Professional Documents

Culture Documents

checklistPSVtesch Bench

Uploaded by

Vũ Minh Nhật0 ratings0% found this document useful (0 votes)

27 views3 pagesOriginal Title

checklistPSVtesch bench

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views3 pageschecklistPSVtesch Bench

Uploaded by

Vũ Minh NhậtCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Checklist

(for Test Benches)

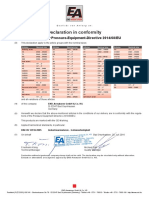

EFCO Maschinenbau GmbH – Valve repair and testing equipment

Otto-Brenner-Straße 5 – 7 D - 52353 Düren/Germany Phone: +49-(0)2421-989-0 Fax: +49-(0)2421-86260

sales@efco-dueren.de info@efco-dueren.de www.efco-dueren.com Agencies in many countries

Company name: Date:

Phone:

Contact person: E-mail:

• Type of valves and how to be tested?

Shut off valves and regulating valves (Page 1)

Safety relief valves (Page 2)

– Shut-off valves and regulating valves –

Valve type: Gate valves Valves Ball valves

Butterfly valves Return flaps Control valves

Others:

Valve end: Flange- Butt welded- Threads-

Others:

Valve shape: 2-Way- Straight form Angular form

Others:

• What kind of tests have to be done?

Water / Air (LP-6 bar (87 psi))

Water / Air (LP-6 bar (87 psi)) / Air/Nitrogen (HP)

Other tests:

(LP = Low pressure; HP = High pressure)

• What is the maximum test pressure at what size (DN)?

(you should only indicate DN sizes and test pressures according to your main program. Exceptions (sizes/pressures) can

increase the price of the test bench and its accessories very much!)

Max. test pressure using water (bar, psi or class)

bar psi class bar psi class bar psi class

DN10 (3/8“) DN80 (3“) DN400 (16“)

DN15 (½“) DN100 (4“) DN500 (20“)

DN20 (3/4“) DN125 (5“) DN600 (24“)

DN25 (1“) DN150 (6“) DN700 (28“)

DN32 (1 ¼“) DN200 (8“) DN800 (32“)

DN40 (1 ½“) DN250 (10“)

DN50 (2“) DN300 (12“)

DN65 (2 ½“) DN350 (14“)

Max. test pressure using air/nitrogen (bar, psi or class)

bar psi class bar psi class bar psi class

DN10 (3/8“) DN80 (3“) DN400 (16“)

DN15 (½“) DN100 (4“) DN500 (20“)

DN20 (3/4“) DN125 (5“) DN600 (24“)

DN25 (1“) DN150 (6“) DN700 (28“)

DN32 (1 ¼“) DN200 (8“) DN800 (32“)

DN40 (1 ½“) DN250 (10“)

DN50 (2“) DN300 (12“)

DN65 (2 ½“) DN350 (14“)

DIE PREMIUM-PRODUKTE – MADE BY EFCO – MADE IN GERMANY

Checkliste_PS_Rev10_EN.docx -1- [ 3 ]

Checklist

(for Test Benches)

– Safety relief valves –

Valve end: Flange- Thread-

Others:

Valve shape: Straight form Angular form

• What kind of tests have to be done?

Set pressure test using Water / Air/nitrogen (HP)

Seat leakage test using Water / Air/nitrogen (HP)

Other tests:

(HP = High pressure)

• What is the maximum test pressure at what size (DN)?

(you should only indicate DN sizes and test pressures according to your main program. Exceptions (sizes/pressures) can

increase the price of the test bench and its accessories very much!)

Max. test pressure using water (bar, psi or class)

bar psi class bar psi class bar psi class

DN10 (3/8“) DN80 (3“) DN400 (16“)

DN15 (½“) DN100 (4“) DN500 (20“)

DN20 (3/4“) DN125 (5“) DN600 (24“)

DN25 (1“) DN150 (6“) DN700 (28“)

DN32 (1 ¼“) DN200 (8“) DN800 (32“)

DN40 (1 ½“) DN250 (10“)

DN50 (2“) DN300 (12“)

DN65 (2 ½“) DN350 (14“)

Max. test pressure using air/nitrogen (bar, psi or class)

bar psi class bar psi class bar psi class

DN10 (3/8“) DN80 (3“) DN400 (16“)

DN15 (½“) DN100 (4“) DN500 (20“)

DN20 (3/4“) DN125 (5“) DN600 (24“)

DN25 (1“) DN150 (6“) DN700 (28“)

DN32 (1 ¼“) DN200 (8“) DN800 (32“)

DN40 (1 ½“) DN250 (10“)

DN50 (2“) DN300 (12“)

DN65 (2 ½“) DN350 (14“)

DIE PREMIUM-PRODUKTE – MADE BY EFCO – MADE IN GERMANY

Checkliste_PS_Rev10_EN.docx -2- [ 3 ]

Checklist

(for Test Benches)

• What kind of valve Clamping is required/preferred?

Unilateral clamping Bilateral clamping Unilateral clamping Horizontal Clamping

of flanged valves of flanged valves of flanged valves of flanged valves

using claws using claws using claws and butt-welded valves

or clamping of flanged or and between two tables

butt-welded valves between

two tables (Horizontal test bench)

(Test bench with upper

clamping yoke) Applicable

Clamping forces 5 - 75t

Applicable Applicable Applicable Clamp. forces 100t -550t

Clamping forces 7,5t - 150t Clamping forces 100t - 150t Clamping forces 15t - 150t Clamp. force 600t-1500t

To avoid damages due to deformation of the test valve during the test our test benches with clamping forces

of more than 75 tons can be furnished with a proportional clamping control function

• Gauge readings preferred?

Reading: bar psi bar/psi MPa kg/cm²

• Available energy resources on the customer side?

Air (shopair): bar

Electricity 110VAC/60Hz 230VAC/50Hz 400VAC/50Hz

Others:

• What options are required?

Digital Bubble counter (bubbles/minute) for seat leakage tests using air/nitrogen

Separate air compressor (booster) up to:

200 bar (2.900 psi) 300 bar (4.350 psi)

350 bar (5.070 psi) 400 bar (5.800 psi)

Digital displays with peak value storage function for the measured highest

pressure (=set pressure of safety valves), including suitable pressure transducer

Display of test result via PC and print out of a test reports

Piping and bolting made of non-rusting steel

Instruction manual and Machine labels in other language than German or English:

Language required is:

Further requirements / country specific requirements (Please describe)

DIE PREMIUM-PRODUKTE – MADE BY EFCO – MADE IN GERMANY

Checkliste_PS_Rev10_EN.docx -3- [ 3 ]

You might also like

- Valve Solutions in More Than 70 Countries: Product RangeDocument16 pagesValve Solutions in More Than 70 Countries: Product RangeharishcsharmaNo ratings yet

- Tecnidro - FirefightingDocument4 pagesTecnidro - FirefightinggtecnidroNo ratings yet

- Griffco Back Pressure ValvesDocument2 pagesGriffco Back Pressure ValvesAlexander KlmNo ratings yet

- Trueline Knife-Gate Valve CatalogueDocument12 pagesTrueline Knife-Gate Valve Cataloguetoto-gmbhNo ratings yet

- De Sanding 2021Document1 pageDe Sanding 2021Phasin ChitutsahaNo ratings yet

- York Check and Foot Valves: Technical CatalogueDocument14 pagesYork Check and Foot Valves: Technical CatalogueWilliam OeyNo ratings yet

- Turbo Lux 3 Technical Data SheetDocument4 pagesTurbo Lux 3 Technical Data Sheetaashiq2006No ratings yet

- Dss020 Standard Us enDocument13 pagesDss020 Standard Us enMilenko TulencicNo ratings yet

- Declaration of Conformity EADocument5 pagesDeclaration of Conformity EAIvan GarciaNo ratings yet

- Orbinox Catalogue PDFDocument15 pagesOrbinox Catalogue PDFalbertoafpNo ratings yet

- Strainers enDocument51 pagesStrainers enmohamadNo ratings yet

- William Valve Catalogue Ball ValveDocument24 pagesWilliam Valve Catalogue Ball ValveVinayNo ratings yet

- Zenith Stainless Solutions Catalogue Hygienic Clamps Ferrules SealsDocument14 pagesZenith Stainless Solutions Catalogue Hygienic Clamps Ferrules SealsMiguel David Celis QuinteroNo ratings yet

- Flow Switches DW 181 DW 182 DW 183 DW 184Document8 pagesFlow Switches DW 181 DW 182 DW 183 DW 184Sridhar TholasingamNo ratings yet

- Floating and Trunnion Mounted Ball ValvesDocument24 pagesFloating and Trunnion Mounted Ball ValvesEHT pipeNo ratings yet

- Mecon-Medidor de Flujo - Mod. TD Turbo Lux 3Document4 pagesMecon-Medidor de Flujo - Mod. TD Turbo Lux 3JoelCristhianVivancoCondeNo ratings yet

- Europa Check and Foot Valves: Technical CatalogueDocument16 pagesEuropa Check and Foot Valves: Technical CatalogueDomagoj ButumovićNo ratings yet

- STAF STAF-SG STAF-R STAG InstructionDocument32 pagesSTAF STAF-SG STAF-R STAG InstructionJoão Felipe Chueh BejaNo ratings yet

- Afco - CV01 Series - Swing Check ValveDocument4 pagesAfco - CV01 Series - Swing Check Valveafie pio pioNo ratings yet

- Check Valve - KRD SWS - Data SheetDocument2 pagesCheck Valve - KRD SWS - Data Sheetbevara santhoshkumarNo ratings yet

- Flange BS10 AS2129 ANSIBS4504Document0 pagesFlange BS10 AS2129 ANSIBS4504Vivek DukareNo ratings yet

- WW C70 Product-Page English 12-2015 1Document5 pagesWW C70 Product-Page English 12-2015 1rafaelcoserNo ratings yet

- Itap - PRV EuropaDocument16 pagesItap - PRV EuropaRajkishorNo ratings yet

- Line Sampler DEDocument1 pageLine Sampler DEcarmaNo ratings yet

- Flujometro TornatechDocument4 pagesFlujometro TornatechHydro Energy GroupNo ratings yet

- Colima Visco and Colima Viscorol Magnetic Level IndicatorsDocument8 pagesColima Visco and Colima Viscorol Magnetic Level IndicatorsRaduNo ratings yet

- Manual de InstrumentacionDocument8 pagesManual de InstrumentacionANDRES SARASTINo ratings yet

- Blue Ocean PP R Piping Product Catalogue EN Edition 012N BlueDocument52 pagesBlue Ocean PP R Piping Product Catalogue EN Edition 012N BlueB-ing-VNo ratings yet

- Product Range - HersheyDocument4 pagesProduct Range - Hersheyheru hsNo ratings yet

- Optimizing Descaling PDFDocument24 pagesOptimizing Descaling PDFKiran DuggarajuNo ratings yet

- Turbo Lux 3 Technical Data SheetDocument8 pagesTurbo Lux 3 Technical Data SheetAntonijeNo ratings yet

- Flow and Level MeterDocument16 pagesFlow and Level MeterDimas Ady PratamaNo ratings yet

- Product Range - Hershey Valve 2016Document2 pagesProduct Range - Hershey Valve 2016marusahaNo ratings yet

- Stainless Steel Flange: SpecificationDocument2 pagesStainless Steel Flange: SpecificationAbate TefferaNo ratings yet

- D690 Round Damper: Low-Leakage, Single-BladeDocument4 pagesD690 Round Damper: Low-Leakage, Single-BladeGustavo AyllonNo ratings yet

- 法兰标准体系Document125 pages法兰标准体系Forest MoNo ratings yet

- Flange DimensionsDocument30 pagesFlange DimensionshibhavuNo ratings yet

- Pressure Reducing Valves Europress: Technical CatalogueDocument14 pagesPressure Reducing Valves Europress: Technical CataloguesuleeshNo ratings yet

- Steel Filter Dimensions and Pressure RatingsDocument11 pagesSteel Filter Dimensions and Pressure RatingsacsNo ratings yet

- Cherne Test Ball Pipe PlugsDocument2 pagesCherne Test Ball Pipe PlugsPromagEnviro.comNo ratings yet

- Sandwich Type Butterfly Valve: I ApplicationDocument2 pagesSandwich Type Butterfly Valve: I ApplicationFery FebryantoNo ratings yet

- As Schneider Flush Rings enDocument2 pagesAs Schneider Flush Rings eneliasNo ratings yet

- Turbo Lux 3 Fact Sheet enDocument2 pagesTurbo Lux 3 Fact Sheet enAntonijeNo ratings yet

- Pressure Regulator D41 Series - W-R2Document2 pagesPressure Regulator D41 Series - W-R2SABU PUTHENPARAMBIL RAJU0% (1)

- 6.09 A DS Flow Meters FM - Caudalimetros EspecialesDocument5 pages6.09 A DS Flow Meters FM - Caudalimetros EspecialesCorporativo InstacomNo ratings yet

- Ficha Tecnica Medidores de Flujo TornatechjDocument4 pagesFicha Tecnica Medidores de Flujo TornatechjCarlos Andres Neira AgudeloNo ratings yet

- FDT500Document3 pagesFDT500ธนาชัย เต็งจิรธนาภาNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Line Sampler ENDocument1 pageLine Sampler ENcarmaNo ratings yet

- 7031 - Data SheetDocument7 pages7031 - Data SheetÁlvaro Martínez FernándezNo ratings yet

- A-627 B&G Field Adjustable Venturi Valves For All HVAC Systems BrochureDocument2 pagesA-627 B&G Field Adjustable Venturi Valves For All HVAC Systems Brochurekeith dietrichNo ratings yet

- Ozone PartsDocument19 pagesOzone PartsEliasDraNo ratings yet

- The Range of Probes For Tool Checks On Machining CentresDocument4 pagesThe Range of Probes For Tool Checks On Machining CentresVN MÁY TỰ ĐỘNGNo ratings yet

- Conductivity sensor-SC4Document12 pagesConductivity sensor-SC4Ziyaur RahmanNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- B703 - MFP - FullJet - Nozzles (Spray Nozzle For Gas Cooling)Document6 pagesB703 - MFP - FullJet - Nozzles (Spray Nozzle For Gas Cooling)Clarence AG YueNo ratings yet

- Flow Switch (DBSF)Document3 pagesFlow Switch (DBSF)Muhammed Abo-FandoodNo ratings yet

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Document11 pagesPDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18No ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Technical Specification D-14 - 2018 - New - HKCDocument15 pagesTechnical Specification D-14 - 2018 - New - HKCVũ Minh NhậtNo ratings yet

- TESON III-Product-Pictures-2019Document8 pagesTESON III-Product-Pictures-2019Vũ Minh NhậtNo ratings yet

- WP Online Safety Valve TestingDocument9 pagesWP Online Safety Valve TestingVũ Minh NhậtNo ratings yet

- TESON III Flyer 2020Document8 pagesTESON III Flyer 2020Vũ Minh NhậtNo ratings yet

- PSV Test Unit: Model: Vc25-Srv RANGE: - 10" / DN15 - 250 MMDocument9 pagesPSV Test Unit: Model: Vc25-Srv RANGE: - 10" / DN15 - 250 MMVũ Minh Nhật100% (1)

- BR Valves Test Benches en Co 61985 PDFDocument12 pagesBR Valves Test Benches en Co 61985 PDFcafe negroNo ratings yet

- Porosity MeasurementDocument10 pagesPorosity MeasurementSaroo MusicNo ratings yet

- Plasma Cleaner: Instructions For UseDocument18 pagesPlasma Cleaner: Instructions For UseOzzyNo ratings yet

- Air Duct Cleanliness TestDocument8 pagesAir Duct Cleanliness TestFahad NaveedNo ratings yet

- Effectiveness of Sootblowers in Boilers Thermal Power StationDocument7 pagesEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123No ratings yet

- Gas Flaring Basic InformationDocument4 pagesGas Flaring Basic InformationFriday IjokgwungNo ratings yet

- Air Conditioning Maintenance ScheduleDocument1 pageAir Conditioning Maintenance ScheduleVontrex EngrNo ratings yet

- Experimental AerodynamicsDocument16 pagesExperimental AerodynamicsthandialNo ratings yet

- TVL Smaw11 Q1 M 8Document10 pagesTVL Smaw11 Q1 M 8Earl Christian BonaobraNo ratings yet

- Gas TurbineDocument43 pagesGas TurbineMuhammad Qusyairi50% (2)

- Equipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating SystemsDocument100 pagesEquipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating Systemsᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- Electrical Nomenclature 02-07Document4 pagesElectrical Nomenclature 02-07Nebur Mtza100% (2)

- Customer Part 2 Print OutDocument14 pagesCustomer Part 2 Print Outradient.freshNo ratings yet

- CE 111 Syllabus 1st Sem 2017-2018Document2 pagesCE 111 Syllabus 1st Sem 2017-2018Christian GalopeNo ratings yet

- Caleffi Central HeatingDocument1 pageCaleffi Central HeatingSite OfficeNo ratings yet

- Class 2 Physical Properties of Hydraulic FluidsDocument31 pagesClass 2 Physical Properties of Hydraulic FluidsMawada RashedNo ratings yet

- Hydraulic System of TractorDocument53 pagesHydraulic System of Tractorsln_rj100% (4)

- Pesticide Application Equipment and Safety: Prepared by Aggrey Atuhaire, +256-779864929Document44 pagesPesticide Application Equipment and Safety: Prepared by Aggrey Atuhaire, +256-779864929aariksaNo ratings yet

- 750-263 5 2015Document456 pages750-263 5 2015weweqweqwNo ratings yet

- (SS0V002) Bi-Directional Sphere Type ProverDocument2 pages(SS0V002) Bi-Directional Sphere Type ProverRoberto Carlos TeixeiraNo ratings yet

- Design of Hydraulics and Pneumatic Systems-April-2011Document2 pagesDesign of Hydraulics and Pneumatic Systems-April-2011SasiKumar Petchiappan100% (1)

- Chapter 1 Refrigeration CycleDocument19 pagesChapter 1 Refrigeration CycleMira FazziraNo ratings yet

- Air Separation Process Primer - Air LiquideDocument28 pagesAir Separation Process Primer - Air LiquideОскар ЛинаресNo ratings yet

- CHE504 - Lab Report On Gas Absorption L8 PDFDocument23 pagesCHE504 - Lab Report On Gas Absorption L8 PDFRakesh KumarNo ratings yet

- Integrate Ethyl Benzene Production With An Olefins Plant, HC Processing, 1999, Pg77-88Document8 pagesIntegrate Ethyl Benzene Production With An Olefins Plant, HC Processing, 1999, Pg77-88ypzoNo ratings yet

- Tuto Chap 3Document3 pagesTuto Chap 3Zakiyah Mohamed Razi50% (2)

- Presentation On CmsDocument14 pagesPresentation On Cmsjanu0% (1)

- Power Plant Technology CourseDocument436 pagesPower Plant Technology CoursecruzleenoNo ratings yet

- Comparing R1233zd and R245fa For Low Temperature ORC Applications PDFDocument8 pagesComparing R1233zd and R245fa For Low Temperature ORC Applications PDFpancawawanNo ratings yet

- Tutorial 1 GD StudentsDocument4 pagesTutorial 1 GD Studentsgokuler137No ratings yet

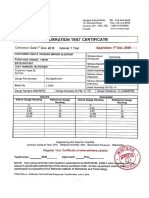

- Calibration Test CertificateDocument7 pagesCalibration Test CertificateMohamed RaafatNo ratings yet