Professional Documents

Culture Documents

V2D7610006

V2D7610006

Uploaded by

Salvador Reyes0 ratings0% found this document useful (0 votes)

1 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pagesV2D7610006

V2D7610006

Uploaded by

Salvador ReyesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Master Cylinders

CHRYSLER CORP. DUAL PISTON MASTER CYLINDER

Dodge

Plymouth

NOTE Some models use other units. See Bendix/Delco-

‘Moraine Tandem Dual Piston Master Cylinders in this Section,

DESCRIPTION

Chrysler tandem dual piston master cylinder iso single casting

with front and rear piston and a separate reservoir and outlet

for each piston. Rear piston is operated by @ push rod con:

nected to brake pedal. Front piston is operated by rear piston.

In @ combination drum and disc brake system, reservoir which

feeds disc brakes is larger, to correspond with larger size of

disc brake caliper cylinders. Master cylinder outlat which feeds

drum brakes has a residual valve under tube seat. Disc brake

‘outlet has no valve, since disc brakes must not have any

residvol. pressure.

ADJUSTMENT

BRAKE PEDAL

On vehicle equipped with adjustuble brake pedal push rod,

turn adjusting rod in or out to obtain brake pedal free travel

of iy", measured of center of pedal pad. After adjustment,

smoke sure reli por in cylinder s open wih broke pede In

{uly disengaged postion,

BRAKE WARNING /METERING VALVE

Hf pressure loss occurs in one side of system, piston in valve will

move toward foiled side and lotch in thot position. This wi

cause warning light 1o come on and stay on until system is

repaired. After repaiting and bleeding system, applying

brakes with moderate force will hydraulically recenter piston

‘ond turn off warning light

REMOVAL & INSTALLATION

(MASTER CYLINDER

Removal — Disconnect front and rear hydraulic brake lin

cf master cylinder. On vehicles equipped with manual brakes,

disconnect brake pedal push rod at brake pedal. Remove

master cylinder oftaching bolts ond remove master cylinder

from vehicle

Installation — Position master cylinder on vehicle and install

eylinder attaching bolt. Connect front ond rear hydraulic

rake lines to cylinder end install brake pedal push rod, if

‘reservoir with clean brake fluid and bleed entire

BRAKE WARNING /METERING VALVE

Removal ~ Disconnect brake warning light wire at valve

‘ossembly switch. Remove hydraulic brake lines at metering

valve. Remove metering valve retaining bolts and remove com-

Installation — To install, reverse removal procedure, bleed

‘entire brake system (See Hydraulic Brake Bleeding in this Sec

tion) ond adjust valve (See Brake Warning/Metering Valve.

‘Adjustment.

OVERHAUL

MASTER CYLINDER

Disassembly ~ Remove cover and gasket, and pour out

emoining broke fluid. Remove front piston retainer screw

from inside reservoir. Remove snap ring from outer end of

master cylinder ond slide out rear piston. Top open end of

master cylinder on bench to remove front piston and spring,

Air pressure can be used fo remove front piston if piston is

‘suck. Remove front piston compression ‘ting from bore

Remove tube seats using an easy out and discord seats. Note

position of lips on rubber cups and remove cups from pistons.

Do not remove center cup on rear piston, if cup is damaged

piston must be replaced.

Fig. 1 Removing Tube Seot from Master Cylinder

Inspection — Clean moster cylinder using suitable solvent,

Gnd dey with compressed ar Inspect elinder bore for signs of

Scoring, piling, and corrosion. Light scratches ond corrosion

mmoy be removed, using crocus cloth. Deeper sratches or or"

ing may be removed by honing cylinder bore, providing bore

diameter is increased no more than .002"

Reassembly — 1) Dip all components in clean broke fluid

before reassembly. Carefully install primary cup on front

piston with lip away from piston, Carefully install second seal

up over rear of frant piston and into second cup land, Lip of

seal must face rear. Slide cup retainer over stem of front

piston with beveled side away from piston cup. Place small

tend of pressure spring into retainer and slide assembly into

bore of evlinder.

Master Cylinders

CHRYSLER CORP. DUAL PISTON MASTER CYLINDER (Cont.)

obles

Bleeding Tubes

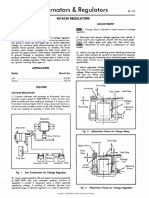

Fig.2 Master Cylinder Bleeding Procedure

2) Carefully install secondary cup over rear af rear piston

with lip of cup toward rear. Center spring retainer of rear

Cover

Gasket

Retainer Screw

G

NL Seats

Oo 9

Primary Cop

piston over shoulder of front piston and push piston assemblies

into bore. Carefully install lips of cups into bore, then seat

piston assemblies, Install piston retaining screw and tube

Seats.

3) Clamp master cylinder in a vise, being careful not to

‘damage housing, ond bleed eylinder as follows: Attach

suitable bleeding tubes (C-4029) to outlet ports of cylinder

with ends of tubes in master cylinder reservoirs. Fill etervoirs

with clean brake fluid ond depress push roc’ ‘owly. Allow

pistons 10 return to normal position under sp..ng pressure

Repeot procedure until all air bubbles are expelled, Remove

bleeding tubes, and instoll cylinder cover and diaphragm.

Remove cylinder from vise.

BRAKE WARNING/ METERING VALVE

Werning/Metering valve should be replaced if found to be

defective. Metering valve ond Brake Warning light switch are

Separate units and each is serviced as © separate unit only.

‘Master Cylinder Body

Spring (-

Front Piston

Seal Cup Rear Piston Snap

DY: why g Asembly Ring

Thin Washer } 1)

O"RMS Primary Cop

Secondory Cup

50003

Fig. 3. Exploded View of Master Cylinder Astembly

1 0 Mil ep

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- V2I783002Document1 pageV2I783002Salvador ReyesNo ratings yet

- V2I803028Document1 pageV2I803028Salvador ReyesNo ratings yet

- V2I803018Document2 pagesV2I803018Salvador ReyesNo ratings yet

- V2I803029Document3 pagesV2I803029Salvador ReyesNo ratings yet

- V2I783004Document3 pagesV2I783004Salvador ReyesNo ratings yet

- V2I803032Document1 pageV2I803032Salvador ReyesNo ratings yet

- V2I803015Document2 pagesV2I803015Salvador ReyesNo ratings yet

- V2I803020Document1 pageV2I803020Salvador ReyesNo ratings yet

- V2I803023Document2 pagesV2I803023Salvador ReyesNo ratings yet

- V2I803021Document2 pagesV2I803021Salvador ReyesNo ratings yet

- V2I803017Document1 pageV2I803017Salvador ReyesNo ratings yet

- V2I803025Document1 pageV2I803025Salvador ReyesNo ratings yet

- V2I803012Document2 pagesV2I803012Salvador ReyesNo ratings yet

- V2I803010Document2 pagesV2I803010Salvador ReyesNo ratings yet

- V2I783015Document2 pagesV2I783015Salvador ReyesNo ratings yet

- V2I803004Document2 pagesV2I803004Salvador ReyesNo ratings yet

- V2I803007Document3 pagesV2I803007Salvador ReyesNo ratings yet

- V2I803003Document1 pageV2I803003Salvador ReyesNo ratings yet

- V2I803002Document1 pageV2I803002Salvador ReyesNo ratings yet

- V2I803006Document1 pageV2I803006Salvador ReyesNo ratings yet

- V2I783011Document2 pagesV2I783011Salvador ReyesNo ratings yet