Professional Documents

Culture Documents

General Description Features: 28V Programmable Current-Limited Load Switch

General Description Features: 28V Programmable Current-Limited Load Switch

Uploaded by

sarmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Description Features: 28V Programmable Current-Limited Load Switch

General Description Features: 28V Programmable Current-Limited Load Switch

Uploaded by

sarmaCopyright:

Available Formats

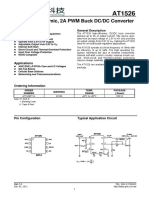

AOZ1360

28V Programmable Current-Limited Load Switch

General Description Features

The AOZ1360 is a member of Alpha and Omega 35m maximum on resistance

Semiconductor’s high-side load switch family intended Programmable current limit

for applications that require circuit protection. The device

5.5V to 28V operating input voltage

operates from a source voltage between 5.5V and 28V.

The internal current limiting circuit protects the input Low quiescent current

supply voltage from large current load. The current limit Under-voltage lockout

can be set with an external resistor. The AOZ1360 Thermal shutdown protection

provides thermal protection function that limits excessive

2.5kV ESD rating

power dissipation. The device employs internal soft-start

circuitry to control in-rush current due to highly capacitive Available in SO-8 or DFN-10 package

loads associated with hot-plug events. It features low

quiescent current of 220 µA and the supply current Applications

reduces to less than 1 µA at shutdown. Notebook PCs

The AOZ1360 is available in either an SO-8 or a Hot swap supplies

DFN-10 4 mm x 4 mm package which can operate over

a -40C to +85C temperature range.

Typical Application

VIN VOUT

IN OUT

C1 C2

1μF 1μF

AOZ1360

OFF ON EN SET

R1

84.5k

SS GND

C3

1nF

Rev. 2.0 January 2015 www.aosmd.com Page 1 of 16

AOZ1360

Ordering Information

Part Number Package Temperature Range Environmental

AOZ1360AIL SO-8

-40 °C to +85 °C Green Product

AOZ1360DIL DFN-10 4x4

AOS Green Products use reduced levels of Halogens, and are also RoHS compliant.

Please visit www.aosmd.com/media/AOSGreenPolicy.pdf for additional information.

Pin Configuration

IN 1 8 OUT

IN 1 10 OUT

IN 2 7 OUT IN 2

OUT

9 OUT

GND 3 6 SET NC 3 8 NC

GND 4

GND

7 SET

SS 4 5 EN SS 5 6 EN

SO-8 DFN-10

(Top View) (Top View)

Pin Description

Pin Number

Pin Name SO-8 DFN 4x4 10L Pin Function

IN 1, 2 1, 2 P-channel MOSFET source. Connect a 1 µF capacitor from IN to GND.

GND 3 4 Ground.

SS 4 5 Soft-Start Pin. Connect a capacitor from SS to GND to set the soft-start time.

Connect SS to IN to set to the default soft-start time of 100us.

EN 5 6 Enable Input.

SET 6 7 Current Limit Set Pin. Connect a resistor from SET to GND to set the switch

current limit.

NC 3, 8 No Connect

OUT 7, 8 9, 10 P-channel MOSFET Drain. Connect a capacitor with 0.1 µF or above from OUT

to GND.

Rev. 2.0 January 2015 www.aosmd.com Page 2 of 16

AOZ1360

Functional Block Diagram

IN OUT

C1 C2

1μF 1μF

5V Linear Gate Driver & SET

Slew Rate Current Limit

Regulator

Control

R1

84.5kΩ

5.5V

SS

UVLO

Comparator C3

Thermal 1nF

EN

Shutdown AOZ1360

Figure 1. Functional Block Diagram

Timing Diagram

VIH

EN VIL

90% 90%

10%

OUT

TD(ON) TD(OFF)

TR

Figure 2. AOZ1360 Timing Diagram

Absolute Maximum Ratings Recommended Operating Conditions

Exceeding the Absolute Maximum Ratings may damage the The device is not guaranteed to operate beyond the maximum

device. Recommended Operating Conditions.

Parameter Rating Parameter Rating

IN to GND -0.3 V to +30 V Junction Temperature (TJ) -40 °C to +125 °C

EN, OUT to GND -0.3 V to VIN + 0.3 V Thermal Resistance

SS, SET -0.3 V to +6 V SO-8 (JA) 82 °C/W

DFN-10 (JA) 63 °C/W

Maximum Junction Temperature (TJ) +150 °C

ESD Rating (Human Body Model) 2.5 kV

Rev. 2.0 January 2015 www.aosmd.com Page 3 of 16

AOZ1360

Electrical Characteristics

VIN = 12V, TA = 25°C unless otherwise stated.

Symbol Parameter Conditions Min. Typ. Max Units

VIN Input Supply Voltage 5.5 28 V

VUVLO Undervoltage Lockout IN rising 4.9 5.4 V

Threshold

VUVHYS Undervoltage Lockout 400 mV

Hysteresis

IIN_ON Input Quiescent Current EN = IN, no load 220 400 A

IIN_OFF Input Shutdown Current EN = GND, no load 1 A

ILEAK Output Leakage Current EN = GND, no load 1 A

RDS(ON) Switch On Resistance AOZ1360AI VIN = 12 V 22 35 m

RDS(ON) Switch On Resistance AOZ1360AI VIN = 5.5 V 33 43 m

ILIM Current Limit RSET = 84.5 k 2 2.7 3.4 A

VEN_L Enable Input Low Voltage 0.8 V

VEN_H Enable Input High Voltage 2.0 V

VEN_HYS Enable Input Hysteresis 100 mV

IEN_BIAS Enable Input Bias Current 1 A

Td_on Turn-On Delay Time RL = 120 , CL = 1 F, SS = Floated 220 s

EN_50% to OUT_10%

tON Turn-On Rise Time RL = 120 , CL = 1 F, SS = Floated 280 s

OUT_10% to 90%

RL = 120 , CL = 1 F, CSS = 1 nF 360

tOFF Turn-Off Fall Time RL = 120 , CL = 1 F, SS = Floated 280 s

TSD Thermal Shutdown Threshold 130 C

TSD_HYS Thermal Shutdown Hysteresis 30 C

Rev. 2.0 January 2015 www.aosmd.com Page 4 of 16

AOZ1360

Typical Performance Characteristics

Input Quiescent Current Input Shutdown Current

290 1.0

0.9

270

0.8

250

Supply Current (μA)

Supply Current (μA)

0.7

0.6

230

85°C 0.5

210 25°C 85°C

0.4

-40°C 25°C

190 0.3 -40°C

0.2

170

0.1

150 0

5 10 15 20 25 30 5 10 15 20 25 30

VIN (V) VIN (V)

Output Leakage Current UVLO Threshold vs. Temperature

1.0 4.8

0.9 VIN = 12V

VIN = 5.5V

4.7

Output Leakage Current (μA)

0.8

0.7

4.6 Rising

Threshold (V)

0.6

Falling

0.5 4.5

0.4

4.4

0.3

0.2

4.3

0.1

0 4.2

-50 -30 -10 10 30 50 70 90 -60 -40 -20 0 20 40 60 80 100 120

Temperature (°C) Temperature (°C)

RDS(ON) vs. Supply Voltage RDS(ON) vs. Temperature

35 40

30 35

30

25

RDS(ON) (mΩ)

RDS(ON) (mΩ)

25

VIN = 12V

20

VIN = 5.5V

20

15

15

10

10

5 5

0 0

-50 -30 -10 10 30 50 70 90 -60 -40 -20 0 20 40 60 80 100 120

VIN (V) Temperature (°C)

Rev. 2.0 January 2015 www.aosmd.com Page 5 of 16

AOZ1360

Typical Performance Characteristics (Continued)

Enable Input Threshold (Rising) vs. Temperature Enable Input Threshold (Falling) vs. Temperature

1.8 1.8

VIN = 12V VIN = 12V

1.6 1.6

VIN = 5.5V VIN = 5.5V

1.4 1.4

1.2 1.2

VEN (V)

VEN (V)

1.0 1.0

0.8 0.8

0.6 0.6

0.4 0.4

0.2 0.2

0 0

-60 -40 -20 0 20 40 60 80 100 120 -60 -40 -20 0 20 40 60 80 100 120

Temperature (°C) Temperature (°C)

Current Derating Curve for SO8 Current Derating Curve for DFN-10 4x4

7.0 6.5

6.3

6.5

6.1

6.0

5.9

5.5

Current (A)

Current (A)

5.7

5.0 5.5

5.3

4.5

5.1

4.0

4.9

3.5 4.7

3.0 4.5

0 10 20 30 40 50 60 70 80 90 -40 -20 0 20 40 60 80 100

Ambient Temperature (°C) Ambient Temperature (°C)

Internal Power MOSFET SOA

100.0

10ms

10.0 100 m

R DS(ON)

limited

- I D (Amps)

1ms

1.0

0.1 TJ(Max) =150e

C

10s

TA =25e

C

DC

0.0

0.01 0.1 1 10 100

- V DS(Volts)

Rev. 2.0 January 2015 www.aosmd.com Page 6 of 16

AOZ1360

Typical Performance Characteristics (Continued)

Turn-On Turn-Off

(VIN = 12V, R = 5.6Ω) (VIN = 12V, R = 5.6Ω)

VIN VIN

2V/div 2V/div

VOUT VOUT

2V/div 2V/div

EN EN

1V/div 1V/div

IOUT IOUT

0.5A/div 0.5A/div

1ms/div 20μs/div

Current Limit Over Temperature

(VIN = 12V, R = 3.6Ω) (VIN = 12V, R = 3.6Ω)

VIN VIN

5V/div 2V/div

VOUT VOUT

2V/div 2V/div

EN EN

1V/div 1V/div

IOUT IOUT

0.5A/div 0.5A/div

5ms/div 100ms/div

Rev. 2.0 January 2015 www.aosmd.com Page 7 of 16

AOZ1360

Detailed Description

Introduction The slew rate rise time, Ton, can be set using the

The AOZ1360 is a 35 m P-channel high-side load following equation:

switch with adjustable soft-start slew-rate control, Css V IN

programmable current limit and thermal shutdown. Ton = --------------------------

It operates with an input voltage range from 5.5 V to 28 V. 30A

Enable Programmable Current Limit

The EN pin is the On/Off control for the output switch. The current limit is programmed by an external resistor

It is an active-high input. The EN pin is active after VIN is connected between the SET pin and ground. This sets a

above the UVLO threshold of 4.9 V. Conversely, the reference voltage to the current limit error amplifier that

EN pin will be deactivated if the VIN falls below the UVLO compares it to a sensed voltage that is generated by

of 2.0V. The EN pin must be driven to a logic high or logic passing a small portion of the load current through an

low state to guarantee operation. While disabled, the internal amplifier. When the sensed load current exceeds

AOZ1360 only draws approximately 1 µA supply current. the set current limit, the load current is then clamped at

The EN is a high impedance input with an ESD protection the set limit and the Vout drops to whatever voltage is

diode to ground and should not be forced below ground. necessary to clamp the load current. The AOZ1360 will

This input level is compatible with most microcontroller stay in this condition until the load current no longer

outputs and other logic families. exceeds the current limit or if the thermal shutdown

protection is engaged.

Under-Voltage Lockout (UVLO)

The under-voltage lockout (UVLO) circuit of the Thermal-Shutdown Protection

AOZ1360 monitors the input voltage and prevents the During current limit or short circuit conditions, the PMOS

output MOSFET from turning on until VIN exceeds 4.9 V. resistance is increased to clamp the load current. This

increases the power dissipation in the chip causing the

Adjustable Soft-Start Slew-Rate Control die temperature to rise. When the die temperature

When the EN pin is high, the slew rate control circuitry reaches 130 °C the thermal shutdown circuitry will

applies voltage on the gate of the PMOS switch in a shutdown the device. There is a 30 °C hysteresis after

manner such that the output voltage and current is which the device will turn back on and go through soft

ramped up linearly until it reaches the steady-state load start. The thermal shutdown will cycle repeatedly until the

current level. The slew rate can be adjusted by an short circuit condition is resolved or the enable pin is

external capacitor connected between the SS pin pulled LOW externally.

and ground.

Rev. 2.0 January 2015 www.aosmd.com Page 8 of 16

AOZ1360

Application Information

Input Capacitor Selection Slew Rate Setting

The input capacitor prevents large voltage transients Slew rate is set by changing the capacitor value on the

from appearing at the input and provides the SS pin of the device. A capacitor connected between the

instantaneous current needed each time the switch SS pin and ground will reduce the output slew-rate. The

turns on. The input capacitor also limits input voltage capacitive range is 0.001 µF to 0.1 µF. Refer to Figure 4.

drop and prevents high-frequency noise on the power 45

line from passing through the output of the power side.

40

The choice of input capacitor is based on its ripple

current and voltage ratings rather than the actual 35

capacitance value. The input capacitor should be located 30

as close to VIN as possible. A 1 µF ceramic cap is

Slew Rate 25

recommended. However, higher capacitor values will (ms)

further reduce the voltage drop at the input. 20

15

Output Capacitor Selection

10

The output capacitor acts in a similar way. A small 0.1 µF

5

capacitor prevents high-frequency noise from going into

the system. Also, the output capacitor has to supply 0

0 0.02 0.04 0.06 0.08 0.1

enough current for any large load that may occur during

Capacitance (μF)

system transients. This bulk capacitor must be large

enough to supply fast transient load in order to

prevent the output from dropping. Figure 4. Output Slew Rate Adjustment vs. Capacitance

Current Limit Setting

The current limit is set by an external resistor connected Power Dissipation Calculation

to the SET pin. Refer to Figure 3 for current limit settings. Calculate the power dissipation for normal load condition

using the following equation:

AOZ1360 Rset vs ILIM PD = RON x (IOUT)2

7

The worst case power dissipation occurs when the

6

load current hits the current limit due to over-current or

5

short circuit faults. The power dissipation under these

conditions can be calculated using the following

4 equation:

ILIM (A)

3 PD = (VIN – VOUT) x ILIMIT

2

0

35 45 55 65 75 85 95 105

RSET (kΩ)

Figure 3

Rev. 2.0 January 2015 www.aosmd.com Page 9 of 16

AOZ1360

Layout Guidelines

Proper PCB layout is important for improving the thermal Place the input and output bypass capacitors as close as

and overall performance of the AOZ1360. To optimize the possible to the IN and OUT pins. The input and output

switch response time for outputting short-circuit PCB traces should be as wide as possible for the given

conditions, keep all traces as short as possible. This will PCB space. Use a ground plane to enhance the power

also reduce the effect of unwanted parasitic inductance. dissipation capability of the device.

IN 1 10 OUT

IN 1 8 OUT OUT

IN 2 9 OUT

IN 2 7 OUT

NC 3 8 NC

C1 C1

C2 C2

GND 3 6 SET GND 4 7 SET

GND

R1

SS 4 5 EN

R1

SS 5 6 EN

C3 C3

GND

Figure 5. AOZ1360AI (SO-8) Layout Figure 6. AOZ1360DI (DFN4x4 10L) Layout

Rev. 2.0 January 2015 www.aosmd.com Page 10 of 16

AOZ1360

Package Dimensions, SO-8L

D Gauge Plane Seating Plane

e 0.25

8

E1 E

h x 45

1 C

θ

7 (4x)

A2 A

0.1

b A1

RECOMMENDED LAND PATTERN Dimensions in millimeters Dimensions in inches

Symbols Min. Nom. Max. Symbols Min. Nom. Max.

A 1.35 1.65 1.75 A 0.053 0.065 0.069

2.20 A1 0.10 — 0.25 A1 0.004 — 0.010

A2 1.25 1.50 1.65 A2 0.049 0.059 0.065

b 0.31 — 0.51 b 0.012 — 0.020

c 0.17 — 0.25 c 0.007 — 0.010

D 4.80 4.90 5.00 D 0.189 0.193 0.197

5.74

E 3.80 3.90 4.00 E 0.150 0.154 0.157

e 1.27 BSC e 0.050 BSC

2.87 1.27 E1 5.80 6.00 6.20 E1 0.228 0.236 0.244

h 0.25 — 0.50 h 0.010 — 0.020

L 0.40 — 1.27 L 0.016 — 0.050

θ 0° — 8° θ 0° — 8°

0.80

0.635 UNIT: mm

Notes:

1. All dimensions are in millimeters.

2. Dimensions are inclusive of plating

3. Package body sizes exclude mold flash and gate burrs. Mold flash at the non-lead sides should be less than 6 mils.

4. Dimension L is measured in gauge plane.

5. Controlling dimension is millimeter, converted inch dimensions are not necessarily exact.

Rev. 2.0 January 2015 www.aosmd.com Page 11 of 16

AOZ1360

Tape and Reel Dimensions, SO-8

Carrier Tape P1

D1

P2

T

E1

E2 E

B0

K0 D0

A0 P0 Feeding Direction

UNIT: mm

Package A0 B0 K0 D0 D1 E E1 E2 P0 P1 P2 T

SO-8 6.40 5.20 2.10 1.60 1.50 12.00 1.75 5.50 8.00 4.00 2.00 0.25

(12mm) ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10 ±0.10

Reel

W1

S

G

N K

M

V

R

H

W

UNIT: mm

Tape Size Reel Size M N W W1 H K S G R V

12mm ø330 ø330.00 ø97.00 13.00 17.40 ø13.00 10.60 2.00 — — —

±0.50 ±0.10 ±0.30 ±1.00 +0.50/-0.20 ±0.50

Leader/Trailer and Orientation

Trailer Tape Components Tape Leader Tape

300mm min. or Orientation in Pocket 500mm min. or

75 empty pockets 125 empty pockets

Rev. 2.0 January 2015 www.aosmd.com Page 12 of 16

AOZ1360

Package Dimensions, DFN-10L, 4x4

D A

3 B e

INDEX AREA D/2 6 10 L3*

(D/2xE/2) L

D/2

*L4 L1 E1/2

E E1

L2

2

* L4 1

Pin #1 IDA

Pin 1 5

Chamfer 0.20

D2 D1

6 TOP VIEW BOTTOM VIEW

A3

A1

C

A Seating

Plane

10x 5

ddd

b 4

SIDE VIEW eee

Dimensions in millimeters Dimensions in inches

Symbols Min. Nom. Max. Symbols Min. Nom. Max.

A 0.70 0.75 0.80 A 0.028 0.030 0.031

RECOMMENDED LAND PATTERN A1 0.00 0.02 0.05 A1 0.000 0.001 0.002

0.65 Typ. A3 0.203 REF A3 0.008 REF

0.65 Typ. b 0.30 0.35 0.40 b 0.012 0.014 0.016

0.35 TYP

D 3.95 4.00 4.05 D 0.156 0.157 0.159

10 6 0.30 D1 1.58 1.68 1.78 D1 0.062 0.066 0.070

D2 1.22 1.32 1.42 D2 0.048 0.052 0.056

E 3.95 4.00 4.05 E 0.156 0.157 0.159

E1 2.20 2.30 2.40 E1 0.087 0.091 0.094

2.30 0.38

3.55 e 0.65 BSC e 0.026 BSC

1.15 L 0.50 0.55 0.60 L 0.020 0.022 0.024

0.02 L1 — 0.02 0.12 L1 — 0.001 0.005

L2 0.28 0.38 0.48 L2 0.011 0.015 0.019

L3 0.85 REF L3 0.033 REF.

Pin #1 IDA

Chamfer 0.20 1 5 0.30 L4 0.30 REF L4 0.012 REF

1.78 1.42 aaa 0.15 aaa 0.006

Unit: mm bbb 0.10 bbb 0.004

ccc 0.10 ccc 0.004

ddd 0.08 ddd 0.003

Notes:

eee 0.05 eee 0.002

1. All dimensions are in millimeters.

2. The dimensions with * are just for reference.

3. The location of the terminal #1 identifier and terminal numbering convention conforms to JEDEC publication 95 SPP-002.

4. Dimension b applies to metallized terminal and is measured between 0.15mm and 0.30mm from the terminal tip. If the terminal has the

optional radius on the other end of the terminal, then dimension b should not be measured in that radius area.

5. Coplanarity applies to the terminals and all other bottom surface metallization.

6. Drawings shown are for illustration only.

Rev. 2.0 January 2015 www.aosmd.com Page 13 of 16

AOZ1360

Tape and Reel Dimensions, DFN-10L, 4x4

Carrier Tape

D1 P1

P2

T

E1

E2

E

C

L B0

K0

P0 D0 A0

Feeding Direction

UNIT: MM

Package A0 B0 K0 D0 D1 E E1 E2 P0 P1 P2 T

DFN 4x4 4.35 4.35 1.10 1.50 1.50 12.0 1.75 5.50 8.00 4.00 2.00 0.30

(12mm) ±0.10 ±0.10 ±0.10 Min. +0.1/-0.0 ±0.3 ±0.10 ±0.05 ±0.10 ±0.10 ±0.05 ±0.05

Reel W1

S

G

N

M K

V

R

H

W

UNIT: MM

Tape Size Reel Size M N W W1 H K S G R V

12 mm ø330 ø330.0 ø79.0 12.4 17.0 ø13.0 10.5 2.0 — — —

±2.0 ±1.0 +2.0/-0.0 +2.6/-0.0 ±0.5 ±0.2 ±0.5

Leader/Trailer and Orientation

Trailer Tape Components Tape Leader Tape

300mm min. or Orientation in Pocket 500mm min. or

75 empty pockets 125 empty pockets

Rev. 2.0 January 2015 www.aosmd.com Page 14 of 16

AOZ1360

Part Marking

SO-8

Underscore Indicates

Z1360AI

Part Number Code

Green Product FAYWLT

Fab & Assembly Location Assembly Lot Code

Year & Week Code

DFN-10

Underscore Indicates

Z1360DI

Part Number Code

Green Product ZA8R1B

Fab & Assembly Location Assembly Lot Code

Year & Week Code

Rev. 2.0 January 2015 www.aosmd.com Page 15 of 16

AOZ1360

LEGAL DISCLAIMER

Applications or uses as critical components in life support devices or systems are not authorized. AOS does not

assume any liability arising out of such applications or uses of its products. AOS reserves the right to make

changes to product specifications without notice. It is the responsibility of the customer to evaluate suitability of the

product for their intended application. Customer shall comply with applicable legal requirements, including all

applicable export control rules, regulations and limitations.

AOS' products are provided subject to AOS' terms and conditions of sale which are set forth at:

http://www.aosmd.com/terms_and_conditions_of_sale

LIFE SUPPORT POLICY

ALPHA AND OMEGA SEMICONDUCTOR PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL

COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS.

As used herein:

1. Life support devices or systems are devices or 2. A critical component in any component of a life

systems which, (a) are intended for surgical implant into support, device, or system whose failure to perform can

the body or (b) support or sustain life, and (c) whose be reasonably expected to cause the failure of the life

failure to perform when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can be effectiveness.

reasonably expected to result in a significant injury of

the user.

Rev. 2.0 January 2015 www.aosmd.com Page 16 of 16

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Expulsion FusesDocument2 pagesExpulsion Fusesvlady33No ratings yet

- 8FBN15-30-RM Vol. 2 PDFDocument462 pages8FBN15-30-RM Vol. 2 PDFCarlos75% (4)

- 34 Samss 621Document15 pages34 Samss 621naruto256No ratings yet

- SEMIKRONPowerSemiconductors PDFDocument466 pagesSEMIKRONPowerSemiconductors PDFDoDuyBac0% (1)

- Aoz1360 A&oDocument12 pagesAoz1360 A&oAnthony SaltNo ratings yet

- TB62747AFG, TB62747AFNG: 16-Output Constant Current LED DriverDocument20 pagesTB62747AFG, TB62747AFNG: 16-Output Constant Current LED DriverSaša DinčićNo ratings yet

- Control de Garganta TACDocument15 pagesControl de Garganta TACmario rosasNo ratings yet

- TB62747AFG ToshibaDocument20 pagesTB62747AFG ToshibavinNo ratings yet

- 5A, 36V, 500Khz Step-Down Converter: General Description FeaturesDocument14 pages5A, 36V, 500Khz Step-Down Converter: General Description FeaturesHitesh GambhavaNo ratings yet

- Datasheet PDFDocument21 pagesDatasheet PDFHamad FathiNo ratings yet

- TMG0565 TitanMicroDocument10 pagesTMG0565 TitanMicroekrem kayaNo ratings yet

- Ultra Low Dropout 1.5A Linear Regulator: General Description FeaturesDocument16 pagesUltra Low Dropout 1.5A Linear Regulator: General Description Featuresedward blancoNo ratings yet

- CS8129-D 5V ChryslerDocument11 pagesCS8129-D 5V Chryslermario rosasNo ratings yet

- 3A Ultra Low Dropout Linear Regulator: General DescriptionDocument11 pages3A Ultra Low Dropout Linear Regulator: General DescriptionIgha Intan PermataNo ratings yet

- RT8289 DatasheetDocument13 pagesRT8289 DatasheetAbdulraouf DefnanyNo ratings yet

- ZXLD1370Document39 pagesZXLD1370Iqbal Muzhaffar IsmailNo ratings yet

- 300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesDocument11 pages300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesPedro RodriguezNo ratings yet

- Data SheetDocument16 pagesData Sheetcarrei JohnNo ratings yet

- RT9173Document10 pagesRT9173duplakave30No ratings yet

- DatasheetDocument18 pagesDatasheeteusebio seguraNo ratings yet

- DatasheetDocument12 pagesDatasheetWAN MOZESNo ratings yet

- AP7331Document13 pagesAP7331a.escalant.tNo ratings yet

- Out Products: Monolithic IC MM192x SeriesDocument16 pagesOut Products: Monolithic IC MM192x SeriesIbrain MoranNo ratings yet

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesMarcius RodriguesNo ratings yet

- High-Side Power Distribution Switch: Features General DescriptionDocument1 pageHigh-Side Power Distribution Switch: Features General DescriptionRafael Roel Robles BaezNo ratings yet

- AP7375Document18 pagesAP7375Can IlicaNo ratings yet

- RT9011Document12 pagesRT9011Bijan AmiriNo ratings yet

- 5V/12V Synchronous Buck PWM DC-DC Controller: Features General DescriptionDocument17 pages5V/12V Synchronous Buck PWM DC-DC Controller: Features General DescriptionLuis Dark-passengerNo ratings yet

- AT1526 GlobalMixed ModetechnologyDocument2 pagesAT1526 GlobalMixed ModetechnologyFafa MangstabNo ratings yet

- 4A Low Dropout Regulator With Enable: Global Mixed-Mode Technology IncDocument1 page4A Low Dropout Regulator With Enable: Global Mixed-Mode Technology Incbengkel_ericNo ratings yet

- AP6265 Series (Preliminary) : Features General DescriptionDocument16 pagesAP6265 Series (Preliminary) : Features General Descriptioni7628807No ratings yet

- Usb Boost Optional U5 Lp6252Document8 pagesUsb Boost Optional U5 Lp6252Sergio SeelingNo ratings yet

- DSA2H0055410Document1 pageDSA2H0055410mauricioguillen92No ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- AOZ2023PIDocument11 pagesAOZ2023PIjuliocunachiNo ratings yet

- AP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterDocument24 pagesAP62200/AP62201/AP62200T: 4.2V To 18V Input, 2A Low Iq Synchronous Buck ConverterAarsol AdvanceNo ratings yet

- TA84007PQ, TA84007SG, TA84007FG: PreliminaryDocument16 pagesTA84007PQ, TA84007SG, TA84007FG: PreliminarywijakesumaNo ratings yet

- TLE7209 R InfineonDocument16 pagesTLE7209 R Infineonmobil benerNo ratings yet

- FAN1112 Regulator (Fairchild)Document8 pagesFAN1112 Regulator (Fairchild)Franz JAHLNo ratings yet

- LP3872/LP3875 1.5A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesDocument18 pagesLP3872/LP3875 1.5A Fast Ultra Low Dropout Linear Regulators: General Description FeaturescurzNo ratings yet

- LM320L/LM79LXXAC Series 3-Terminal Negative Regulators: General DescriptionDocument7 pagesLM320L/LM79LXXAC Series 3-Terminal Negative Regulators: General DescriptionSantiago SerranoNo ratings yet

- Features DescriptioDocument8 pagesFeatures Descriptioalamgir80No ratings yet

- AOZ3018PIDocument14 pagesAOZ3018PIpravin jadavNo ratings yet

- RT9080N Datasheet ModDocument14 pagesRT9080N Datasheet ModDavid MAILLOTNo ratings yet

- Tbd62502apg, Tbd62502afg, Tbd62502afng, Tbd62502afwg Tbd62503apg, Tbd62503afg, Tbd62503afng, Tbd62503afwgDocument12 pagesTbd62502apg, Tbd62502afg, Tbd62502afng, Tbd62502afwg Tbd62503apg, Tbd62503afg, Tbd62503afng, Tbd62503afwgHeroe APNo ratings yet

- Aoz 1331 DiDocument14 pagesAoz 1331 DiA'andi PutraNo ratings yet

- Sharp-Microelectronics-PC925LENIP0F C28113Document20 pagesSharp-Microelectronics-PC925LENIP0F C28113jorwernNo ratings yet

- Tbd62003apg, Tbd62003afg, Tbd62003afng, Tbd62003afwg Tbd62004apg, Tbd62004afg, Tbd62004afng, Tbd62004afwgDocument11 pagesTbd62003apg, Tbd62003afg, Tbd62003afng, Tbd62003afwg Tbd62004apg, Tbd62004afg, Tbd62004afng, Tbd62004afwgFrancisco Meza BenavidezNo ratings yet

- 3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument13 pages3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesKavinda Jayasinghege DonNo ratings yet

- Lite-On Technology Corp.: 6N137 - High Speed 10Mbd Optocouplers Description FeaturesDocument10 pagesLite-On Technology Corp.: 6N137 - High Speed 10Mbd Optocouplers Description FeaturesAsharNo ratings yet

- AL8812Document11 pagesAL8812julio cesar calveteNo ratings yet

- L6234 3 Fazlı Motor SürücüDocument10 pagesL6234 3 Fazlı Motor SürücüEngin UzunNo ratings yet

- Treasure Link Technology LTD.: TL995-C15 Dual Tone Door ChimeDocument2 pagesTreasure Link Technology LTD.: TL995-C15 Dual Tone Door ChimeAlberto LimónNo ratings yet

- Aoz1212ai PDFDocument18 pagesAoz1212ai PDF060279No ratings yet

- 1 Tle5206 2 - 1Document23 pages1 Tle5206 2 - 1Fran CastanoNo ratings yet

- AP2280Document11 pagesAP2280NoelNo ratings yet

- LP3871/LP3874 0.8A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesDocument18 pagesLP3871/LP3874 0.8A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesPaulo Henrique ValérioNo ratings yet

- Ezbuck™ 3A Synchronous Buck Regulator: General Description FeaturesDocument15 pagesEzbuck™ 3A Synchronous Buck Regulator: General Description FeaturesJulio BarrosNo ratings yet

- 7N60 7N65 Data SheetDocument7 pages7N60 7N65 Data Sheetsunder punjabiNo ratings yet

- RT9183-12GL RT9183HGS RT9183-25GG RT9183-12GG RT9183-12GGF RT9183-12GM RT9183-18GLF RT9183-25GM RT9183-33GG RT9183-33GLDocument20 pagesRT9183-12GL RT9183HGS RT9183-25GG RT9183-12GG RT9183-12GGF RT9183-12GM RT9183-18GLF RT9183-25GM RT9183-33GG RT9183-33GLmhasansharifiNo ratings yet

- Ic Driver LCD HP G5121 5121M PDFDocument9 pagesIc Driver LCD HP G5121 5121M PDFBudi PrayitnoNo ratings yet

- Description Features: Ait Semiconductor IncDocument8 pagesDescription Features: Ait Semiconductor Incteranet tbtNo ratings yet

- General Description Features: EzbuckDocument9 pagesGeneral Description Features: EzbuckCristina NistorNo ratings yet

- Toa 60Document74 pagesToa 60Johan Guanchez100% (1)

- Data Manual: TVP5147M1Document109 pagesData Manual: TVP5147M1Johan GuanchezNo ratings yet

- Advanced Transition-Mode PFC Controller: FeaturesDocument39 pagesAdvanced Transition-Mode PFC Controller: FeaturesJohan GuanchezNo ratings yet

- DS 2857FG 02 PDFDocument12 pagesDS 2857FG 02 PDFJohan GuanchezNo ratings yet

- DatasheetDocument2 pagesDatasheetJohan GuanchezNo ratings yet

- Max9694evkit PDFDocument12 pagesMax9694evkit PDFJohan GuanchezNo ratings yet

- NJM2884 2884a eDocument13 pagesNJM2884 2884a eJohan GuanchezNo ratings yet

- 20W Class D Mono Single Ended Audio Amplifer: The Future of Analog IC TechnologyDocument12 pages20W Class D Mono Single Ended Audio Amplifer: The Future of Analog IC TechnologyJohan GuanchezNo ratings yet

- E13082 e Tarjome PDFDocument12 pagesE13082 e Tarjome PDFHa Duy ThaiNo ratings yet

- Electromagnetic Induction: Theory and Exercise BookletDocument62 pagesElectromagnetic Induction: Theory and Exercise Bookletabc9999999999No ratings yet

- 680-203-01A Mx-5000 Termination-Utility EnclosuresDocument12 pages680-203-01A Mx-5000 Termination-Utility EnclosuresmotaNo ratings yet

- Reference MaterialDocument18 pagesReference Materialwalcha9999No ratings yet

- DIY k148Document5 pagesDIY k148Mayeh BalicoNo ratings yet

- Osram Do Lighting Program 2013 2014 GB PDFDocument114 pagesOsram Do Lighting Program 2013 2014 GB PDFeuqehtbNo ratings yet

- Mulagada, Mindi, Visakhapatnam, Andhra Pradesh 530012.: Ashida ADR141A 19I141A0091 50/1ADocument17 pagesMulagada, Mindi, Visakhapatnam, Andhra Pradesh 530012.: Ashida ADR141A 19I141A0091 50/1AsanjayNo ratings yet

- IES - Electrical Engineering - Communication SystemDocument36 pagesIES - Electrical Engineering - Communication SystemNuman KhanNo ratings yet

- 1Cx16mm2 ECCDocument2 pages1Cx16mm2 ECCMariam AwadNo ratings yet

- Dielectric (Compatibility Mode)Document70 pagesDielectric (Compatibility Mode)P Praveen KumarNo ratings yet

- Cuck ConverterDocument14 pagesCuck ConverterTechnos_IncNo ratings yet

- Technical Data Sheet A11: 1 OBO - WWW - Obo.de - A 11 - Stand 10/2012Document2 pagesTechnical Data Sheet A11: 1 OBO - WWW - Obo.de - A 11 - Stand 10/2012kosthsNo ratings yet

- Merlin Gerin: Varlogic RT6 Power Factor ControllerDocument4 pagesMerlin Gerin: Varlogic RT6 Power Factor ControllerCata CatalinNo ratings yet

- Cambridge IGCSE: Global Perspectives 0457/11Document4 pagesCambridge IGCSE: Global Perspectives 0457/11Hsu Labb WaiNo ratings yet

- Monitoring Modules For MPC-6000 & 7000 Control Panels: FeaturesDocument2 pagesMonitoring Modules For MPC-6000 & 7000 Control Panels: FeaturesJakaria ShawonNo ratings yet

- EN Specification Sheet VEGAPULS 63 4 20 Ma HART Two Wire PDFDocument2 pagesEN Specification Sheet VEGAPULS 63 4 20 Ma HART Two Wire PDFJose JohnNo ratings yet

- Pro - ACTpro 4200 Installation ManualDocument7 pagesPro - ACTpro 4200 Installation Manuallazhar75No ratings yet

- (600kW) LEROY SOMER ALTERNATOR LSA47.2L9 3 PHASEDocument12 pages(600kW) LEROY SOMER ALTERNATOR LSA47.2L9 3 PHASEChan Yee ChooNo ratings yet

- MPR63 User Manual Eng v1.67Document41 pagesMPR63 User Manual Eng v1.67nagesh795No ratings yet

- Emec IIDocument15 pagesEmec IIjeetendrasidhiNo ratings yet

- Datasheet Adani Solar India 520w 530w 535w 540w 545w MBB P Type Mono Perc Half Cut Bifacial 182mm Eternal ShineDocument2 pagesDatasheet Adani Solar India 520w 530w 535w 540w 545w MBB P Type Mono Perc Half Cut Bifacial 182mm Eternal ShineShah Shrey0% (1)

- Test I Direction: Encircle The Letter of The Correct AnswerDocument3 pagesTest I Direction: Encircle The Letter of The Correct AnswerArnel Sumagaysay GalloNo ratings yet

- DRS 71M4Document2 pagesDRS 71M4carlos alfonsoNo ratings yet

- Packaged Gas/Electric Rooftop Units: Precedent™ 3 - 10 Tons - 60 HZDocument100 pagesPackaged Gas/Electric Rooftop Units: Precedent™ 3 - 10 Tons - 60 HZHéctor LombardiNo ratings yet

- Arkel AR500 Gray - Binary Converte - 1 PDFDocument1 pageArkel AR500 Gray - Binary Converte - 1 PDFHenri KleineNo ratings yet

- 3.155J/6.152J Lecture 2: IC Lab Overview: Massachusetts Institute of Technology 02/09/2004Document19 pages3.155J/6.152J Lecture 2: IC Lab Overview: Massachusetts Institute of Technology 02/09/2004stansilawNo ratings yet