Professional Documents

Culture Documents

Literatur Anchor Block

Uploaded by

kikisakinahr_Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Literatur Anchor Block

Uploaded by

kikisakinahr_Copyright:

Available Formats

Optimum Design of Buried Pipeline Block Anchors

Husain Jubran Al-Gahtani1

Abstract: The paper presents a simple procedure for the optimum design of a pipeline block anchor. The forces exerted by the soil on

the block are computed using Rankine’s theory. The dimensioning of the block anchor is formulated as an optimization problem in which

the objective function is the volume of the block to be minimized. The optimization constraints are related to block sliding, block

overturning, and soil bearing capacity. The optimization problem is solved using Excel. Several examples are given to illustrate the steps

of the design procedure. Simple relationships between the thrust force and the minimum required block dimensions are generated.

DOI: 10.1061/共ASCE兲1084-0680共2009兲14:4共190兲

CE Database subject headings: Optimization; Anchors; Pipeline design.

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 07/08/14. For personal use only.

Introduction Formulation

When a pipeline is put into operation, it will expand under the Analysis of Forces on the Block

influence of internal pressure and temperature gradient. The

Fig. 1 shows a free-body diagram of the considered rectangular

movement due to such expansion is significant for large diameter anchor block with all forces acting on it. Let us first define vari-

pipelines such as those carrying crude oil and gas. These pipes ous geometrical and material parameters and variables involved

need to be fully restrained at some points near some equipment/ in the analysis of the block.

structures such as well heads, pumps, pressure vessels, storage a. Dimensions

tanks, etc., in order to prevent the transmission of movement to • H: height of the block;

these sensitive equipment. Massive concrete block anchors are • W: width of the block;

commonly used to fully restrain the pipeline and resist the result- • B: thickness of the block;

ing high thrust force. The literature search by the writer shows • H P: level of the pipe; and

that a number of studies on the design of such special structures • C: soil cover.

are limited 共Watkins 2000; Sidqi 2005兲. Watkins 共2000兲 presented b. Material properties

• ␥c: unit weight of concrete;

a simplified iterative procedure for the design of cubical block

• ␥s: unit weight of soil;

anchor. Their procedure neglects the friction forces on the sides of • : soil angle of internal friction

the block and the bearing capacity of the soil underneath the • : coefficient of friction between concrete and soil;

block. Sidqi 共2005兲 studied the pullout capacity of block anchor • ka: active pressure coefficient= 共1 − sin 兲 / 共1 + sin 兲;

using experimental works and analytical calculation. The objec- • K p: passive pressure coefficient= 1 / ka; and

tive of this paper is to present a procedure for optimizing the • qal: allowable soil bearing pressure.

dimensions of massive block anchors. The procedure yields charts Based on Rankine theory, various forces acting on the block

and simplified formulas that can be easily used by practicing en- are calculated as follows:

gineers for determining the required block dimensions for a given 1. Forces acting on the front and back of the block 共Fa and F p兲.

pipe thrust force and material properties. The analysis of the These forces are due to active and passive pressures exerted

forces acting on the block is based on the well-known Rankin by soil on the block. They are given by

theory for modeling earth pressures 共George 1970兲. It should be Fa = ka␥sHW共C + 2 H兲

1

共1兲

noted that other more refined theories such as Coulomb’s and log

spiral 共Terzaghi et al. 1996兲 can be accommodated in the current F p = k p␥sHW共C + 2 H兲

1

共2兲

analysis. However, the uncertainty and approximation involved in

characterization of the soil properties and the block-soil interac- The line of action of each of the above forces is located at a

tion are so high that employing more accurate and complicated height HF which can be derived by integration. After simpli-

fication, the result is

theories is not justified.

H共3C + H兲

1 h= 共3兲

Associate Professor, Dept. of Civil Engineering, King Fahd Univ. of 3共2C + H兲

Petroleum and Minerals, KFUPM 800, Dhahran 31261, Saudi Arabia.

Note. This manuscript was submitted on June 14, 2006; approved on 2. Friction forces FRt, FRb, and FRs, on the top, bottom, and

November 18, 2008; published online on October 15, 2009. Discussion each side of the block, respectively, are given by

period open until April 1, 2010; separate discussions must be submitted

for individual papers. This paper is part of the Practice Periodical on FRt = ␥sCBW 共4兲

Structural Design and Construction, Vol. 14, No. 4, November 1, 2009.

©ASCE, ISSN 1084-0680/2009/4-190–193/$25.00. FRb = BW共␥sC + ␥cH兲 共5兲

190 / PRACTICE PERIODICAL ON STRUCTURAL DESIGN AND CONSTRUCTION © ASCE / NOVEMBER 2009

Pract. Period. Struct. Des. Constr. 2009.14:190-193.

R = F p − Fa + FRt + FRb + 2FRs 共7兲

Ws C

FRt Using Eqs. 共1兲, 共2兲, and 共4兲–共6兲 in Eq. 共7兲, we get

1

R = ␥sH共2C + H兲共Ka − K p兲W + B关2C␥s共HKa + W兲

Q Wc 2

H

Hp Fa FRs Fp + H共␥bHKa + ␥cW兲兴 共8兲

h

3. Vertical forces due to weights of the concrete block and soil

σ1 σ2 cover which are given by

FRb Wc = ␥cBWH 共9兲

B Ws = ␥sBWC 共10兲

Fig. 1. Forces acting on the block anchor

Design Constraints

The geometric design of the block must satisfy the following

conditions:

FRs = ka␥sHB共C + 2 H兲 1. The block must be stable against sliding. This is guaranteed

1

共6兲

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 07/08/14. For personal use only.

if the net soil resistance R is greater than the thrust force Q.

It should be noted that the location of line of action of FRs is The ratio R / Q must be ⱖFSS, where FSS is the factor of

the same as that of Fa and F p. The net soil resistance R is safety against sliding. After simplification, this constraint

given by becomes

− H共2C + H兲W共− K p + Ka兲␥ S+2B关2C共W + HKa兲␥s + H共W␥ C+HKa␥s兲兴

ⱖ FSS 共11兲

2Q

2. The block must be stable against overturning. This constraint is satisfied if the resisting moment M R provided by the net soil

resistance and the weight of the block is greater than the overturning moment M o caused by the thrust force. After simplification, we

get

− H2共3C + H兲W共− K p + Ka兲␥ S+2BH关H2Ka + 3C共W + HKa兲兴␥s + 3B2W关共H␥ C+C␥s兲兴

ⱖ FSO 共12兲

6H PQ

where FSO= factor of safety against overturning. BHW␥c + BCW␥s

3. The bearing stress underneath the block must be less than the 0ⱕ ⫾ 共− 6H PFa + H兵− H共3C + H兲W

BW

allowable soil pressure qal, i.e.

⫻共− K p + Ka兲 + 2B关H2Ka + 3C共W + HKa兲兴其␥s兲 ⱕ qal

共17兲

0 ⱕ ⱕ qal 共13兲

where = bearing stress which is given by

Optimization of Block Dimensions

Ws + Wc 6共M R − M 0兲 Our objective is to determine the minimum block dimensions 共B,

= ⫾ 共14兲 H, and W兲 and the level of pipe 共H P兲, which are required to

WB WB2

anchor the pipe while satisfying the constraints given by the in-

where M o and M R = overturning and resistance moment, re- equalities in Eqs. 共11兲–共13兲. The optimization problem can be

spectively, which are given by solved using “Solver” tool of Excel. The optimization procedure

of this tool is well explained in many recent books on Excel. In

order to illustrate the procedure, let us assume the following prop-

M o = H PF a 共15兲 erties: ␥c = 23 kN/ m3, ␥s = 15 kN/ m3, = 30°, = 0.4, qal

= 150 kN/ m2, FSS = 1.25, and FSO = 1.5. As an example, let us

consider the block design for Q = 3 , 500 kN and soil cover C

1 = 1 m. Let us also put constraints on the minimum values of H,

M R = 兵− H2共3C + H兲W共− K p + Ka兲␥s + 2BH关H2Ka

6 B, and W that allow for pipe anchorage, reinforcement, etc., say

H ⬎ 1 m, B ⬎ 1 m, and W ⬎ 1 m. The Solver yields the follow-

+ 3C共W + HKa兲␥s + 3B2W共H␥c + C␥s兲兴其 共16兲

ing block dimensions: H = 1.47 m, B = 1.00 m, W = 34.30, and

After simplification, we get H p = 0.64 m so that the volume V = 50.33 m3. However, the value

PRACTICE PERIODICAL ON STRUCTURAL DESIGN AND CONSTRUCTION © ASCE / NOVEMBER 2009 / 191

Pract. Period. Struct. Des. Constr. 2009.14:190-193.

3.5

5.0

4.5 3.0

4.0

2.5

3.5 B (m)

C = 0.5 m

H (m) 3.0 2.0 C = 1.0 m

C = 0.5 m C = 1.5 m

2.5 C = 1.0 m C = 2.0 m

C =1.5 m 1.5 C = 2.5 m

2.0 C =2.0 m C = 3.0 m

C =2.5 m

1.5

C = 3.0 m 1.0

1 1.5 2 2.5 3 3.5 4 4.5 5

1.0 H (m)

0 1 2 3 4 5 6 7 8 9 10

Q (MN) Fig. 4. Required pipe level H p versus block depth H

Fig. 2. Minimum required block depth H versus thrust force Q

B-H and H p-H relationships can be represented by linear equa-

of W is impractical. Therefore, we will repeat the calculations by

tions, as given in Table 1. In order to check the accuracy of these

imposing a maximum value of W = 3 H. The results become H

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 07/08/14. For personal use only.

relationships, let us repeat Example 1. In this case, the relation-

= 3.29 m, B = 2.05 m, W = 9.88 m, and H P = 1.31 m so that the

ships between the variables are

volume V = 66.6 m3. As a second example, let us design a cubical

block 共W = B = H兲 for the same force and soil cover assumed in

Example 1. The solver yields H = B = W = 4.66 m and H p H = 2.039 5Q0.378 9, B = 0.658 4H − 0.094

= 1.93 m. The volume in this case is 101.24 m3, which requires and H p = 0.382 8H + 0.053 5.

50% more concrete as compared to the rectangular block. As a

third example, consider the dimensioning of the block for a thrust Substituting for Q = 3 , 500 kN= 3.5 MN, we get H = 3.28 m.

force Q = 5 , 000 kN and soil cover CO = 1.5 m with the following Using this value of H, we get B = 2.06 m and H p = 1.31 m, which

properties: ␥c = 23 kN/ m3, ␥s = 15 kN/ m3, = 40°, = 0.45, qal are almost the same as those values obtained by Excel through its

= 120 kN/ m2, FSS = FSO = 2. The Solver yields H = 3.96 m, B solver package.

= 5.39 m, W = 7.92 m, and H p = 2.74 m with a volume V

= 168.99 m3. It should be noted that the same sheet can be used

for any other given data. Conclusions

Procedure for Generating Design Charts The paper presents an automated procedure for computing the

and Equations optimum dimensions of a pipe block anchor. The forces acting on

the block have been calculated based on the well-known Rankin

In the following, we will illustrate how one can generate simpli- theory. Practical examples have been given to demonstrate the

fied design charts and formulas for determining the minimum proposed procedure. The parametric study has shown that the

block dimensions and the required pipe level H p for a given thrust height of the block is related to the thrust force through a power

force F and soil cover C. Let us assume the following practical equation while other dimensions are linearly proportional to the

properties: ␥c = 23 kN/ m3, ␥s = 15 kN/ m3, = 30°, = 0.4, qal depth of the block. Such relationships enable the engineer to de-

= 150 kN/ m2, FSS = 1.25, and FSO = 1.5. Let us fix the maximum sign the block without performing the optimization analysis.

value of W to be 3 H. If we run Excel calculations for Q

= 1 , 000, 2,000,…10,000 kN and C = 0.5, 1, 1.5, …4 m and com-

pute the design variables H, B, W, and H P in each run, we can

generate the data shown in Figs. 2–4. After trying several poly- Acknowledgments

nomial and power relationships, it has been found that the H-Q

relationship is best represented by simple power equations while The writer would like to express his appreciation for King Fahd

University of Petroleum and Minerals 共KFUPM兲 for their support.

2.0

Table 1. Design Equations for the Block Anchor Dimensions

1.5

Soil

Hp (m)

C = 0.5 m cover H-Q B-H H p-H

C =1.0 m C 共m兲 relationship relationship relationship

1.0 C =1.5 m

C =2.0 m

C = 2.5 m 0.5 H = 2.2775Q0.3563 B = 0.6227H − 0.2322 H p = 0.3612H + 0.0072

C =3.0 m

1.0 H = 2.0395Q0.3789 B = 0.6584H − 0.094 H p = 0.3828H + 0.0535

0.5

1.5 H = 1.8502Q0.3971 B = 0.7015H − 0.0179 H p = 0.4065H + 0.0649

1 1.5 2 2.5 3 3.5 4 4.5 5

H (m)

2.0 H = 1.6975Q0.4117 B = 0.7484H + 0.0207 H p = 0.4297H + 0.0617

2.5 H = 1.5722Q0.4233 B = 0.797H + 0.0369 H p = 0.4513H + 0.0529

Fig. 3. Required block length B versus block depth H 3.0 H = 1.4663Q0.4331 B = 0.8403H + 0.0576 H p = 0.4698H + 0.0467

192 / PRACTICE PERIODICAL ON STRUCTURAL DESIGN AND CONSTRUCTION © ASCE / NOVEMBER 2009

Pract. Period. Struct. Des. Constr. 2009.14:190-193.

Notation W ⫽width of the block anchor;

Wb ⫽weight of the block anchor;

The following symbols are used in this paper: Ws ⫽weight of the soil cover;

B ⫽ length of block anchor; ␥c ⫽unit weight of concrete;

C ⫽ soil cover above the block anchor; ␥s ⫽unit weight of soil;

Fb ⫽ resultant force of soil passive pressure; ⫽coefficient of friction between concrete and

Fa ⫽ resultant force of soil active pressure; soil;

FRb ⫽ friction force at bottom of the block anchor; ⫽ soil pressure underneath the block anchor;

FRs ⫽ friction force on side of the block anchor; and

FRt ⫽ friction force on top of the block anchor; ⫽ soil angle of internal friction.

FSO ⫽ factor of safety against overturning;

FSS ⫽ factor of safety against sliding;

H ⫽ height of the block anchor; References

H P ⫽ level of restrained pipe;

h ⫽ location of line of action of active and George, F. S. 共1970兲. Introductory soil mechanics and foundations: Geo-

passive pressures;

technical engineering, 4th Ed., Macmillan, New York.

K p ⫽ passive pressure coefficient;

Sidqi, A. 共2005兲. “Pullout capacity of block anchor in sand.” MS thesis,

ka ⫽ active pressure coefficient;

King Fahd Univ. of Petroleum and Minerals, Dhahran, Saudi Arabia.

M O ⫽ overturning moment;

Downloaded from ascelibrary.org by UNIVERSITE LAVAL on 07/08/14. For personal use only.

Terzaghi, K., Peck, R., and Mesri, G. 共1996兲. Soil mechanics in engineer-

M R ⫽ resisting moment;

ing practice, 3rd Ed., Wiley, New York.

Q ⫽ thrust force;

Watkins, R. K. and Anderson, L. R. 共2000兲. Structural mechanics of

qal ⫽ allowable soil bearing pressure;

buried pipes, CRC, Boca Raton, Fla.

R ⫽ net soil resistance;

PRACTICE PERIODICAL ON STRUCTURAL DESIGN AND CONSTRUCTION © ASCE / NOVEMBER 2009 / 193

Pract. Period. Struct. Des. Constr. 2009.14:190-193.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Principles of Soil Mechanics by Ronald F. Scott. - Compressed PDFDocument572 pagesPrinciples of Soil Mechanics by Ronald F. Scott. - Compressed PDFkikisakinahr_100% (2)

- Principles of Soil Mechanics by Ronald F. Scott. - Compressed PDFDocument572 pagesPrinciples of Soil Mechanics by Ronald F. Scott. - Compressed PDFkikisakinahr_100% (2)

- Drillef Shaft Manual FHWA NHI 10 016Document973 pagesDrillef Shaft Manual FHWA NHI 10 016nicthegreek100% (3)

- Water and Gas Coning 1 PDFDocument15 pagesWater and Gas Coning 1 PDFBunga Arafah100% (2)

- Jörg Polzehl, Karsten Tabelow - Magnetic Resonance Brain ImagingDocument242 pagesJörg Polzehl, Karsten Tabelow - Magnetic Resonance Brain ImagingSándor SzabóNo ratings yet

- Tunnel Lining Design GuideDocument195 pagesTunnel Lining Design GuideJasminka Vilotijevic Bozinovic100% (8)

- Evaluating Soil Liquefaction with a Simplified MethodDocument46 pagesEvaluating Soil Liquefaction with a Simplified Methodjoake spas100% (3)

- Foundation Design Using Standard Penetration Test (SPT) N-ValueDocument39 pagesFoundation Design Using Standard Penetration Test (SPT) N-Valueneilmark undagNo ratings yet

- Plaxis Tutorial Manual - 3DFoundation v15Document94 pagesPlaxis Tutorial Manual - 3DFoundation v15krainajackaNo ratings yet

- A Brief Guide To Design of Bored Piles Under Axial CompressionDocument15 pagesA Brief Guide To Design of Bored Piles Under Axial Compressiondanielsu87No ratings yet

- PLAXIS 3D Tutorial Manual 2018Document138 pagesPLAXIS 3D Tutorial Manual 2018arpitNo ratings yet

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDocument23 pagesHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNo ratings yet

- Fundamentals of Soil Behavior (J.K. Mitchell & K. Soga)Document560 pagesFundamentals of Soil Behavior (J.K. Mitchell & K. Soga)EmílioFariasVaz100% (4)

- Wika CLTDocument2 pagesWika CLTYuly Elizabeth AryatnieNo ratings yet

- Price List: Programs Personal License Flexible License Lease Perpetual Lease PerpetualDocument1 pagePrice List: Programs Personal License Flexible License Lease Perpetual Lease Perpetualkikisakinahr_No ratings yet

- Efficiency of Pile Groups in Clay Under DifferentDocument7 pagesEfficiency of Pile Groups in Clay Under Differentkikisakinahr_No ratings yet

- Leading Precast Concrete Company in Southeast AsiaDocument36 pagesLeading Precast Concrete Company in Southeast AsiaAde ChakraNo ratings yet

- Leading Precast Concrete Company in Southeast AsiaDocument36 pagesLeading Precast Concrete Company in Southeast AsiaAde ChakraNo ratings yet

- (Jonathan T. H. Wu, Kevin Z. Z. Lee, Sam B. Helwan (B-Ok - Xyz) PDFDocument206 pages(Jonathan T. H. Wu, Kevin Z. Z. Lee, Sam B. Helwan (B-Ok - Xyz) PDFmahdNo ratings yet

- Assignment #4: PROBLEMA STABILITAS DALAM GEOTEKNIK (SI-5222Document1 pageAssignment #4: PROBLEMA STABILITAS DALAM GEOTEKNIK (SI-5222kikisakinahr_No ratings yet

- Tugas 4. MektanDocument5 pagesTugas 4. Mektankikisakinahr_No ratings yet

- Tugas 4. Mektan PDFDocument5 pagesTugas 4. Mektan PDFkikisakinahr_No ratings yet

- Piecewise, Odd, Dan Even Continuous Periodic Function GraphsDocument2 pagesPiecewise, Odd, Dan Even Continuous Periodic Function Graphskikisakinahr_No ratings yet

- Class 10 - Physics - Refraction of Light at Plane Surfaces SolutionsDocument68 pagesClass 10 - Physics - Refraction of Light at Plane Surfaces SolutionsAndrik LalNo ratings yet

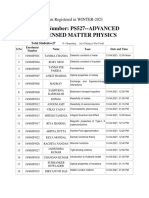

- Course Number: PS527 - ADVANCED Condensed Matter Physics: Students Registered in WINTER-2021Document2 pagesCourse Number: PS527 - ADVANCED Condensed Matter Physics: Students Registered in WINTER-2021Kiron SkNo ratings yet

- Cone Penetration Test (CPT) for soil investigationDocument53 pagesCone Penetration Test (CPT) for soil investigationDaanyal Ibn UmarNo ratings yet

- Depth Perception: Monocular CuesDocument4 pagesDepth Perception: Monocular CuesjeslynamNo ratings yet

- Jstor Research PaperDocument10 pagesJstor Research Paperv devNo ratings yet

- Matrices EssentialsDocument22 pagesMatrices Essentialsmolahstudios100% (12)

- Strength of Materials (SOM) Concept Inventory: Jim Morgan, Jim RichardsonDocument13 pagesStrength of Materials (SOM) Concept Inventory: Jim Morgan, Jim Richardsonbadboys123No ratings yet

- Ampacity and Other Design Considerations For Medium Voltage Cables Used in Renewable Energy ApplicationsDocument319 pagesAmpacity and Other Design Considerations For Medium Voltage Cables Used in Renewable Energy ApplicationsDominic SantiagoNo ratings yet

- 1Document3 pages1rahulNo ratings yet

- Activity 3: Bjective Aterial EquiredDocument3 pagesActivity 3: Bjective Aterial EquiredMalati MauryaNo ratings yet

- Gen Chem ActivityDocument2 pagesGen Chem ActivityMiguel RañadaNo ratings yet

- MV March2018 EsasDocument9 pagesMV March2018 EsasMargo Isay EriveNo ratings yet

- ME-204 - Slides Set# 09 (Phase Changes-I)Document29 pagesME-204 - Slides Set# 09 (Phase Changes-I)mamoona noreenNo ratings yet

- Sampling and QuantizationDocument7 pagesSampling and QuantizationShravani KodeNo ratings yet

- Light Emitting Diodes: Figure 1: Schematic Diagram of An LEDDocument9 pagesLight Emitting Diodes: Figure 1: Schematic Diagram of An LEDVikash SingleNo ratings yet

- EBM Axial - EN - Mini - 070921Document108 pagesEBM Axial - EN - Mini - 070921a ferreira e oliveiraNo ratings yet

- Pfi Es-24 2001Document9 pagesPfi Es-24 2001mohammedNo ratings yet

- Cheat Sheet - ElectromagnetismDocument26 pagesCheat Sheet - Electromagnetismu2100128No ratings yet

- Thermal Engineering For The Construction of Large Concrete Arch DamsDocument10 pagesThermal Engineering For The Construction of Large Concrete Arch DamsOscar LopezNo ratings yet

- WITH SOLUTIONS Open Channel and Alternate Stages of FlowDocument43 pagesWITH SOLUTIONS Open Channel and Alternate Stages of FlowMark PulongbaritNo ratings yet

- Determination of DensitiesDocument4 pagesDetermination of DensitiesJulian CarantoNo ratings yet

- Unit 6 - Week 5: Metal-Semiconductor Junctions: Assignment 5Document4 pagesUnit 6 - Week 5: Metal-Semiconductor Junctions: Assignment 5shashank barsainyaNo ratings yet

- Calculating UV Dose For UV/AOP Reactors Using Dose/Log As A Water-Quality MetricDocument6 pagesCalculating UV Dose For UV/AOP Reactors Using Dose/Log As A Water-Quality Metricchirag vyasNo ratings yet

- EN 13706-3-2002 (Doc - Xuehai.net)Document6 pagesEN 13706-3-2002 (Doc - Xuehai.net)Qiu davidfantasyNo ratings yet

- The 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsDocument45 pagesThe 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsFrancisco EstrellaNo ratings yet

- Dynamic Torque MeasurementDocument8 pagesDynamic Torque MeasurementDanNo ratings yet

- Dryer Results Both1Document37 pagesDryer Results Both1rashid sikandarNo ratings yet