stock 7 11 −

Dip and dunk machines (min/24°C/75°F)

ILFOTEC DD 1+4 8½ 11½ 14

Kodak T-Max RS stock 6 7 9

Kodak Xtol stock 7 9 11½

ILFOLAB FP40, roller transport and short leader machines (sec/26°C/79°F)

ILFOTEC RT RAPID 1+1+2 54 65 88

1+1+5 65 90 120

Note. Development times may need adjusting to suit individual processing systems and working practices. If an

established system is producing good results, adjust the recommended development times until the desired

contrast level is obtained. Development times in other manufacturers’ developers are included for your

convenience and are only a general guide. Other manufacturers can and do change their product

specifications from time to time, and the development times may change as a result.

Page 4 of 6 Nov 2018

SFX 200Technical Information

PROCESSING

Processing at Different Temperatures

SFX 200 film can be processed over a range of temperatures. Approximate development times at temperatures

other than 20°C/68°F may be calculated from the charts below. For example, if 4 minutes at 20°C/68°F is

recommended, the time at 23°C/73°F will be 3 minutes and the time at 16°C/61°F will be 6 minutes.

PROCESSING

SFX 200 can be processed in all types of processing equipment including spiral tanks, rotary processors, deep

tanks and automatic processors. Standard capacity figures and replenishment rates can be maintained.

Safelight recommendations

Handle SFX 200 film in total darkness.

Agitation

Intermittent agitation is recommended for use in spiral tanks and deep tanks. With spiral tanks, invert the tank

four times during the first 10 seconds, then invert the tank four times again during the first 10 seconds of each

further minute. Otherwise, follow the recommendations given by the processing equipment manufacturer.

Stop, fix, wash and rinse

For best results it is recommended that all process solutions are kept at the same temperature or at least within

5ºC (9ºF) of the developer temperature.

Stop Bath

After development the film can be rinsed in

water, but we recommend that an acid stop ILFORD ILFOSTOP

bath is used such as ILFORD ILFOSTOP (with

indicator dye). ILFOSTOP is also Dilution 1+19

recommended for all machine processing

applications. When tanks or dishes (trays) of Temperature Range 18–24ºC (64–75ºF)

process solutions are in use a stop bath

immediately stops development and reduces Time (sec) at 20ºC (68ºF) 10

carry over of excess developer into the fixer

bath. This helps to maintain the activity and Capacity (films per litre,

15x (135-36)

prolong the life of the fixer solution. unreplenished)

Page 5 of 6 Nov 2018

SFX 200Technical Information

Fix

The recommended fixers are ILFORD RAPID ILFORD RAPID OR HYPAM FIXERS

FIXER or ILFORD HYPAM FIXER.

Dilution 1+4

Wash

Wash the films in running water for 5–10 Temperature Range 18–24ºC (64–75ºF)

minutes at a temperature within 5ºC (9ºF) of

the process temperature. Or see note below Time (mins) at 20ºC (68ºF) 2-5

for greater economy when using spiral tanks.

Capacity (films per litre,

24x (135-36)

unreplenished)

Note: For spiral tank use, the following method of washing is recommended. This method of washing is faster,

uses less water yet still gives negatives suitable for long term storage.

After fixing, fill the spiral tank with water at the same temperature, ± 5ºC (9ºF), as the processing solutions and

invert it five times. Drain the water away and refill. Invert the tank ten times. Once more drain the water away

and refill. Finally, invert the tank twenty times and drain the water away.

Rinse

For a final rinse use ILFORD ILFOTOL wetting agent added to water, it helps the film to dry rapidly and evenly.

Start by using 5ml per litre of rinse water (1+200), however the amount of ILFOTOL used may need some

adjustment depending on the local water quality and drying method. Too little or too much wetting agent can

lead to uneven drying. Remove excess rinse solution from the film before drying.

Drying

To avoid drying marks, use a clean squeegee or chamois cloth to wipe SFX 200 film before hanging it to dry.

Dry SFX 200at 30–40°C/86-104°F in a drying cabinet or at room temperature in a clean dust-free area.

STORAGE

For immediate use, store SFX 200in a cool (10–20°C/50-68°F), dry place in its original packaging.

SFX 200 may be stored in a fridge/freezer but allow plenty of time for the film to acclimatise prior to use.

Exposed film

Once exposed, process SFX 200 as soon as practical.

Exposed films should always be stored in cool, dry conditions - as recommended above.

Negatives

Store processed negatives in a cool (10–20°C/50-68°F), dry place, in the dark. Suitable storage sleeves

include those made of cellulose triacetate, Mylar, paper (pH6.5–7.5) or inert polyester.

A wide range of fact sheets is available which describe and give guidance on using ILFORD PHOTO products.

Some products in this fact sheet might not be available in your country.

HARMAN technology Limited, Ilford Way, Mobberley,

Knutsford, Cheshire WA16 7JL, England

www.ilfordphoto.com

Page 6 of 6 Nov 2018

You might also like

- Ilford Pan 100 y 400 FilmDocument9 pagesIlford Pan 100 y 400 FilmJohann Walter Carpio AcurioNo ratings yet

- Ilford Pan F PlusDocument6 pagesIlford Pan F PlusPabloMartinezNo ratings yet

- Ilford Pan F PlusDocument6 pagesIlford Pan F Plusmathun1No ratings yet

- High Speed B&W Film GuideDocument7 pagesHigh Speed B&W Film GuideFernando GiorgioNo ratings yet

- Fp4 Plus: Technical InformationDocument6 pagesFp4 Plus: Technical Informationgiovanni.castelletti2004No ratings yet

- Ilford Pan 50 PlusDocument6 pagesIlford Pan 50 PlusJohann Walter Carpio AcurioNo ratings yet

- PDFDocument7 pagesPDFmibblNo ratings yet

- Fact Sheet: Spectral Sensitivity Wedge Spectrogram To Tungsten Light (2850K)Document7 pagesFact Sheet: Spectral Sensitivity Wedge Spectrogram To Tungsten Light (2850K)c64thorgalNo ratings yet

- Ilford Data SheetsDocument7 pagesIlford Data Sheetstester1972No ratings yet

- DELTA 100 Technical Data Sheet April 23Document7 pagesDELTA 100 Technical Data Sheet April 23Itzel BravoNo ratings yet

- DELTA 400 Professional: Technical InformationDocument7 pagesDELTA 400 Professional: Technical Informationgiovanni.castelletti2004No ratings yet

- Iso 125/22º Black and White Professional Film For High Print Quality and Flexibility in UseDocument6 pagesIso 125/22º Black and White Professional Film For High Print Quality and Flexibility in UseAlexandre PereiraNo ratings yet

- DELTA 100 Professional: Technical InformationDocument6 pagesDELTA 100 Professional: Technical Informationgiovanni.castelletti2004No ratings yet

- Ilford Delta 100Document6 pagesIlford Delta 100gstabNo ratings yet

- Ilford Delta 400 Film GuideDocument7 pagesIlford Delta 400 Film GuideKiel BryantNo ratings yet

- ISO 400 BLACK & WHITE FILM FOR HIGH PRINT QUALITYDocument7 pagesISO 400 BLACK & WHITE FILM FOR HIGH PRINT QUALITYfalariotisNo ratings yet

- HP5 Plus Film Guide for High Print QualityDocument6 pagesHP5 Plus Film Guide for High Print QualitySteve MorleyNo ratings yet

- ISO 400 B&W Film Guide for High PrintsDocument7 pagesISO 400 B&W Film Guide for High PrintsbigzuruNo ratings yet

- Ilford Pan 100 400 Manual EngDocument9 pagesIlford Pan 100 400 Manual Engalchy00No ratings yet

- Developing Instructions: Fomapan Action 400Document3 pagesDeveloping Instructions: Fomapan Action 400Roberto RutkauskasNo ratings yet

- Kodak Hp5 PlusDocument8 pagesKodak Hp5 PlusGabriele LicitraNo ratings yet

- ILFOTEC DD-X Technical Data Sheet H19Document8 pagesILFOTEC DD-X Technical Data Sheet H19cayolucilioNo ratings yet

- Ilford Film DevelopingDocument11 pagesIlford Film Developingreadalotbutnowisdomyet100% (1)

- MG4RC - Vs - MGRC DELUXE Comparison c20Document3 pagesMG4RC - Vs - MGRC DELUXE Comparison c20duncanNo ratings yet

- Multigrade RC Papers: Technical InformationDocument6 pagesMultigrade RC Papers: Technical InformationduncanNo ratings yet

- MULTIGRADE IV RC Papers 060619Document5 pagesMULTIGRADE IV RC Papers 060619Layne OrtegaNo ratings yet

- MP 2554-6054 Series - Full-Ct - EN - 1.0.aDocument277 pagesMP 2554-6054 Series - Full-Ct - EN - 1.0.aArlindPacuku100% (1)

- Fomapan 200Document3 pagesFomapan 200Jovan Mac TireNo ratings yet

- Kodak Professional Tri-X 320 and 400 Films: Technical Data / Black-And-White FilmDocument9 pagesKodak Professional Tri-X 320 and 400 Films: Technical Data / Black-And-White FilmVilla ClaudioNo ratings yet

- En IeliteDocument4 pagesEn Ielitefernando machadoNo ratings yet

- Toshiba FDX3543RP X Ray Flat Panel DetectorDocument14 pagesToshiba FDX3543RP X Ray Flat Panel DetectorJairo Manzaneda100% (1)

- KODAK VISION Expression 500T Color Negative Film / 5284, 7284Document12 pagesKODAK VISION Expression 500T Color Negative Film / 5284, 7284Omar García MNo ratings yet

- PTZ Series BrochureDocument20 pagesPTZ Series BrochureAny LunaNo ratings yet

- Dow Filmtec LP 4040Document2 pagesDow Filmtec LP 4040Alejandro AliNo ratings yet

- EASTMAN DOUBLE X Negative Film Datasheet US 180924 ENDocument2 pagesEASTMAN DOUBLE X Negative Film Datasheet US 180924 ENtonyNo ratings yet

- Fomapan-400 Info FilmDocument2 pagesFomapan-400 Info FilmRoberto RutkauskasNo ratings yet

- Kodak Professional Plus-X 125 Film / 125PX: Technical Data / Black-And-White FilmDocument10 pagesKodak Professional Plus-X 125 Film / 125PX: Technical Data / Black-And-White FilmGreg MartNo ratings yet

- Fomapan 100Document3 pagesFomapan 100hxbxrtNo ratings yet

- FOCAS-2000 instruction manual postscript and emendationsDocument5 pagesFOCAS-2000 instruction manual postscript and emendationsSumit ChandwaniNo ratings yet

- Kentmere 100Document3 pagesKentmere 100paulhaffendenNo ratings yet

- The Nation's Sound Source Since 1930Document22 pagesThe Nation's Sound Source Since 1930waldoNo ratings yet

- ELFTEX 570-EnglishDocument2 pagesELFTEX 570-EnglishLeandro EsvizaNo ratings yet

- Diestone D TDS EnglishDocument3 pagesDiestone D TDS EnglishMILTON GABRIEL GRANDES ROMANNo ratings yet

- Kodak D 76Document1 pageKodak D 76ssakissNo ratings yet

- ILFORD PHOTO To Kodak EquivalentsDocument2 pagesILFORD PHOTO To Kodak EquivalentsMichael ZhangNo ratings yet

- Sw30-Hrle400 Data SheetDocument3 pagesSw30-Hrle400 Data SheetdimasNo ratings yet

- YgojDocument25 pagesYgojAnshul SainiNo ratings yet

- Kodak Verichrome PanDocument4 pagesKodak Verichrome Panfoster747No ratings yet

- Readme PDFDocument5 pagesReadme PDFdarshNo ratings yet

- Corro-Coat PE Series 50Document4 pagesCorro-Coat PE Series 50Biju_PottayilNo ratings yet

- FX 39Document1 pageFX 39Massimo RapoNo ratings yet

- Kodak Tri-X Data SheetDocument16 pagesKodak Tri-X Data SheetNate CochraneNo ratings yet

- VISION3 200T Color Negative Film 7213 TECHNICAL DATADocument5 pagesVISION3 200T Color Negative Film 7213 TECHNICAL DATASeleneSchwarzNo ratings yet

- TB1240ANDocument85 pagesTB1240ANPaulo Roberto s freireNo ratings yet

- FD 8030 User ManualDocument2 pagesFD 8030 User ManualPopa DanNo ratings yet

- Fosroc CatalogueDocument298 pagesFosroc CatalogueGeorge Tsiamtsouris75% (4)

- Mitsubishi FX Programmable Logic Controllers: Applications and ProgrammingFrom EverandMitsubishi FX Programmable Logic Controllers: Applications and ProgrammingNo ratings yet

- Nikon D850 Experience - The Still Photography Guide to Operation and Image Creation with the Nikon D850From EverandNikon D850 Experience - The Still Photography Guide to Operation and Image Creation with the Nikon D850No ratings yet

- Anaesth Pain Intensive Care 2016 20 Supp 91 96Document6 pagesAnaesth Pain Intensive Care 2016 20 Supp 91 96totoNo ratings yet

- Fuze SFX: PreliminaryDocument2 pagesFuze SFX: PreliminarytotoNo ratings yet

- Vishay Electro-Films: FeaturesDocument3 pagesVishay Electro-Films: FeaturestotoNo ratings yet

- CSM Tamping Cylinder SpecificationDocument4 pagesCSM Tamping Cylinder SpecificationtotoNo ratings yet

- LM Guide Separate Type (Radial) Model GSRDocument8 pagesLM Guide Separate Type (Radial) Model GSRtotoNo ratings yet

- اهم مشاريع الرسمDocument10 pagesاهم مشاريع الرسمtotoNo ratings yet

- 411e HSV G AttiDocument4 pages411e HSV G Attigianmarco1810No ratings yet

- Vaccinations Given With The FIADocument2 pagesVaccinations Given With The FIAtotoNo ratings yet

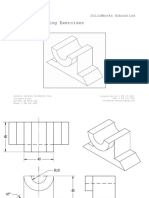

- SolidWorks Education Detailed Drawing ExercisesDocument51 pagesSolidWorks Education Detailed Drawing ExercisestotoNo ratings yet

- Hooks and Attention Grabbers PDFDocument2 pagesHooks and Attention Grabbers PDFWalid SolimanNo ratings yet

- Sorry: Please Downloa DDocument1 pageSorry: Please Downloa DtotoNo ratings yet

- Activate GRAPE TrialDocument7 pagesActivate GRAPE TrialtotoNo ratings yet

- Chap4 ADocument14 pagesChap4 AtotoNo ratings yet

- Houh - Emily Pathfinder Branded Bio 2019Document1 pageHouh - Emily Pathfinder Branded Bio 2019totoNo ratings yet

- Emily M.S. Houh University of Cincinnati College of LawDocument6 pagesEmily M.S. Houh University of Cincinnati College of LawtotoNo ratings yet

- Simulink: Rms Rms Rms Rms - 1Document8 pagesSimulink: Rms Rms Rms Rms - 1Ahmed JamalNo ratings yet

- Simulink: Rms Rms Rms Rms - 1Document8 pagesSimulink: Rms Rms Rms Rms - 1Ahmed JamalNo ratings yet

- GRAPE Activation GuideDocument7 pagesGRAPE Activation GuidetotoNo ratings yet

- Mapletut 2Document145 pagesMapletut 2bogo_bogdanNo ratings yet

- Matlab Quick ReferenceDocument12 pagesMatlab Quick Referencevahid100% (3)

- Relap5/Mod3.3 Code Manual Summaries and Reviews of Independent Code Assessment ReportsDocument152 pagesRelap5/Mod3.3 Code Manual Summaries and Reviews of Independent Code Assessment ReportstotoNo ratings yet

- Tutorial To Run CalculationsDocument14 pagesTutorial To Run CalculationstotoNo ratings yet

- Iss Software BrochureDocument8 pagesIss Software BrochuretotoNo ratings yet

- Matlab Quick ReferenceDocument12 pagesMatlab Quick Referencevahid100% (3)

- Iss Software BrochureDocument8 pagesIss Software BrochuretotoNo ratings yet

- RELAP5/MOD3.3 USER'S GUIDE AND INPUT REQUIREMENTSDocument160 pagesRELAP5/MOD3.3 USER'S GUIDE AND INPUT REQUIREMENTSWilhelm ThorleyNo ratings yet

- Hydraulics For Fluid Systems and Reactors: - Detailed System ThermalDocument2 pagesHydraulics For Fluid Systems and Reactors: - Detailed System ThermaltotoNo ratings yet

- RELAP5-SCDAP data deck and input formatDocument285 pagesRELAP5-SCDAP data deck and input formattotoNo ratings yet

- GRAPE User's GuideDocument114 pagesGRAPE User's GuidetotoNo ratings yet

- CSWIP Welding Inspector Certification RequirementsDocument27 pagesCSWIP Welding Inspector Certification RequirementsshrikantajitNo ratings yet

- Canon EOS 50D and 5D Mark II White PaperDocument77 pagesCanon EOS 50D and 5D Mark II White Papertomasek100% (7)

- A Handheld Gun Detection Using Faster R-CNN Deep LearningDocument5 pagesA Handheld Gun Detection Using Faster R-CNN Deep LearningJanderson LiraNo ratings yet

- Arista Liquid C41Document2 pagesArista Liquid C41jbenscrNo ratings yet

- Radiography ArtifactsDocument15 pagesRadiography ArtifactsLavinia BaracNo ratings yet

- Listening Part BDocument13 pagesListening Part BUmmu ArkaanNo ratings yet

- 'Give Us Day by Day Our Daily Bread.': Continental Army Bread, Ovens, and BakersDocument43 pages'Give Us Day by Day Our Daily Bread.': Continental Army Bread, Ovens, and BakersJohn U. Rees100% (4)

- Mail Order BrochureDocument5 pagesMail Order BrochureVirat GadhviNo ratings yet

- PHOTOJOURNALISMDocument2 pagesPHOTOJOURNALISMJosephNo ratings yet

- Ir4570 Series PDFDocument876 pagesIr4570 Series PDFHan SonNo ratings yet

- 1 Fdtimes-40Document16 pages1 Fdtimes-40Lorena Hoyos GómezNo ratings yet

- (Adam Schlecter) BookDocument55 pages(Adam Schlecter) BookJames Warren50% (2)

- Changes in Protein Compositions and Their Effects On Physical PDFDocument11 pagesChanges in Protein Compositions and Their Effects On Physical PDFCarolina Botani GóesNo ratings yet

- Langsford Agfa Silette 1958 CLADocument21 pagesLangsford Agfa Silette 1958 CLAJan CocNo ratings yet

- Vectorian Giotto ManualDocument45 pagesVectorian Giotto Manualutchanovsky92% (13)

- Where I'm FromDocument5 pagesWhere I'm FromGjorgiNo ratings yet

- How To Make HDR Shots With The Nokia 808 PureView - SmartCamClubDocument7 pagesHow To Make HDR Shots With The Nokia 808 PureView - SmartCamClubGdgtGuillermoNo ratings yet

- The Messenger: No. 124 - June 2006Document48 pagesThe Messenger: No. 124 - June 2006European Southern ObservatoryNo ratings yet

- Roger Deakins Crafts Eerie Atmosphere for The VillageDocument5 pagesRoger Deakins Crafts Eerie Atmosphere for The VillagePhilip SkorykhNo ratings yet

- Goh Shu Ching - Resume - 2020 - NovartisDocument2 pagesGoh Shu Ching - Resume - 2020 - NovartisSouseiseki ChromeNo ratings yet

- Logical Reasoning AnswersDocument133 pagesLogical Reasoning AnswersVidhu OberoiNo ratings yet

- Poems For Practice AnnotationDocument6 pagesPoems For Practice AnnotationxxpolxxNo ratings yet

- The Express Picture Dictionary - Activity BookDocument122 pagesThe Express Picture Dictionary - Activity BookNatalia Niewiadomska83% (6)

- Noise Exposure at Work: Hearing Loss Prevention Rule (Noise) WAC 296-817Document48 pagesNoise Exposure at Work: Hearing Loss Prevention Rule (Noise) WAC 296-817Gunnie PandherNo ratings yet

- Quantum Q RadDocument4 pagesQuantum Q RadDante NuevoNo ratings yet

- Bronica SQ-B ManualDocument24 pagesBronica SQ-B ManualBA (Hons) Photography, Contemporary PracticeNo ratings yet

- Top Selling Appliances and Electronics VendorsDocument144 pagesTop Selling Appliances and Electronics VendorsAdhy AthariNo ratings yet

- On-Site Manual SteelgridHR (Rev2-1)Document30 pagesOn-Site Manual SteelgridHR (Rev2-1)wandamektanNo ratings yet

- Art of 3d ToonsDocument183 pagesArt of 3d ToonsAna RosaNo ratings yet

- ReasoningDocument363 pagesReasoningSHAHRUKH KHANNo ratings yet