Professional Documents

Culture Documents

Locator Plate Instructions: Instructions For The Assembly of 3M .100" X .100" and .100" X .200" Socket Connectors

Uploaded by

Trần Long VũOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Locator Plate Instructions: Instructions For The Assembly of 3M .100" X .100" and .100" X .200" Socket Connectors

Uploaded by

Trần Long VũCopyright:

Available Formats

3443-94

Locator Plate Instructions

Instructions for the assembly of

3M .100" x .100" and .100" x .200"

socket connectors

General information

3M manual and pneumatic assembly presses and accessory

assembly equipment are recommended for the termination of

3M socket connectors. 3M assembly equipment is offered to

reduce set-up time, to provide easy and fast assembly, and to

reduce assembly error.

.100" x .200" Backplane System Chart

Contact 3M Socket Locator* Locator Assembly Shut Height Adjustment for 3M Assembly Press

Quantity Part No. Plate No. Plate No. Platen

3316 & 3335 3830

3443 3443 3442

3640

20 3575 -60 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

26 3501 -60 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

34 3310 -60 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

40 3318 -60 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

50 3307 -60 or -73 -94 -9A 12 12 1⁄2 Self-adjusting

.100" x .100" Grid System Chart

Contact 3M Socket Locator* Locator Assembly Shut Height Adjustment for 3M Assembly Press

Quantity Part No. Plate No. Plate No. Platen

3316 & 3335 3830

3443 3443 3442

3640

10 3473 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

14 3385 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

16 3452 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

20 3421 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

24 3626 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

26 3399 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

30 3419 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

34 3414 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

36 9436 -54 or -73 -94 -1A 12 12 1⁄2 Self-adjusting

40 3417 -54 or -73 -94 -9A 12 12 1⁄2 Self-adjusting

44 9444 -54 or -73 -94 -9A 12 12 1⁄2 Self-adjusting

50 3425 -54 or -73 -94 -9A 12 12 1⁄2 Self-adjusting

60 3334 -54 or -73 -94 -9A 12 12 1⁄2 Self-adjusting

64 7964 -54 or -73 -94 -9A 12 12 1⁄2 Self-adjusting

*The 3443-94 Locator Plate was designed to assemble all socket connectors, and replaces plates 3443-54, 3443-60, and 3443-73.

Set-up procedures for sockets, cables and guides

Adjustments to plate viewing port points to the respective .1" x .1" or .l" x .2"

Various adjustments are required to the locator plate, label guide.

depending on which socket connector or cable is being

assembled. Locator Plate 3443-94 is the recommended Standard flat cable

assembly aid. (See Figure 1) To assemble standard flat cable, the cable width is guided

between:

The 3443-94 Locator Plate can be used to assemble:

• The narrow end guide area

• .1" x .1" and .1" x .2" socket connectors with and without • The side of the end guide with the viewing port feature

center bump feature

• Socket connectors with standard flat cable and with ground Ground plane cable

plane cable To assemble ground plane cable, the cable width is guided

between:

End Guide set-up

To adjust the position of the end guide for the connector • The wide end guide area

length position, lift the end guide up and move it left or right. • The side of the end guide that does not have the viewing

The viewing port on each end guide must align with the port feature

appropriate connector conductor size. The connector

conductor size is specified by the numbers on the respective Center bump feature

labels. The center bump connector does not require any special set-

To adjust the end guide position for the .l" x .1" or .l" x .2" up procedure.

connector, lift and rotate the end guide 180 so that the

.1” x .2” Side

Standard

Viewing

Port Cable

Locating

Edge

Ground Plane

Cable

Locating Edge

Locator Plate End Guide

Positioning Hole .1” x .1” Side

Figure 1. 3443-94 Locator Plate

Shut height adjustment procedures

The shut height setting is referenced in the .100" x .200"

Backplane System Chart and .100" x .100" Grid System

Chart on page l. Shut height settings are guidelines for proper

termination depth. Assembly Press

Casting

The shut height should be adjusted from the base before the

locator plate is put into place. The 3316 and 3640 are Press Shaft

adjusted with a knob at the top of the press. Press 3335 is Press Height Guage

adjusted with the collar on the press shaft, and Press 3830 is

self-adjusting.

l. Place the shut height gauge, #3436-lA, across the base of

Figure 2.

the assembly press. Lower the handle of the press until the

handle casting makes contact with the press casting.

(See Figure 2)

Locking

Ring

Shut Height

2. Determine the type of assembly press you are using: Adjustment

Collar

• With the 3335 Press, lock the shut height adjustment

collar toward the base of the press shaft. (See Figure 3a)

• With the 3316 and 3640 Presses, turn the shut height

adjustment knob until the bottom of the press shaft

contacts the desired position on the shut height gauge.

(See Figure 3b).

Figure 3a. 3335 Press Assembly

3. Install the locator plate and appropriate platen on the press.

The platen should be positioned so that it is parallel with

the connector body and cover.

CW (Lower)

CCW (Raise)

Shut Height

Adjustment Knob

Figure 3b. 3316 & 3640 Press Assemblies

Connector/cable assembly procedures

1. Grasp a socket cover strip between thumb and

forefinger of both hands, with the liner facing you.

Rotate the outermost cover down against the adjacent

cover on the strip, breaking it from the liner. Pull

laterally away from the strip, leaving a clean adhesive

edge on the removed cover. (See Figure 4)

2. Firmly press ribbed side of cable into alignment grooves

on cover. The adhesive will help it stay in place. (See

Figure 5)

Figure 4.

3. Visually inspect to insure that:

• Cable is properly aligned to cover grooves.

• Cable end is flush with cover for end terminations,

or perpendicular to cover for midspan terminations.

Figure 5.

4. Place the cable/cover sub-assembly between the guides

on the locator plate, cover side down. (See Figure 6)

5. Orient and position connector body — contacts down

over the cable/cover sub-assembly, engaging cover

retainer devices with body slots. (See Figure 6)

6. Lower the assembly press handle fully to complete the

connection. (See Figure 7)

7. Raise press handle and remove completed assembly.

Visually inspect to insure that: Figure 6.

• Cover is fully seated and parallel with the body.

• Cable is properly aligned with the cover grooves.

• Cover retaining devices are completely engaged with

the body.

Call 800-225-5373

for sales, ordering and technical product information Figure 7.

Important Notice

All statements, technical information and recommendations related to officer of the Seller. The statements contained herein are made in lieu

the Seller’s products are based on information believed to be reliable, of all warranties, express or implied, including but not limited to the

but the accuracy or completeness thereof is not guaranteed. Before implied warranties of merchantability and fitness for a particular

utilizing the product, the user should determine the suitability of the purpose which warranties are hereby expressly disclaimed.

product for its intended use. The user assumes all risks and liability

whatsoever in connection with such use. Seller shall not be liable to the user or any other person under any

legal theory, including but not limited to negligence or strict liability,

Any statements or recommendations of the Seller which are not for any injury or for any direct or consequential damages sustained or

contained in the Seller’s current publications shall have no force or incurred by reason of the use of any of the seller’s products that were

effect unless contained in an agreement signed by an authorized defective.

Electronic Products Division

Printed in the USA

6801 River Place Blvd.

Austin, Texas 78726-9000 Printed on recycled paper. © 3M 1993 34 7027 4814 5

You might also like

- DH5010B Manual de ServicioDocument6 pagesDH5010B Manual de ServiciosilvertronicNo ratings yet

- Fd059 Product Catalogue 2017 Wiper Systems SML WfvzjldzforrDocument41 pagesFd059 Product Catalogue 2017 Wiper Systems SML Wfvzjldzforramandoh leonelNo ratings yet

- mainteESAO301 2 0Document191 pagesmainteESAO301 2 0Enrique PeraltaNo ratings yet

- Sterndrive Unit: Drive Shaft HousingDocument36 pagesSterndrive Unit: Drive Shaft HousingAlister CaraNo ratings yet

- HF23Document60 pagesHF23izzywaanNo ratings yet

- TM 9-2330-246-14 M348a2/xm1007Document484 pagesTM 9-2330-246-14 M348a2/xm1007AdvocateNo ratings yet

- HCH-MaintenanceManual2 4Document171 pagesHCH-MaintenanceManual2 4Jonathan Lara FandiñoNo ratings yet

- Eja 21Document144 pagesEja 21Myasaga AdrianNo ratings yet

- Curtis InstrumentsDocument9 pagesCurtis InstrumentsGaby Djin ThemixNo ratings yet

- Manual Del Operador Del TB120 PDFDocument96 pagesManual Del Operador Del TB120 PDFLourdes Hernandez GonzalezNo ratings yet

- OM - HB Breaker (DICC) - Operation Manual - ENDocument57 pagesOM - HB Breaker (DICC) - Operation Manual - ENLuisa Fernanda Salazar Pulgarin100% (1)

- Operator's Manual: Rating LabelDocument20 pagesOperator's Manual: Rating Labelangel aguilarNo ratings yet

- Orbit Double Acting ActuatorDocument26 pagesOrbit Double Acting Actuatorkeertiraj09No ratings yet

- 8004 PDFDocument48 pages8004 PDFlungu mihai100% (1)

- GR00002600 23a PDFDocument180 pagesGR00002600 23a PDFStephen JordanNo ratings yet

- Section 35 - Hydraulic SystemDocument48 pagesSection 35 - Hydraulic SystemCristian SterieNo ratings yet

- Actuador Detroit ElectronicoDocument8 pagesActuador Detroit ElectronicoSuministros Mantenimiento100% (1)

- S2 EN1513 A - M5AF M5AF1 Vane Motor Service InstructionsDocument31 pagesS2 EN1513 A - M5AF M5AF1 Vane Motor Service InstructionsDaniel BorgesNo ratings yet

- Sección 23 - Linea Motriz.. Ford-New-Holland-8670-8770-8870-8970-Wsm-388-411Document24 pagesSección 23 - Linea Motriz.. Ford-New-Holland-8670-8770-8870-8970-Wsm-388-411yerson smith sanjinez rodriguez0% (1)

- 4600 OsmDocument149 pages4600 Osmdoraemon007No ratings yet

- Rotary Broom: SW2160 SW2172 SW2184Document52 pagesRotary Broom: SW2160 SW2172 SW2184Jairresistenciagt123No ratings yet

- 928-0222-Supl Onan ES Genset 04146 WOODWARD TQ-125 CONTROLER MANUALDocument4 pages928-0222-Supl Onan ES Genset 04146 WOODWARD TQ-125 CONTROLER MANUALfarar100% (1)

- 8997 6483 00 Diagrams and Drawings PDFDocument112 pages8997 6483 00 Diagrams and Drawings PDFGabriel Alejandro Pascual RamirezNo ratings yet

- Malabar: Read AND SaveDocument8 pagesMalabar: Read AND SavedairucNo ratings yet

- Pfaff Hobby 1122-1142 Service ManualDocument26 pagesPfaff Hobby 1122-1142 Service ManualiliiexpugnansNo ratings yet

- RF4287Document132 pagesRF4287The Best ITNo ratings yet

- Side by Side Refrigerator: Service ManualDocument42 pagesSide by Side Refrigerator: Service ManualAmadou Ba100% (1)

- TD (012) - DML Serie 7431Document470 pagesTD (012) - DML Serie 7431victor chuquiruna bardalesNo ratings yet

- Dash 8 CH13Document20 pagesDash 8 CH13soufiane jouadiNo ratings yet

- Power Swivel Ps85Document28 pagesPower Swivel Ps85jjcastiblanco100% (1)

- Hydraulic Side Acting GripsDocument4 pagesHydraulic Side Acting Gripsmohamed ahmedNo ratings yet

- VPRS-4300D Catalogue PDFDocument4 pagesVPRS-4300D Catalogue PDFHoàngTrầnNo ratings yet

- Technical Series 92 User ManualDocument4 pagesTechnical Series 92 User ManualrandallshNo ratings yet

- EN FANOXPC DATA MPC MotorProtection GL GC17 R03 PDFDocument2 pagesEN FANOXPC DATA MPC MotorProtection GL GC17 R03 PDFarolnNo ratings yet

- Impactor Box 03-06-03Document89 pagesImpactor Box 03-06-03bercketowzhenya100% (1)

- Instruction Manual Fisher 377 TRDocument20 pagesInstruction Manual Fisher 377 TRGabrielA.MaffioldA.No ratings yet

- Pneumatic Positiioner FisherDocument64 pagesPneumatic Positiioner FisherAhmad Adel El TantawyNo ratings yet

- Steering: Group 37ADocument56 pagesSteering: Group 37ADanNo ratings yet

- Operator's Manual: Rating LabelDocument16 pagesOperator's Manual: Rating LabelChancey FosterNo ratings yet

- Meridian Gyrocompass SurveyorDocument78 pagesMeridian Gyrocompass SurveyorNguyen Phuoc HoNo ratings yet

- Getec Hydr. Welder Manual Hw225Document33 pagesGetec Hydr. Welder Manual Hw225Kenneth Sambolin0% (1)

- General Conversion Instructions For 3 X 4 In. (75 X 00 MM) Orbital SandersDocument2 pagesGeneral Conversion Instructions For 3 X 4 In. (75 X 00 MM) Orbital Sandersherysyam1980No ratings yet

- 42C, D, S, V Series Fan Coil Installation, Start-Up and Service InstrctionsDocument84 pages42C, D, S, V Series Fan Coil Installation, Start-Up and Service InstrctionsJovany SegoviaNo ratings yet

- TD (013) - DML Serie 7435Document476 pagesTD (013) - DML Serie 7435victor chuquiruna bardalesNo ratings yet

- Valve Trip 377 InglesDocument20 pagesValve Trip 377 Ingleshades_x3No ratings yet

- Merc Service Manual 6 4bDocument40 pagesMerc Service Manual 6 4bHayduke them100% (4)

- mainteCD2 E1-00Document185 pagesmainteCD2 E1-00NisaiyhoutNo ratings yet

- Microwave Sharp R-244 Service ManualDocument28 pagesMicrowave Sharp R-244 Service ManualminhtqNo ratings yet

- Transfer: Workshop ManualDocument92 pagesTransfer: Workshop ManualmailforspamNo ratings yet

- Auma ManualDocument17 pagesAuma ManualAhmed EldosokyNo ratings yet

- Caterpillar 3306 Engine Service Manual SN 3npdfDocument9 pagesCaterpillar 3306 Engine Service Manual SN 3npdfChris rainbowNo ratings yet

- Meritor 9-10-13 Speed TransmissionsDocument203 pagesMeritor 9-10-13 Speed TransmissionsJose Angel Melendez100% (8)

- A Automatic TransmissionDocument130 pagesA Automatic TransmissionJorge CaiomboNo ratings yet

- Manual Kansai PDFDocument35 pagesManual Kansai PDFZacuna PazNo ratings yet

- P-3881 CrimpInformationSheetDocument53 pagesP-3881 CrimpInformationSheetTrần Long VũNo ratings yet

- Crimp Information Sheet: SN 0,41 3,00 - 5,00 1005 (C) Crimp Only - Terminal Is Applied Crimp Only 3,00 - 4,07 NoneDocument6 pagesCrimp Information Sheet: SN 0,41 3,00 - 5,00 1005 (C) Crimp Only - Terminal Is Applied Crimp Only 3,00 - 4,07 NoneTrần Long VũNo ratings yet

- Ul1911 (25KV) 18 FT110824Document2 pagesUl1911 (25KV) 18 FT110824Trần Long VũNo ratings yet

- 56 Series 2971962Document3 pages56 Series 2971962Trần Long VũNo ratings yet

- R2G3 3fwsav Avssx Aessx EEX Vctf2 Sfaex1 M2 Avssh Afoss Savssf AVSS105 Fsavs Fsaexs AV Avss AVS F-Avs R2G3Document1 pageR2G3 3fwsav Avssx Aessx EEX Vctf2 Sfaex1 M2 Avssh Afoss Savssf AVSS105 Fsavs Fsaexs AV Avss AVS F-Avs R2G3Trần Long VũNo ratings yet

- Terminals & Connectors: Delphi Packard Metri-Pack 150 Series Sealed ConnectorsDocument1 pageTerminals & Connectors: Delphi Packard Metri-Pack 150 Series Sealed ConnectorsTrần Long VũNo ratings yet

- Crimp Information Sheet: SN 0,41 3,00 - 5,00 1005 (C) Crimp Only - Terminal Is Applied Crimp Only 3,00 - 4,07 NoneDocument31 pagesCrimp Information Sheet: SN 0,41 3,00 - 5,00 1005 (C) Crimp Only - Terminal Is Applied Crimp Only 3,00 - 4,07 NoneTrần Long VũNo ratings yet

- CrimpinformationsheetDocument12 pagesCrimpinformationsheetTrần Long VũNo ratings yet

- 02965142Document2 pages02965142Trần Long VũNo ratings yet

- 7114-4151-02 (7158-3112-70) - P-6692 Spec.Document2 pages7114-4151-02 (7158-3112-70) - P-6692 Spec.Trần Long VũNo ratings yet

- Terminal Tools and Terminal Selection GuideDocument2 pagesTerminal Tools and Terminal Selection GuideTrần Long VũNo ratings yet

- CT-1525 ManualDocument2 pagesCT-1525 ManualTrần Long VũNo ratings yet

- P-3138 - UL1007 - 24ga 7strd - TC - InduDocument1 pageP-3138 - UL1007 - 24ga 7strd - TC - InduTrần Long VũNo ratings yet

- Tooling Selection Guide For PANDUIT Terminals, Splices, and DisconnectsDocument5 pagesTooling Selection Guide For PANDUIT Terminals, Splices, and DisconnectsTrần Long VũNo ratings yet

- Ul10086 22awg FT111021Document2 pagesUl10086 22awg FT111021Trần Long VũNo ratings yet

- CT-1525 DrawingDocument1 pageCT-1525 DrawingTrần Long VũNo ratings yet

- Manual Tensioning Tool With Metal Housing: Application Tooling For Cable TiesDocument1 pageManual Tensioning Tool With Metal Housing: Application Tooling For Cable TiesTrần Long VũNo ratings yet

- JST SFPS-41T-187 Crimping SpecDocument1 pageJST SFPS-41T-187 Crimping SpecTrần Long VũNo ratings yet

- Connector: Board-In Crimp Style ConnectorsDocument3 pagesConnector: Board-In Crimp Style ConnectorsTrần Long VũNo ratings yet

- JST Cmkdpsaita03064 Jst-065Document2 pagesJST Cmkdpsaita03064 Jst-065Trần Long VũNo ratings yet

- JST - 03R JWPF Vsle SDocument2 pagesJST - 03R JWPF Vsle STrần Long VũNo ratings yet

- CMKS-L: Industry Standard ApplicatorDocument31 pagesCMKS-L: Industry Standard ApplicatorTrần Long VũNo ratings yet

- JST AP-k2n PressDocument39 pagesJST AP-k2n PressTrần Long VũNo ratings yet

- CMK-R Dies Construction Sheet: SRS-NDocument2 pagesCMK-R Dies Construction Sheet: SRS-NTrần Long VũNo ratings yet

- CMKS-L Dies Construction Sheet: B AdeDocument2 pagesCMKS-L Dies Construction Sheet: B AdeTrần Long VũNo ratings yet

- Handling Manual CHM-1-2156 - For SPC SpliceDocument4 pagesHandling Manual CHM-1-2156 - For SPC SpliceTrần Long VũNo ratings yet

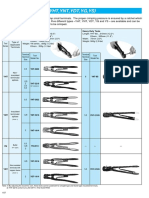

- Ratchet Hand Tools (YHT, YNT, YDT, YG, YS)Document12 pagesRatchet Hand Tools (YHT, YNT, YDT, YG, YS)Trần Long VũNo ratings yet

- CMKS-L Dies Construction SheetDocument2 pagesCMKS-L Dies Construction SheetTrần Long VũNo ratings yet

- Process Layout - MERIT - 2005975 - Q22562-001 - Rev 0.10 - CD-62725-R.A0.2 - Rev 1.0Document1 pageProcess Layout - MERIT - 2005975 - Q22562-001 - Rev 0.10 - CD-62725-R.A0.2 - Rev 1.0Trần Long VũNo ratings yet

- CMKS-L Dies Construction Sheet: QIJG:.Document2 pagesCMKS-L Dies Construction Sheet: QIJG:.Trần Long VũNo ratings yet

- Ancylostoma DuodenaleDocument12 pagesAncylostoma DuodenaleIbrahim Mahmoud Ali100% (1)

- Book Review Assignment Book: The Da Vinci Code Group Members: Sadia Jabeen World LiteratureDocument5 pagesBook Review Assignment Book: The Da Vinci Code Group Members: Sadia Jabeen World LiteratureZone MusicNo ratings yet

- Unit 1 Management Styles: NO: 1. It's Not NecessaryDocument8 pagesUnit 1 Management Styles: NO: 1. It's Not NecessaryjulianaNo ratings yet

- 5 Bivariate Statistics - P1 - QPDocument7 pages5 Bivariate Statistics - P1 - QPSarah HilyNo ratings yet

- Artifact K Portfolio ReflectionDocument2 pagesArtifact K Portfolio Reflectionapi-275969485No ratings yet

- Activities Report BisiteDocument186 pagesActivities Report BisitebisiteNo ratings yet

- Big O Exercises and SolutionsDocument14 pagesBig O Exercises and SolutionsAlhaji BatureyNo ratings yet

- Research Annulment of SaleDocument7 pagesResearch Annulment of Saledayve dacanayNo ratings yet

- Princess Shoebelyn CDocument5 pagesPrincess Shoebelyn CPrincess Shoebelyn Cañete MauricioNo ratings yet

- Museum Ebt ListDocument17 pagesMuseum Ebt ListDavid SalazarNo ratings yet

- Goldaman Facebook Deal - WhartonDocument4 pagesGoldaman Facebook Deal - WhartonRafael CarlosNo ratings yet

- Rademacher Dropout: An Adaptive Dropout For Deep Neural Network Via Optimizing Generalization GapDocument11 pagesRademacher Dropout: An Adaptive Dropout For Deep Neural Network Via Optimizing Generalization Gapbob aaNo ratings yet

- MediastinumDocument27 pagesMediastinumAndrei PanaNo ratings yet

- CIOB Membership RegulationsDocument9 pagesCIOB Membership RegulationskasunNo ratings yet

- English Lesson Plan KSSR Year 2: Responding With Wonderment and AweDocument3 pagesEnglish Lesson Plan KSSR Year 2: Responding With Wonderment and Awehady91No ratings yet

- Act 518 National Land Code (Penang & Malacca Titles) 1963Document145 pagesAct 518 National Land Code (Penang & Malacca Titles) 1963Raymond ChanNo ratings yet

- Revolt of 1857Document20 pagesRevolt of 1857Online SubsNo ratings yet

- QFTCT DemoExample DescriptionDocument13 pagesQFTCT DemoExample DescriptionSalman ZafarNo ratings yet

- Kuhn's Algorithm For Finding The Greatest Matching in A Bipartite GraphDocument6 pagesKuhn's Algorithm For Finding The Greatest Matching in A Bipartite GraphRavi GohelNo ratings yet

- Ansys Manual CombinesDocument240 pagesAnsys Manual CombinesNo ShieelaNo ratings yet

- Cost Based AnalysisDocument14 pagesCost Based AnalysisAyesha KashaNo ratings yet

- The Verb TO BE (Affirmative - Negative) in Simple PresentDocument2 pagesThe Verb TO BE (Affirmative - Negative) in Simple PresentEisya AbdullahNo ratings yet

- Engineering Mathematics 2 Jan 2014Document4 pagesEngineering Mathematics 2 Jan 2014Prasad C MNo ratings yet

- Court-Annexed Mediation & Judicial Dispute Resolution: Diversion of Pending Court CasesDocument9 pagesCourt-Annexed Mediation & Judicial Dispute Resolution: Diversion of Pending Court CasesSheera Laine V. ManzanoNo ratings yet

- Indian Political Science AssociationDocument12 pagesIndian Political Science Associationjohn haltNo ratings yet

- Lean PDFDocument166 pagesLean PDFLucky Parashar100% (1)

- Ain't No Mountain High Enough: Electric Bass GuitarDocument2 pagesAin't No Mountain High Enough: Electric Bass GuitarJules PeirlinckxNo ratings yet

- AVMP Script PDFDocument63 pagesAVMP Script PDFgregNo ratings yet

- 2016 03 31 Basa Pilipinas Quarter 3 Grade 1 English Teacher's Guide (Second Edition) PDFDocument186 pages2016 03 31 Basa Pilipinas Quarter 3 Grade 1 English Teacher's Guide (Second Edition) PDFIris SamonteNo ratings yet

- Module 7Document9 pagesModule 7Lance AustriaNo ratings yet