Professional Documents

Culture Documents

010 - TPL Hot Work Checklist

Uploaded by

john raj0 ratings0% found this document useful (0 votes)

10 views1 pageOriginal Title

010- TPL Hot work checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 page010 - TPL Hot Work Checklist

Uploaded by

john rajCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

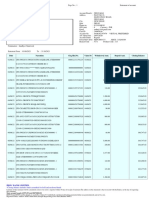

FN: 13.02.

01/HSE-OCP-06/F-

CHECKLIST FOR 01/R1

HOT WORK (WELDING, GRINDING & GAS CUTTING) Rev. No: 00

Date: 05.09.2019

Name of Project: Work Location:

Sub-Contractor: Date: Time: Shift: Day □ / Night □

S.N Description Yes No NA Remarks

1 Whether approved Method Statement for specific work is available?

Has Job Safety Analysis (JSA) along with LMRA prepared for hot work as per the method

2

statement?

All the workers have been explained regarding safe work-procedures, including the specific

3

identified activity for which the PTW is being issued?

Whether Suitable Emergency arrangement including Evacuation system, Ambulance/Emergency

4 vehicle with driver & first aider, Fire extinguisher/ fire hose, fire watch (trained person looking out

for fire incidents, exclusively) is available and kept standby in case of gas leakage, fire & explosion?

5 Are competent welder/gas cutter/grinder engaged to perform activity?

6 Are all power cables underground or over head as per safety standards?

7 Is the work area free from any combustible material?

All floor openings and cut outs covered with fire blanket (in addition to covering the floor opening

8

and cut outs with reinforcement mesh/hard barricading)?

Ensure availability of metal tray or fire retardant cloth beneath & sides of working place to arrest

9

hot molten slag / spatter /spark?

Before hot work, whether closed container (eg. Storage tank) / existing hydrocarbon pipe line

10

purged/pigging for flammable vapours?

Welding Related Work:

11 Is welding machine routed through RCCB/ELCB?

12 Is voltage reduction devise (VRD) installed/inbuilt in welding machine?

13 Is Power cable for welding machine guarded / protected and free from persons tripping / falling?

14 Is return path cable of welding machine is free from damage?

15 Is electrode holder insulated and in good condition?

Whether standard lugs & connector (spark free clamp) used for cable joint & connection with rigid

16

crimping?

17 Receptacles are provided for collecting welding buts?

Grinding Related Work:

18 Is wheel guard available in the Grinding machine?

20 Is the expiry date for grinding wheel checked at Stores before issue?

21 Is RPM of grinding wheel is > Grinding Machine?

22 Is ring test for Grinding wheel conducted at Store / work location?

23 Is dead man switch inbuilt in grinding machine?

24 Is cord strain reliever (glands) available in grinding machine?

Gas Cutting Related Work:

25 Is gas cylinder trolley available?

26 Are two flash back arrestors fitted at torch and cylinder end?

27 Are proper crimp clamp use at both ends of gas cutting hoses?

28 Are gas hoses checked visually & with soap solution for any leakage?

29 All regulator, pressure gauges and cutting torch are in good condition?

30 Is worker having necessary work specific PPE?

If hot work in specific location (such as height, confined space, underground, on shore, oil & gas

31

field etc.), specific PTW obtained?

NOTE: Before issuing PTW, Site Safety In-charge and Execution Engineer/Supervisor shall ensure the above points are checked and complied.

• The above Checklist is mandatory at every site & manufacturing units of TPL wherever Hot Work is involved.

• Wherever the Checklist prescribed by client/ customer is mandated for compliance, the same shall be followed.

Signature of the Execution Engineer/Supervisor Signature of Site Safety In-charge/ Supervisor

Checked by Reviewed By

Page 1 of 1

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- SDS - 43 - BR Acrylic Pu Enl Partb - 00 - 204Document4 pagesSDS - 43 - BR Acrylic Pu Enl Partb - 00 - 204john rajNo ratings yet

- SDS - 31 - Epilux 4 Clear Lacquer Part A - 00 - 159Document4 pagesSDS - 31 - Epilux 4 Clear Lacquer Part A - 00 - 159john rajNo ratings yet

- SDS - 34 - Epilux 9 HB Phenolic Coating Part B - 00 - 175Document4 pagesSDS - 34 - Epilux 9 HB Phenolic Coating Part B - 00 - 175john rajNo ratings yet

- Safety Day - Letter - 2023Document6 pagesSafety Day - Letter - 2023john rajNo ratings yet

- SC Judgment - ESI Will Continue To Be Applicable Though Number of Person Falls Below The Applicability LimitDocument13 pagesSC Judgment - ESI Will Continue To Be Applicable Though Number of Person Falls Below The Applicability Limitjohn rajNo ratings yet

- My TripsDocument1 pageMy Tripsjohn rajNo ratings yet

- Safety Day Leaflet - 2023Document2 pagesSafety Day Leaflet - 2023john rajNo ratings yet

- 27 Competency Evaluation - 1Document2 pages27 Competency Evaluation - 1john rajNo ratings yet

- 12 Portable Tools Inspection ChecklistDocument1 page12 Portable Tools Inspection Checklistjohn rajNo ratings yet

- Book Magazine Q4 2022-3Document20 pagesBook Magazine Q4 2022-3john rajNo ratings yet

- 8 A Pick and Carry Hydra Crane Daily ChecklistDocument1 page8 A Pick and Carry Hydra Crane Daily Checklistjohn raj100% (2)

- 10 Crane Tyre Crawler Check ListDocument1 page10 Crane Tyre Crawler Check Listjohn rajNo ratings yet

- 8 B Pick and Carry Hydra Crane Daily ChecklistDocument1 page8 B Pick and Carry Hydra Crane Daily Checklistjohn raj100% (1)

- 9 Daily Dumper, Trailor ChecklistDocument1 page9 Daily Dumper, Trailor Checklistjohn rajNo ratings yet

- Heavy Lifting PostersDocument1 pageHeavy Lifting Postersjohn rajNo ratings yet

- 02 Crawler Checklist Monthly ChecklistDocument1 page02 Crawler Checklist Monthly Checklistjohn rajNo ratings yet

- 1 B Air Compressor ChecklistDocument1 page1 B Air Compressor Checklistjohn rajNo ratings yet

- 03 DG Checklist DailyDocument1 page03 DG Checklist Dailyjohn rajNo ratings yet

- Gas TestingDocument35 pagesGas Testingjohn rajNo ratings yet

- Your Msa Scba System: Cleaning/DisinfectingDocument1 pageYour Msa Scba System: Cleaning/Disinfectingjohn rajNo ratings yet

- Dos and Don'ts For CycloneDocument15 pagesDos and Don'ts For Cyclonejohn rajNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Green Roof HYDROPACKDocument4 pagesGreen Roof HYDROPACKJuan Manuel Roldán GuerreroNo ratings yet

- Wireless Rugged Remotes 868 MHZ Tyro PyxisDocument2 pagesWireless Rugged Remotes 868 MHZ Tyro PyxisVikram NagaNo ratings yet

- GE CatalogDocument3 pagesGE CatalogBob sageNo ratings yet

- Kuratko10e IE PPT Ch03Document33 pagesKuratko10e IE PPT Ch03Lyza PasionNo ratings yet

- Pioneer vsx-415k vsx-415sDocument76 pagesPioneer vsx-415k vsx-415selekossNo ratings yet

- Myers Briggs Type Indicator PIODocument1 pageMyers Briggs Type Indicator PIODesi Tri SatrianiNo ratings yet

- Master Budgeting (Sample Problems With Answers)Document11 pagesMaster Budgeting (Sample Problems With Answers)Jonalyn TaboNo ratings yet

- Projects and Programmes Committee ReportDocument5 pagesProjects and Programmes Committee ReportElbekriNo ratings yet

- D31P-20 Komatsu S4D102E PDFDocument3 pagesD31P-20 Komatsu S4D102E PDFsrabesh basnetNo ratings yet

- VAF BinderDocument109 pagesVAF BinderCarlosJosePerezCardona100% (1)

- Cswip - Section 06-Wps and Welders QualificationDocument15 pagesCswip - Section 06-Wps and Welders QualificationNsidibe Michael Etim100% (1)

- ODI 11g Master and Work Repository Creation Steps - 1Document20 pagesODI 11g Master and Work Repository Creation Steps - 1Asad HussainNo ratings yet

- M1009en PDFDocument5 pagesM1009en PDFk.r.sureshbabuNo ratings yet

- Theme Theme: Fishing Operation Case Fishing Operation ENF#25Document36 pagesTheme Theme: Fishing Operation Case Fishing Operation ENF#25salah aissa babahamouNo ratings yet

- Neutrosophic TopologyDocument6 pagesNeutrosophic TopologyMia AmaliaNo ratings yet

- 24 C Hevacomp: Solar RadiationDocument21 pages24 C Hevacomp: Solar RadiationHumaid ShaikhNo ratings yet

- Air Quality Control SystemsDocument24 pagesAir Quality Control SystemsSupakint SuteepichatpuntNo ratings yet

- Spirit One DatasheetDocument3 pagesSpirit One DatasheetVincent BoninNo ratings yet

- Deutsche Bank CaseDocument3 pagesDeutsche Bank CaseVamsee Krishna Reddy Bheri67% (3)

- NEC Art 500Document2 pagesNEC Art 500Kranthi Kumar0% (1)

- I DenDocument34 pagesI DenGajendra SettyNo ratings yet

- Ameron Calculation Manual For Bondstand GRE Pipe SystemsDocument16 pagesAmeron Calculation Manual For Bondstand GRE Pipe Systemsgbuckley9630No ratings yet

- ManualDocument24 pagesManualAnonymous 2I6zroTNo ratings yet

- Simplicity Soverign ManualDocument54 pagesSimplicity Soverign Manualcoyote556No ratings yet

- ADAPTERDocument4 pagesADAPTERBipro BaraiNo ratings yet

- Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument21 pagesDate Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceAmbuj ChaturvediNo ratings yet

- MD - Biodata (By Createmybiodata - Com)Document1 pageMD - Biodata (By Createmybiodata - Com)restaurant thevintageNo ratings yet

- Accugas Company Profile v2Document6 pagesAccugas Company Profile v2Oribuyaku DamiNo ratings yet

- Model 5 Operating and Maintenance ManualDocument98 pagesModel 5 Operating and Maintenance ManualgfollertNo ratings yet

- Gilchrist & Soames Order # 18270013Document1 pageGilchrist & Soames Order # 18270013vision23No ratings yet